Suggest you abandon the hope that some kind of "prep" or miracle goop will solve this problem. Unless you're thinking JB Weld

first you want to confirm that the seatpost is the right size. Look for a small gap in the seat tube between the binder ears. Also the inner bore of the seat tube should be as nearly round as possible

and the binder bolt not stripped or bottoming out. Again look for that small gap.

assuming all the above is good.then you need to establish some interference between the seatpost and the inner bore of the seatpost. First, with the seat at your desired height, draw the outline of the seat lug with a sharpie so you know what's in the frame.and hidden from view. Then pull the seat post out.

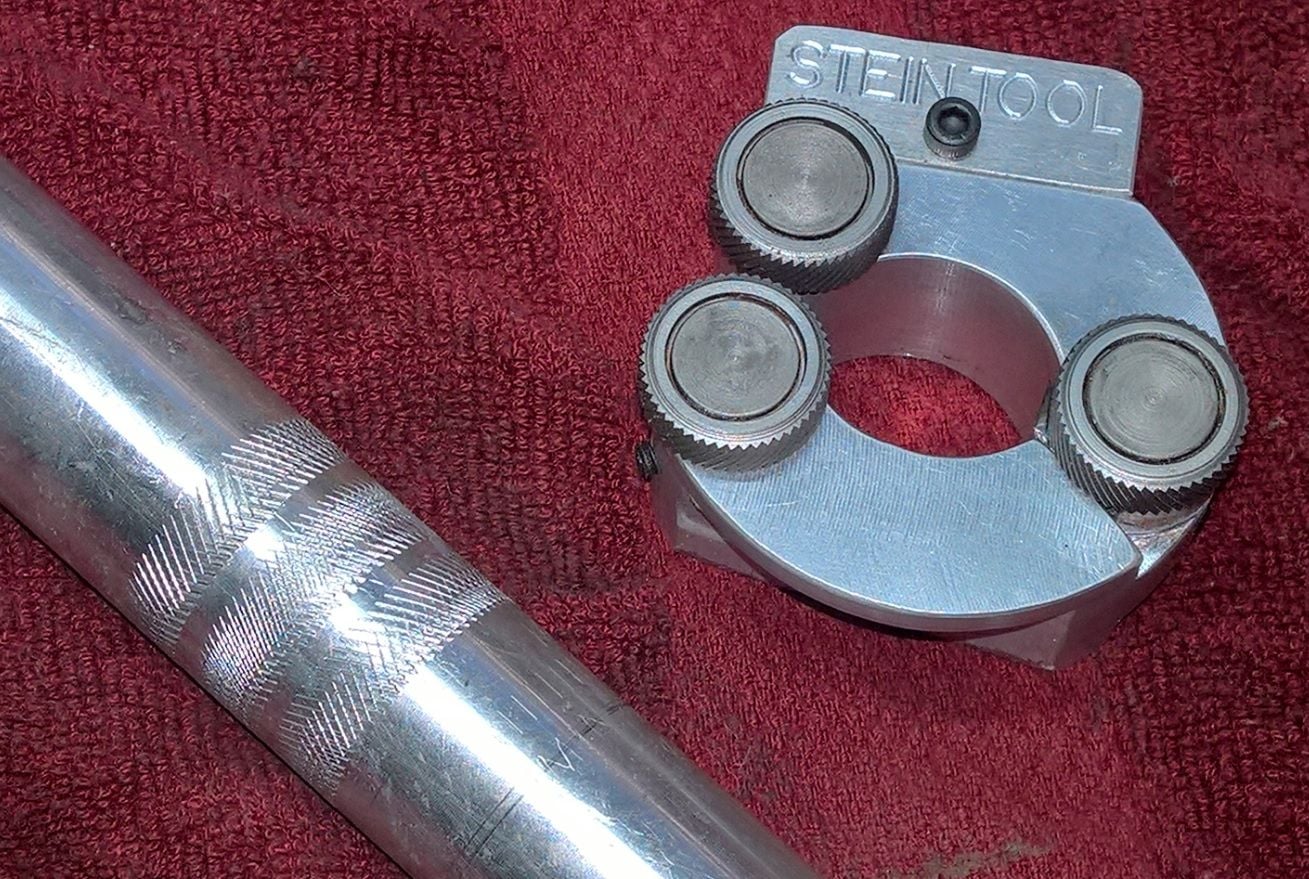

I have the wonderful J.A Stein knurling tool which will let you put knurling marks on the seat post below the insertion line.

If you don't have a knurling tool, you can use your automatic center punch to put some "dimples" on the post, again below the insertion line, to establish some interference, so when you tighten the pinch bolt, it will "bite".

Last and least favorite option is a shim. It need not go all the way around the post - just a strip of beer can 1/2" wide might be enough if all the steps previously listed fail.

proper attention to the above should help with the slipping seat post problem.

/markp