I wanted to address how exactly these things work, because I think this debate about the screw has something to do with how we understand how they work:

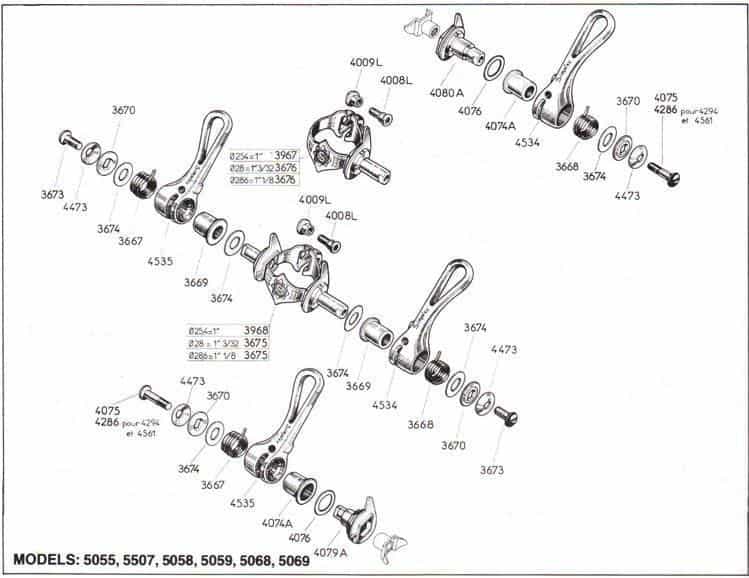

Referring to the shifter in the top of the diagram, we have four parts of real interest:

1. 4080 A - the mounting post that goes over the braze on. This item has a square female base which completely prevents it from rotating.

2. 4074 A - the flared Bushing that slides over the mounting post and is what the clutch spring grips.

3. 4076 - the washer that goes between the mounting post and the flared end of the bushing.

4. 3668 - the clutch spring

What is obvious is that when you pull the lever toward you to downshift on the freewheel, the lever pulls the Spring tip and "unwinds" the Spring, increasing it's inner diameter. This makes the Spring loose on the Bushing, allowing the lever to move without the Bushing moving.

But when the lever is moved forward for an upshift, the Spring inner diameter decreases, and the Spring grips the Bushing.

The Bushing is smooth on the inside and outside. It can turn smoothly under the untensioned Spring, or it can turn on the Post. What prevents it from turning easily on the Post is the mounting screw and washers are pushing it toward the base of the Post. Between them is the 4076 washer.

So the question is: When the lever is pushed forward and the clutch Spring tightens, what is supposed to move? Two possibilities:

1. The Spring moves, but the Bushing does not. In this scenario, the mounting screw has been tightened to the point that the Bushing is locked to the Post. The friction then comes from the tightend spring dragging on the outside of the Bushing to counter the derailleur return spring. Upshifts force the Spring to drag on the Bushing.

2. The Spring locks on to the Bushing, and they move together. In this scenario the mounting screw has been tightened to a moderate setting that allows the bushing to swivel around the post, and the friction resistance to the derailleur return spring comes from the tension of the mounting screw pressuring the outer washers and the inner Washer between the Bushing flange and the Post. In this case the clutch Spring is completely static to the Bushing, and all movement comes from the Bushing slipping past the various washers.

I think #2 is the case, because it explains why the Bushing is smooth on the inside rather than fixed to the Post. It also would prevent a great deal of friction wear to the Bushing from forcing the hardened Spring to push over it in upshifts. This explanation would be why the upshift friction can be varied by the mounting screw tension. The shifter is a pretty normal friction shifter in one direction, and relatively friction free in the other.

#1 is the scenario where mounting screw tension is immaterial to the function of the shifter. It has to be quite tight to make sure the Bushing doesn't slip. This scenario seems like it would wear the Bushing and Spring interface quickly.

Am I missing something?