Originally Posted by

WizardOfBoz

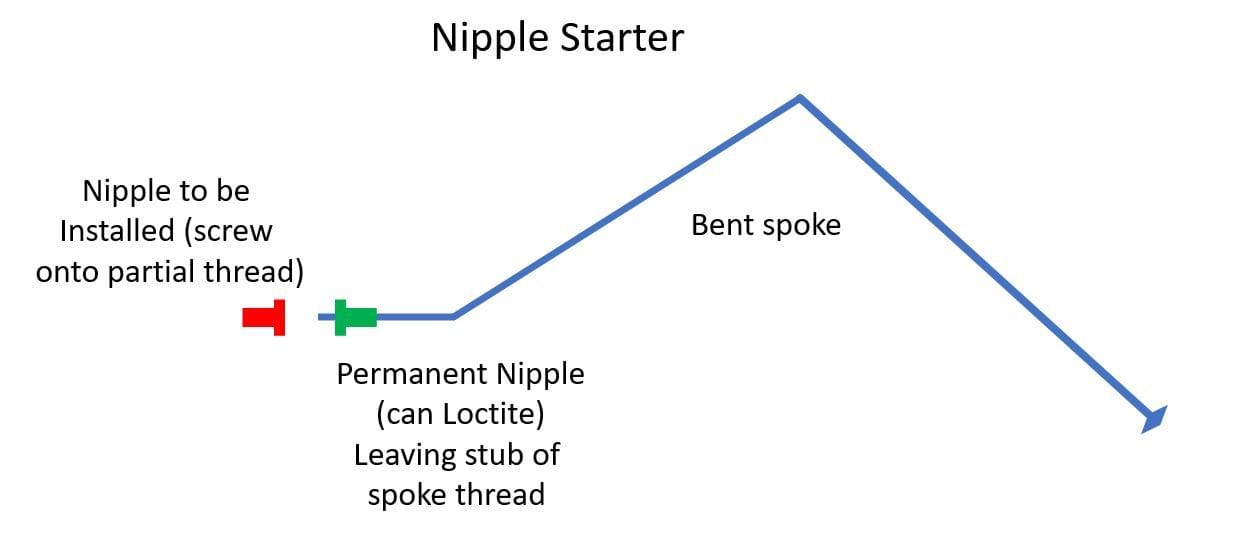

This is what I use. The working nipple just threads onto the few remaining threads. (BTW, this is not my idea - can't recall where I saw this - one of the wheelbuildling books?). This gives good purchase. Easy to twirl the eccentrically bent spoke down. Easy to remove the tool and move onto the next one. Commercially, hard to beat the old VAR version of a Yankee Screwdriver, with a spoke tip (screwdriver with a nub) on the end.

Wiz,

If you make a minor adjustment to your tool, it will make starting the nipple on the spoke a bit easier. I have used this tool since the mid 70's and it speeds up my build time, If you make your bend in the spoke like this tool it will aid in getting the nipple started easily. The company is no longer around but occasionally one will show up on the auction sites.

Smiles, MH