Two updates:

First, fun with FW hubs. I have an original from @

nlerner which I'm using as a spring reference for the parts pile hub that I've had lying around for 10 years or so, minus springs.

The Sturmey FW manual insists that both the small

K813B Compensator Spring and the larger

K410B Low Gear Spring must be replaced as a pair. I'm pretty sure this is how the hub achieves the balancing act of engaging the primary sun pinion in first gear, but not in second - if the springs aren't matched, the primary sun pinion may not engage in first, or stay engaged in second.

At any rate, I

think I've found stand-in springs for the original Sturmey parts. At least, they seem to have the same compression rate.

This is McMaster Carr

1986K242 (https://www.mcmaster.com/1986K242/) next to Sturmey-Archer K410B - I'm pretty confident about this one. The dimensions are nearly perfect, and the spring rate feels identical to the original spring. The major difference is that the ends aren't ground. I can always fix that pretty quickly, but I'm worried that heat from the grinding may affect the tensile strength and spring rate.

This is McMaster Carr

9657K65 (https://www.mcmaster.com/9657K65/) next to Sturmey-Archer K813B. The McMaster spring is slightly longer, requiring Dremel work. I have cut one, and it didn't seem as if it would change the spring rate enough to be a problem. It is and about 0.3mm smaller in diameter. A bit of a PITA because of the compensator spring collar (

X8), but the factory X8 will fit in it with a bit of shoving.

Now, the big issue is that the Oillite bushing that I had turned into a compensator collar...fell apart. It didn't have the strength to be thinned and shoved in the spring. I plan to 3D print this part. Might have better luck.

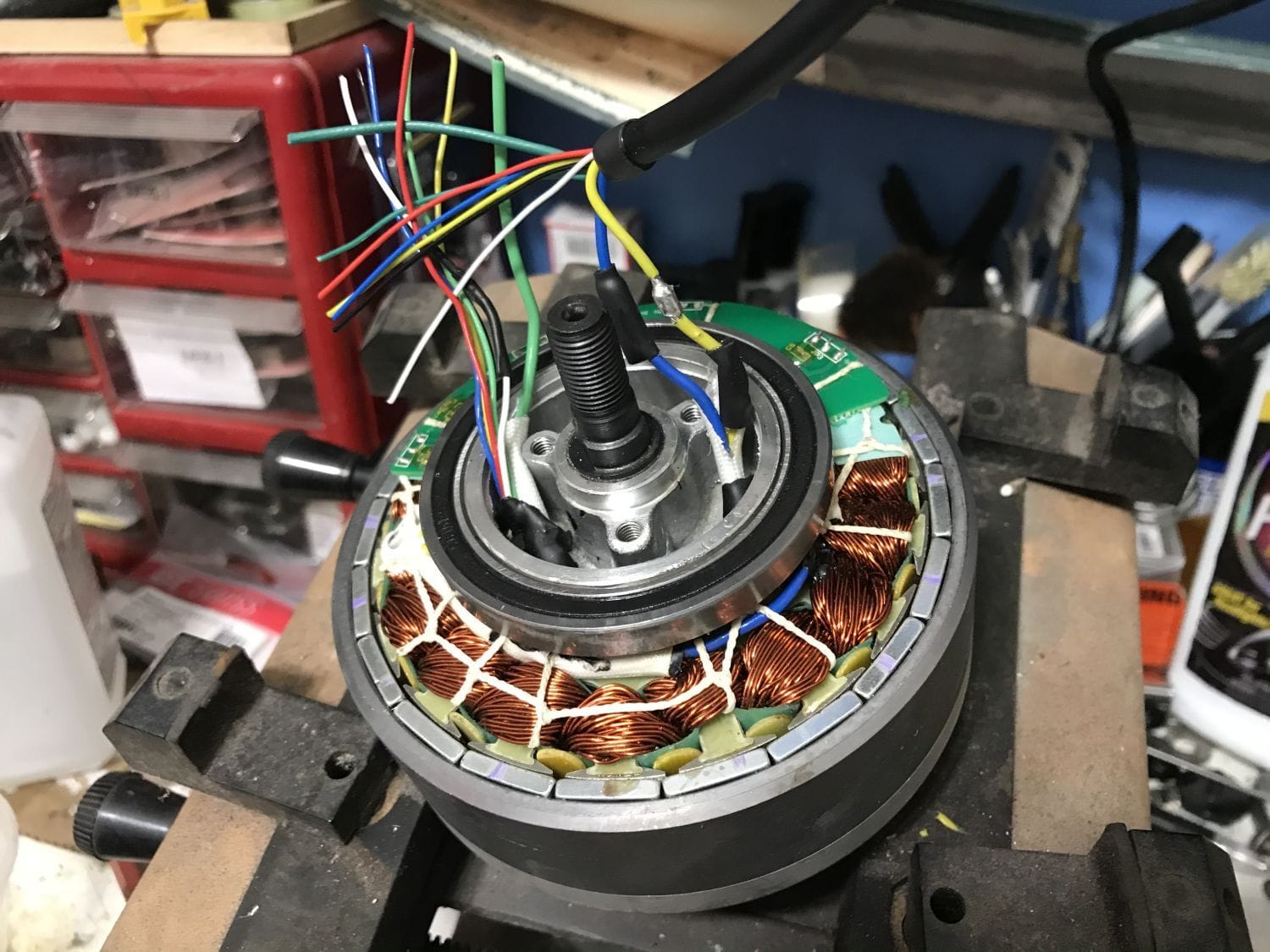

Secondly, I did some ill-advised re-wiring of the hub to accept a HIGO Z910-style 9-pin connector. There's barely any space to fit the soldered and shrunk wires. Crossing my fingers I don't have any shorts from chafed wires. If I do, I'll have to pull the sealed bearing and solder directly to the PCB, which should prove to be a big pain in the butt - if I have to resort to it.

-Kurt