1kosmos1, Iíll continue my educational series on the steps I use to build custom frames with my Ukrainian made fixture so you can get a better idea of what you may eventually want to do. I build one-off custom frames designed to fit just one customer. To begin I put the customer/student on a stationary adjustable fitting bicycle. The seat is adjusted for height (which helps determines frame size) and setback (which determines seat angle). Next the position of the handlebars is determined. How far away it is from the nose of the saddle and how much drop it has compared to the seat (subtract the height of the bars from the height of the top of the saddle) can also be found pedaling the fitting bicycle. This handlebar placement is probably a compromise between biomechanical and aerodynamic efficiency and comfort.

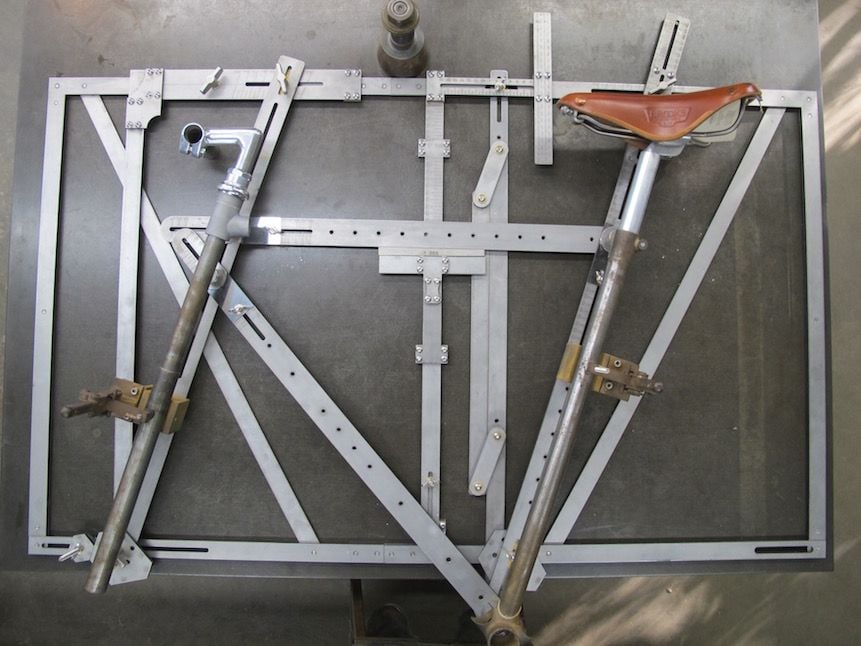

To design a frame I put the saddle and stem the customer wants to use in the same position found on the fitting bicycle on my fixture. That is the reason for extra fixture pieces so I can place them on the fixture easily and conveniently. Now I move the pieces that represent the tubes to match the stem and saddle. Other factors like how much bottom bracket drop, head angle and fork rake are chosen. It is important to me that I am able to see life size everything is in proportion (it looks right). For example that there is the right amount of seatpost showing and there are not too many/too few headset stackers or quill stem extension. In my forty some years of building frames I have not built 2 custom frames exactly the same. Even people with very similar body measurements can sit in a different position on a bicycle. This is why I use a fitting bicycle more than measuring a person to design their frame.

Of course it is much faster to build frames in groups. This probably means there is some compromise for the customer because they adjust themselves to fit the bicycle (instead of the frame adjusting to them). Decreasing manufacturer time may increase profits (or lower the price). One way to customize a semi-production frame is let the customer choose his colors and perhaps braze-on bits. Other jobs a custom builder can do to make money is make custom racks and stems.