So I received the lights from Aliexpress yesterday and proceeded to build my magnetic breakaway helmet lights. Here they are.

As previously mentioned, I got a new helmet and this time I used double sided tape underneath the washer instead of gluing it. I cut a hole in the center of the double sided tape wider than the diameter of the hole in washer (not shown), so that as much of the outer edge of the tape would contact the domed surface of the helmet. I then covered the washer with tape. This time, the 3D printed part has a small cup edge that fits around the washer to add some resistance against sliding off. It does work as intended, but I didn't factor in the thickness of the duct tape over the magnet, so it's a very tight fit and takes a few extra seconds for me to blindly find the center when reattaching the light to the helmet. If I had made the cup a few millimeters wider, it would have fit much better.

Just like the old lights that I built, the new lights also have a male and female 3D printed part that fit together to prevent them from separating when stuck together. The new lights are heavier though, 70g each pair for a total of 140g (including magnet and overly thick 3D printed part). The old lights were 40g each for a total of 80g, but because of their smaller batteries and lower light output. Just like the old lights, the new lights have 3D printed parts that are over 40mm in diameter even though the magnet is only 20mm in diameter, to serve as a protection buffer around the magnet to make it more difficult to unintentionally attract metal objects.

Each pair of lights are held to the 3D printed part with a rubber O-ring.

The 3D printed part has a hole in the middle which allows the small protrusion in the back of the light to be inserted.

The lights come with a band that is screwed in from the back, which is easily removed.

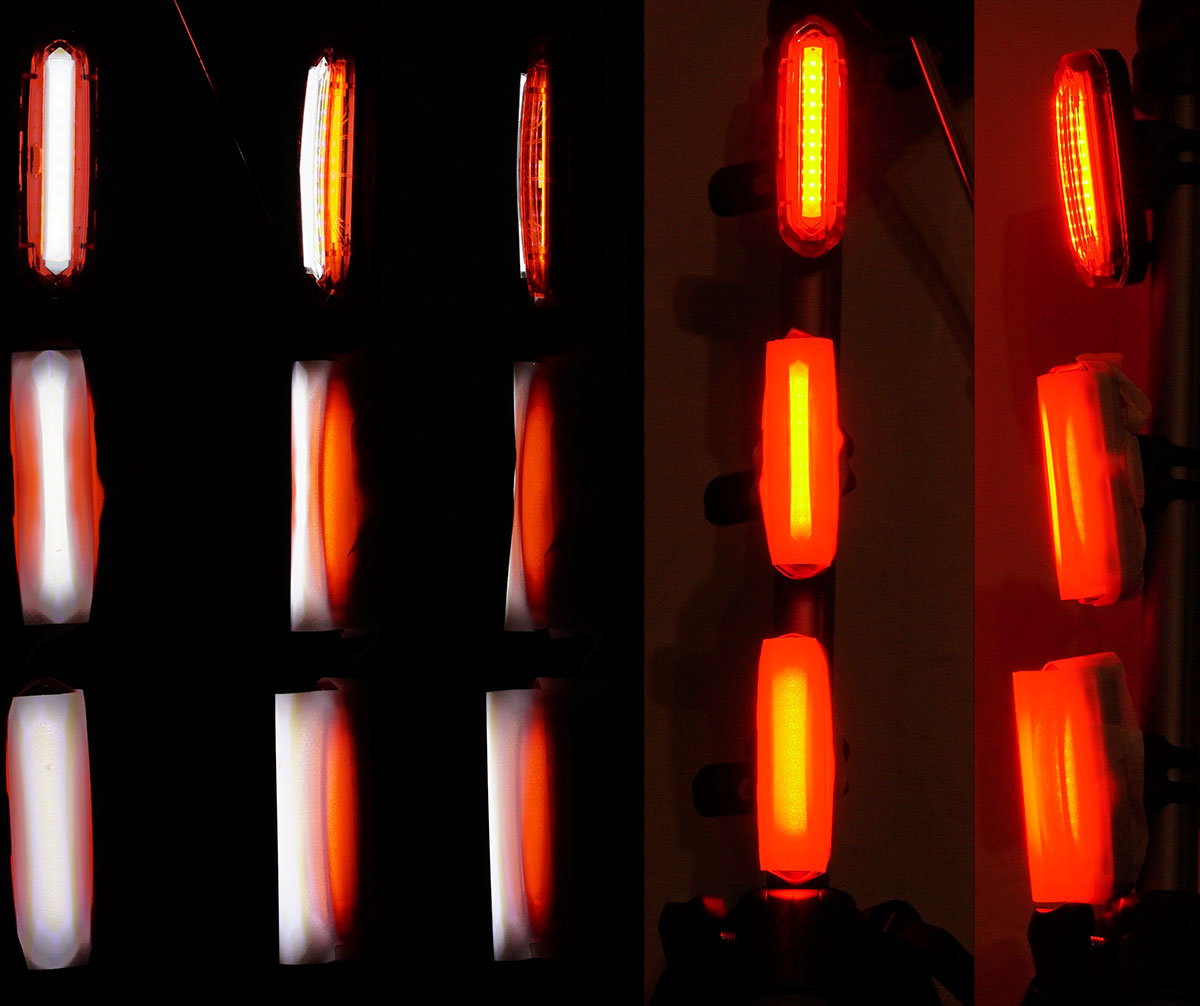

The lights are really bright. The description says they're COB chip-on-board LED lights. I don't know if it's unique or if most LED lights do this. But it causes glare and is bothersome to look into directly. So I experimented with attaching a layer of translucent PVC privacy film that normally is applied to glass windows. I tested 3 types: naked, film directly against the light, film offset from the light.

Naked had too much glare. The film offset from the light had too much loss of light transmission. The film directly against the light was ok, but the white lights still had too much glare so I eventually applied a double layer of film for the white lights, while the red lights had a single layer of film. In the comparison image below in the top row, the red light is naked, while the white light has a single film. Having a large film wrapped around the entire light was too bulky and made it difficult to attach the O-rings. So instead I cut a small strip that only covers the center area of the light.

The light is very bright, although a little heavy. I run it on low mode instead of high mode. But low mode seems to be pulse modulated, which means that it is flashing on and off at very high frequency to make it appear darker even though the intensity of the light output is the same. When your eyes are looking at it, your brain feels a little bit confused. If you hold the light in your hands and shake them very fast from side to side, it seems to strobe. If you hold the light still, it appears to be a steady output. I don't know how many Hertz is the pulsing, but probably slower than 150 Hz, which is why it feels strange to look at.