I am back to this.

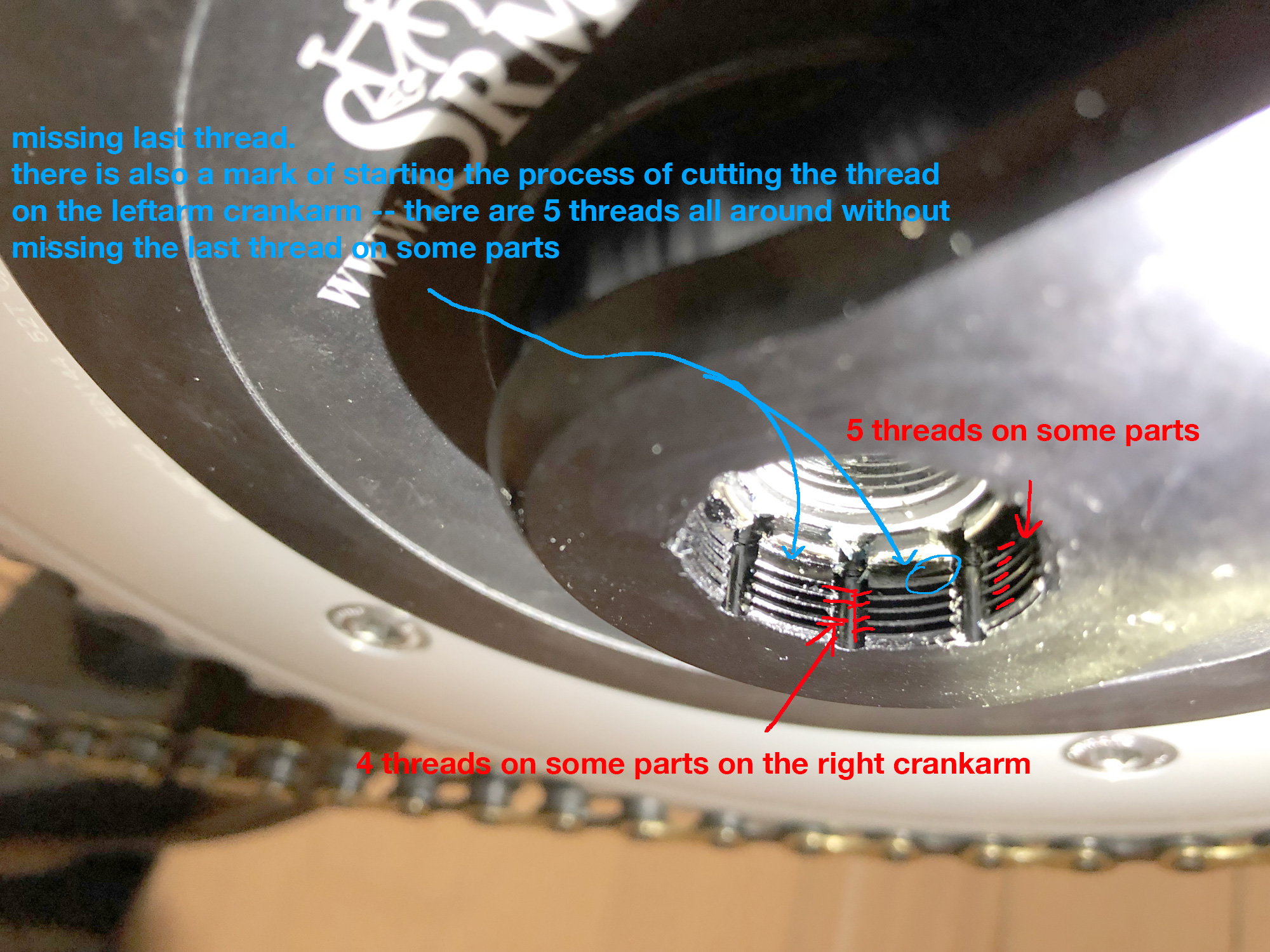

I unscrewed the extractor bolt and verified that all threads look mint. I noticed that on the crankarm there is full 4 threads and part of the 5th only when on the left arm there are full 5 threads. Interesting that the finishing thread is still black anodized.

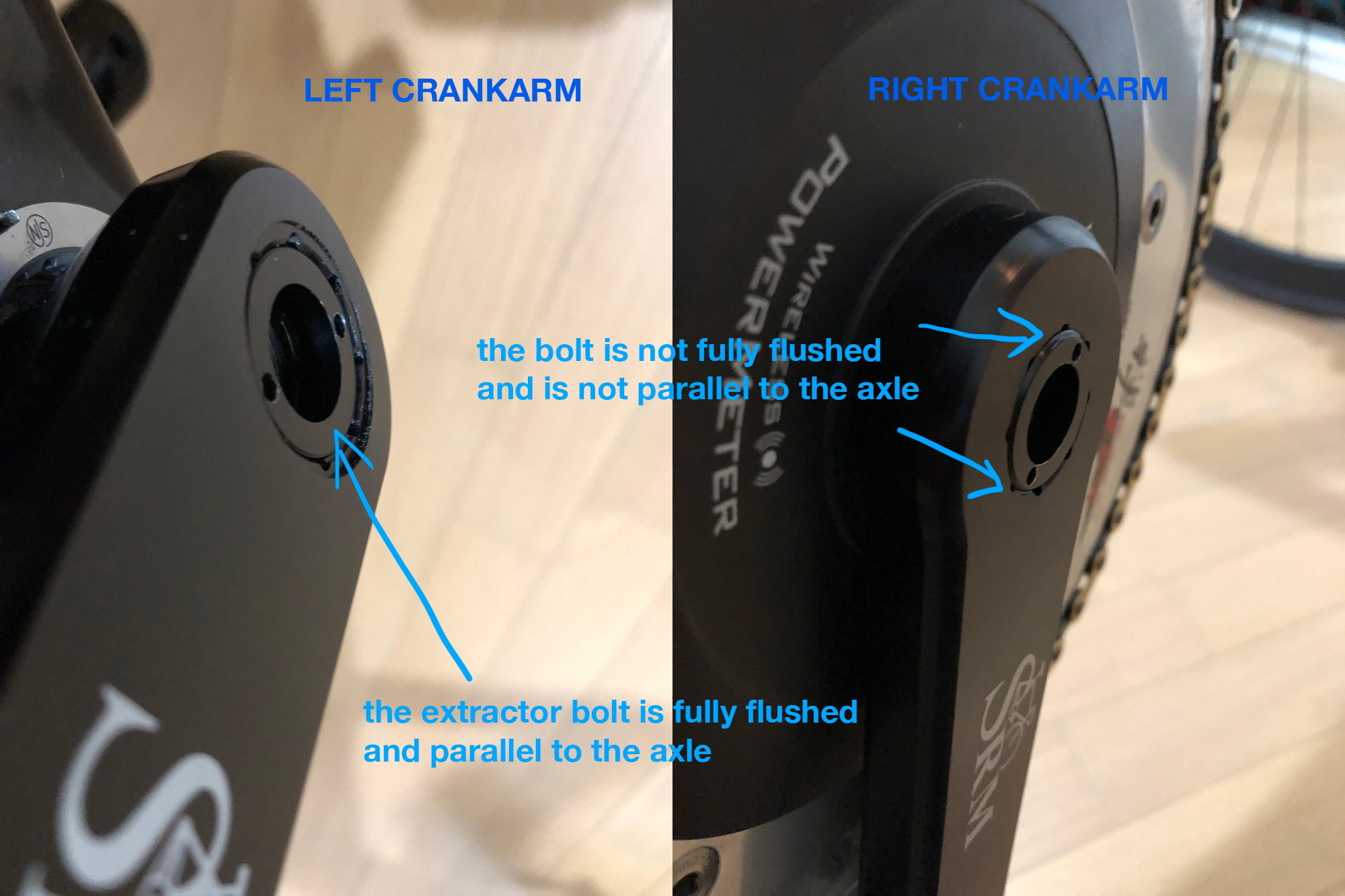

Seems like the right extractor should be simply shorter and maybe I got 2 left arm extractor bolts by mistake. I talked to SRM Customer Service and they verified both extractor bolts are identical. They also confirm that on the right side the extractor shouldn't be fully flushed and basically everything is ok. They even sent me pictures of another crankset with the same situation.

So, is anyone can confirm that a right extractor bolt should be fully flushed? I'm talking here about the Track Science model where the spider is fully connected with the right crankarm. I know a previous version a spider and crankarm were separated.

The Octalink interface looks solid and in mint condition. It's possible to insert a printer paper between spindle and crankarm. However it's a maximum and it's exactly the same on both sides and very constant on all parts. I think this is correct. The position of the spindle also is correct.

I haven't extract the crankarm yet. I waited for a confirmation from the SRM that everything is OK and it's safe to do this. I will extract the crankarm and bottom-bracket, clean, regrease and mount back. We will see.

I'm just not sure if I should go with a grease or blue loctite on a crank bolt. I assume greasing should be all I need. The correct tighten value is 40-50Nm.