"Yes it's a dilly of a pickle". as guy153 says. This is why many builders avoid repairs of frames they didn't build, too much chance to have the situation mushroom bigger then it needs to be. I asked about the shop's manor of working with you and with the very nice description I see issues on both sides that have resulted in where you're at now. I assume the shop is fairly new to this stuff, or I hope they are as it's easier to understand their choices then if they knew what they were doing the whole time and with the complete situation. I do wonder about if they would have done differently if they were the ones to also paint and assemble the bike, although changing components during this just further complicates the path.

So as I earlier mentioned the only one that cares to do something is you. There are many ways to compress/crimp/dent stays for more clearance. I've done many and always cold. It's always preferred to use a method that if something slips or shifts from position unintended "damage" (remember a crimp is a specific and contained damage) doesn't happen. So using a force involving hammers takes some real focus

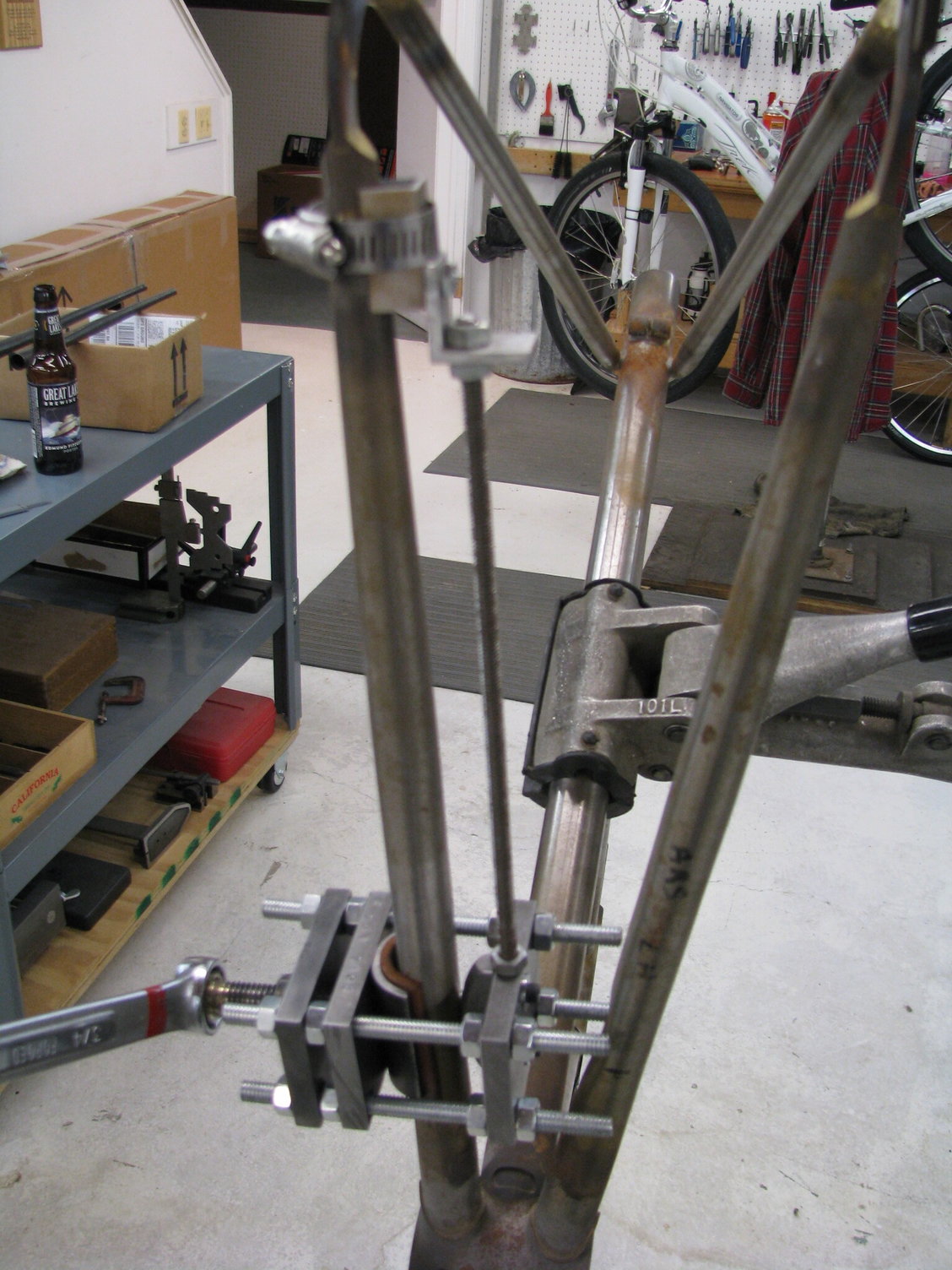

Using screw driven forces reduce the OOPS results. Here's a shot of what I made to do this.