Rechroming a chrome fork

#51

Senior Member

Worries laid to rest.

Ok, I work in the machine industry (shop Christmas party below). I have witnessed hydrogen embrittlement on some long 2.5" shafts we needed to "heavy plate" with industrial plating, not decorative that is totally different. Hydrogen embrittlement will never happen on a decorative part. Don't believe me, call your plater and ask.

#52

Decrepit Member

Ok, I work in the machine industry (shop Christmas party below). I have witnessed hydrogen embrittlement on some long 2.5" shafts we needed to "heavy plate" with industrial plating, not decorative that is totally different. Hydrogen embrittlement will never happen on a decorative part. Don't believe me, call your plater and ask.

Jim Cunningham at Cyclart has an excellent article on plating bike frames on the Cyclart website: Chrome Plating Bicycle Parts

Originally Posted by Cyclart

Few people realize that the part must fully polished before the chrome is applied. The part must then again be meticulously cleaned and then can be immersed in the first of several baths for plating. Most of the actual plating is done with nickel. Chrome is then applied as a final coat. We then bake parts to remove any “hydrogen embrittlement” which may have occurred in plating. Next, masking tape is applied and precisely cut the areas to remain exposed. We then protect the masking tape and abrasive blast the area to be painted, “frosting” the surface of the chrome to increase paint adhesion. After painting, the making is removed and the edges trimmed precisely with a knife.

The plating we do is called “decorative” chrome plating and always involves plating nickel before plating the chrome. The chrome plating in decorative chrome plating is exceptionally thin, measured in millionths of an inch rather than in thousandths. It is still a very hard surface, but simple 'anvil' type hardness measurements don't detect the hardness because the anvil just punches through such a thin coating.

The plating we do is called “decorative” chrome plating and always involves plating nickel before plating the chrome. The chrome plating in decorative chrome plating is exceptionally thin, measured in millionths of an inch rather than in thousandths. It is still a very hard surface, but simple 'anvil' type hardness measurements don't detect the hardness because the anvil just punches through such a thin coating.

#53

Senior Member

Maybe things got mistranslated? I was told there is no worries with hydrogen embrittlement decorative chrome from the plater.

I don't work in the machine industry, but my dad worked for Schwinn for thirty years and Schwinn did lots of chrome plating of bicycle frames and forks made with high strength thin-walled steel tubing. There is a risk of hydrogen embrittlement when doing 'decorative' plating (which ideally involves plating with copper, then nickel, and finally a thin layer of chromium) if the plated frames and forks aren't baked after plating.

Jim Cunningham at Cyclart has an excellent article on plating bike frames on the Cyclart website: Chrome Plating Bicycle Parts

Jim Cunningham at Cyclart has an excellent article on plating bike frames on the Cyclart website: Chrome Plating Bicycle Parts

#54

Decrepit Member

Decorative chrome plating on thicker carbon steel probably presents insignificant risk. High strength thin-walled bicycle frame tubing is a different matter.

#55

Senior Member

Join Date: Jun 2006

Posts: 20,305

Mentioned: 130 Post(s)

Tagged: 0 Thread(s)

Quoted: 3464 Post(s)

Liked 2,831 Times

in

1,997 Posts

When I talked to a few platers, the concept was to know the material, different materials require different minimum baking times, I did not have the strength of the tubing at hand, but the general consensus was minimum of 3 hrs at 200degrees C. AFTER each plating step and before the initial plate too.

#56

Senior Member

Join Date: Jun 2006

Posts: 20,305

Mentioned: 130 Post(s)

Tagged: 0 Thread(s)

Quoted: 3464 Post(s)

Liked 2,831 Times

in

1,997 Posts

That was within an hour of finishing each plate step too.

#57

Senior Member

After looking around on the Web,I mostly see this condition pertaining to industrial applications. I did a search of "broken chrome fork" but only found broken carbon.

#58

Senior Member

Join Date: Jun 2006

Posts: 20,305

Mentioned: 130 Post(s)

Tagged: 0 Thread(s)

Quoted: 3464 Post(s)

Liked 2,831 Times

in

1,997 Posts

In all instances, the platers I talked to were concerned about cross tank contamination much more than hydrogen embrittlement.

They shifted gears a bit when I advised that the material was a mix of steels, some being close to 4130, an alloy they were familiar with.

Basically in my view, why not have it done right?

#59

Decrepit Member

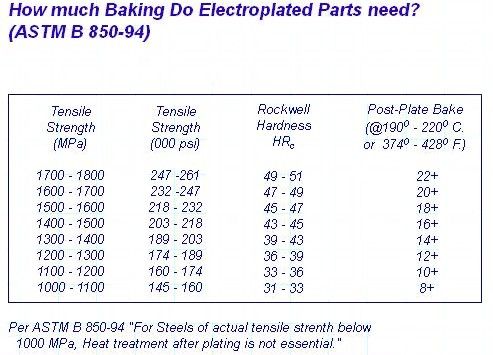

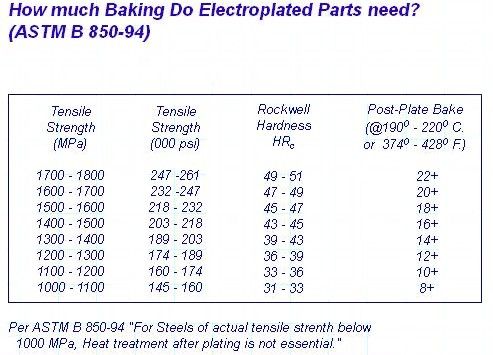

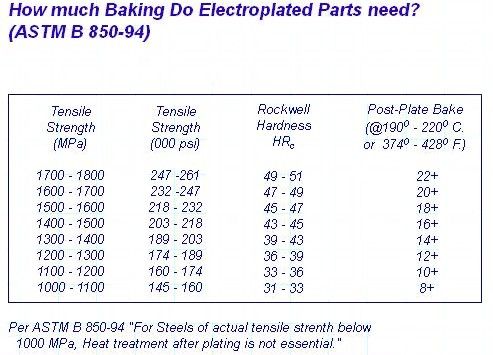

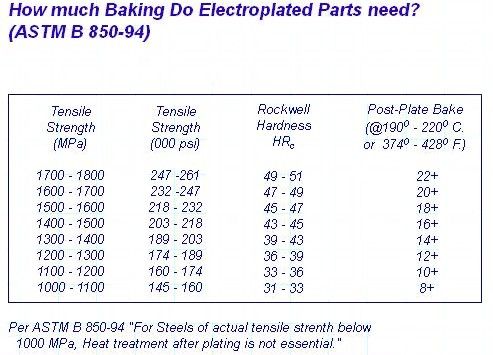

The ASTM standard procedure of performing post plating heat treatment of some steels for reducing susceptibility to hydrogen embrittlement or degradation that may arise in the finishing processes is contained in ASTM B850-98 (2009). This table specifying baking time is from B850-94, an earlier version. The standard specifies baking for 8 plus hours at 374°F - 428°F for steels with tensile strengths between 1000 and 1100 MPa. Steel alloys with higher tensile strength need to bake longer. Also, since hydrogen is introduced by diffusion near the surface during plating, thin-walled tubing < 1mm (most bicycle frame tubing) is at higher risk for hydrogen embrittlement than thicker tubing or plate.

There is a 4-hour time limit for baking out entrapped hydrogen after acid treating the parts. This is the time between the end of acid exposure and the beginning of the heating cycle in the baking furnace per SAE AMS 2759/9D Section 3.3.3.1 which calls out the correct procedure for eliminating entrapped hydrogen, but the sooner the baking is begun after acid treating the parts, the better.

There is a 4-hour time limit for baking out entrapped hydrogen after acid treating the parts. This is the time between the end of acid exposure and the beginning of the heating cycle in the baking furnace per SAE AMS 2759/9D Section 3.3.3.1 which calls out the correct procedure for eliminating entrapped hydrogen, but the sooner the baking is begun after acid treating the parts, the better.

#60

Phyllo-buster

Join Date: Jan 2010

Location: Nova Scotia

Posts: 8,847

Bikes: roadsters, club bikes, fixed and classic

Mentioned: 133 Post(s)

Tagged: 0 Thread(s)

Quoted: 2298 Post(s)

Liked 2,055 Times

in

1,255 Posts

I'm quite happy for you because about 15 years ago they charged me a fortune for some small part, can't remember what. Must have been the prep work,

Last edited by clubman; 12-23-14 at 04:37 PM.

#61

Banned.

You and those dang facts

The ASTM standard procedure of performing post plating heat treatment of some steels for reducing susceptibility to hydrogen embrittlement or degradation that may arise in the finishing processes is contained in ASTM B850-98 (2009). This table specifying baking time is from B850-94, an earlier version. The standard specifies baking for 8 plus hours at 374°F - 428°F for steels with tensile strengths between 1000 and 1100 MPa. Steel alloys with higher tensile strength need to bake longer. Also, since hydrogen is introduced by diffusion near the surface during plating, thin-walled tubing < 1mm (most bicycle frame tubing) is at higher risk for hydrogen embrittlement than thicker tubing or plate.

There is a 4-hour time limit for baking out entrapped hydrogen after acid treating the parts. This is the time between the end of acid exposure and the beginning of the heating cycle in the baking furnace per SAE AMS 2759/9D Section 3.3.3.1 which calls out the correct procedure for eliminating entrapped hydrogen, but the sooner the baking is begun after acid treating the parts, the better.

There is a 4-hour time limit for baking out entrapped hydrogen after acid treating the parts. This is the time between the end of acid exposure and the beginning of the heating cycle in the baking furnace per SAE AMS 2759/9D Section 3.3.3.1 which calls out the correct procedure for eliminating entrapped hydrogen, but the sooner the baking is begun after acid treating the parts, the better.

#62

Senior Member

As I said, I work in a machine shop. I asked the boss today, one that is well versed in metallurgy. He said the fork had to be carberized before the copper went on, protecting the steel. You guys will be the first to know if I end up loosing any teeth once the fork fails. Pictures to follow.

#63

Decrepit Member

Carburizing will harden the steel, but I'm not sure how that prevents the hydrogen, in atomic form, from entering and diffusing through the steel alloy surface during the subsequent plating.

Anyway, good luck with your fork. Seriously.

Anyway, good luck with your fork. Seriously.

#64

Decrepit Member

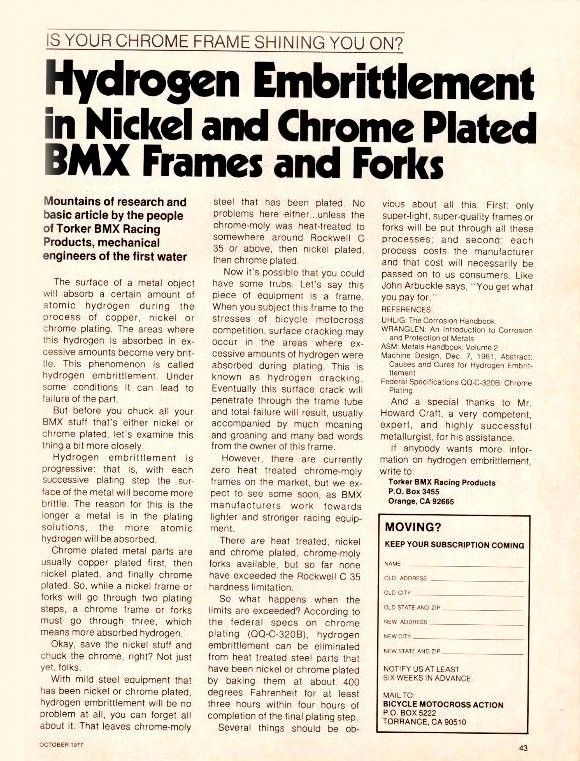

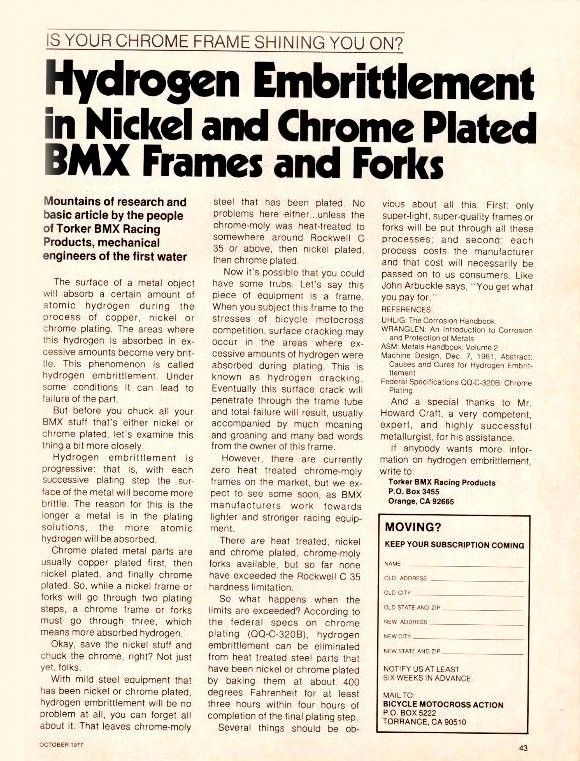

A 1977 article on the subject for everybody's amusement.

#65

Senior Member

Thanks Stan. I do have a little concern. This is a good thread for future restorers to discuss with the plater BEFORE the job.

#66

Senior Member

Join Date: Jul 2009

Posts: 11,128

Bikes: 1986 Alan Record Carbonio, 1985 Vitus Plus Carbone 7, 1984 Peugeot PSV, 1972 Line Seeker, 1986(est.) Medici Aerodynamic (Project), 1985(est.) Peugeot PY10FC

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 150 Post(s)

Likes: 0

Liked 34 Times

in

27 Posts

Mehhh.... I wouldn't worry to much about chroming forks, Peugeot chromed jillions of forks on their upper model bikes in the 80's having Reynolds 501, 531 tubesets and IIRC some top of the line race reps with 753 and SLX tubing. Include to that the lots of Vitus 980 tubed bikes which had quite thin gauges....And I have not heard or seen of any epidemic-like Peugeot chrome weakened fork failures and rampant tin worn disease yet, after all these years.....and we know how hard Peugeots are ridden by most owners, being that they weren't considered instant cherished classics when bought....I suspect it's just a case of "overthunking" by some builders/comapnies happening here.... My Peugoet PSV was ridden quite a bit in the rain in the 80's and spent a good chunk of the 90's hibernating in damp garages before I pulled it back into service in the early 2000's and only suffered a few freckle spots on its fork chrome that easily polished off with some metal polish.... And it has not asploded on me yet.

JMOs

JMOs

#67

Banned.

Whoosh

Mehhh.... I wouldn't worry to much about chroming forks, Peugeot chromed jillions of forks on their upper model bikes in the 80's having Reynolds 501, 531 tubesets and IIRC some top of the line race reps with 753 and SLX tubing. Include to that the lots of Vitus 980 tubed bikes which had quite thin gauges....And I have not heard or seen of any epidemic-like Peugeot chrome weakened fork failures and rampant tin worn disease yet, after all these years.....and we know how hard Peugeots are ridden by most owners, being that they weren't considered instant cherished classics when bought....I suspect it's just a case of "overthunking" by some builders/comapnies happening here.... My Peugoet PSV was ridden quite a bit in the rain in the 80's and spent a good chunk of the 90's hibernating in damp garages before I pulled it back into service in the early 2000's and only suffered a few freckle spots on its fork chrome that easily polished off with some metal polish.... And it has not asploded on me yet.

JMOs

JMOs

#68

Decrepit Member

Mehhh.... I wouldn't worry to much about chroming forks, Peugeot chromed jillions of forks on their upper model bikes in the 80's having Reynolds 501, 531 tubesets and IIRC some top of the line race reps with 753 and SLX tubing. Include to that the lots of Vitus 980 tubed bikes which had quite thin gauges....And I have not heard or seen of any epidemic-like Peugeot chrome weakened fork failures and rampant tin worn disease yet, after all these years.....and we know how hard Peugeots are ridden by most owners, being that they weren't considered instant cherished classics when bought....I suspect it's just a case of "overthunking" by some builders/comapnies happening here.... My Peugoet PSV was ridden quite a bit in the rain in the 80's and spent a good chunk of the 90's hibernating in damp garages before I pulled it back into service in the early 2000's and only suffered a few freckle spots on its fork chrome that easily polished off with some metal polish.... And it has not asploded on me yet.

JMOs

JMOs

#69

Banned.

Stan, your posts have been most informative. They explain why I was quoted over 10X what some folks are paying to have bicycle chrome done. Thank you for your contributions, and presentation of FACTS. I think even @J T CUNNINGHAM would agree.

You are truly an asset to the forum, and that is not to be taken lightly. One could drown in the misinformation here.

If I ever make it to your neck of the woods, dinner and drinks are on me.

You are truly an asset to the forum, and that is not to be taken lightly. One could drown in the misinformation here.

If I ever make it to your neck of the woods, dinner and drinks are on me.

The bicycle manufacturers all baked their frames and forks after plating, so factory chrome plated frames and forks aren't a problem. Aftermarket platers who normally don't plate thin-walled high strength steel tubing may not relieve hydrogen embrittlement by baking the frames and forks immediately after each plating process, and that could be a problem.

#70

Senior Member

Join Date: Nov 2006

Location: TORONTO , ONT , CA

Posts: 813

Bikes: '86 AMBROSI / C RECORD. PINARELLO MONTELLO / FRAME, FORK.

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

There are certainly some sane posts in the above, but as is said, There are Other Matters, as well. lol

I haven't read within this forum at any time, the possibility of after a part has been OEM plated without

being baked-out "because it doesn't matter", just what happens after the rechrome is done which only

exasperates the situation?

Plating is a Science, with many "master Apprentices"; Walt Disney produced a film, taken from a book,

the name of which I don't remember, about a similar scenario. Here again, there are few concours (s?)

plating companies in business and if anyone believes they are entitled to a first class fork plating job

for $50.00, I have a Bridge in Brooklyn.

Regards,

J T

I haven't read within this forum at any time, the possibility of after a part has been OEM plated without

being baked-out "because it doesn't matter", just what happens after the rechrome is done which only

exasperates the situation?

Plating is a Science, with many "master Apprentices"; Walt Disney produced a film, taken from a book,

the name of which I don't remember, about a similar scenario. Here again, there are few concours (s?)

plating companies in business and if anyone believes they are entitled to a first class fork plating job

for $50.00, I have a Bridge in Brooklyn.

Regards,

J T

#71

Senior Member

I will ride this fork and post back. It was actually $50 for plate and $15 for stripping. I believe it came out beautiful. Hopefully this will be a test tube test to see if question brought up is justified. Let's see if the arm chair criticism is founded.

There are certainly some sane posts in the above, but as is said, There are Other Matters, as well. lol

I haven't read within this forum at any time, the possibility of after a part has been OEM plated without

being baked-out "because it doesn't matter", just what happens after the rechrome is done which only

exasperates the situation?

Plating is a Science, with many "master Apprentices"; Walt Disney produced a film, taken from a book,

the name of which I don't remember, about a similar scenario. Here again, there are few concours (s?)

plating companies in business and if anyone believes they are entitled to a first class fork plating job

for $50.00, I have a Bridge in Brooklyn.

Regards,

J T

I haven't read within this forum at any time, the possibility of after a part has been OEM plated without

being baked-out "because it doesn't matter", just what happens after the rechrome is done which only

exasperates the situation?

Plating is a Science, with many "master Apprentices"; Walt Disney produced a film, taken from a book,

the name of which I don't remember, about a similar scenario. Here again, there are few concours (s?)

plating companies in business and if anyone believes they are entitled to a first class fork plating job

for $50.00, I have a Bridge in Brooklyn.

Regards,

J T

#72

Senior Member

Join Date: Jul 2009

Posts: 11,128

Bikes: 1986 Alan Record Carbonio, 1985 Vitus Plus Carbone 7, 1984 Peugeot PSV, 1972 Line Seeker, 1986(est.) Medici Aerodynamic (Project), 1985(est.) Peugeot PY10FC

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 150 Post(s)

Likes: 0

Liked 34 Times

in

27 Posts

There seems to be enough evidence out there of lots and lots old light gauge steel tubed chromed frames and forks by made all sorts of companies, big and small, that surely have not had this "baking" process done as these embrittlement studies most likely had not seen the light of day when they were built. And they still roll on riding in all sorts of conditions without any catastrophic failures....

Sure, have the baking done if you can, and afford to do so for that added safety factor, but I think for most riders, it will not be a critical requirement for them to have a safe and fun bike to ride for many years and the life of the bike.

Sure, have the baking done if you can, and afford to do so for that added safety factor, but I think for most riders, it will not be a critical requirement for them to have a safe and fun bike to ride for many years and the life of the bike.

#73

Decrepit Member

I had no idea there would be such contention when I commented that chrome plated frames and forks without post process baking to relieve hydrogen embrittlement could risk brittleness and fracture. I mentioned it in this thread because I was concerned that some here were taking a risk by having platers who don't bake the parts after plating perform chrome plating at very low cost without understanding the risk of not baking. This is the last comment I'll make about it. Take it for what it is.

The phenomenon we know as hydrogen embrittlement resulting from finishing operations like plating was first observed and described in 1875, several years before the development of the modern safety bicycle, and plating bicycle frames with copper and nickel to prevent rust is described in the 1899 book, The Modern Safety Bicycle by H.A. Garrett. Baking plated frames and forks to mitigate hydrogen embrittlement as part of the plating process became standard procedure in the early twentieth century.

In his chapter on refinishing, Eugene A. Sloane, author of The All New Complete Book of Bicycling, says this about chrome plating forks.

I'm done.

The phenomenon we know as hydrogen embrittlement resulting from finishing operations like plating was first observed and described in 1875, several years before the development of the modern safety bicycle, and plating bicycle frames with copper and nickel to prevent rust is described in the 1899 book, The Modern Safety Bicycle by H.A. Garrett. Baking plated frames and forks to mitigate hydrogen embrittlement as part of the plating process became standard procedure in the early twentieth century.

In his chapter on refinishing, Eugene A. Sloane, author of The All New Complete Book of Bicycling, says this about chrome plating forks.

Originally Posted by Eugene A. Sloane

Chrome plating has its disadvantages, such as the corrosive actions of the plating process (for example, rust forming on the insides of the frame tubes). Hydrogen embrittlement, another bugaboo of the plating process, is caused when hydrogen diffuses into the metal being plated during the chroming operation. Oven baking at a prescribed temperature/time setting will relieve the hydrogen. However, some platers will not do this, do not want to be bothered with it and simply do not care. The question is, do you? Some cyclists are very wary about riding with front forks weakened or made brittle by the plating process.

#74

Senior Member

Stan, your posts have been most informative. They explain why I was quoted over 10X what some folks are paying to have bicycle chrome done. Thank you for your contributions, and presentation of FACTS. I think even @J T CUNNINGHAM would agree.

You are truly an asset to the forum, and that is not to be taken lightly. One could drown in the misinformation here.

If I ever make it to your neck of the woods, dinner and drinks are on me.

You are truly an asset to the forum, and that is not to be taken lightly. One could drown in the misinformation here.

If I ever make it to your neck of the woods, dinner and drinks are on me.