Wheel lateral stiffness. WHat makes it stiff?

#26

Junior Member

#27

Senior Member

Everything in combination makes a stiff wheel - rim stiffness, spoke gauge, spoke count, hub flanges, lacing pattern, tension, etc.

Spoke count in and of itself is about meaningless. My 16/20 spoke Shimano C50's ride a lot stiffer than most 32 spoke 3x aluminum box rim wheelset I've tried!

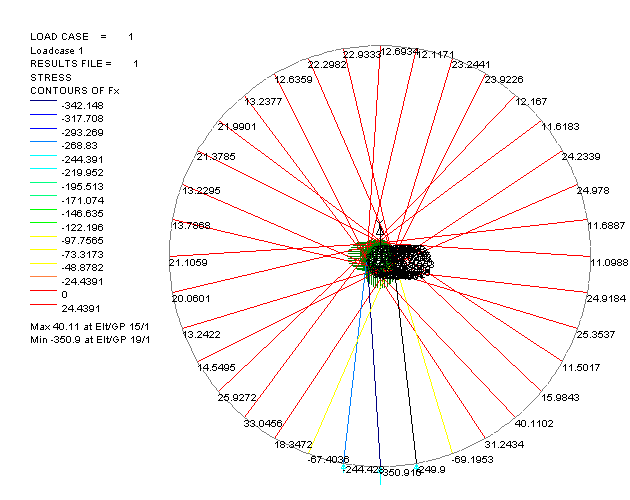

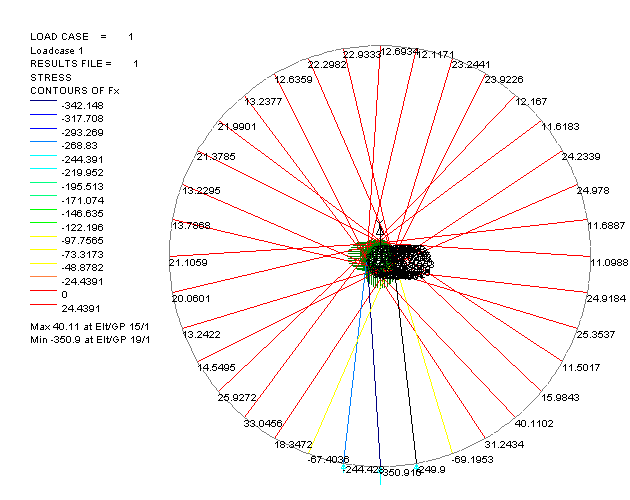

Here's a C75:

Spoke count in and of itself is about meaningless. My 16/20 spoke Shimano C50's ride a lot stiffer than most 32 spoke 3x aluminum box rim wheelset I've tried!

Here's a C75:

Last edited by Jamminatrix; 07-29-15 at 10:54 PM.

#28

Senior Member

Join Date: Apr 2015

Location: Morris County, NJ

Posts: 1,102

Bikes: 90's Bianchi Premio, Raleigh-framed fixed gear, Trek 3500, Centurion hybrid, Dunelt 3-spd, Trek 800

Mentioned: 40 Post(s)

Tagged: 0 Thread(s)

Quoted: 2167 Post(s)

Likes: 0

Liked 2 Times

in

2 Posts

@FBinNY: From reading many of your posts, I'm sure you know exactly what you are talking about. Otherwise, I wouldn't ask that you please elaborate on these two statements:

1. "wheel stiffness depends almost entirely on the total amount of steel, namely the cross section X the no. of spokes."

2. "TENSION HAS NO EFFECT ON STIFFNESS."

In Statement 1, you suggest that rim profile counts for little. I was hoping that my deep-V rims at least gave me some strength for their extra weight. (I recently hit a bump in the road and suffered a snake-bite puncture but no deformation of the rim. Could a flexier rim have saved the tube? Just speculating.)

In Statement 2, you suggest that I could loosen the tension on all (or even only some) spokes and it would have no effect on wheel stiffness. If I understand you correctly, this runs counter to everything I've read about wheel building. What am I missing?

1. "wheel stiffness depends almost entirely on the total amount of steel, namely the cross section X the no. of spokes."

2. "TENSION HAS NO EFFECT ON STIFFNESS."

In Statement 1, you suggest that rim profile counts for little. I was hoping that my deep-V rims at least gave me some strength for their extra weight. (I recently hit a bump in the road and suffered a snake-bite puncture but no deformation of the rim. Could a flexier rim have saved the tube? Just speculating.)

In Statement 2, you suggest that I could loosen the tension on all (or even only some) spokes and it would have no effect on wheel stiffness. If I understand you correctly, this runs counter to everything I've read about wheel building. What am I missing?

Last edited by habilis; 07-30-15 at 07:15 AM.

#29

Senior Member

Frank, I have a fairly flexible wheel set and there is no issue with the brakes rubbing the rim in spite of noticeable deflection between the hub and the ground at the front wheel. I had posted this observation, but I can't find it no matter what.

The wheel set is 28H CXP23 built with 15-16 butted spokes and Shimano 6500 hubs. Your rim maybe stiffer than mine causing deflection further towards the top of the rim (?), but basically I'd just allow more clearance between the brake pad and the rim.

Brad

The wheel set is 28H CXP23 built with 15-16 butted spokes and Shimano 6500 hubs. Your rim maybe stiffer than mine causing deflection further towards the top of the rim (?), but basically I'd just allow more clearance between the brake pad and the rim.

Brad

#30

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5792 Post(s)

Liked 2,583 Times

in

1,432 Posts

@FBinNY: From reading many of your posts, I'm sure you know exactly what you are talking about. Otherwise, I wouldn't ask that you please elaborate on these two statements:

1. "wheel stiffness depends almost entirely on the total amount of steel, namely the cross section X the no. of spokes."

2. "TENSION HAS NO EFFECT ON STIFFNESS."

In Statement 1, you suggest that rim profile counts for little. I was hoping that my deep-V rims at least gave me some strength for their extra weight. (I recently hit a bump in the road and suffered a snake-bite puncture but no deformation of the rim. Could a flexier rim have saved the tube? Just speculating.)

In Statement 2, you suggest that I could loosen the tension on all (or even only some) spokes and it would have no effect on wheel stiffness. If I understand you correctly, this runs counter to everything I've read about wheel building. What am I missing?

1. "wheel stiffness depends almost entirely on the total amount of steel, namely the cross section X the no. of spokes."

2. "TENSION HAS NO EFFECT ON STIFFNESS."

In Statement 1, you suggest that rim profile counts for little. I was hoping that my deep-V rims at least gave me some strength for their extra weight. (I recently hit a bump in the road and suffered a snake-bite puncture but no deformation of the rim. Could a flexier rim have saved the tube? Just speculating.)

In Statement 2, you suggest that I could loosen the tension on all (or even only some) spokes and it would have no effect on wheel stiffness. If I understand you correctly, this runs counter to everything I've read about wheel building. What am I missing?

Within the working range the amount a spoke will stretch with added load, ie. your weight, is the same whether the tension starts at 10okgf and goes to 120, or starts at 70 and goes to 90 is exactly the same. So, it's not the initial tension that matters, only the change. So applying the principles of Young/s Modulus, it's apparent that since the elastic properties of the materials can't change, the easiest way improve the stiffness of a given tension structure, ie. a bicycle wheel is to add material (steel) so either fatter spokes or more spokes or both.

There are other things that improve stiffness, for example changing the spoke's bracing angle, but this isn't as easy as it seems at first glance. For example we could increase flange separation (best option), but we're constrained by space available. Or we can increase flange size, but since the spokes are tangent or near tangent, flange size has little effect because spokes are pulling from near the center-line anyway. So it's back to more steel, or as I sometimes write more "spoke". There's no magic here.

Rim stiffness does make a difference, but it's not as great as people would like to believe. Even the stiffest rim is like taffy compared to the stiffness the spokes provide. The rim's main contribution, besides being a tire mounting surface is as a compression ring to hold the spokes under tension. But some added rim stiffness does help because it spreads the loads among more spokes, especially in lateral deflections. Consider truss bridge construction. As spans get longer the depth of the trusses is increased, and likewise deeper or wider rims will be stiffer and spread the load bringing more spokes into play, and thereby improving stiffness somewhat.

The key to understanding stiffness in wheels isn't to think about what it's like statically, but what will happen as it deflects under loads, keeping in mind that it's a system of elements working as a whole, not acting independently of each other.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

Last edited by FBinNY; 07-30-15 at 09:02 AM.

#31

Senior Member

#32

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5792 Post(s)

Liked 2,583 Times

in

1,432 Posts

The entire hanging from top, supported from the bottom debate is nonsense, there are elements of truth and error in both statements.

First, let's end the supported from the bottom error. It's not possible, for the simple reason that the nipple isn't attached to the rim, and the rim can't push it toward center. Try that with a single spoke in a hole of some kind and it'll be obvious.

But the hanging form the top theory is likewise weak. If you press the axle of a built wheel toward the rim, you won't see enough change in the tension of the spokes opposite (the top) to account for the force involved.

Instead of thinking inn terms of either wrong answer, think of a wheel as a system where ALL spokes support the hub at all times. When loaded, the tensions in the various spokes change so there's a net change among the spokes to offset the load. How that change is represented among the individual spokes depends on the radial stiffness of the rim.

Looking at extremes helps. If we assume the rim is absolutely rigid (radially) there will be a reduction in tension among lower spokes, and a symmetrical increase among upper. But if the rim has very little radial rigidity, the area directly above the bottom spoke will move in slackening that one spoke, while then rest will have a very small increase in tension distributed nearly equally all the way around. The reality is that rims are in between those extremes, so you get a blended result, with it looking more or less like one of the extremes according to the rim's ability to spread the load.

First, let's end the supported from the bottom error. It's not possible, for the simple reason that the nipple isn't attached to the rim, and the rim can't push it toward center. Try that with a single spoke in a hole of some kind and it'll be obvious.

But the hanging form the top theory is likewise weak. If you press the axle of a built wheel toward the rim, you won't see enough change in the tension of the spokes opposite (the top) to account for the force involved.

Instead of thinking inn terms of either wrong answer, think of a wheel as a system where ALL spokes support the hub at all times. When loaded, the tensions in the various spokes change so there's a net change among the spokes to offset the load. How that change is represented among the individual spokes depends on the radial stiffness of the rim.

Looking at extremes helps. If we assume the rim is absolutely rigid (radially) there will be a reduction in tension among lower spokes, and a symmetrical increase among upper. But if the rim has very little radial rigidity, the area directly above the bottom spoke will move in slackening that one spoke, while then rest will have a very small increase in tension distributed nearly equally all the way around. The reality is that rims are in between those extremes, so you get a blended result, with it looking more or less like one of the extremes according to the rim's ability to spread the load.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

Last edited by FBinNY; 07-30-15 at 08:35 AM.

#33

Junior Member

The entire hanging from top, supported from the bottom debate is nonsense, there are elements of truth and error in both statements.

First, let's end the supported from the bottom error. It's not possible, for the simple reason that the nipple isn't attached to the rim, and the rim can't push it toward center. Try that with a single spoke in a hole of some kind and it'll be obvious.

But the hanging form the top theory is likewise weak. If you press the axle of a built wheel toward the rim, you won't see enough change in the tension of the spokes opposite (the top) to account for the force involved.

Instead of thinking inn terms of either wrong answer, think of a wheel as a system where ALL spokes support the hub at all times. When loaded, the tensions in the various spokes change so there's a net change among the spokes to offset the load. How that change is represented among the individual spokes depends on the radial stiffness of the rim.

Looking at extremes helps. If we assume the rim is absolutely rigid (radially) there will be a reduction in tension among lower spokes, and a symmetrical increase among upper. But if the rim has very little radial rigidity, the area directly above the bottom spoke will move in slackening that one spoke, while then rest will have a very small increase in tension distributed nearly equally all the way around. The reality is that rims are in between those extremes, so you get a blended result, with it looking more or less like one of the extremes according to the rim's ability to spread the load.

First, let's end the supported from the bottom error. It's not possible, for the simple reason that the nipple isn't attached to the rim, and the rim can't push it toward center. Try that with a single spoke in a hole of some kind and it'll be obvious.

But the hanging form the top theory is likewise weak. If you press the axle of a built wheel toward the rim, you won't see enough change in the tension of the spokes opposite (the top) to account for the force involved.

Instead of thinking inn terms of either wrong answer, think of a wheel as a system where ALL spokes support the hub at all times. When loaded, the tensions in the various spokes change so there's a net change among the spokes to offset the load. How that change is represented among the individual spokes depends on the radial stiffness of the rim.

Looking at extremes helps. If we assume the rim is absolutely rigid (radially) there will be a reduction in tension among lower spokes, and a symmetrical increase among upper. But if the rim has very little radial rigidity, the area directly above the bottom spoke will move in slackening that one spoke, while then rest will have a very small increase in tension distributed nearly equally all the way around. The reality is that rims are in between those extremes, so you get a blended result, with it looking more or less like one of the extremes according to the rim's ability to spread the load.

I was just trying to break it down to the simplest form but I may have gone just a little too far. My main point was that spokes don't (for all practical purposes) support a load in compression.

Last edited by KJK; 07-30-15 at 09:01 AM.

#34

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5792 Post(s)

Liked 2,583 Times

in

1,432 Posts

Once you realize that the rim can't push the nipple, it helps redirect the mind to more real possibilities.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

#35

Senior Member

The entire hanging from top, supported from the bottom debate is nonsense, there are elements of truth and error in both statements.

First, let's end the supported from the bottom error. It's not possible, for the simple reason that the nipple isn't attached to the rim, and the rim can't push it toward center. Try that with a single spoke in a hole of some kind and it'll be obvious.

But the hanging form the top theory is likewise weak. If you press the axle of a built wheel toward the rim, you won't see enough change in the tension of the spokes opposite (the top) to account for the force involved.

Instead of thinking inn terms of either wrong answer, think of a wheel as a system where ALL spokes support the hub at all times. When loaded, the tensions in the various spokes change so there's a net change among the spokes to offset the load. How that change is represented among the individual spokes depends on the radial stiffness of the rim.

Looking at extremes helps. If we assume the rim is absolutely rigid (radially) there will be a reduction in tension among lower spokes, and a symmetrical increase among upper. But if the rim has very little radial rigidity, the area directly above the bottom spoke will move in slackening that one spoke, while then rest will have a very small increase in tension distributed nearly equally all the way around. The reality is that rims are in between those extremes, so you get a blended result, with it looking more or less like one of the extremes according to the rim's ability to spread the load.

First, let's end the supported from the bottom error. It's not possible, for the simple reason that the nipple isn't attached to the rim, and the rim can't push it toward center. Try that with a single spoke in a hole of some kind and it'll be obvious.

But the hanging form the top theory is likewise weak. If you press the axle of a built wheel toward the rim, you won't see enough change in the tension of the spokes opposite (the top) to account for the force involved.

Instead of thinking inn terms of either wrong answer, think of a wheel as a system where ALL spokes support the hub at all times. When loaded, the tensions in the various spokes change so there's a net change among the spokes to offset the load. How that change is represented among the individual spokes depends on the radial stiffness of the rim.

Looking at extremes helps. If we assume the rim is absolutely rigid (radially) there will be a reduction in tension among lower spokes, and a symmetrical increase among upper. But if the rim has very little radial rigidity, the area directly above the bottom spoke will move in slackening that one spoke, while then rest will have a very small increase in tension distributed nearly equally all the way around. The reality is that rims are in between those extremes, so you get a blended result, with it looking more or less like one of the extremes according to the rim's ability to spread the load.

True that it begins with the pretension of the spokes which requires a complete system as all of the spokes together is what allows the spokes at the bottom to be under tension: that's what makes it all work. And, the greater the pretension, the greater the applied compression can be. I'm just passing along what I've read as to the understanding of engineers or most engineers or at least all of the engineers that you can Google on the net (e.g., "bicycle wheel stands spoke compression") that it all works because, a wheel stands on its spokes, not because the hub is suspended by the spokes from the top of the rim.

Looking at the matter by focusing on extremes what you then 'see' is a lengthening of the spokes at the top of the rim, reflecting an increase in tension, and a decrease in length of the spokes at the bottom that are under the greatest amount of stress as evidenced by their loss of tension caused by compression. Among those factors about which there seems to common agreement: to carry more load (withstand more compression) you need a stronger rim to withstand the greater pretension forces; the spokes carrying the load –i.e., those that are under the most compression – are still under tension or they would collapse (a spoke under tension can only support compression loads up to point that it becomes 'slack'); and, the spoke at the bottom of the wheel does not gain compression but rather, it pushes up on the hub as it shortens due to its decrease in tension.

#36

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5792 Post(s)

Liked 2,583 Times

in

1,432 Posts

True that it begins with the pretension of the spokes which requires a complete system as all of the spokes together is what allows the spokes at the bottom to be under tension: that's what makes it all work. And, the greater the pretension, the greater the applied compression can be. I'm just passing along what I've read as to the understanding of engineers or most engineers or at least all of the engineers that you can Google on the net (e.g., "bicycle wheel stands spoke compression") that it all works because, a wheel stands on its spokes, not because the hub is suspended by the spokes from the top of the rim.....

Moreover, the concept of "standing on the bottom" belies the actual condition, which spreads the changes among ALL the spokes. In the case of a more flexible rim, the tension of spokes near the bottom increases along with all the others.

We can debate semantics forever, but the only realistic models are those that describe the entire system, and discuss net changes in tension bottom to top, including the sides.

If you consider that a deflected rim would ovalize under load, you can see that the hub is also supported from the sides at the same time.

BTW- one of the problems in all wheel discussions is that many people (on all sides) are simply repeating things they've heard and read, and have become very committed to in a way that someone stranded in the ocean clings to whatever floats.

So to those who want to understand this kind of stuff. Don't latch onto partial explanations. Stop, think, draw yourself diagrams and sketches, and try to see the whole picture, not a few pixels.

....

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

#37

Senior Member

The phrase "stands on the bottom spokes" is part of the problem. It's a semantic trick whereby someone describes a reduction of tension as a compression. In that way it's analogous to how some in Congress will describe a reduction in revenue, ie. a tax credit for certain items, as an "expense". Yes, it's functionally the same in terms of the net effect, but it's not the same thing.

Moreover, the concept of "standing on the bottom" belies the actual condition, which spreads the changes among ALL the spokes. In the case of a more flexible rim, the tension of spokes near the bottom increases along with all the others.

We can debate semantics forever, but the only realistic models are those that describe the entire system, and discuss net changes in tension bottom to top, including the sides.

If you consider that a deflected rim would ovalize under load, you can see that the hub is also supported from the sides at the same time.

BTW- one of the problems in all wheel discussions is that many people (on all sides) are simply repeating things they've heard and read, and have become very committed to in a way that someone stranded in the ocean clings to whatever floats.

So to those who want to understand this kind of stuff. Don't latch onto partial explanations. Stop, think, draw yourself diagrams and sketches, and try to see the whole picture, not a few pixels.

....

Moreover, the concept of "standing on the bottom" belies the actual condition, which spreads the changes among ALL the spokes. In the case of a more flexible rim, the tension of spokes near the bottom increases along with all the others.

We can debate semantics forever, but the only realistic models are those that describe the entire system, and discuss net changes in tension bottom to top, including the sides.

If you consider that a deflected rim would ovalize under load, you can see that the hub is also supported from the sides at the same time.

BTW- one of the problems in all wheel discussions is that many people (on all sides) are simply repeating things they've heard and read, and have become very committed to in a way that someone stranded in the ocean clings to whatever floats.

So to those who want to understand this kind of stuff. Don't latch onto partial explanations. Stop, think, draw yourself diagrams and sketches, and try to see the whole picture, not a few pixels.

....

#38

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5792 Post(s)

Liked 2,583 Times

in

1,432 Posts

Forget about "standing" and "hanging" if that only invokes thoughts of nothing more than a debate over semantics. The real question is which spokes are actually doing the work and that has been calculated by engineers using finite element analysis. The spokes at the bottom are carrying the load so that evokes the use of a word like 'stands' to connote something being supported by something else that is resting on the ground, as opposed to the word 'hangs' that might seem more appropriate if the physics of the matter were more like a hub being supported from something else above the hub. Jobst Brandt ("The Bicycle Wheel") is pointed to as the seminal work on the structural mechanics underlying the functioning of the bicycle wheel.

You characterize the lower spokes as doing the work, but would be fairer to say that the lower spokes are doing less work.

Imagine a tug of war. Two teams are pulling equally on the rope with the flag centered over the mud hole. On a signal, all the members of one team let go and send the others back onto their asses, taking the flag with them. So how would you describe this. Would you say they pushed the rope? Maybe, and the effect is as if they did, but they didn't push, they simply failed to pull and that was enough.

Likewise with a bicycle wheel. The lower spokes don't support the hub, they simply don't pull it down as hard, and the rest happens. Notice that like with tug of war, the upper spokes don't have to pull any harder, they just have to keep doing what they were all along.

That's why I hate the up from the bottom or down from the top argument. Neither is true.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

#39

Calamari Marionette Ph.D

Forget about "standing" and "hanging" if that only invokes thoughts of nothing more than a debate over semantics. The real question is which spokes are actually doing the work and that has been calculated by engineers using finite element analysis. The spokes at the bottom are carrying the load so that evokes the use of a word like 'stands' to connote something being supported by something else that is resting on the ground, as opposed to the word 'hangs' that might seem more appropriate if the physics of the matter were more like a hub being supported from something else above the hub. Jobst Brandt ("The Bicycle Wheel") is pointed to as the seminal work on the structural mechanics underlying the functioning of the bicycle wheel.

#40

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5792 Post(s)

Liked 2,583 Times

in

1,432 Posts

YOU are not missing anything at all. Some people use "compression" rather than reduction in tension the same way people would describe spending $6,000 on a $7,000 bike as savings. If that's savings than reduction in tension is compression by the same logic.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

#41

Senior Member

I am not an engineer either but I think it begins with taking the initial state of the spokes as a given. Looking at the bicycle wheel the engineer begins with the prestessed structure where initially, all of the spokes are under tension. It's like perhaps looking at the compressive strength of a pretensioned concrete bridge.

Last edited by McBTC; 07-30-15 at 12:13 PM.

#42

Calamari Marionette Ph.D

I've spent more time (much) thinking about wheels, and trying to truly understand them than I have building them. I've reached a point where the building is easy now, but I still try to learn more about what, and how they experience things as a whole unit.

#43

working on my sandal tan

Join Date: Aug 2011

Location: CID

Posts: 22,629

Bikes: 1991 Bianchi Eros, 1964 Armstrong, 1988 Diamondback Ascent, 1988 Bianchi Premio, 1987 Bianchi Sport SX, 1980s Raleigh mixte (hers), All-City Space Horse (hers)

Mentioned: 98 Post(s)

Tagged: 0 Thread(s)

Quoted: 3871 Post(s)

Liked 2,568 Times

in

1,579 Posts

Discussions like these are probably why decades of wheel builders haven't minded not knowing how wheels work, as long as theirs do.

#44

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5792 Post(s)

Liked 2,583 Times

in

1,432 Posts

As a rule, I avoid the hang vs stand argument the same way I avoid chain lube debates, but sometimes feel the desire to step in and clear the air on public forums, where people are pushed to choose sides between two equally untrue choices.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

#45

Senior Member

I'm always willing to listen..

Now things start to get technical, and you won't be alone if what follows is a little confusing and counterintuitive. There's vigorous disagreement over whether a bike in effect hangs from the upper spokes (those above the hub as you view the bike from the side) or rather is being supported by the lower ones, acting like tiny pillars. 'The latter view, odd as it seems, is definitively the case,' says Jim Papadopoulos from Northeastern University's College of Engineering in Boston, USA, and the co-author of Bicycling Science. Mike Glaskin (Cyclist, 28 April 2015)

#46

working on my sandal tan

Join Date: Aug 2011

Location: CID

Posts: 22,629

Bikes: 1991 Bianchi Eros, 1964 Armstrong, 1988 Diamondback Ascent, 1988 Bianchi Premio, 1987 Bianchi Sport SX, 1980s Raleigh mixte (hers), All-City Space Horse (hers)

Mentioned: 98 Post(s)

Tagged: 0 Thread(s)

Quoted: 3871 Post(s)

Liked 2,568 Times

in

1,579 Posts

Actually most skilled and experienced builders do understand the basics. Knowing them doesn't help with the build, but is critical to choosing and matching the components for a better wheel.

As a rule, I avoid the hang vs stand argument the same way I avoid chain lube debates, but sometimes feel the desire to step in and clear the air on public forums, where people are pushed to choose sides between two equally untrue choices.

As a rule, I avoid the hang vs stand argument the same way I avoid chain lube debates, but sometimes feel the desire to step in and clear the air on public forums, where people are pushed to choose sides between two equally untrue choices.

#47

Senior Member

Join Date: Nov 2014

Location: Eugene, Oregon, USA

Posts: 27,547

Mentioned: 217 Post(s)

Tagged: 0 Thread(s)

Quoted: 18378 Post(s)

Liked 4,512 Times

in

3,354 Posts

Here are a couple of diagrams on load stress on spokes.

Ian's Bicycle Wheel Analysis

https://www.******.com/r/askscience/..._the/t3_25mmxp

(oops, lost r e d d i t from my source link, at least that is where Google took me).

What is interesting about the charts is that the highest tension on the spokes is those spokes at about a 45° from the BOTTOM of the wheel.

No simply hanging from the top.

It is also why a stiffer rim should help somewhat with stress distribution. Although, I'm not quite sure how much that is associated with lateral flex as the OP was asking.

Ian's Bicycle Wheel Analysis

https://www.******.com/r/askscience/..._the/t3_25mmxp

(oops, lost r e d d i t from my source link, at least that is where Google took me).

What is interesting about the charts is that the highest tension on the spokes is those spokes at about a 45° from the BOTTOM of the wheel.

No simply hanging from the top.

It is also why a stiffer rim should help somewhat with stress distribution. Although, I'm not quite sure how much that is associated with lateral flex as the OP was asking.

#48

Calamari Marionette Ph.D

#49

Senior Member

#50

Calamari Marionette Ph.D