'83 720 - Swapped to 700c, freewheel too close to dropout, fender bolt won't fit etc.

#1

Senior Member

Thread Starter

Join Date: Oct 2017

Posts: 2,046

Mentioned: 26 Post(s)

Tagged: 0 Thread(s)

Quoted: 838 Post(s)

Liked 1,082 Times

in

522 Posts

'83 720 - Swapped to 700c, freewheel too close to dropout, fender bolt won't fit etc.

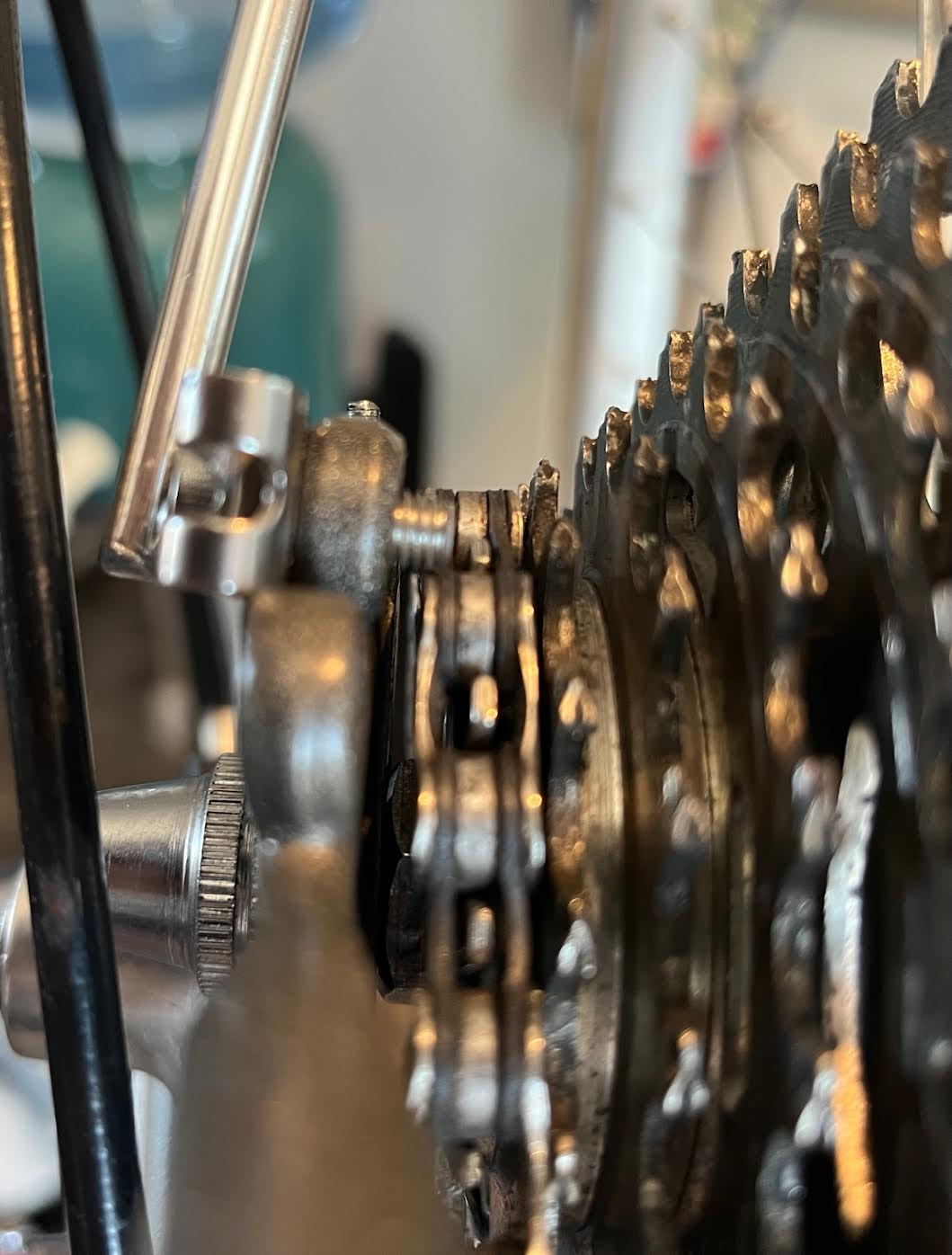

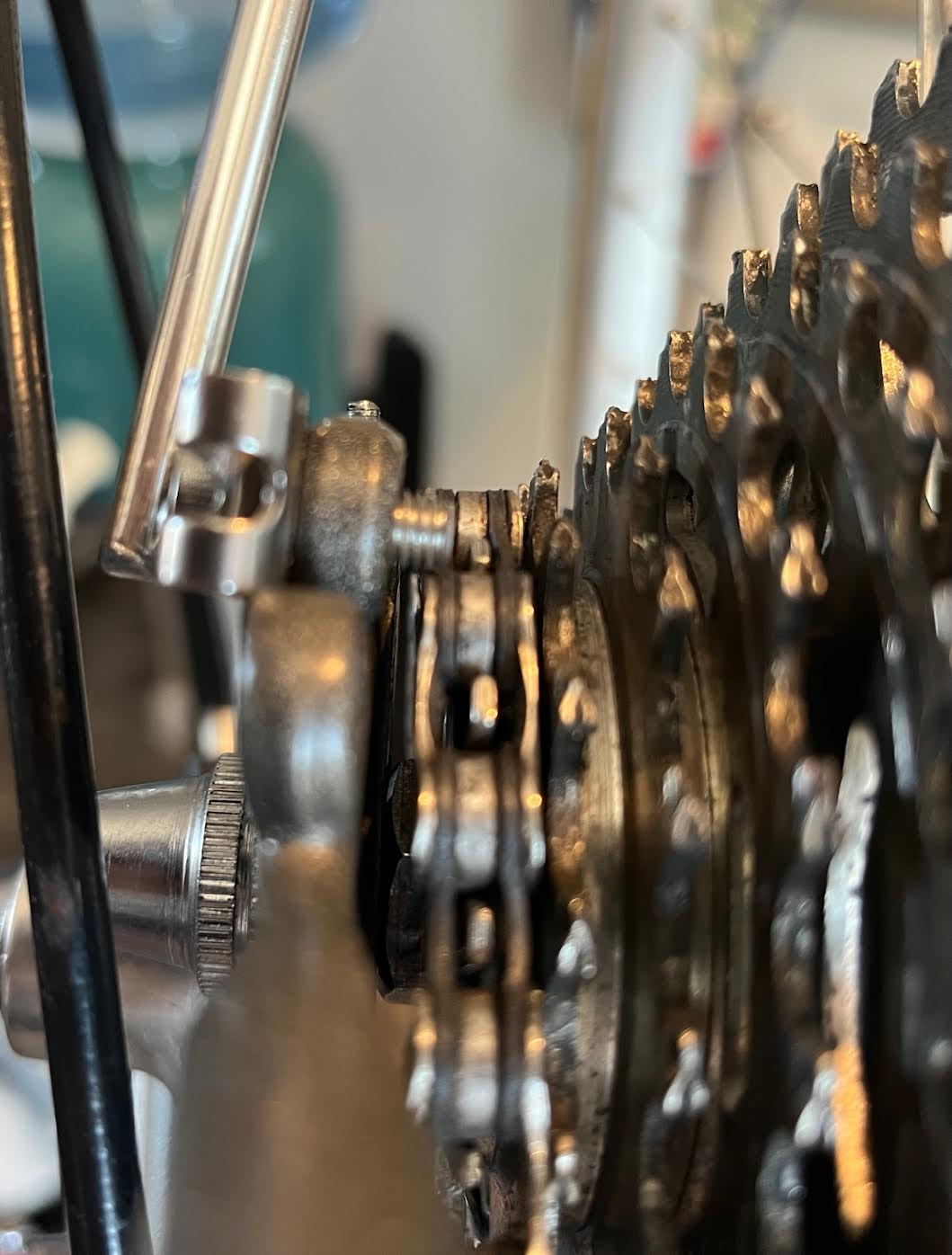

Picked up an 83 Trek 720. Took the freewheel that was on it (a 7spd Maillard, I don't think this is catalog spec) and put it on the new set of 700c wheels. The wheels are Araya wheels from a late 80s Miyata 610.

The first thing I noticed when seating the back wheel is that the smallest cog was now sitting quite close to the dropout. Then, when I went to screw the fender in, the bolt went too far through the other side and is overlapping with the small cog. I also noticed that there is a very large gape between the tire and the seat stay bridge, even with fender on, making me think that perhaps the wheel is seated too far back in the dropout, although it is right about in the middle.

RD is a Deore DX, indexed.

I know that moving the wheel forward will kill the chain length and I'll need a new one. Other than that, any issues? Or should I just use a more shallow bolt for the fender mount and call it a day? The closeness of freewheel to dropout still seems concerning.

Bike shifted correctly with original 27" wheels with wheel seated where it is.

Some photos:

The first thing I noticed when seating the back wheel is that the smallest cog was now sitting quite close to the dropout. Then, when I went to screw the fender in, the bolt went too far through the other side and is overlapping with the small cog. I also noticed that there is a very large gape between the tire and the seat stay bridge, even with fender on, making me think that perhaps the wheel is seated too far back in the dropout, although it is right about in the middle.

RD is a Deore DX, indexed.

I know that moving the wheel forward will kill the chain length and I'll need a new one. Other than that, any issues? Or should I just use a more shallow bolt for the fender mount and call it a day? The closeness of freewheel to dropout still seems concerning.

Bike shifted correctly with original 27" wheels with wheel seated where it is.

Some photos:

Last edited by polymorphself; 09-03-23 at 03:06 PM.

#2

seŮor miembro

Join Date: Dec 2018

Location: Pac NW

Posts: 6,628

Bikes: '70s - '80s Campagnolo

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 3890 Post(s)

Liked 6,491 Times

in

3,213 Posts

1. The fender bolt doesn't need to be so long for a threaded eyelet. You only need to see one or two threads on the other side.

2. You can simply use a hacksaw on the bolt. Before you cut it, put a nut on there, so that when you remove the nut, it cleans the threads of the cut.

3. Without the fender bolt in place, see if the hub spacing is correct for that freewheel. Place the chain on the biggest gear, which is your largest chainring and smallest rear cog. Does the chain clear the frame when pedaling? if so, there's probably enough clearance, so you do not need to respace the hub. If not, you will need to respace the hub and redish the wheel. You may even need a longer axle.

2. You can simply use a hacksaw on the bolt. Before you cut it, put a nut on there, so that when you remove the nut, it cleans the threads of the cut.

3. Without the fender bolt in place, see if the hub spacing is correct for that freewheel. Place the chain on the biggest gear, which is your largest chainring and smallest rear cog. Does the chain clear the frame when pedaling? if so, there's probably enough clearance, so you do not need to respace the hub. If not, you will need to respace the hub and redish the wheel. You may even need a longer axle.

Likes For SurferRosa:

#3

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,820

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 840 Post(s)

Liked 1,262 Times

in

667 Posts

it's a tight fit. you can cut the bolt or use a spacer or two and get the bolt end flush with the inner face of the DO.

Might add a spacer on the axle too if the chain is dragging on the inside of the drop out.

if the rear derailleur has a b-screw you can tighten that about a half turn and take up some chain length / maintain tension

/markp

Might add a spacer on the axle too if the chain is dragging on the inside of the drop out.

if the rear derailleur has a b-screw you can tighten that about a half turn and take up some chain length / maintain tension

/markp

#4

Senior Member

Join Date: Feb 2010

Location: Bloomington/Normal IL

Posts: 1,062

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 152 Post(s)

Liked 237 Times

in

139 Posts

Picked up an 83 Trek 720. Took the freewheel that was on it (a 7spd Maillard, I don't think this is catalog spec) and put it on the new set of 700c wheels. The wheels are Araya wheels from a late 80s Miyata 610.

The first thing I noticed when seating the back wheel is that the smallest cog was now sitting quite close to the dropout. Then, when I went to screw the fender in, the bolt went too far through the other side and is overlapping with the small cog. I also noticed that there is a very large gape between the tire and the seat stay bridge, even with fender on, making me think that perhaps the wheel is seated too far back in the dropout, although it is right about in the middle.

RD is a Deore indexed.

The first thing I noticed when seating the back wheel is that the smallest cog was now sitting quite close to the dropout. Then, when I went to screw the fender in, the bolt went too far through the other side and is overlapping with the small cog. I also noticed that there is a very large gape between the tire and the seat stay bridge, even with fender on, making me think that perhaps the wheel is seated too far back in the dropout, although it is right about in the middle.

RD is a Deore indexed.

I am having almost the exact same issue using nearly identical pieces/parts. ARRRRGH

Have an 83 Trek 720.

It was running a 6 speed non indexed no problem.

I swapped out the 6 for a Shimano 7 using the wheelset from a Miyata 610 and it rubs on the smallest cog enough to jam.

I am also using an indexed Deore RD. I put the 6 speed freewheel back on and it shifts fine.

It has been 2 weeks and it is still in the stand. I wanted to go 7 speed bar end indexed and I feel I may be staying with 6 speed for now.

I will be very interested in seeing how you resolve this with the collective knowledge here.

Likes For OTS:

#5

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,994

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1181 Post(s)

Liked 2,576 Times

in

1,076 Posts

In my opinion, a frame that doesn't allow the chain to ride close to the dropout is incorrectly designed. Adding a spacer to the hub axle is the usual fix, but that adds wheel dish making your wheel weaker, and adds axle stickout past the bearing, making the axle more likely to bend. Both of these changes are incremental and often inconsequential, but it bothers me to make other parts weaker to fix what the framebuilder did wrong.

For that reason I have no qualms about taking a file or grinding wheel to the offending part of the seatstay that rubs the chain. Yes it weakens the frame, but a properly-made frame will never break there, and if it does break it can be repaired. (Easy for me to say, since I'm a framebuilder ó the repair is easy and practically free to me ó not so for most folks)

This is not a popular opinion here! Most folks would rather not mar their paint, void the frame warranty etc. I'm OK with that. I'm just mentioning the frame mod as another option.

I'd need more photos to know whether the frame really is made wrong (by my strict definition), or if the hub axle is just too dang short. I don't know how Trek finished the seatstay bottoms on those bikes; maybe they're perfect and you can't improve the frame by grinding. But lots of supposedly top-end bikes were made with the seatstay sticking well into the space the chain wants to inhabit. I wouldn't grind on one with great rarity or historical significance, but I would do it (and have, many times) on frames that are just for riding.

As others have pointed out, shortening the rack screw is a no-brainer. You can stack washers on the outside if you don't have a shorter screw or a hacksaw.

Mark B

For that reason I have no qualms about taking a file or grinding wheel to the offending part of the seatstay that rubs the chain. Yes it weakens the frame, but a properly-made frame will never break there, and if it does break it can be repaired. (Easy for me to say, since I'm a framebuilder ó the repair is easy and practically free to me ó not so for most folks)

This is not a popular opinion here! Most folks would rather not mar their paint, void the frame warranty etc. I'm OK with that. I'm just mentioning the frame mod as another option.

I'd need more photos to know whether the frame really is made wrong (by my strict definition), or if the hub axle is just too dang short. I don't know how Trek finished the seatstay bottoms on those bikes; maybe they're perfect and you can't improve the frame by grinding. But lots of supposedly top-end bikes were made with the seatstay sticking well into the space the chain wants to inhabit. I wouldn't grind on one with great rarity or historical significance, but I would do it (and have, many times) on frames that are just for riding.

As others have pointed out, shortening the rack screw is a no-brainer. You can stack washers on the outside if you don't have a shorter screw or a hacksaw.

Mark B

Likes For bulgie:

#6

Senior Member

Join Date: Dec 2005

Posts: 17,160

Mentioned: 481 Post(s)

Tagged: 0 Thread(s)

Quoted: 3811 Post(s)

Liked 6,717 Times

in

2,614 Posts

For a spacer on that fender stay bolt, I often use one of those round nuts from a presta valve tube.

Likes For nlerner:

#7

Newbie

Before taking any radical steps-

Compare your new hub to the previous one: confirm hub OLD, then measure to the shoulder where the freewheel seats. It is possible the new hub just needs a small (maybe 2mm?) spacer shuffled from the NDS to the DS, and then redish the wheel.

Sheldon's 'cassette / freewheel spacing table' may provide some useful context for the relevant dimensions:

https://sheldonbrown.com/cribsheet-spacing.html.

While making measurements, double-check alignment of the rear triangle and the drop-outs.

And of course, a shorter fender stay bolt.

Compare your new hub to the previous one: confirm hub OLD, then measure to the shoulder where the freewheel seats. It is possible the new hub just needs a small (maybe 2mm?) spacer shuffled from the NDS to the DS, and then redish the wheel.

Sheldon's 'cassette / freewheel spacing table' may provide some useful context for the relevant dimensions:

https://sheldonbrown.com/cribsheet-spacing.html.

While making measurements, double-check alignment of the rear triangle and the drop-outs.

And of course, a shorter fender stay bolt.

#8

Senior Member

Thread Starter

Join Date: Oct 2017

Posts: 2,046

Mentioned: 26 Post(s)

Tagged: 0 Thread(s)

Quoted: 838 Post(s)

Liked 1,082 Times

in

522 Posts

A handful of things to consider and respond to here and I'll engage more in depth soon. I should take more photos as well.

Re: shortening the fender bolt, while it does seem to be the simple solution, it still leaves me wondering how there is so much space between the wheel and seat tube. For a bike designed to take fenders, it sure looks awkward, at least with the axle sitting in the middle of the dropouts. I've mounted fenders on 6 or so bikes, all sport tour or touring from the early 70s to late 80s and never had such a gap, though these might be the longest chainstays I've worked with before.

The good news is I can always throw the 27" wheels back on and call it a day, albeit with a likely less attractive fender line, but now I'm just determined to get these 700c to work.

I'm embarrassed that I didn't think about Hub spacing, it's not something I've been in a situation to have to consider before, but my time here has taught me enough to know to take that step!

Re: shortening the fender bolt, while it does seem to be the simple solution, it still leaves me wondering how there is so much space between the wheel and seat tube. For a bike designed to take fenders, it sure looks awkward, at least with the axle sitting in the middle of the dropouts. I've mounted fenders on 6 or so bikes, all sport tour or touring from the early 70s to late 80s and never had such a gap, though these might be the longest chainstays I've worked with before.

The good news is I can always throw the 27" wheels back on and call it a day, albeit with a likely less attractive fender line, but now I'm just determined to get these 700c to work.

I'm embarrassed that I didn't think about Hub spacing, it's not something I've been in a situation to have to consider before, but my time here has taught me enough to know to take that step!

Last edited by polymorphself; 09-03-23 at 06:15 PM.

#9

Old fart

Join Date: Nov 2004

Location: Appleton WI

Posts: 24,792

Bikes: Several, mostly not name brands.

Mentioned: 153 Post(s)

Tagged: 0 Thread(s)

Quoted: 3591 Post(s)

Liked 3,401 Times

in

1,935 Posts

The frame wasn't designed to use a 7-spocket cluster. Use a 6-sprocket cluster instead, or accept that you'll need to make some compromises, e.g. a spacer and redishing the wheel, or filing the stay ends to create clearance.

Likes For JohnDThompson:

#10

Senior Member

Join Date: Sep 2014

Location: Baton Rouge La

Posts: 1,214

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 394 Post(s)

Liked 346 Times

in

230 Posts

According to the '83 catalog, these came with an ultra six speed freewheel, which is the same width or just slightly wider than a five speed and narrower than a standard six or a seven a helicomatic six speed . As John said above, it wasn't designed for a seven speed, and the solution is a six speed with Shimano compatible cog spacing, and / or seven speed and respacing the axle and re-dishing if needed.

Last edited by Hobbiano; 09-04-23 at 10:19 AM. Reason: a bunch of bad information - duh

Likes For Hobbiano:

#11

Senior Member

Thread Starter

Join Date: Oct 2017

Posts: 2,046

Mentioned: 26 Post(s)

Tagged: 0 Thread(s)

Quoted: 838 Post(s)

Liked 1,082 Times

in

522 Posts

According to the '83 catalog, these came with an ultra six speed freewheel, which is the same width or just slightly wider than a five speed and narrower than a standard six or a seven. As John said above, it wasn't designed for a seven speed, and the solution is to use a narrower six speed ultra or maybe a standard six speed, and / or respacing the axle and redishing.

Leaving it indexed would be fine as well? I imagine Iíll need to set that up again, which Iíve never done, always had friction.

Regarding the several inch gap between the tire and fender at the chain stay bridge, is this a possible indicator that the wheel is too far back in the dropouts? Iíve just never seen such a massive gap here on a bike, or if I have they werenít wearing fenders so it wasnít obvious.

#12

Senior Member

For what is worth I had the exact same problem on mine when I installed an 8 speed hub. Trimming the bolt did the trick.

Having a cassette/free wheel that fits that snuggly is actually a good thing

Having a cassette/free wheel that fits that snuggly is actually a good thing

#14

Senior Member

Join Date: Sep 2014

Location: Baton Rouge La

Posts: 1,214

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 394 Post(s)

Liked 346 Times

in

230 Posts

As to the space between the wheel and the chainstay bridge - I have seen in at least one post here where a spacer was used with a longer bolt to get the fender spacing closer.

I have to correct my previous post where I said the catalog had these with ultra six freewheels. I miss-read that. They came with a helicomatic 6-speed. At any rate, not a seven speed. But the solution is the same - six speed, or seven and re-space / re-dish.

I think your Deore indexing should still be able to work with six speed after re-setting the limit screws but that will depend on the cog spacing being compatible. For me, it would be trial and error, but others here surely should be able to more definitively answer that question.

If you want to use your seven speed, you would need to add a spacer under the drive side locknut and subtract the same from the non-drive side, or you may be able to just add the spacer on the drive side. It would probably be easy enough to still get the wheel in place. When everything is working, check and re-dish if necessary.

If you remove the fender bolt, does the chain clear without rubbing the frame? If so, just use a shorter bolt (as SuferRosa said in post #2).

I have to correct my previous post where I said the catalog had these with ultra six freewheels. I miss-read that. They came with a helicomatic 6-speed. At any rate, not a seven speed. But the solution is the same - six speed, or seven and re-space / re-dish.

I think your Deore indexing should still be able to work with six speed after re-setting the limit screws but that will depend on the cog spacing being compatible. For me, it would be trial and error, but others here surely should be able to more definitively answer that question.

If you want to use your seven speed, you would need to add a spacer under the drive side locknut and subtract the same from the non-drive side, or you may be able to just add the spacer on the drive side. It would probably be easy enough to still get the wheel in place. When everything is working, check and re-dish if necessary.

If you remove the fender bolt, does the chain clear without rubbing the frame? If so, just use a shorter bolt (as SuferRosa said in post #2).

Last edited by Hobbiano; 09-04-23 at 10:32 AM. Reason: addition

Likes For Hobbiano:

#15

Senior Member

Thread Starter

Join Date: Oct 2017

Posts: 2,046

Mentioned: 26 Post(s)

Tagged: 0 Thread(s)

Quoted: 838 Post(s)

Liked 1,082 Times

in

522 Posts

As to the space between the wheel and the chainstay bridge - I have seen in at least one post here where a spacer was used with a longer bolt to get the fender spacing closer.

I have to correct my previous post where I said the catalog had these with ultra six freewheels. I miss-read that. They came with a helicomatic 6-speed. At any rate, not a seven speed. But the solution is the same - six speed, or seven and re-space / re-dish.

I think your Deore indexing should still be able to work with six speed after re-setting the limit screws but that will depend on the cog spacing being compatible. For me, it would be trial and error, but others here surely should be able to more definitively answer that question.

If you want to use your seven speed, you would need to add a spacer under the drive side locknut and subtract the same from the non-drive side, or you may be able to just add the spacer on the drive side. It would probably be easy enough to still get the wheel in place. When everything is working, check and re-dish if necessary.

I have to correct my previous post where I said the catalog had these with ultra six freewheels. I miss-read that. They came with a helicomatic 6-speed. At any rate, not a seven speed. But the solution is the same - six speed, or seven and re-space / re-dish.

I think your Deore indexing should still be able to work with six speed after re-setting the limit screws but that will depend on the cog spacing being compatible. For me, it would be trial and error, but others here surely should be able to more definitively answer that question.

If you want to use your seven speed, you would need to add a spacer under the drive side locknut and subtract the same from the non-drive side, or you may be able to just add the spacer on the drive side. It would probably be easy enough to still get the wheel in place. When everything is working, check and re-dish if necessary.

I just took a look at the Shimano bar ends and if needed I can set them to friction, which I don't mind. I will try to set it up with indexed shifting putting the new 6spd freewheel on. If I can't get it to work well myself I'll have a mechanic friend set it up. If all else fails, I don't have any issues with friction as it is all I've ever used (this bike is not for me anyways, too small, going to my partner).

#16

Senior Member

Join Date: Dec 2005

Posts: 17,160

Mentioned: 481 Post(s)

Tagged: 0 Thread(s)

Quoted: 3811 Post(s)

Liked 6,717 Times

in

2,614 Posts

On the fender spacing, that’s really common in my experience, particularly for 70s Brit bikes. My usual solution is to use a wine cork, cut to the size needed.

Last edited by nlerner; 09-04-23 at 12:49 PM.

Likes For nlerner:

Likes For Vintage_Cyclist:

Likes For abdon:

#20

Senior Member

Thread Starter

Join Date: Oct 2017

Posts: 2,046

Mentioned: 26 Post(s)

Tagged: 0 Thread(s)

Quoted: 838 Post(s)

Liked 1,082 Times

in

522 Posts

Fair, though there are some saying keeping it a 6spd as intended makes sense. Whats the argument for having the freewheel so close to the frame, snug, as you say? Reverting 6 to spd seems appropriate and easy enough.

#21

Senior Member

The main benefit is that on a loaded touring bike, a hub is a f* ton stronger than a freewheel, less likely to give you any issues while hundreds of miles from home. As far as clearance goes, the closer things are together the stronger they are; added space that is not necessary for it to work only adds to twisting forces. You get the best of both worlds; adequate clearance under a pretty tight fitting package.

I'm happy with a freewheel on my Raleigh Alyeska. I'm happy with my mountain hub on my Trek 720. It will work either way.

But you have to trim the mounting bolt so it doesn't protrude.

#22

Senior Member

Join Date: Feb 2010

Location: Bloomington/Normal IL

Posts: 1,062

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 152 Post(s)

Liked 237 Times

in

139 Posts

Shimano made a long cage 6 speed indexed rear derailleur

Shimano RD-L525, Light Action (long cage)

If you want to consider something other than your Deore.

Max cog is 28.

I had considered an Ultra 7 speed freewheel but wasn't sure how well the Suntour Ultra 7 would play with the indexed Shimano RD.

For now I'm still at 6 speed on the 27" wheelset.

I'm a flat-lander and I think I will be more than fine.

Shimano RD-L525, Light Action (long cage)

If you want to consider something other than your Deore.

Max cog is 28.

I had considered an Ultra 7 speed freewheel but wasn't sure how well the Suntour Ultra 7 would play with the indexed Shimano RD.

For now I'm still at 6 speed on the 27" wheelset.

I'm a flat-lander and I think I will be more than fine.

#23

aka: Dr. Cannondale

Join Date: Jul 2009

Posts: 7,735

Mentioned: 234 Post(s)

Tagged: 0 Thread(s)

Quoted: 2155 Post(s)

Liked 3,406 Times

in

1,206 Posts

That Deore RD will shift anything from 6 to 10 speed without issues.

__________________

Hard at work in the Secret Underground Laboratory...

Hard at work in the Secret Underground Laboratory...

Likes For rccardr:

#24

Senior Member

Join Date: May 2010

Location: Bastrop Texas

Posts: 4,486

Bikes: Univega, Peu P6, Peu PR-10, Ted Williams, Peu UO-8, Peu UO-18 Mixte, Peu Dolomites

Mentioned: 13 Post(s)

Tagged: 0 Thread(s)

Quoted: 969 Post(s)

Liked 1,632 Times

in

1,048 Posts

Had the same problem a few years ago. Solved it by re-tapping the eye and going to another type bolt with finer threads. But in the end changed out my wheel set and went back to 6 speeds. Actually I don't know what I was thinking. In the long run I did not need 7 speeds at all...

__________________

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

#25

Senior Member

7 speed freewheel is weaker than a 6 speed freewheel (unless one of those oddball skinny chain freewheels with the same axle size). Any freewheel is weaker than a hub.

As I said, I have bikes with freewheels I'm happy with, I have my heavy load tourer on a hub. On freewheel I prefer 5-speed freewheels, 120mm axles. The way freewheels work the longer you go on the axle/sprocket count the weaker it gets.

As I said, I have bikes with freewheels I'm happy with, I have my heavy load tourer on a hub. On freewheel I prefer 5-speed freewheels, 120mm axles. The way freewheels work the longer you go on the axle/sprocket count the weaker it gets.