Do you use spoke washers on Shimano road hubs?

#1

Senior Member

Thread Starter

Join Date: Jan 2017

Posts: 1,064

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 350 Post(s)

Likes: 0

Liked 122 Times

in

90 Posts

Do you use spoke washers on Shimano road hubs?

Spoke Washers

Do you use spoke washers on Shimano road rear hubs, or are they not needed?

The webshops that I'm looking at for purchasing spokes, also sell Sapim brass spoke washers, and they write that if the spokes are 1.8 to 2mm diameter, and the holes are 2.6mm like Shimano or greater, then they recommend using washers. The washers are 0.5mm thick, which seems quite a lot though. But isn't brass soft, and won't it deform under load (get thinner) after a while, with some minute displacement of the spoke in the future?

I think the majority of the Shimano road models have identical flanges. The one I'm going to use for new wheel is the FH-RS400, and has 2.6mm diameter spoke holes, and flange is somewhere between 3.1 to 3.4mm thick. They're tapered so measurement is approximate, and left flange is slightly thinner than right flange. I'm going to use Sapim Race spokes 2.0/1.8/2.0mm on both sides, which are double butted, 2.0mm at the elbow.

I'm using 406mm rims so the spoke angles are greater than with larger wheels. I stuck some Sapim Race spokes through the flange, and they can be aligned all the way vertically before needing any bending to go further. When the heads are on the inside of the flange, the spokes will need a little bit of bending for nipple alignment. When the heads are on the outside of the flange, there is quite a lot of elbow exposed on the inside of the flange, and these spokes will not touch the inside of flange for nipple alignment.

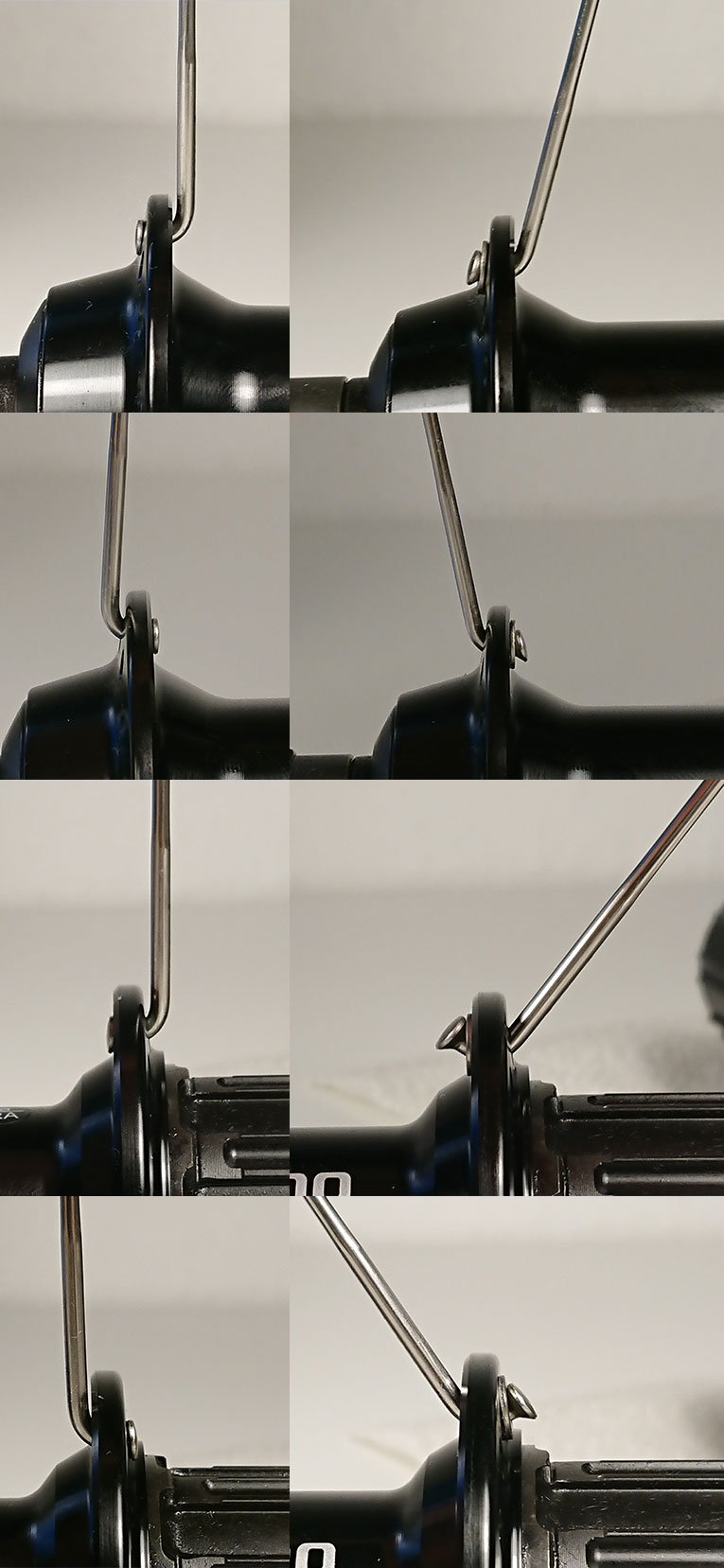

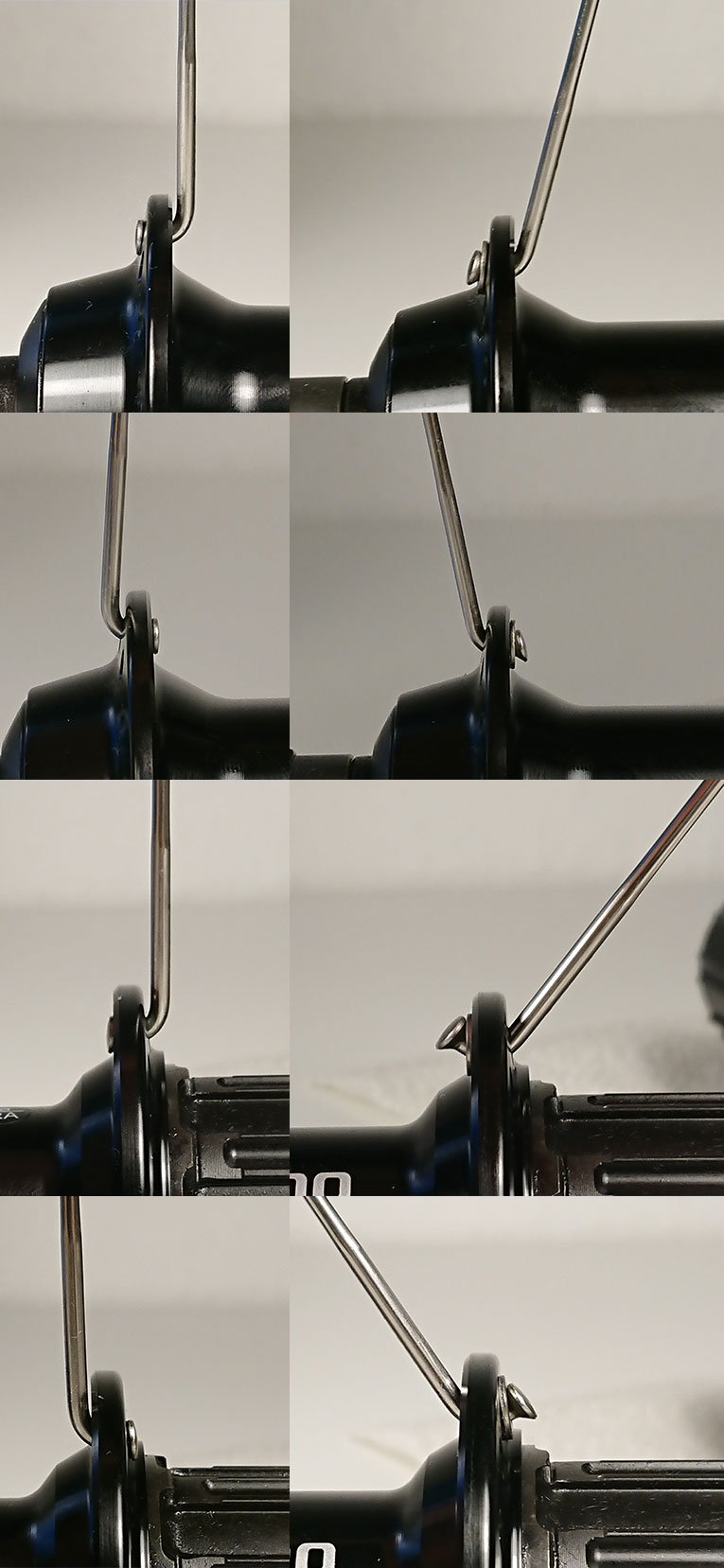

As an experiment, I inserted a 2.7mm inner diameter 0.6mm thick washer (because I don't have the Sapim washers) under the spoke head. (update, here are some photos)If any, it would maybe only be used for spokes that run on the inside with the heads out?

After looking at the photos, it seems that the heads sit more flush to the flange without the washers. So it looks to me like 0.6mm washers are bad for Shimano Hubs with 2.0mm elbows and 2.6mm holes.

Thicker drive side spokes

Also, I was considering using thicker spokes on the drive side rear, while using Sapim race 2.0/1.8/2.0 on the non drive side, and there are many threads on the forum both against and for it.

If the reason was for stiffness, with 406 rims, the spoke lengths are around 70% of the spokes on 559 rims, so the spokes on 406 rims will only stretch 70% of the amount that identical diameter spokes on 559 rims while under the same tension, since spoke length is a direct factor in stretch. 1.8mm diameter spokes are 81% of the cross sectional area of 2.0mm diameter spokes, so 1.8mm spokes will stretch 123% of 2.0mm spokes for the same length and tension. So then, double butted 2.0/1.8/2.0 spokes on a 406 rim will stretch 0.7x1.23 = 86% of the amount of a 2.0mm spoke on a 559 rim with the same tension.

So then the double butted 2.0/1.8/2.0 spoke is fine for drive side on 406 rims, since it's still just as stiff as larger rims with thicker spokes?

Alternatively, if I were to use thicker drive side spokes (let's say on a larger wheel), should I use straight gauge 2.0mm, or single buted Sapim Strong, which is 2.3mm at the elbow and 2.0mm the rest of the way?

I stuck a Sapim Strong spoke through the Shimano hub flange, and they really need a lot of bending to get into alignment with the nipple.

Number of spokes

I'm doing touring on 406 rims. Wheelbase is 101cm, and chainstay is 40cm, so the majority of rider weight is on the rear wheel. I also carry 20-25kg on the rear rack, and 5-7kg on the front handlebar. In the past I've done this on the stock Dahon 18c-19c rims with 20F/28R spokes straight gauge 2.0mm, with Big Apple tires 2.00", and it was generally ok.

For the new wheels, I am thinking of using Kinlin DDT32 rims, 26mm inside, 32mm outside, 21mm deep, 465g. It should be very stiff and strong. With Big Ben Plus tires 55mm (2.15").

For the rear, I have the option of 36 or 32 spokes. Which should I choose?

For the front, I've already bought a 28 hole hub, but I don't think this rim is available in 28 holes. So I'll probably have to get another hub with 32 holes.

Do you use spoke washers on Shimano road rear hubs, or are they not needed?

The webshops that I'm looking at for purchasing spokes, also sell Sapim brass spoke washers, and they write that if the spokes are 1.8 to 2mm diameter, and the holes are 2.6mm like Shimano or greater, then they recommend using washers. The washers are 0.5mm thick, which seems quite a lot though. But isn't brass soft, and won't it deform under load (get thinner) after a while, with some minute displacement of the spoke in the future?

I think the majority of the Shimano road models have identical flanges. The one I'm going to use for new wheel is the FH-RS400, and has 2.6mm diameter spoke holes, and flange is somewhere between 3.1 to 3.4mm thick. They're tapered so measurement is approximate, and left flange is slightly thinner than right flange. I'm going to use Sapim Race spokes 2.0/1.8/2.0mm on both sides, which are double butted, 2.0mm at the elbow.

As an experiment, I inserted a 2.7mm inner diameter 0.6mm thick washer (because I don't have the Sapim washers) under the spoke head. (update, here are some photos)

After looking at the photos, it seems that the heads sit more flush to the flange without the washers. So it looks to me like 0.6mm washers are bad for Shimano Hubs with 2.0mm elbows and 2.6mm holes.

Thicker drive side spokes

Also, I was considering using thicker spokes on the drive side rear, while using Sapim race 2.0/1.8/2.0 on the non drive side, and there are many threads on the forum both against and for it.

If the reason was for stiffness, with 406 rims, the spoke lengths are around 70% of the spokes on 559 rims, so the spokes on 406 rims will only stretch 70% of the amount that identical diameter spokes on 559 rims while under the same tension, since spoke length is a direct factor in stretch. 1.8mm diameter spokes are 81% of the cross sectional area of 2.0mm diameter spokes, so 1.8mm spokes will stretch 123% of 2.0mm spokes for the same length and tension. So then, double butted 2.0/1.8/2.0 spokes on a 406 rim will stretch 0.7x1.23 = 86% of the amount of a 2.0mm spoke on a 559 rim with the same tension.

So then the double butted 2.0/1.8/2.0 spoke is fine for drive side on 406 rims, since it's still just as stiff as larger rims with thicker spokes?

Alternatively, if I were to use thicker drive side spokes (let's say on a larger wheel), should I use straight gauge 2.0mm, or single buted Sapim Strong, which is 2.3mm at the elbow and 2.0mm the rest of the way?

I stuck a Sapim Strong spoke through the Shimano hub flange, and they really need a lot of bending to get into alignment with the nipple.

Number of spokes

I'm doing touring on 406 rims. Wheelbase is 101cm, and chainstay is 40cm, so the majority of rider weight is on the rear wheel. I also carry 20-25kg on the rear rack, and 5-7kg on the front handlebar. In the past I've done this on the stock Dahon 18c-19c rims with 20F/28R spokes straight gauge 2.0mm, with Big Apple tires 2.00", and it was generally ok.

For the new wheels, I am thinking of using Kinlin DDT32 rims, 26mm inside, 32mm outside, 21mm deep, 465g. It should be very stiff and strong. With Big Ben Plus tires 55mm (2.15").

For the rear, I have the option of 36 or 32 spokes. Which should I choose?

For the front, I've already bought a 28 hole hub, but I don't think this rim is available in 28 holes. So I'll probably have to get another hub with 32 holes.

Last edited by tomtomtom123; 09-13-19 at 06:18 PM.

#2

Really Old Senior Member

Look for 2 mm brass washers.

Spoke tension is determined by how far the hub flanges are offset by the wheel center, not spoke length.

Note how the DS spokes of a wheel with multiple cogs are in a more vertical plane than the spokes the NDS.

Now look at a single speed. Pretty much symmetrical like a "conventional" front. Spokes will have equal/very similar tension to each other.

Spoke tension is determined by how far the hub flanges are offset by the wheel center, not spoke length.

Note how the DS spokes of a wheel with multiple cogs are in a more vertical plane than the spokes the NDS.

Now look at a single speed. Pretty much symmetrical like a "conventional" front. Spokes will have equal/very similar tension to each other.

#3

Senior Member

I have never used washers on a shimano or Suntour hub and had no problems. I have built with DT and Wheelsmith spokes, both 14 and 15 double butted.

#4

working on my sandal tan

Join Date: Aug 2011

Location: CID

Posts: 22,627

Bikes: 1991 Bianchi Eros, 1964 Armstrong, 1988 Diamondback Ascent, 1988 Bianchi Premio, 1987 Bianchi Sport SX, 1980s Raleigh mixte (hers), All-City Space Horse (hers)

Mentioned: 98 Post(s)

Tagged: 0 Thread(s)

Quoted: 3870 Post(s)

Liked 2,563 Times

in

1,577 Posts

I use #2 brass washers when I get a spoke that has an extra-long elbow which prevents it from fully seating in the hub drilling. It's not the hub's fault -- DT and some other brands have at times made spokes with that longer elbow for whatever reason, and depending on the outfit I order from, the spokes might come from different batches, so only some of them will need it.

#5

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

IMHO, from the pictures you showed, no washers are needed and indeed, washers would not be desirable.

#6

Senior Member

I generally don't build with washers at the hub, and would only think to do so if I couldn't get the elbow to seat against the flange. Hub washers are relatively uncommon out in the wild in my experience. Rim washers are pretty common on carbon and super WW aluminum rims.

I think the primary logic for building with thicker spokes on the DS of a rear wheel is that the NDS spokes will be in a greater state of elongation and will stay in an elastic state at lower tensions, leading to less fatigue. While the spoke thickness has some theoretical effect on lateral stiffness I think its pretty minor compared to the wheel's geometry, the spoke count, the spoke tension, and the rim design. 20" wheels built with plenty of spokes at good tension is going to be stiff AF, I wouldn't worry about it.

Given the choice, I'd do thicker spokes DS, but wouldn't go far out of my way to do so on most builds. I might be tempted to do 2.0/1.5/2.0 spokes on the NDS and 2.0/1.8/2.0 on the rest of the wheel.

20" rims build up pretty strong so I bet the 32H would be fine, but why not do 32/36 for the build, as parts are easy to obtain and will make the rear wheel stronger and more fault tolerant. Weight/aero difference is negligible, and hey, you're touring.

I think the primary logic for building with thicker spokes on the DS of a rear wheel is that the NDS spokes will be in a greater state of elongation and will stay in an elastic state at lower tensions, leading to less fatigue. While the spoke thickness has some theoretical effect on lateral stiffness I think its pretty minor compared to the wheel's geometry, the spoke count, the spoke tension, and the rim design. 20" wheels built with plenty of spokes at good tension is going to be stiff AF, I wouldn't worry about it.

Given the choice, I'd do thicker spokes DS, but wouldn't go far out of my way to do so on most builds. I might be tempted to do 2.0/1.5/2.0 spokes on the NDS and 2.0/1.8/2.0 on the rest of the wheel.

20" rims build up pretty strong so I bet the 32H would be fine, but why not do 32/36 for the build, as parts are easy to obtain and will make the rear wheel stronger and more fault tolerant. Weight/aero difference is negligible, and hey, you're touring.

#7

Senior Member

I think the primary logic for building with thicker spokes on the DS of a rear wheel is that the NDS spokes will be in a greater state of elongation and will stay in an elastic state at lower tensions, leading to less fatigue. While the spoke thickness has some theoretical effect on lateral stiffness I think its pretty minor compared to the wheel's geometry, the spoke count, the spoke tension, and the rim design. 20" wheels built with plenty of spokes at good tension is going to be stiff AF, I wouldn't worry about it.

Given the choice, I'd do thicker spokes DS, but wouldn't go far out of my way to do so on most builds. I might be tempted to do 2.0/1.5/2.0 spokes on the NDS and 2.0/1.8/2.0 on the rest of the wheel.

Given the choice, I'd do thicker spokes DS, but wouldn't go far out of my way to do so on most builds. I might be tempted to do 2.0/1.5/2.0 spokes on the NDS and 2.0/1.8/2.0 on the rest of the wheel.

it's advisable to go high spoke count first and only if you want to shed some weight pick thinner spokes. if the safety margin dictates you need a wheel that is able to sustain such high loads then you should look for rims that have:

1. high spoke count;

2. higher - up to 20mm height (not many rims go higher than that, aero rims are designed for low spoke count);

3. as thick spokes as the rim height makes sense.

just suppose - for a bit - the DS:NDS is 1:1 in tension (dishless) and spoke thickness... the external load is added to the remaining tension that spokes still exert on the rim. the thinner the spokes the more force they exert on the rim at large loads if the static tension is the same (therefore the conclusion is that the build tension should be less for thin spokes... or higher for thick spokes but few people get this point). think A+B+B+A where spoke A is in more tension than B (different distances to the equilibrium points). think A+B+C+C+B+A if the spokes are thinner, wider gap between the equilibrium points, spoke tension that is not yet excessive (for the not very uncommon maximum dynamic loads when riding) for those thin spokes.

the rim needs to be compressed enough as to have a short enough gap in between the equilibrium points; the flexural stress will be lower for a smaller gap (if the proper tension is achieved in building the wheel) but if the spokes are still in large tension when the maximum load occurs then the tension is excessive - the maximum load could be higher if not excessive tension. the higher the remaining spoke tension the smaller the limit for the largest external load. in other words... thicker spokes lose more tension for the same rim deflection and add less flexural stress to that from the external load because there would also be a smaller gap (larger rim compression from higher tension) to begin with.

thinner spokes on the non drive side are picked for the reason of preventing them hitting back whenever they would otherwise have gotten completely slack if they were as thick as on the DS. if NDS would get more tension at 4:30 and 7:30 positions because of thin DS spokes then spoke fatigue is not too much a concern. other reasons are for having thick enough DS... and also for having thick enough NDS. it's the rim profile and the largest possible dynamic load for the bike (like heavy touring).

imagine you would have 0.1mm spokes that are from such a steel that can't possibly exist (same modulus of elasticity, but 1000x higher yield strength). it never yields/breaks but is also on the low extreme of stiffness because of that low section area. how would the rim be working then? would it be more susceptible to being bent out of shape (not only flat spots but also taco)?

1.8mm DS and 1.5mm NDS is a good setup with very wide and shallow rims, more flexible radially but also wide enough to have good lateral stiffness. example:

"Oozy 350 rim with 17mm high profile & 30.5mm inner width"

i'd rather have 2mm DS with at least 1.65mm NDS (21% more section area than for 1.5mm) for the more common rims. i would not pick them to be so thin except for dishless or rear suspension etc.. such rims as from the example above are meant to be used with large tires that spread the load over a longer contact patch when large dynamic loads - such as landing etc. but... if a sudden puncture occurs at high speed (with large enough bumps) the rim will be quite vulnerable radially. having suspension can ensure a lower dynamic load so shallow and wide rims make sense. the suspension works better if the tire and rim (smaller than the tire but yet...) have more give.

if you lack experience with wheel building i would suggest keeping thick spokes and learning your stuff by trying to fix wheels. but if you study more extensively as to figure out how to use the elastic modulus concept when balancing radial runout with spoke tension variance (you do that for DS spokes at medium tension, when NDS are rather slack) you won't be resorting to luck and you will be able to achieve +/-0.05mm both radial and lateral runout with ~+/-5% tension variance even for the first wheel you would begin to apply these things - provided you are able to accurately measure the values and follow the calculated adjustments of nipple turn for each spoke. radial true is more important than lateral true. thin spokes get more elastic stretch in tension (think delta from the average) for a rim that is not perfect, hence the more important aspect of balancing these things out. you either more or less (depending on the stress relieving methods) straighten the rim and minimize these figures against each other or you just balance radial runout with tension variance. i would rather have the wheel straightened in controlled conditions through slow growing stresses and freshly lubricated surfaces when stress relieving.

final maximum spoke tension (goal) depends on both spoke thickness and the tension variance - the rim being in the proper shape with the spokes completely slack or not.

wheels that have same thick spokes DS and NDS can be built with higher spoke tension; look at the spokes at 4:30 and 7:30 (as angles) in

Last edited by adipe; 09-15-19 at 03:19 AM.

#8

Steel is real

I built a rear wheel with spokes that are thinner dia than the flange holes, spokes - 2.0mm, flange holes - 2.3 or was it 2.5?! can't remember.

So far so good, but i think washers have their place, if i start breaking spokes at the J bend inserting washers on replacement spokes will fix it. I did think about it when building that wheel, but I didn't have washers at hand.

So far so good, but i think washers have their place, if i start breaking spokes at the J bend inserting washers on replacement spokes will fix it. I did think about it when building that wheel, but I didn't have washers at hand.

#9

Senior Member

Join Date: Dec 2007

Location: San Jose, California

Posts: 3,504

Bikes: 2001 Tommasini Sintesi w/ Campagnolo Daytona 10 Speed

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 145 Post(s)

Likes: 0

Liked 35 Times

in

30 Posts

You don't need spoke head washers when using 6.2mm elbows in 3.2mm thick alloy hub flanges.

Pretty much all your DT, Sapim, Wheelsmith, CN MAC and Pillar spokes will have 6.2mm (14g) and 6.0mm (15g) elbows.

Pretty much all your alloy hubs will have 3.2mm to 3.4mm hub flanges.

=8-)

Pretty much all your DT, Sapim, Wheelsmith, CN MAC and Pillar spokes will have 6.2mm (14g) and 6.0mm (15g) elbows.

Pretty much all your alloy hubs will have 3.2mm to 3.4mm hub flanges.

=8-)

__________________

5000+ wheels built since 1984...

Disclaimer:

1. I do not claim to be an expert in bicycle mechanics despite my experience.

2. I like anyone will comment in other areas.

3. I do not own the preexisting concepts of DISH and ERD.

4. I will provide information as I always have to others that I believe will help them protect themselves from unscrupulous mechanics.

5. My all time favorite book is:

Kahane, Howard. Logic and Contemporary Rhetoric: The Use of Reason in Everyday Life

5000+ wheels built since 1984...

Disclaimer:

1. I do not claim to be an expert in bicycle mechanics despite my experience.

2. I like anyone will comment in other areas.

3. I do not own the preexisting concepts of DISH and ERD.

4. I will provide information as I always have to others that I believe will help them protect themselves from unscrupulous mechanics.

5. My all time favorite book is:

Kahane, Howard. Logic and Contemporary Rhetoric: The Use of Reason in Everyday Life

#10

Senior Member

Thread Starter

Join Date: Jan 2017

Posts: 1,064

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 350 Post(s)

Likes: 0

Liked 122 Times

in

90 Posts

Thanks for all the advice. I realized after I took the photos that the spoke washers weren't needed on this hub with Sapim spokes.

I decided on 32/36 spoke holes for the 406 rims (with Sapim Race 2.0/1.8/2.0 spokes). I just received the rims today, and am testing how nipple washers would fit in them. But I've never used nipple washers before. Could someone tell me if this is normal behavior?

The Sapim HM washer has a similar diameter as the hole, but when the nipple angles away from the centerline, the washer shifts to the side and the overhanging edge drops into the hole, or perhaps the washer is inside the hole but one side is coming out, causing the "pop" sound in the video below. I'm worried that the washers won't be seated properly, so I'm thinking not to use the washers. The holes don't appear to be chamfered. The small cut edges around the holes are probably from the deburring process.

Or will the washer settle itself after the spokes are under high tension, and it's better to use them?

Image source: https://www.bikeraceinfo.com/tech/wh...e-washers.html

I also tried Sapim MS washers, which are much wider and so don't have the problem that the HM washers have, but the rim bottom seems to be slightly curved laterally, causing the flat MS washers to rock back and forth, and so they're probably not appropriate.

The rims are Kinlin DDT32 rims. First thing I noticed is that the pin joint is very beautiful. No gaps, flush through the entire height. But one strange thing is that the 32 and 36 hole rims are slightly different profile from each other. Perhaps they were made at different times with different extrusion profiles. The 36 hole rim is 20mm high, while the 32 hole rim is 20.7mm high. The 0.7mm difference also affects the brake wall heights, which are 8.0mm and 8.7mm respectively. This will make a little bit of a problem with the brake pads which are wider than the brake walls, and I'll have to trim them narrower. The 0.7mm height difference also affects the ERD, 384.5 and 286.0, by 1.5mm.

The 36 hole rim is also 0.2mm wider internally and externally, compared to the 32 hole rim. And the 36 hole rim width varies 0.3mm between it's thickest and narrowest sections, while the 32 hole rim only varies by 0.2mm.

I decided on 32/36 spoke holes for the 406 rims (with Sapim Race 2.0/1.8/2.0 spokes). I just received the rims today, and am testing how nipple washers would fit in them. But I've never used nipple washers before. Could someone tell me if this is normal behavior?

The Sapim HM washer has a similar diameter as the hole, but when the nipple angles away from the centerline, the washer shifts to the side and the overhanging edge drops into the hole, or perhaps the washer is inside the hole but one side is coming out, causing the "pop" sound in the video below. I'm worried that the washers won't be seated properly, so I'm thinking not to use the washers. The holes don't appear to be chamfered. The small cut edges around the holes are probably from the deburring process.

Or will the washer settle itself after the spokes are under high tension, and it's better to use them?

Image source: https://www.bikeraceinfo.com/tech/wh...e-washers.html

I also tried Sapim MS washers, which are much wider and so don't have the problem that the HM washers have, but the rim bottom seems to be slightly curved laterally, causing the flat MS washers to rock back and forth, and so they're probably not appropriate.

The rims are Kinlin DDT32 rims. First thing I noticed is that the pin joint is very beautiful. No gaps, flush through the entire height. But one strange thing is that the 32 and 36 hole rims are slightly different profile from each other. Perhaps they were made at different times with different extrusion profiles. The 36 hole rim is 20mm high, while the 32 hole rim is 20.7mm high. The 0.7mm difference also affects the brake wall heights, which are 8.0mm and 8.7mm respectively. This will make a little bit of a problem with the brake pads which are wider than the brake walls, and I'll have to trim them narrower. The 0.7mm height difference also affects the ERD, 384.5 and 286.0, by 1.5mm.

The 36 hole rim is also 0.2mm wider internally and externally, compared to the 32 hole rim. And the 36 hole rim width varies 0.3mm between it's thickest and narrowest sections, while the 32 hole rim only varies by 0.2mm.

Last edited by tomtomtom123; 09-19-19 at 02:42 PM.

#11

Senior Member

Join Date: Dec 2007

Location: San Jose, California

Posts: 3,504

Bikes: 2001 Tommasini Sintesi w/ Campagnolo Daytona 10 Speed

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 145 Post(s)

Likes: 0

Liked 35 Times

in

30 Posts

I import the DDT32s.

For brake pads, Kool Stop actually has a line that are super narrow, can be used for road, hybrid, mtb setups with v-brakes.

The DDT32s are essentially downhill rims with a road brake track.

Did yours come with double-eyelets?

=8-)

For brake pads, Kool Stop actually has a line that are super narrow, can be used for road, hybrid, mtb setups with v-brakes.

The DDT32s are essentially downhill rims with a road brake track.

Did yours come with double-eyelets?

=8-)

__________________

5000+ wheels built since 1984...

Disclaimer:

1. I do not claim to be an expert in bicycle mechanics despite my experience.

2. I like anyone will comment in other areas.

3. I do not own the preexisting concepts of DISH and ERD.

4. I will provide information as I always have to others that I believe will help them protect themselves from unscrupulous mechanics.

5. My all time favorite book is:

Kahane, Howard. Logic and Contemporary Rhetoric: The Use of Reason in Everyday Life

5000+ wheels built since 1984...

Disclaimer:

1. I do not claim to be an expert in bicycle mechanics despite my experience.

2. I like anyone will comment in other areas.

3. I do not own the preexisting concepts of DISH and ERD.

4. I will provide information as I always have to others that I believe will help them protect themselves from unscrupulous mechanics.

5. My all time favorite book is:

Kahane, Howard. Logic and Contemporary Rhetoric: The Use of Reason in Everyday Life

#12

Senior Member

Thread Starter

Join Date: Jan 2017

Posts: 1,064

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 350 Post(s)

Likes: 0

Liked 122 Times

in

90 Posts

No eyelets. I guess the German importer did not order the production run with eyelets. I'm not sure that the HM washers are seating properly, so I was wondering if it's better to simply use the nipple directly on the rim. Would you use the HM washers if your DDT32 did not have eyelets? I should decide soon to order the correct spoke lengths.

Here is a table of the approximate differences between the 36 and 32 hole rims:

The rims are not exactly flat, maybe a slight bow of up to 2-3mm. Is it normal, and will flatten out after tensioning? I didn't bother measuring the previous wheels that I built, so I wasn't aware of any bowing.

I also saw that Halo T2 with single eyelets looks like the DDT32, except with a taller profile height of 21.5mm and heavier weight. There is a Halo importer a 2.5 hour ride away, but the CNC sidewall is only for 36. No CNC on 32.

I use the Kool Stop Cross pads. Because I need short pads on 406 rims due to the curvature of the rims. The new Dura2 cross pad replacements are supposed to be 7.6mm wide, but the middle doesn't curve enough, so it's more like effectively 8mm on 406 rims. They're 1.5mm thicker than the original Dura(1). I bought a pack of the originals because my brake bosses are a little bit too close for the DDT32. But the Dura(1) tapers from 9 to 10mm wide, so would need more trimming. So I'll probably stick to the Dura2. With the Dura2, I calculated that the brake arm pivots would be 9 degrees tilted from parallel on each brake arm, so I lose at most 3% braking power, which is ok. I've got longish 105mm pivots anyway.

Previously I had been looking at the Halo Sub4 with single eyelets for $35, which looks exactly like the Sun Ringle Rhyno XL Lite, except pinned instead of welded. It comes in both 36 and 32 with CNC wall. But it's only 16mm tall and I was looking for something with a larger cross section. Although the taller sidewall would have solved the brake pad problem.

Here is a table of the approximate differences between the 36 and 32 hole rims:

The rims are not exactly flat, maybe a slight bow of up to 2-3mm. Is it normal, and will flatten out after tensioning? I didn't bother measuring the previous wheels that I built, so I wasn't aware of any bowing.

I also saw that Halo T2 with single eyelets looks like the DDT32, except with a taller profile height of 21.5mm and heavier weight. There is a Halo importer a 2.5 hour ride away, but the CNC sidewall is only for 36. No CNC on 32.

I use the Kool Stop Cross pads. Because I need short pads on 406 rims due to the curvature of the rims. The new Dura2 cross pad replacements are supposed to be 7.6mm wide, but the middle doesn't curve enough, so it's more like effectively 8mm on 406 rims. They're 1.5mm thicker than the original Dura(1). I bought a pack of the originals because my brake bosses are a little bit too close for the DDT32. But the Dura(1) tapers from 9 to 10mm wide, so would need more trimming. So I'll probably stick to the Dura2. With the Dura2, I calculated that the brake arm pivots would be 9 degrees tilted from parallel on each brake arm, so I lose at most 3% braking power, which is ok. I've got longish 105mm pivots anyway.

Previously I had been looking at the Halo Sub4 with single eyelets for $35, which looks exactly like the Sun Ringle Rhyno XL Lite, except pinned instead of welded. It comes in both 36 and 32 with CNC wall. But it's only 16mm tall and I was looking for something with a larger cross section. Although the taller sidewall would have solved the brake pad problem.

Last edited by tomtomtom123; 09-19-19 at 07:14 PM.

#13

Senior Member

Thread Starter

Join Date: Jan 2017

Posts: 1,064

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 350 Post(s)

Likes: 0

Liked 122 Times

in

90 Posts

I looked again, and the HM washer has almost the same inner diameter as the rim hole, 4.4mm, so when centered the washer sits on top of the hole instead of inside the hole. But when the washer shifts to one side, the overhanging edge will drop into the hole. Will the washer self-center itself when tensioning the spokes? Or will this uneven seating cause problems?

Also the area around the hole is not exactly smooth. There are some small ridges a little bit away from the edges of the hole from the machining process. I wonder if the washer would sit on the ridges.

Rim bottom is 1.9 to 2.1mm thick.

Update: the rim importer says that washers aren't needed with the DDT32. So I might simply build without them.

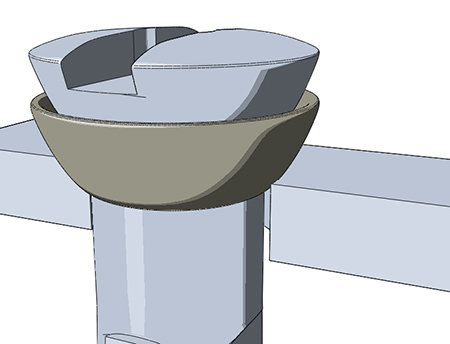

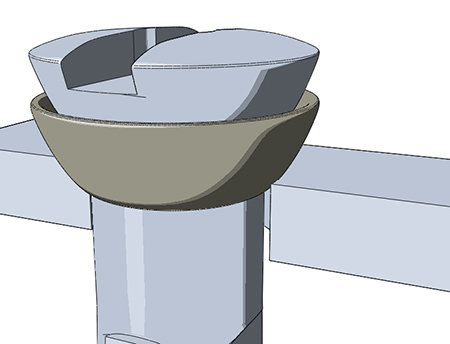

HM washer over the hole. looks almost the same diameter, 4.4mm

extrusion profile from the catalog

Also the area around the hole is not exactly smooth. There are some small ridges a little bit away from the edges of the hole from the machining process. I wonder if the washer would sit on the ridges.

Rim bottom is 1.9 to 2.1mm thick.

Update: the rim importer says that washers aren't needed with the DDT32. So I might simply build without them.

HM washer over the hole. looks almost the same diameter, 4.4mm

extrusion profile from the catalog

Last edited by tomtomtom123; 09-20-19 at 09:12 AM.

#14

Senior Member

Thread Starter

Join Date: Jan 2017

Posts: 1,064

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 350 Post(s)

Likes: 0

Liked 122 Times

in

90 Posts

Here are some photos of the very short brake wall height on the DDT32 rims. The height isn't uniform and fluctuates. I guess it's because of CNC milling of tapered walls, and setting the zero height of the machine doesn't always match if the taper is slightly different on one side compared to the other side, or if another rim has a slightly different width. As a result, one side of the 36 hole rim has much shorter brake wall of 8mm than the other side. The rebranded Halo T2 rims appear to have wider brake walls due to the taller extrusion profile.

The Kool Stop Dura2 pads will have to be trimmed. I made a 3D printed cutting template, with an inner curvature of 402mm diameter. I modeled it at 7mm wide. I will use this to judge the curvature of the pads as I trim sides, either with an x-acto knife or with a Proxxon/Dremel tool.

I can also adjust the curvature to 305 rims if anyone is interested in printing out a template for themselves.

Kool Stop says that all the compounds are "rim friendly" when asked about the abrasiveness of the pads. But I wonder if one compound is less abrasive than the others. Salmon supposedly has iron oxide in it. Isn't that abrasive?

36 vs 32 hole rim brake wall heights at narrowest and widest sections.

pads on the rim

dura2 vs dura pad

7.2mm template on Dura2 pad

7.2mm template on 8mm brake wall

The Kool Stop Dura2 pads will have to be trimmed. I made a 3D printed cutting template, with an inner curvature of 402mm diameter. I modeled it at 7mm wide. I will use this to judge the curvature of the pads as I trim sides, either with an x-acto knife or with a Proxxon/Dremel tool.

I can also adjust the curvature to 305 rims if anyone is interested in printing out a template for themselves.

Kool Stop says that all the compounds are "rim friendly" when asked about the abrasiveness of the pads. But I wonder if one compound is less abrasive than the others. Salmon supposedly has iron oxide in it. Isn't that abrasive?

36 vs 32 hole rim brake wall heights at narrowest and widest sections.

pads on the rim

dura2 vs dura pad

7.2mm template on Dura2 pad

7.2mm template on 8mm brake wall

Last edited by tomtomtom123; 09-21-19 at 10:37 AM.

#15

Senior Member

Thread Starter

Join Date: Jan 2017

Posts: 1,064

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 350 Post(s)

Likes: 0

Liked 122 Times

in

90 Posts

I made another version of the 3D printed template with an enlarged size to serve as a routing guide for a T-bit on a proxxon/dremel tool fixed to a drill stand. Photos below.

I had to make 3 layers of passes since the brake block usable height is 2.0-2.5mm, and the T-bit is only 1.0mm. There were little bits leftover that still needed cleaning up with an x-acto knife. I made the design silly, and didn't raise the height of the edge of the guide so that the T-bit could cut the top edge of the brake block. I'll make a raised edge next time.

I also tried manually cutting with an x-acto knife instead of the T-bit, but it was difficult because of the gummy nature of the brake block. So the T-bit made a cleaner cut.

I had to make 3 layers of passes since the brake block usable height is 2.0-2.5mm, and the T-bit is only 1.0mm. There were little bits leftover that still needed cleaning up with an x-acto knife. I made the design silly, and didn't raise the height of the edge of the guide so that the T-bit could cut the top edge of the brake block. I'll make a raised edge next time.

I also tried manually cutting with an x-acto knife instead of the T-bit, but it was difficult because of the gummy nature of the brake block. So the T-bit made a cleaner cut.

Last edited by tomtomtom123; 09-22-19 at 07:23 AM.

#16

Senior Member

Thread Starter

Join Date: Jan 2017

Posts: 1,064

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 350 Post(s)

Likes: 0

Liked 122 Times

in

90 Posts

I've finally finished building the wheels and rode them a few times. The wider 26mm interior width feels more stable and responsive than the original 19mm interior width rims that I used with my Big Ben Blus 2.15" (55mm) tires.

I noticed that each time I reinflate the tires, I keep getting a huge 3-5mm radial dip that spans across an arc length of around 6 to 10 spokes. I suspect that the rim bead seat diameter is slightly larger than the tire beads, so a short arc of the bead is getting pulled deeper into the hollow of the rim. If I deflate the tire, massage it to pull it towards the dip, then the dip moves to the opposite arc. After 10 times repeating this, I finally reduced the dip to 1mm.

I also noticed that the 25mm wide Schwalbe high pressure rim band keeps shifting around, and sometimes it gets trapped between the rim wall and tire bead, which might be a part of the problem that I'm having. I'm going to replace it with a narrower adhesive tape, but how narrow is too small? The 25mm rim band when centered is riding halfway up the magenta line in the diagram below.

Or maybe I could attach some double sided tape to the underside of the band to temporarily stop it from moving when inflating?

A local store 1 hour ride away seems to be selling a 20mm wide Mighty High Pressure Adhesive Rim Tape, for around $1.50, 2 meter strip to be cut. It would ride up the cyan lines in the diagram above. Amazon review seems to say that the adhesive oozes out after some time. Are these reusable, or do I have to replace them each time I remove?

https://www.amazon.com/Mighty-Race-G.../dp/B007ZLL7XQ

It seems to be a brand of a German company that imports Asian bike parts.

https://euipo.europa.eu/eSearch/#det...arks/003242311

Oh, the Mighty tape seems to be old stock. New stock is rebranded M-wave.

https://www.messingschlager.com/en/p...m-tape_a519401

https://euipo.europa.eu/eSearch/#det...arks/003242278

Otherwise for better quality, I could order from the internet the 18mm Schwalbe High Pressure Adhesive Rim Tape for $2.00 each, but is 18mm too narrow? It would fit exactly on the bottom of the rim along the red line, but I'm worried it's too close to the spoke holes.

Or there are also wider 22, 23, 24, 25mm tubeless tapes on the internet for $10 for 10 meters, like Stan's or Sun Ringle tape, but I'd probably have to wrap 2 times around for the same strength as a band. I don't think they're reusable, unless I rewrap it in reverse, so the outer 2nd layer gets reapplied first.

I noticed that each time I reinflate the tires, I keep getting a huge 3-5mm radial dip that spans across an arc length of around 6 to 10 spokes. I suspect that the rim bead seat diameter is slightly larger than the tire beads, so a short arc of the bead is getting pulled deeper into the hollow of the rim. If I deflate the tire, massage it to pull it towards the dip, then the dip moves to the opposite arc. After 10 times repeating this, I finally reduced the dip to 1mm.

I also noticed that the 25mm wide Schwalbe high pressure rim band keeps shifting around, and sometimes it gets trapped between the rim wall and tire bead, which might be a part of the problem that I'm having. I'm going to replace it with a narrower adhesive tape, but how narrow is too small? The 25mm rim band when centered is riding halfway up the magenta line in the diagram below.

Or maybe I could attach some double sided tape to the underside of the band to temporarily stop it from moving when inflating?

A local store 1 hour ride away seems to be selling a 20mm wide Mighty High Pressure Adhesive Rim Tape, for around $1.50, 2 meter strip to be cut. It would ride up the cyan lines in the diagram above. Amazon review seems to say that the adhesive oozes out after some time. Are these reusable, or do I have to replace them each time I remove?

https://www.amazon.com/Mighty-Race-G.../dp/B007ZLL7XQ

It seems to be a brand of a German company that imports Asian bike parts.

https://euipo.europa.eu/eSearch/#det...arks/003242311

Oh, the Mighty tape seems to be old stock. New stock is rebranded M-wave.

https://www.messingschlager.com/en/p...m-tape_a519401

https://euipo.europa.eu/eSearch/#det...arks/003242278

Otherwise for better quality, I could order from the internet the 18mm Schwalbe High Pressure Adhesive Rim Tape for $2.00 each, but is 18mm too narrow? It would fit exactly on the bottom of the rim along the red line, but I'm worried it's too close to the spoke holes.

Or there are also wider 22, 23, 24, 25mm tubeless tapes on the internet for $10 for 10 meters, like Stan's or Sun Ringle tape, but I'd probably have to wrap 2 times around for the same strength as a band. I don't think they're reusable, unless I rewrap it in reverse, so the outer 2nd layer gets reapplied first.

Last edited by tomtomtom123; 10-18-19 at 10:40 PM.

#17

working on my sandal tan

Join Date: Aug 2011

Location: CID

Posts: 22,627

Bikes: 1991 Bianchi Eros, 1964 Armstrong, 1988 Diamondback Ascent, 1988 Bianchi Premio, 1987 Bianchi Sport SX, 1980s Raleigh mixte (hers), All-City Space Horse (hers)

Mentioned: 98 Post(s)

Tagged: 0 Thread(s)

Quoted: 3870 Post(s)

Liked 2,563 Times

in

1,577 Posts

I personally donít see the need for tape wider than 17.5mm here. Thatís enough to cover the spoke drillings but not so wide that itíll climb up the rim walls and interfere with tire seating. Use a thin, sticky tape like Stanís (or generics like Tesa 4289 or 3M 8898). Iíve cut it to a narrower width by just making a few marks on a roll and then slicing around it with a box cutter.

BTW, I always appreciate your willingness to capture data for these problem-solving threads, Tom.

BTW, I always appreciate your willingness to capture data for these problem-solving threads, Tom.

#18

Senior Member

Thread Starter

Join Date: Jan 2017

Posts: 1,064

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 350 Post(s)

Likes: 0

Liked 122 Times

in

90 Posts

ok, I ordered the Tesa 4289 from an industrial supply website for around $6. Shipping was $5 =). 19mm x 66m. They also had 25mm. Otherwise, there was an internet bike shop selling widths in 2mm increments starting from 17mm, but for 3x the price, I guess because of the small batch order and having to keep stock. I'll give it try when I receive it. It could also probably work as a chainstay protector. I noticed I've got pock marks from the chain on the seatstay and chainstay.

When I was building the Kinlin DDT32 rims, I noticed that the rims were divided into 4 arcs, where each arc would twist slightly to one side so that one wall would be up to 0.2mm lower than the other wall. Then it would twist in the other direction when reaching the next arc. I used a dial gauge to record accurate measurements on a paper spoke diagram and used the average deviation between both sides. At the end points of each arc was a high bump or low dip of up to 0.3mm which I couldn't smooth out with spoke tension, so I left it alone. There were also a few places where the rim width would be up to 0.3mm wider or narrower than the average width, so I had to measure both sides at those spots to determine whether or not to ignore them. This made me take several sessions and many days to true the wheels until I was satisfied that I did the best that I could. Here is a diagram that I used in case anyone wants to use them. I put left and right spokes on different circles to record the spoke tensions, and then wrote the radial deviation on the outermost circle, for both sidewalls.

When I was building the Kinlin DDT32 rims, I noticed that the rims were divided into 4 arcs, where each arc would twist slightly to one side so that one wall would be up to 0.2mm lower than the other wall. Then it would twist in the other direction when reaching the next arc. I used a dial gauge to record accurate measurements on a paper spoke diagram and used the average deviation between both sides. At the end points of each arc was a high bump or low dip of up to 0.3mm which I couldn't smooth out with spoke tension, so I left it alone. There were also a few places where the rim width would be up to 0.3mm wider or narrower than the average width, so I had to measure both sides at those spots to determine whether or not to ignore them. This made me take several sessions and many days to true the wheels until I was satisfied that I did the best that I could. Here is a diagram that I used in case anyone wants to use them. I put left and right spokes on different circles to record the spoke tensions, and then wrote the radial deviation on the outermost circle, for both sidewalls.

#19

working on my sandal tan

Join Date: Aug 2011

Location: CID

Posts: 22,627

Bikes: 1991 Bianchi Eros, 1964 Armstrong, 1988 Diamondback Ascent, 1988 Bianchi Premio, 1987 Bianchi Sport SX, 1980s Raleigh mixte (hers), All-City Space Horse (hers)

Mentioned: 98 Post(s)

Tagged: 0 Thread(s)

Quoted: 3870 Post(s)

Liked 2,563 Times

in

1,577 Posts

ok, I ordered the Tesa 4289 from an industrial supply website for around $6. Shipping was $5 =). 19mm x 66m. They also had 25mm. Otherwise, there was an internet bike shop selling widths in 2mm increments starting from 17mm, but for 3x the price, I guess because of the small batch order and having to keep stock. I'll give it try when I receive it. It could also probably work as a chainstay protector. I noticed I've got pock marks from the chain on the seatstay and chainstay.

#20

Senior Member

Thread Starter

Join Date: Jan 2017

Posts: 1,064

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 350 Post(s)

Likes: 0

Liked 122 Times

in

90 Posts

The Tesa 4289 strapping tape works really well. I wrapped 2 rounds. I punched the hole through the tape at the valve hole with the tip of a pair of scissors, but it cut a cross into the tape. I was worried the tape would eventually split, so I added a 3rd and 4th layer of short strips over the hole, using a paper hole puncher to punch out the hole. The hole in the 2 upper layers is a nice round shape.

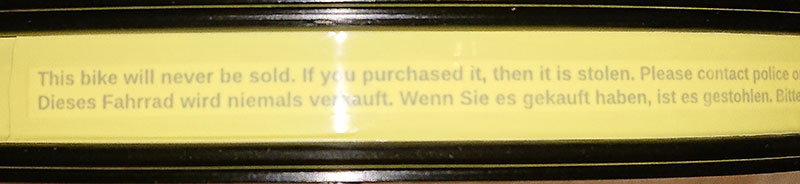

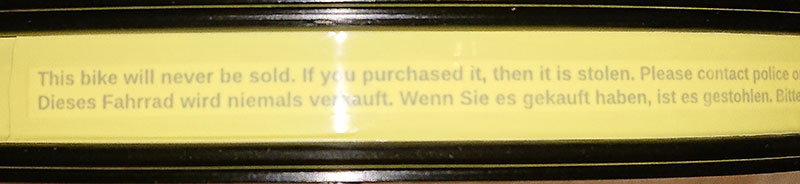

I also decided to glue stick strips of paper with hidden text over the tape to help with recovery if stolen, and added a 3rd round of tape on top. I could fit 10 languages of the text onto the tape. The text contains a dummy email address that I created to be forward to my main address.

I also decided to glue stick strips of paper with hidden text over the tape to help with recovery if stolen, and added a 3rd round of tape on top. I could fit 10 languages of the text onto the tape. The text contains a dummy email address that I created to be forward to my main address.

Likes For tomtomtom123: