Filet Brazing with 30% silver

#1

Senior Member

Thread Starter

Filet Brazing with 30% silver

Can it be done and does anyone have any experience with it? Does it just flow like regular silver brazing for lugs or can it Be built up?

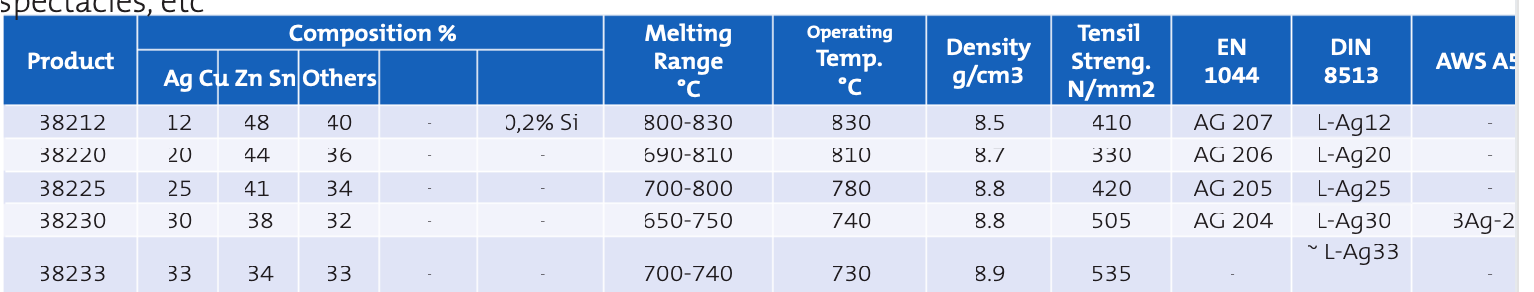

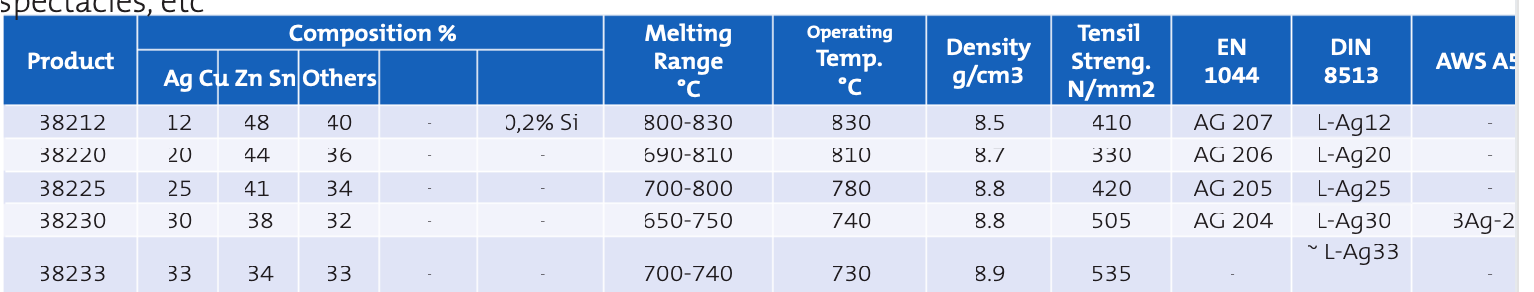

I bought a Columbus Cento tube set and they recommend Castoline Silver Alloy 38230 for brazing or Tig it. I would like to filet braze it otherwise I have to send it out to have it welded.

Thanks for any info

I bought a Columbus Cento tube set and they recommend Castoline Silver Alloy 38230 for brazing or Tig it. I would like to filet braze it otherwise I have to send it out to have it welded.

Thanks for any info

Likes For wsteve464:

#2

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,394

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,694 Times

in

2,516 Posts

that's interesting, I wonder if they would recommend against something like filletpro? I'm not sure what causes the lower silver percentage to build more.

#3

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,071

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4199 Post(s)

Liked 3,851 Times

in

2,301 Posts

I would wonder about the strength first. 45% silver can be built up although I would not consider it for true fillets. It can flow close to like what 56% does but is still "thicker". And then there's 50N, which I believe is FDA approved for stainless. With all I've read about the Cycle Design stuff I would look into that. A side note is that I wouldn't scrimp on filler. After all is totaled up the filler cost is relatively minor. Andy

__________________

AndrewRStewart

AndrewRStewart

Likes For Andrew R Stewart:

#4

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,394

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,694 Times

in

2,516 Posts

There might be some differences, but for me, 45% and fillet pro build fillets about the same. You have to be pretty careful about it or it will collapse

#5

Senior Member

Thread Starter

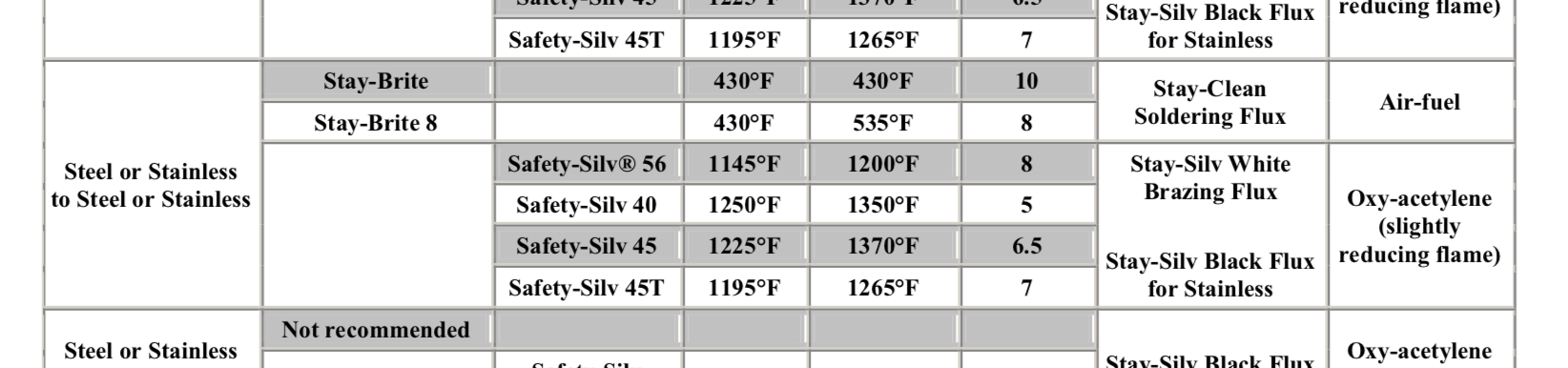

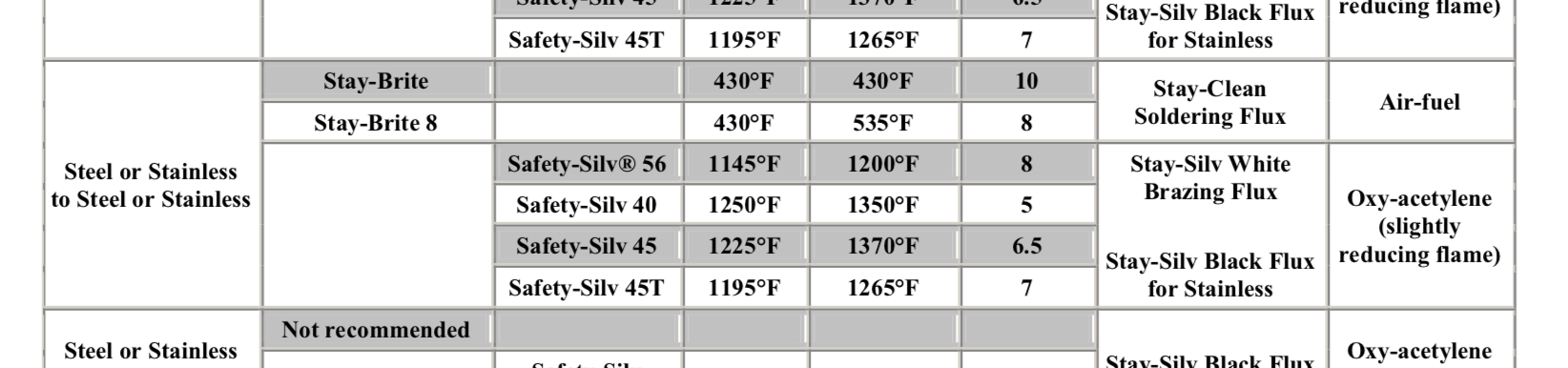

I have looked up specs for various Harris silver %s. I ended up buying some 45% to try on another frame made from similar Columbus tubing to see if I like the results if that doesn't work I'll try filet pro. The working temps are within those specified on the Castoline chart. If this doesn't work out then I'll have to find a good west coast frame builder that can tig it.

#6

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,071

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4199 Post(s)

Liked 3,851 Times

in

2,301 Posts

I note the "slightly reducing flame" reference. This is what I was first taught wayyyy back when with silver in general. I always assumed it was to reduce the hot spots that an oxidizing flame can cause so quickly. Thoughts from the smarter people? Andy

__________________

AndrewRStewart

AndrewRStewart

#7

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,394

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,694 Times

in

2,516 Posts

Not sure if they are worried about hot spots or oxidation in general. The part where they mention "useful for wider gaps" is promising.

#8

Senior Member

Thread Starter

On the Harris chart for the different silver formulas they give a "fluidity rating" the lower the number the thicker it is after melting. I have heard back from Castoline the 38230 is special order in the US. I am waiting to hear if there is a minimum order or not and if there is an equivalent in stock in the US.

Likes For wsteve464:

#9

Newbie

Join Date: Oct 2020

Posts: 4

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 3 Times

in

2 Posts

On the Harris chart for the different silver formulas they give a "fluidity rating" the lower the number the thicker it is after melting. I have heard back from Castoline the 38230 is special order in the US. I am waiting to hear if there is a minimum order or not and if there is an equivalent in stock in the US.

The Johnson Matthey silver braze catalogue is a great reference list where you can see the effects of filler composition on material properties such as wetting, flow and UTS. Unfortunately the UTS for fillers without tin like 38230 (Ag 230) is not listed in the JM catalogue, however, Stella from Italy has this information.

Unfortunately as a new member I cannot insert URLs or attachments.

You will see that the addition of tin is to lower the melting temperature, however, it does not necessarily make the filler more fluid, e.g. JM Silver-flo 33 (Ag 33%, Cu 33.5%, Zn 33.5%, Sn 0%) has a fluidity of 1 with an upper liquid temp of 740 C compared to Silver-flo 34 (Ag 34%, Cu 36%, Zn 27.5%, Sn 2.5%) with a fluidity of 3 and an upper liquid temp of 730 C. Silver-flo 33 UTS 540 MPa, Silver-flo 34 UTS 470 MPa, Ag 230 UTS 490 MPa. Flo 33 has a narrow 40 C liquid range, Flo 34 has a wide 100 C liquid range, Ag 230 has a wide 95 C liquid range.

Also of importance are the braze filler properties such as joint bonding strength, resistance to corrosion, ductility (elongation) and fatigue resistance. So you need to use a material that works and is matched to the tube material. In this regard I would trust the Columbus recommendation.

What is my experience? I have manufactured 6 frames since 2010, 3 using nickel bronze (nickel silver in the USA), and 3 using silver (Ag 38%, CU 32%, Zn 28%, Sn 2%). The 3rd frame I was set up to use Fillet Pro but could not get results I was happy with (unable to weld up slope and down slope like nickel bronze, and some porosity). I did use Fillet Pro to finish the rear triangle on the 3rd frame. This included breezer rear dropouts (first time). Following this I sought advice from the Fillet Pro agent in Australia about the best welding technique. His advice was pretty well was the same as from a post on this forum in 2009. It's tricky. Very fluid weld pool, a real technique to build a wider fillet, unable to weld in a position other than very slightly up hill. On a whim after finishing this 3rd frame I did a trial weld using a 38% silver filler rod from the UK sold as a lower cost rod for lug brazing (SIF No. 39) and found it was easier to build a fillet and porosity was much less. But, still no where near as 'weldable' as nickel bronze (SIF No. 2) with the purity of weld. I have never had any porosity using nickel bronze and I can weld at high angles up slope and down slope. It's just that the high temp of nickel bronze creates distortion of head tubes, bottom brackets and seat tube / seat stay junctions that require post reaming and re tapping / facing of BB threads. Hence, why trialling Fillet Pro and using SIF No. 39, but no more. Either I find a silver filler that is weldable or I go back to nickel bronze and weld smaller size fillets similar to the size that Dave Anderson uses. The importance of filler size was drummed into me by Jim Cook from Nimbus Cycles. According to Jim the fillet throat size is calculated by the ratio of tube UTS versus filler UTS plus 100% safety factor. e.g. Columbus Niobium (Spirit / HSS / Life) UTS 1250 MPa, Fillet Pro 430 MPa, Max 35 dia bi-oval 0.8mm joint end = 1250/430 x 0.8 x 2 = 5.8mm. Using nickel bronze at 540 MPa UTS reduces this fillet throat size to 4.6mm. Of course if a Spirit 35 dia down tube was used the throat size would reduce by the ratio of 0.65 / 0.80. I have also tried to contact Vincenzo Forgione in Italy to discuss silver filler materials. Vincenzo exclusively uses silver for his fillet brazed frames. He has been using the same technique for over 25 years making everything from mountain to fold up bikes. Vincenzo's fillet sizes are small, similar Saffron.

Nickel bronze was my initial filler material of choice after many discussions with Jim Cook of Nimbus Cycles. Jim was a mechanical engineer and metallurgist in the UK nuclear power generation before he started Nimbus Cycles. He made many bikes for TdF riders as well as doing research for time trial rider positioning for maximum output in the early days of sports science medicine with the University of Leicester. Jim was 76 back in 2010 when I did this research for making frames. He was a big believer in nickel bronze due to its higher strength (UTS 540MPa) and very low porosity. He also used to post shape the fillet welds using the torch rather than shaping with a file. This was a technique he learnt from a welder that used to weld engine subframes in Spitfire WWII aircraft. I have yet to try the post weld torch shaping technique.

One thing to consider is that with silver where the position (only slightly up hill) is required and building a fillet is difficult, it therefore takes longer to weld a joint and hence more heat builds up in the job. Hopefully Castolin 38230 (Ag 230) takes away these downsides. Any opinions and information is welcome.

Likes For evr:

#10

Senior Member

Join Date: Dec 2019

Posts: 955

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Liked 263 Times

in

212 Posts

Can it be done and does anyone have any experience with it? Does it just flow like regular silver brazing for lugs or can it Be built up?

I bought a Columbus Cento tube set and they recommend Castoline Silver Alloy 38230 for brazing or Tig it. I would like to filet braze it otherwise I have to send it out to have it welded.

Thanks for any info

I bought a Columbus Cento tube set and they recommend Castoline Silver Alloy 38230 for brazing or Tig it. I would like to filet braze it otherwise I have to send it out to have it welded.

Thanks for any info

#11

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,394

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,694 Times

in

2,516 Posts

evr, welcome to the forum and thanks for your informative first post. My guess is that the Columbus recommended filler is still pretty tricky to use, but I would be interested in contradictory reports. I know there are people that use a lot of nickel silver. The downside being that you can develop a sensitivity to it. I think that happened to me when I used it a lot. Nothing too serious, but just enough to be annoying.

#12

Newbie

Join Date: Oct 2020

Posts: 4

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 3 Times

in

2 Posts

Agree, Omnicrom is just another cromoly alloy, so use whatever you have been using, LFB, Fillet Pro, SIF No. 39, Nickel Bronze etc will do the job. Matthew Sowter of Saffron replied that he uses SIF No. 39 (Ag 38%, CU 32%, Zn 28%, Sn 2%) on all his stainless steel frames (XCR, 953). So the filler specs on some of the Saffron XCR frames is meant to say 38% silver instead of 33%. From my experience SIF No. 39 is far more usable than Fillet Pro. It will be interesting to see what silver filler Vinzenzo Forgione uses.

#13

Newbie

Join Date: Oct 2020

Posts: 4

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 3 Times

in

2 Posts

Thanks for the welcome. Yes I heard that some people develop a skin sensitivity to nickel bronze, pity because it forms a very pure weld. I used nickel bronze for my first frame as I had used it quite a bit as young fellow in the motor racing business on cromoly tube chassis. Also, it was Jim Cook's filler of choice. I did consider TIG for my first frame and even had a lesson from an ex F1 chief engineer. The lesson went very well but I decided there would be far too much practise required to become proficient using TIG. Regarding Castolin 38230 (Ag 30%), my guess is it will be much easier to build a fillet than SIF No. 39 (Ag38%) as it's flow / fluidity is rated less. The key question for 38230 will be control of porosity and ability to post rework a joint without introducing more porosity. If the porosity is controlled as well as SIF no. 39 and you can weld more up slope and down slope then it should be a goer.

#14

Newbie

Join Date: Oct 2020

Posts: 4

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 3 Times

in

2 Posts

I received a reply from Vincenzo Forgione. He uses a 45% AG rod from Fontargen designated AF 320. This is a flux coated rod. The 45% Ag aligns with a post from Fred Parr recalling; "When I was testing oversized handmade tubes that were reeled very thin I used a similar alloy to make the "Whats holding it together" look but the oversized tubes were not accepted, they in fact were rejected and almost a decade went by before anyone made anything with bigger dia tubes,and of course that was Masi. Masi in Italy joined with brazing methods but when it came to California A45C quickly was adopted and most if not all were made with Cad 45 Silver." Fontargen AF320 ISO 176272 designation Ag 145. Ag 45%, Cu 27%, Zn 25.5%, Sn 2.5%. UTS 420 MPa. The equivalent Harris material is Safety Silv 45T. I have procured the same material in Australia supplied by Johnson Matthey (Sliver-flo 452). Flowability of 2, same as Safety-Silv 38T, so I suspect welding up slope and down slope will not be possible but figuring porosity will be low with the reduced zinc content. I am going to trial a flux coated rod alongside a bare rod with silver flux paste. Cheers.

Likes For evr:

#15

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,394

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,694 Times

in

2,516 Posts

Thanks for following up.