Mid-'40s René Herse tandem

#26

Senior Member

Join Date: Jun 2006

Posts: 20,305

Mentioned: 130 Post(s)

Tagged: 0 Thread(s)

Quoted: 3464 Post(s)

Liked 2,828 Times

in

1,995 Posts

Galli made a very similar tapered roller BB:

VeloBase.com - Component: Galli Criterium (roller bearing)

VeloBase.com - Component: Galli Criterium (roller bearing)

#27

Senior Member

Join Date: Jun 2006

Posts: 20,305

Mentioned: 130 Post(s)

Tagged: 0 Thread(s)

Quoted: 3464 Post(s)

Liked 2,828 Times

in

1,995 Posts

#28

Senior Member

Thread Starter

Join Date: Jun 2010

Location: Medford MA

Posts: 2,089

Bikes: Ron Cooper touring, 1959 Jack Taylor 650b ladyback touring tandem, Vitus 979, Joe Bell painted Claud Butler Dalesman, Colin Laing curved tube tandem, heavily-Dilberted 1982 Trek 6xx, René Herse tandem

Mentioned: 80 Post(s)

Tagged: 0 Thread(s)

Quoted: 964 Post(s)

Liked 1,451 Times

in

723 Posts

Damn. This is getting more interesting with every post!

Contact Brian Chapman or Peter Weigle to find out which chrome plater they use. Once they know you're working on your tandem Herse, I'd bet they'd let you slip in some bits on one of their runs.

Jamie Swan is another good contact, you probably met him at FFD last year. He's in Long Island.

Contact Brian Chapman or Peter Weigle to find out which chrome plater they use. Once they know you're working on your tandem Herse, I'd bet they'd let you slip in some bits on one of their runs.

Jamie Swan is another good contact, you probably met him at FFD last year. He's in Long Island.

__________________

Owner & co-founder, Cycles René Hubris. Unfortunately attaching questionable braze-ons to perfectly good frames since about 2015. With style.

Owner & co-founder, Cycles René Hubris. Unfortunately attaching questionable braze-ons to perfectly good frames since about 2015. With style.

#29

Fat Guy on a Little Bike

Join Date: Jun 2008

Location: Philadelphia, PA

Posts: 15,944

Bikes: Two wheeled ones

Mentioned: 42 Post(s)

Tagged: 0 Thread(s)

Quoted: 1254 Post(s)

Liked 345 Times

in

174 Posts

I don't know if I met Jamie, there were so many people. I'll try e-mailing Peter and Brian to see if they'll help me out with the chrome. I've been cautioned about the chromers here in the Boston area, that's for sure. The machinists I consult with when I make scientific apparatus in the shop have told me that the local chromers have a propensity for losing parts, and these Herse parts are irreplaceable, for sure! I have Jack Taylor parts too. Two Herse racks, two Jack Taylor stems, and possibly a lot of bolts if the chromer will play along with that. I could even do all the pre-prep myself, on the polishing wheels and belts I have access to - to take out the pitting and whatnot, and make it easier for the chromers. Hell, I'd even settle for nickel, but not electroless nickel.

#30

Senior Member

Thread Starter

Join Date: Jun 2010

Location: Medford MA

Posts: 2,089

Bikes: Ron Cooper touring, 1959 Jack Taylor 650b ladyback touring tandem, Vitus 979, Joe Bell painted Claud Butler Dalesman, Colin Laing curved tube tandem, heavily-Dilberted 1982 Trek 6xx, René Herse tandem

Mentioned: 80 Post(s)

Tagged: 0 Thread(s)

Quoted: 964 Post(s)

Liked 1,451 Times

in

723 Posts

I hear ya. But there's so much patina on the frame already! I'll for sure only do it if I'm guaranteed good results. It's not worth the risk otherwise.

__________________

Owner & co-founder, Cycles René Hubris. Unfortunately attaching questionable braze-ons to perfectly good frames since about 2015. With style.

Owner & co-founder, Cycles René Hubris. Unfortunately attaching questionable braze-ons to perfectly good frames since about 2015. With style.

#31

Senior Member

Well that there is quite a bike, to say the least. Fantastic and historic find. Definitely subscribed. Your efforts on reproducing the irrational crankset are commendable.

I think you are correct in replating the rusted chrome. That is just proper maintenance, and that rust is too far along. It's not like the French had some special kind of chrome that only grows there. New chrome will be indistinguishable from the original chrome, except not rusty.

OTOH and quite obviously, the original paint has to stay. One of the best parts IMO of a Herse is the hand painted downtube lettering. I bet the old paint looks great with a little cleaning and polishing, and maybe some very restrained touch up here and there if any spots are rusting badly.

I think you are correct in replating the rusted chrome. That is just proper maintenance, and that rust is too far along. It's not like the French had some special kind of chrome that only grows there. New chrome will be indistinguishable from the original chrome, except not rusty.

OTOH and quite obviously, the original paint has to stay. One of the best parts IMO of a Herse is the hand painted downtube lettering. I bet the old paint looks great with a little cleaning and polishing, and maybe some very restrained touch up here and there if any spots are rusting badly.

#32

Full Member

Join Date: Aug 2014

Location: Vancouver, BC

Posts: 236

Bikes: 48 Alleluia, 52 Blondin, 57 Cattaneo, 68 CNC, 55 Dujay, 46 Herse, 76 Singer, 48 LeGreves, 55 Metropole, 62 Holdsworth Cyclone, 49 Carpenter, 55 Condor, 65 Masi Special, 81 Sequoia, 76 Eisentraut, 72 Proteus, 60 Paramount, 77 Trek TX700, 82 Ross

Mentioned: 11 Post(s)

Tagged: 0 Thread(s)

Quoted: 79 Post(s)

Liked 137 Times

in

55 Posts

I wandered into a local spring making business and to my surprise they had the correct diameter in stainless steel spring wire, which they just gave me. The wire is wound cold and doesn't require heat treatment afterwards, although it's optional for residual stress relief. The fellow there also gave me some good advice about sizing the mandrel, as you have to make it somewhat smaller than the final spring ID you want.

Likes For Duke7777:

#33

Senior Member

Join Date: Sep 2011

Location: Baltimore MD

Posts: 3,331

Bikes: '72 Motobecane Grand Record, '72 Gitane tandem, '72 Raleigh Super Course, '73 Raleigh Gran Sport, '73 Colnago Super, '76 Fiorelli Coppi, '78 Raleigh SBDU Team Pro, '78 Trek 930, '81 Holdsworth Special 650B, '86 Masi GC, ’94 Bridgestone RB-T

Mentioned: 67 Post(s)

Tagged: 0 Thread(s)

Quoted: 786 Post(s)

Liked 517 Times

in

280 Posts

Franklin Frame in OH has a local chromer who does quality bike work. Might be worth dropping Jack a line.

__________________

The man who dies with the most toys…is dead. - Rootboy

The man who dies with the most toys…is dead. - Rootboy

Likes For jeirvine:

#34

Fat Guy on a Little Bike

Join Date: Jun 2008

Location: Philadelphia, PA

Posts: 15,944

Bikes: Two wheeled ones

Mentioned: 42 Post(s)

Tagged: 0 Thread(s)

Quoted: 1254 Post(s)

Liked 345 Times

in

174 Posts

Franklin Frame in OH has a local chromer who does quality bike work. Might be worth dropping Jack a line.

in terms of bang for the buck, that’s where I’d go.

#35

Fat Guy on a Little Bike

Join Date: Jun 2008

Location: Philadelphia, PA

Posts: 15,944

Bikes: Two wheeled ones

Mentioned: 42 Post(s)

Tagged: 0 Thread(s)

Quoted: 1254 Post(s)

Liked 345 Times

in

174 Posts

This is truly an extraordinary find. I would watch Indiana Jones hunt through a jungle to find this.

#36

working on my sandal tan

Join Date: Aug 2011

Location: CID

Posts: 22,629

Bikes: 1991 Bianchi Eros, 1964 Armstrong, 1988 Diamondback Ascent, 1988 Bianchi Premio, 1987 Bianchi Sport SX, 1980s Raleigh mixte (hers), All-City Space Horse (hers)

Mentioned: 98 Post(s)

Tagged: 0 Thread(s)

Quoted: 3871 Post(s)

Liked 2,568 Times

in

1,579 Posts

I wouldn't be surprised if some of those quirks you're observing in early chainrings are due to tool limitations rather than being purely intentional. In order to do the cutouts, they would have had to drill into the blank as a starting point. For the cutouts behind each chainring bolt, I'm betting they drilled three starter holes and used a coping saw (or similar) to connect the dots. Early ones might have been drilled close to the chainring bolt, and if they used a relatively large bit to do it, that might explain why the arms of the web are so thin in that area. You can see that there would be about as much material directly behind the holes as left around them at the mounting points:

The picture of a late chainring blank on Joel Metz's site shows two punched spots at the outer corners, so perhaps when they decided to leave more material by the chainring bolts, it made more sense to just drill in two spots and cut out the rest.

That later style appears to use smaller circles to flow into the crank arms:

The picture of a late chainring blank on Joel Metz's site shows two punched spots at the outer corners, so perhaps when they decided to leave more material by the chainring bolts, it made more sense to just drill in two spots and cut out the rest.

That later style appears to use smaller circles to flow into the crank arms:

__________________

RUSA #7498

Originally Posted by noglider

People in this forum are not typical.

Last edited by ThermionicScott; 11-03-19 at 06:04 PM.

Likes For ThermionicScott:

#37

working on my sandal tan

Join Date: Aug 2011

Location: CID

Posts: 22,629

Bikes: 1991 Bianchi Eros, 1964 Armstrong, 1988 Diamondback Ascent, 1988 Bianchi Premio, 1987 Bianchi Sport SX, 1980s Raleigh mixte (hers), All-City Space Horse (hers)

Mentioned: 98 Post(s)

Tagged: 0 Thread(s)

Quoted: 3871 Post(s)

Liked 2,568 Times

in

1,579 Posts

BTW, @Duke7777, I was flipping through my BQ's from the last couple of years recently, and really dug your feature on restoring the 1946 RH.

Likes For gomango:

#39

Senior Member

Join Date: Jun 2006

Location: NW Burbs, Chicago

Posts: 12,053

Mentioned: 201 Post(s)

Tagged: 0 Thread(s)

Quoted: 3015 Post(s)

Liked 3,792 Times

in

1,406 Posts

Perhaps. But a stamping tool is actually pretty cheap. Can't imagine the time to cut 50 teeth versus the 3 seconds a power press would take.

#40

working on my sandal tan

Join Date: Aug 2011

Location: CID

Posts: 22,629

Bikes: 1991 Bianchi Eros, 1964 Armstrong, 1988 Diamondback Ascent, 1988 Bianchi Premio, 1987 Bianchi Sport SX, 1980s Raleigh mixte (hers), All-City Space Horse (hers)

Mentioned: 98 Post(s)

Tagged: 0 Thread(s)

Quoted: 3871 Post(s)

Liked 2,568 Times

in

1,579 Posts

ETA: With TA coming into existence around 1947, maybe RH made chainrings entirely in-house at the time of the OP's bike?

#41

Senior Member

Join Date: Jun 2006

Location: NW Burbs, Chicago

Posts: 12,053

Mentioned: 201 Post(s)

Tagged: 0 Thread(s)

Quoted: 3015 Post(s)

Liked 3,792 Times

in

1,406 Posts

Could very well be. But stamping tech was available long before WW2. And there will always post-process machining to put the ramps on teeth and countersinks for bolts. I could imagine hand cutting if you are doing a few dozen rings a year. But cutting hundreds in hours instead of months isn't a stretch of the imagination.

#42

Senior Member

Join Date: Apr 2006

Location: Washington County, Vermont, USA

Posts: 3,777

Bikes: 1966 Dawes Double Blue, 1976 Raleigh Gran Sport, 1975 Raleigh Sprite 27, 1980 Univega Viva Sport, 1971 Gitane Tour de France, 1984 Lotus Classique, 1976 Motobecane Grand Record

Mentioned: 77 Post(s)

Tagged: 0 Thread(s)

Quoted: 765 Post(s)

Liked 658 Times

in

350 Posts

I need new chainrings. All four are pretty worn-out, in my estimation!

Classic René Herse cranks are a little different from the ones Jan Heine sells now. These may have been among the very very first, in fact! While the 70mm bolt circle was retained throughout the years, the bolt size changed as well as the interface between the crank and the ring. Now, I had thought that Jan Heine sold replacement classic René Herse chainring "blanks" on his website, that could be filed or drilled to fit the various iterations of classic Herse cranks. He does, but not the big ring.

So I will have to make them myself. Simple decision is what metal to use. 7075-t6 is the premium stuff - much harder than 6061, and @jonwvara who makes triplizers happily confirmed he used it as well. Thanks Jon

Next is how to make them. First, the big ring, which is a 48t. I like 48. It is divisible by 3 and 2, several times over, so geometry can reference the teeth tips and achieve a lot of symmetry

There are well-defined engineering formulae for sprocket teeth. These formulae take three variables: chain pitch; roller diameter; and number of teeth, and use geometry to create the sprocket profile. Interestingly, only one CAD software I have access to had a macro that implemented the formula for me. I grabbed a tooth profile from there and imported it into Autodesk Fusion 360.

From here, I had to decide how to geometrically define those beautiful René Herse chainring curves. This is challenging.

Some of you may know I have some mixed feelings about Jan Heine taking over the Herse brand. I didn't really understand why I felt this way until I started really looking at the chainrings he designed. You see, the way you approach designing a chainring is a bit of a Rorschach test on your cycling philosophy. I'll explain.

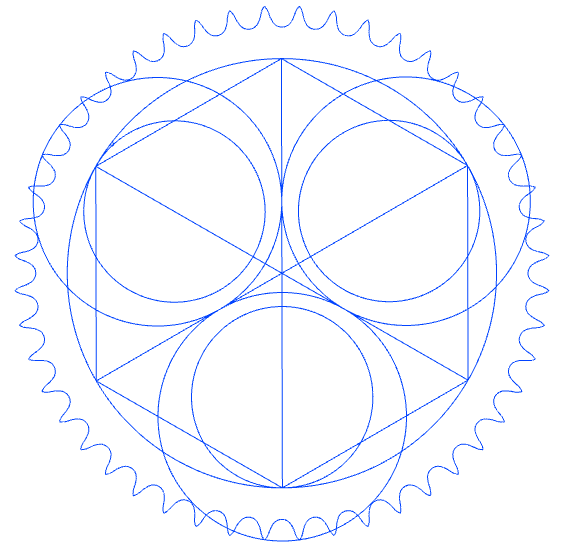

Jan's ring looks like this:

The circular cutouts are perfectly concentric, making structurally-sound limbs of non-varying thickness to carry the load of pedaling from the spider to the teeth. It's very pragmatic. Very German.

And that's not how René Herse did it - at least in his early days, according to the google images I've found, plus my own ring.

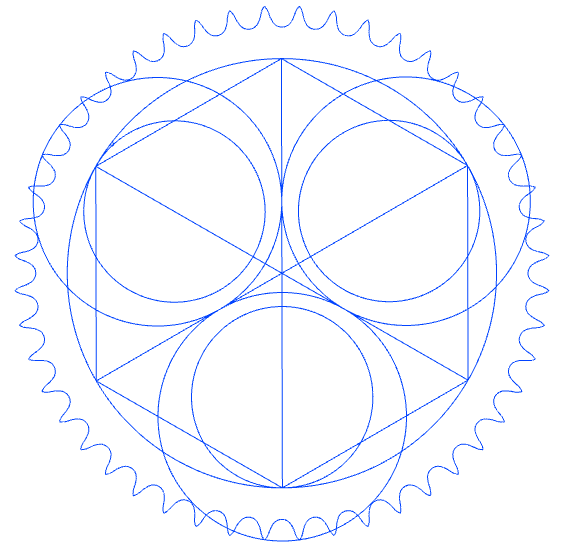

As my friend and Cycles René Hubris co-founder Kevin put it, "René Herse managed to be both pragmatic and whimsical." His ring looks really art nouveau. Like this:

It's subtle, as most tasteful things are.

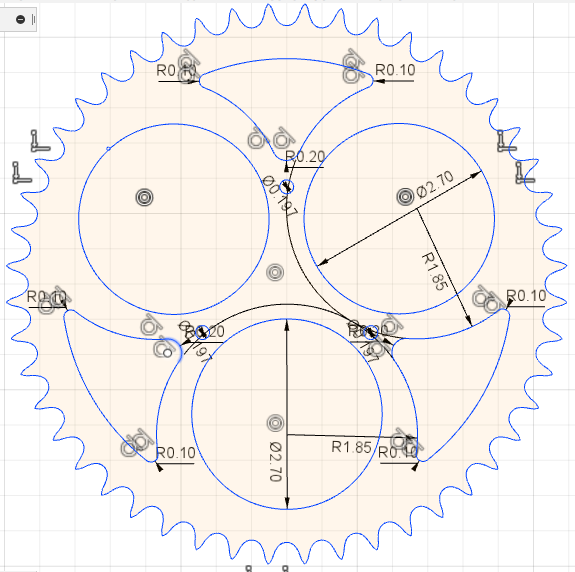

So I am a biologist, and I thought about how the chainring looks kinda art nouveau. I have no knowledge of art nouveau, but of course I thought about how a lot of those curves must have come from biology. The cast iron vines around the Métro entrance, for example (really the only example of art nouveau I can come up with). So drawing from my love of molluscs, which have really nice, platonic, well-defined geometry, I drew this in Fusion 360:

Every circle is referenced to be tangent to or bisected by either some other circle (inner or total or bolt circle) or one of the six lines radiating outward from the center to make a hexagon, on three of which the bolt circle sits. Make some nice fillets and cut out the superfluous geometry and you get this.

It is close, but no cigar. Even with seashell-inspired geometry, I'm still not as good as RH. Kevin says, "better than Jan, but still not whimsical enough."

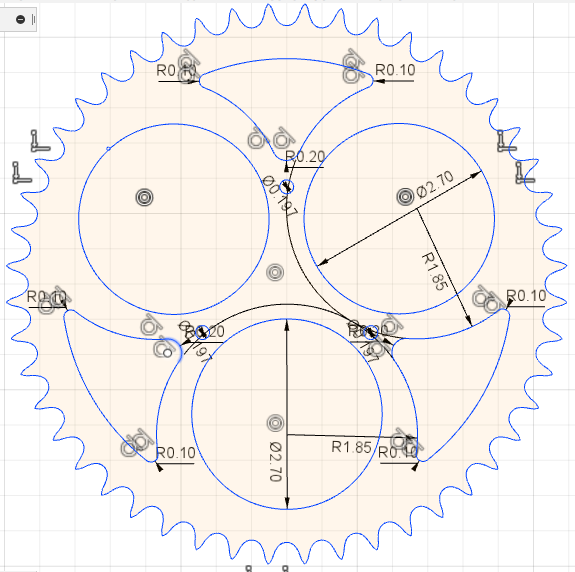

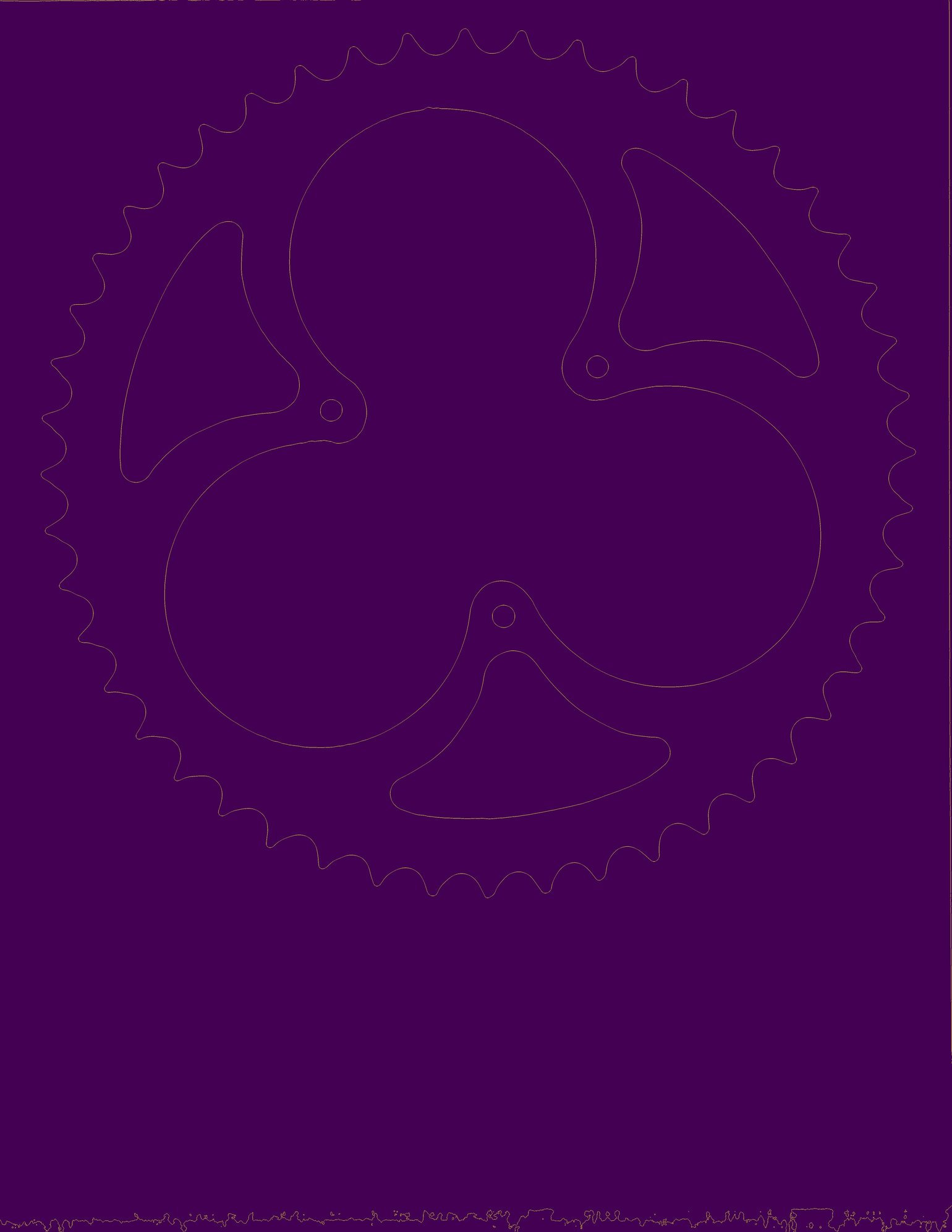

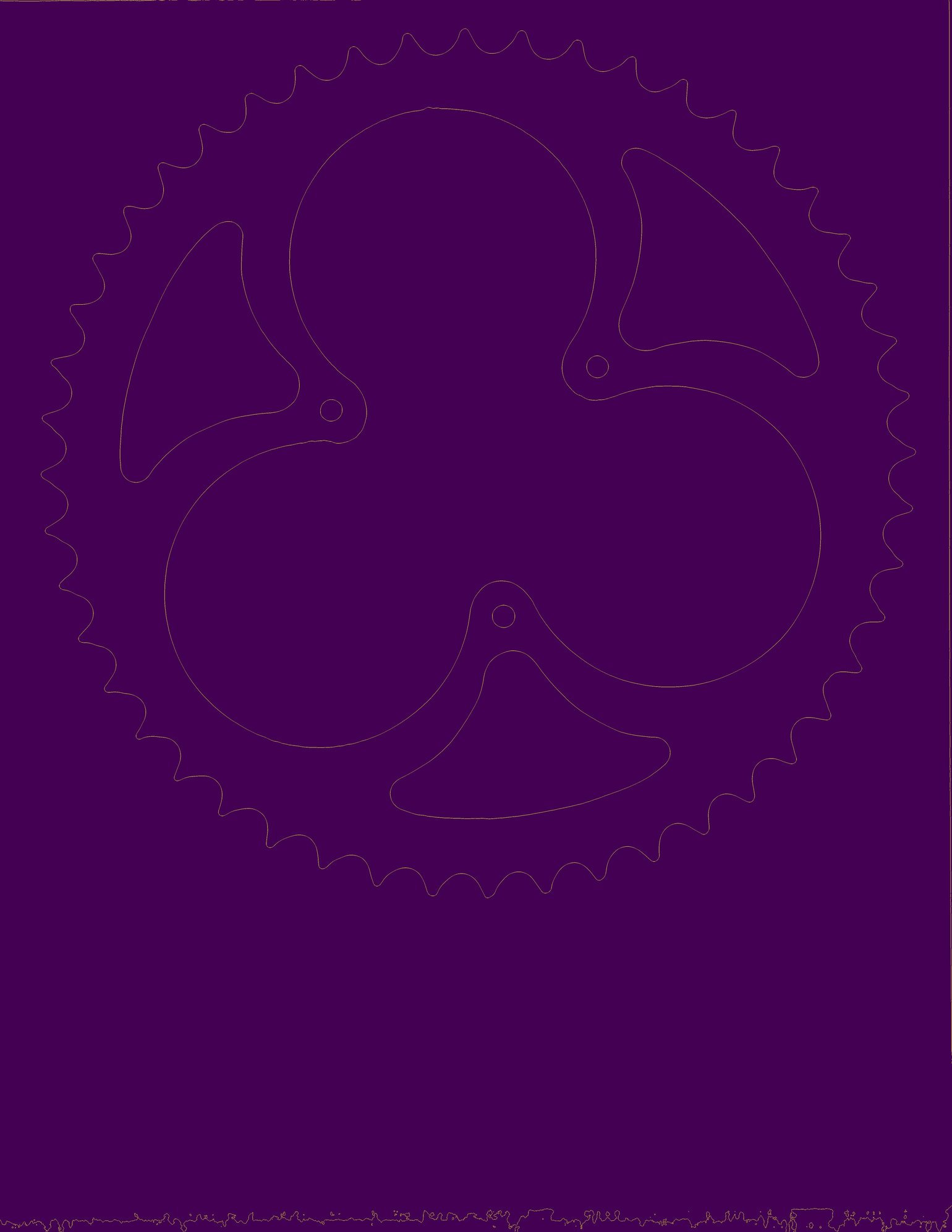

So Kevin, who writes image processing software, took the chainring away from me and brute-forced things. He put it in an expensive flatbed scanner and he wrote a simple edge-finding algorithm to process it, and now we have this.

This is a raster file, but I think I can just put it into a vectorizing program such as Adobe Illustrator, and I'll have it! Then I'll delete the teeth, which are of course a scan of the worn ones, and overlay teeth from my sprocket-maker macro. Then the plan is to waterjet cut the ring and thin/bevel the teeth with a lathe and hand polish/file to round off the edges as the original was done.

The interesting thing about all this is we still have no idea how the original René Herse curve is geometrically defined. Kevin bets it is from a set of French curve templates, or an Euler spiral. It's interesting food for thought. It will come to one of us while in the shower, and will quickly be forgotten, before it can be posted, of course.

All this Rorschach test talk makes me wonder what Grant/Rivendell's interpretation of the chainring design would be.

Classic René Herse cranks are a little different from the ones Jan Heine sells now. These may have been among the very very first, in fact! While the 70mm bolt circle was retained throughout the years, the bolt size changed as well as the interface between the crank and the ring. Now, I had thought that Jan Heine sold replacement classic René Herse chainring "blanks" on his website, that could be filed or drilled to fit the various iterations of classic Herse cranks. He does, but not the big ring.

So I will have to make them myself. Simple decision is what metal to use. 7075-t6 is the premium stuff - much harder than 6061, and @jonwvara who makes triplizers happily confirmed he used it as well. Thanks Jon

Next is how to make them. First, the big ring, which is a 48t. I like 48. It is divisible by 3 and 2, several times over, so geometry can reference the teeth tips and achieve a lot of symmetry

There are well-defined engineering formulae for sprocket teeth. These formulae take three variables: chain pitch; roller diameter; and number of teeth, and use geometry to create the sprocket profile. Interestingly, only one CAD software I have access to had a macro that implemented the formula for me. I grabbed a tooth profile from there and imported it into Autodesk Fusion 360.

From here, I had to decide how to geometrically define those beautiful René Herse chainring curves. This is challenging.

Some of you may know I have some mixed feelings about Jan Heine taking over the Herse brand. I didn't really understand why I felt this way until I started really looking at the chainrings he designed. You see, the way you approach designing a chainring is a bit of a Rorschach test on your cycling philosophy. I'll explain.

Jan's ring looks like this:

The circular cutouts are perfectly concentric, making structurally-sound limbs of non-varying thickness to carry the load of pedaling from the spider to the teeth. It's very pragmatic. Very German.

And that's not how René Herse did it - at least in his early days, according to the google images I've found, plus my own ring.

As my friend and Cycles René Hubris co-founder Kevin put it, "René Herse managed to be both pragmatic and whimsical." His ring looks really art nouveau. Like this:

It's subtle, as most tasteful things are.

So I am a biologist, and I thought about how the chainring looks kinda art nouveau. I have no knowledge of art nouveau, but of course I thought about how a lot of those curves must have come from biology. The cast iron vines around the Métro entrance, for example (really the only example of art nouveau I can come up with). So drawing from my love of molluscs, which have really nice, platonic, well-defined geometry, I drew this in Fusion 360:

Every circle is referenced to be tangent to or bisected by either some other circle (inner or total or bolt circle) or one of the six lines radiating outward from the center to make a hexagon, on three of which the bolt circle sits. Make some nice fillets and cut out the superfluous geometry and you get this.

It is close, but no cigar. Even with seashell-inspired geometry, I'm still not as good as RH. Kevin says, "better than Jan, but still not whimsical enough."

So Kevin, who writes image processing software, took the chainring away from me and brute-forced things. He put it in an expensive flatbed scanner and he wrote a simple edge-finding algorithm to process it, and now we have this.

This is a raster file, but I think I can just put it into a vectorizing program such as Adobe Illustrator, and I'll have it! Then I'll delete the teeth, which are of course a scan of the worn ones, and overlay teeth from my sprocket-maker macro. Then the plan is to waterjet cut the ring and thin/bevel the teeth with a lathe and hand polish/file to round off the edges as the original was done.

The interesting thing about all this is we still have no idea how the original René Herse curve is geometrically defined. Kevin bets it is from a set of French curve templates, or an Euler spiral. It's interesting food for thought. It will come to one of us while in the shower, and will quickly be forgotten, before it can be posted, of course.

All this Rorschach test talk makes me wonder what Grant/Rivendell's interpretation of the chainring design would be.

__________________

www.redclovercomponents.com

"Progress might have been all right once, but it has gone on too long."

--Ogden Nash

www.redclovercomponents.com

"Progress might have been all right once, but it has gone on too long."

--Ogden Nash

Likes For jonwvara:

#43

Rustbelt Rider

Join Date: Oct 2008

Location: Canton, OH

Posts: 9,104

Bikes: 1990 Trek 1420 - 1978 Raleigh Professional - 1973 Schwinn Collegiate - 1974 Schwinn Suburban

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 261 Post(s)

Liked 372 Times

in

177 Posts

Oh my goodness! Subscribing to this one! Those Timken bearings rock. I live in Canton, home of the Timken company. My Dad and my grandfather worked their entire careers at Timken, so I always appreciate seeing the name on quality items.

Likes For mkeller234:

#44

Senior Member

Join Date: Jul 2007

Location: Manhattan & Woodstock NY

Posts: 2,746

Bikes: 1987 Mercian Pro, 1985 Shogun 500, early '70s Falcon San Remo, 1972 Peugeot PX-10, 1972 Schwinn Paramount P13-9, 1971 Raleigh International, 1971 Peugeot PX-10, 1970 Raleigh Professional Mk1

Mentioned: 109 Post(s)

Tagged: 0 Thread(s)

Quoted: 938 Post(s)

Liked 2,939 Times

in

980 Posts

Wowza

__________________

1987 Mercian Pro, 1985 Shogun 500, 197? Falcon San Remo, 1972 Peugeot PX-10, 1972 Schwinn Paramount P13-9, 1971 Peugeot PX-10, 1971 Raleigh International, 1970 Raleigh Professional Mark I

Curator/Team Mechanic: 2016 Dawes Streetfighter, 1984 Lotus Eclair, 1975 Motobecane Jubile Mixte, 1974 Raleigh Sports, 1973 Free Spirit Ted Williams, 1972 Raleigh Super Course, 1971 Philips Sport

1987 Mercian Pro, 1985 Shogun 500, 197? Falcon San Remo, 1972 Peugeot PX-10, 1972 Schwinn Paramount P13-9, 1971 Peugeot PX-10, 1971 Raleigh International, 1970 Raleigh Professional Mark I

Curator/Team Mechanic: 2016 Dawes Streetfighter, 1984 Lotus Eclair, 1975 Motobecane Jubile Mixte, 1974 Raleigh Sports, 1973 Free Spirit Ted Williams, 1972 Raleigh Super Course, 1971 Philips Sport

Likes For ascherer:

#45

Junior Member

Congratulations! This is a super-cool tandem. It seems to be roughly the same vintage as ours, which dates from 1947.

I can add a few things: The serial numbers changed in 1950. So yes, '11' could be the 11th bike of any year in the 1940s (after 1945, during the war, the numbers seem to have already included the year, at least in 1942). Jean Desbois (son-in-law of René Herse) told me that in 1949, their accountant said that the system they had wasn't going to work long-term, so they should add the year...

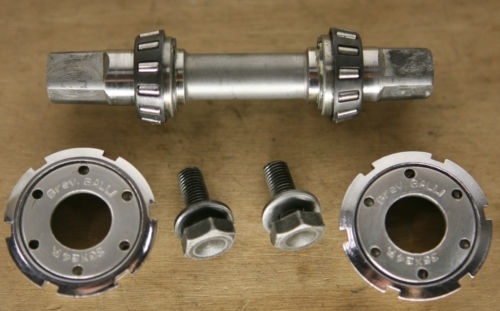

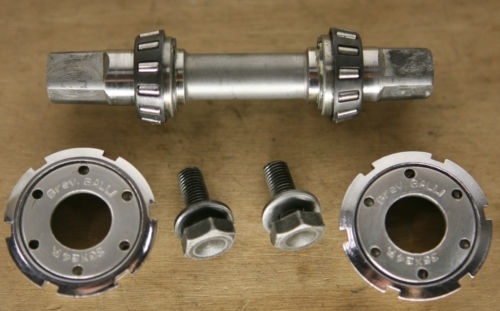

The BB is made by Herse. The pre-war C.A.R. was similar, but used ball bearings. The roller-bearing BBs are great, but standard bicycle grease is too 'light' for them. We had ours bind after a 600 km brevet. Using grease for car wheel bearings solved that issue. The later Herse BBs with SKF cartridge bearings are simpler and require less maintenance, but the early ones are incredibly cool.

Most of all, I really enjoyed your analysis of the chainrings. We went through the same exercise when we designed our cranks. We also wondered about the shape, which didn't match any curves. We didn't get all the way to Euler curves when we realized that there had to be a simpler explanation. Of course, these rings were cut by hand – it was usually the job for the apprentice in the Herse shop, before they graduated to filing stems! The teeth were machined and the bolt holes were drilled by an outside supplier, but then the big circles were cut by hand. So they are all a bit different.

That leads to the big question: what is the 'ideal' shape – the one that Herse had in mind when he designed these rings? We looked at three things: First, we have photos from early ads, and we can assume that these 'prototypes' were made to the 'ideal' shape. Second, we know of a few bikes made for bike shows. Again, we assume that René Herse made sure those rings were 'just right.' And third, we examined some chainring blanks, on which the outline of the holes was marked, but not yet cut. All of those rings are the more geometric – you called it 'pragmatic' – style. So the Art Nouveau flourishes simply appear to be an artifact of the hand-filed nature of these rings. That makes sense – Herse wasn't really one given to flourishes – witness how his seatstay bridges always are straight, not curved, because a straight tube is lightest and strongest. The artistry of his bikes doesn't come from ornamentation...

The tandem on p. 182-185 of the Rene Herse book appears to have been a show bike (the first Herse we know with internal cables), and it shows the 'ideal' chainring shape. The cover bike of 'The Golden Age of Handbuilt Bicycles' also was a show bike, and it also shows the 'ideal' chainring shape.

Since our current Rene Herse rings aren't hand-filed, we decided not to pretend that they were, but instead made them to the 'ideal' design that Herse used for his prototypes and show bikes.

For making a one-off replica, I'd go the route Herse did: Machine the teeth, but cut the circles by hand. That way, you'll get something that really is the same as the original. And by all means add the Art Nouveau flourishes - not only will the rings be closer to the original, it'll also easier to make them that way. The original rings were made from 6000-series, by the way. 7000-series was invented in Japan in the late-1930s (the secret behind the superior performance of the Mitsubishi Zero fighters), but this super-strong (yet brittle) material did not become widely available until a few decades later. 6000-series chainrings won't last as long, but you probably won't ride this tandem for thousands of miles a year. And on the plus side, 6000-series is much easier to machine and file.

In fact, if you make blanks with the teeth and holes, please make a few more. There are others who want them. You can contact me for more information – perhaps we can collaborate on these.

Finally, I recommend our Rene Herse book, as many of the information you're looking for is discussed in there.

Good luck with the project! Once you get it on the road, I look forward to the ride report. From my experience, those 1940s Herse tandems are the best-performing and best-handling tandems ever made. For those of you who've missed our video of riding our 1947 Herse tandem in the French Alps,

Jan Heine

Rene Herse Cycles

Reborn in the Cascade Mountains

www.renehersecycles.com

I can add a few things: The serial numbers changed in 1950. So yes, '11' could be the 11th bike of any year in the 1940s (after 1945, during the war, the numbers seem to have already included the year, at least in 1942). Jean Desbois (son-in-law of René Herse) told me that in 1949, their accountant said that the system they had wasn't going to work long-term, so they should add the year...

The BB is made by Herse. The pre-war C.A.R. was similar, but used ball bearings. The roller-bearing BBs are great, but standard bicycle grease is too 'light' for them. We had ours bind after a 600 km brevet. Using grease for car wheel bearings solved that issue. The later Herse BBs with SKF cartridge bearings are simpler and require less maintenance, but the early ones are incredibly cool.

Most of all, I really enjoyed your analysis of the chainrings. We went through the same exercise when we designed our cranks. We also wondered about the shape, which didn't match any curves. We didn't get all the way to Euler curves when we realized that there had to be a simpler explanation. Of course, these rings were cut by hand – it was usually the job for the apprentice in the Herse shop, before they graduated to filing stems! The teeth were machined and the bolt holes were drilled by an outside supplier, but then the big circles were cut by hand. So they are all a bit different.

That leads to the big question: what is the 'ideal' shape – the one that Herse had in mind when he designed these rings? We looked at three things: First, we have photos from early ads, and we can assume that these 'prototypes' were made to the 'ideal' shape. Second, we know of a few bikes made for bike shows. Again, we assume that René Herse made sure those rings were 'just right.' And third, we examined some chainring blanks, on which the outline of the holes was marked, but not yet cut. All of those rings are the more geometric – you called it 'pragmatic' – style. So the Art Nouveau flourishes simply appear to be an artifact of the hand-filed nature of these rings. That makes sense – Herse wasn't really one given to flourishes – witness how his seatstay bridges always are straight, not curved, because a straight tube is lightest and strongest. The artistry of his bikes doesn't come from ornamentation...

The tandem on p. 182-185 of the Rene Herse book appears to have been a show bike (the first Herse we know with internal cables), and it shows the 'ideal' chainring shape. The cover bike of 'The Golden Age of Handbuilt Bicycles' also was a show bike, and it also shows the 'ideal' chainring shape.

Since our current Rene Herse rings aren't hand-filed, we decided not to pretend that they were, but instead made them to the 'ideal' design that Herse used for his prototypes and show bikes.

For making a one-off replica, I'd go the route Herse did: Machine the teeth, but cut the circles by hand. That way, you'll get something that really is the same as the original. And by all means add the Art Nouveau flourishes - not only will the rings be closer to the original, it'll also easier to make them that way. The original rings were made from 6000-series, by the way. 7000-series was invented in Japan in the late-1930s (the secret behind the superior performance of the Mitsubishi Zero fighters), but this super-strong (yet brittle) material did not become widely available until a few decades later. 6000-series chainrings won't last as long, but you probably won't ride this tandem for thousands of miles a year. And on the plus side, 6000-series is much easier to machine and file.

In fact, if you make blanks with the teeth and holes, please make a few more. There are others who want them. You can contact me for more information – perhaps we can collaborate on these.

Finally, I recommend our Rene Herse book, as many of the information you're looking for is discussed in there.

Good luck with the project! Once you get it on the road, I look forward to the ride report. From my experience, those 1940s Herse tandems are the best-performing and best-handling tandems ever made. For those of you who've missed our video of riding our 1947 Herse tandem in the French Alps,

Jan Heine

Rene Herse Cycles

Reborn in the Cascade Mountains

www.renehersecycles.com

Last edited by janheine; 11-04-19 at 12:49 AM.

Likes For janheine:

#46

Junior Member

Jan Heine

Rene Herse Cycles

Reborn in the Cascade Mountains

www.renehersecycles.com

Likes For janheine:

#47

Junior Member

I've dug into the archives a bit, and there are a few more things that help date your tandem:

1. As you and others pointed out, the die-cast brakes (not forged on the originals, you can see the thin parting lines of the casting as a web inside the triangles) are post-1945. During the war, Herse didn't have access to industrial processes – all the factories were requisitioned by the Germans – so everything was hand-made. After the war, he quickly had his brakes die-cast and his cranks forged. The old machined cranks (identifiable by the smooth arms without a groove) appear to have been 'soft-recalled': Any time a bike came to Herse for work, it seems to have left the shop with new, forged cranks. I suspect the machined cranks had a tendency to break, even though I haven't heard of any incidents in all my research, whereas the forged ones were stronger. That is why the machined cranks are so rare, and many war-time bikes have the later forged cranks. The early 'Speedy' brakes were not replaced usually, so they are more common. You have the die-cast brakes, which were introduced at the Foire de Paris in September 1945. The mid-1945 bike in the Herse book still has the Speedy brakes, so it's unlikely that they were used before their 'official' introduction. In any case, it's amazing how quickly Herse was able to get brakes die-cast and cranks forged, considering that the war ended only in May. I can only suspect that with the war ending, the factories that had been requisitioned by the Germans needed work to continue operation, and Herse, as a small bicycle maker, was able to act quickly while the rest of the French industry was only slowly getting back on its feet. Unfortunately, that part of the history is difficult to reconstruct, as Herse didn't share the inside workings of the company with his employees.

2. Your tandem has the very early camping rear rack. The lower, single leg isn't triangulated - it's not as stiff as the later triangulated style. I've seen only one other of these – on a war-time frame that was one of the very first bikes to leave the Herse shop, probably in 1940. It's also shown in the very first Herse catalogue (p. 144 of the Rene Herse book), which dates from 1946 or 1947, yet the camping bike in that catalog (p. 139 of the Herse book) already has the later triangulated style. Also, as you noted, the roller-bearing BB didn't last long. My 1946 (or possibly late 1945, it has a very high serial number, indicating an end-of-year production) tandem – the one I rode in Paris-Brest-Paris 2003 – has the roller bearings. The 1946/7 catalogue also mentions the Timken roller bearings for the 'Grand Routier' tandem, but the SKF for the 'Cyclotouriste' single. Our 1947 tandem already has the SKF style. I've only seen the Timken on tandems, plus one very heavy-duty porteur. I suspect that once the SKF style had proven itself on single bikes, Herse used it for the tandems, too.

3. Assuming the taillight is original, it's a post-war style that came out sometime around 1946. I'd have to dig deeper to make sure the exact date. My 1945/6 tandem has an earlier pre-war or war-time Soubitez that Herse seemed to use in 1945.

1. and 2. clearly date your tandem between mid-1945 and late-1947. The taillight suggests it's post-1945. So I think 1946 or early 1947 is a good guess. Unfortunately, the record of serial numbers in the Rene Herse archives is incomplete, and we don't have the early post-war years. Otherwise, we could check name and number and figure out the exact year.

Jan Heine

Rene Herse Cycles

Reborn in the Cascade Mountains

www.renehersecycles.com

1. As you and others pointed out, the die-cast brakes (not forged on the originals, you can see the thin parting lines of the casting as a web inside the triangles) are post-1945. During the war, Herse didn't have access to industrial processes – all the factories were requisitioned by the Germans – so everything was hand-made. After the war, he quickly had his brakes die-cast and his cranks forged. The old machined cranks (identifiable by the smooth arms without a groove) appear to have been 'soft-recalled': Any time a bike came to Herse for work, it seems to have left the shop with new, forged cranks. I suspect the machined cranks had a tendency to break, even though I haven't heard of any incidents in all my research, whereas the forged ones were stronger. That is why the machined cranks are so rare, and many war-time bikes have the later forged cranks. The early 'Speedy' brakes were not replaced usually, so they are more common. You have the die-cast brakes, which were introduced at the Foire de Paris in September 1945. The mid-1945 bike in the Herse book still has the Speedy brakes, so it's unlikely that they were used before their 'official' introduction. In any case, it's amazing how quickly Herse was able to get brakes die-cast and cranks forged, considering that the war ended only in May. I can only suspect that with the war ending, the factories that had been requisitioned by the Germans needed work to continue operation, and Herse, as a small bicycle maker, was able to act quickly while the rest of the French industry was only slowly getting back on its feet. Unfortunately, that part of the history is difficult to reconstruct, as Herse didn't share the inside workings of the company with his employees.

2. Your tandem has the very early camping rear rack. The lower, single leg isn't triangulated - it's not as stiff as the later triangulated style. I've seen only one other of these – on a war-time frame that was one of the very first bikes to leave the Herse shop, probably in 1940. It's also shown in the very first Herse catalogue (p. 144 of the Rene Herse book), which dates from 1946 or 1947, yet the camping bike in that catalog (p. 139 of the Herse book) already has the later triangulated style. Also, as you noted, the roller-bearing BB didn't last long. My 1946 (or possibly late 1945, it has a very high serial number, indicating an end-of-year production) tandem – the one I rode in Paris-Brest-Paris 2003 – has the roller bearings. The 1946/7 catalogue also mentions the Timken roller bearings for the 'Grand Routier' tandem, but the SKF for the 'Cyclotouriste' single. Our 1947 tandem already has the SKF style. I've only seen the Timken on tandems, plus one very heavy-duty porteur. I suspect that once the SKF style had proven itself on single bikes, Herse used it for the tandems, too.

3. Assuming the taillight is original, it's a post-war style that came out sometime around 1946. I'd have to dig deeper to make sure the exact date. My 1945/6 tandem has an earlier pre-war or war-time Soubitez that Herse seemed to use in 1945.

1. and 2. clearly date your tandem between mid-1945 and late-1947. The taillight suggests it's post-1945. So I think 1946 or early 1947 is a good guess. Unfortunately, the record of serial numbers in the Rene Herse archives is incomplete, and we don't have the early post-war years. Otherwise, we could check name and number and figure out the exact year.

Jan Heine

Rene Herse Cycles

Reborn in the Cascade Mountains

www.renehersecycles.com

Likes For janheine:

#48

Senior Member

The cranks seem to be about 1 tooth out of sync. This wasn't something intentional, was it? I would assume it's just sloppiness, but perhaps at some point it was thought that a slight syncopation was a good idea?

#49

Used to be Conspiratemus

Join Date: Jan 2009

Location: Hamilton ON Canada

Posts: 1,512

Mentioned: 4 Post(s)

Tagged: 0 Thread(s)

Quoted: 297 Post(s)

Liked 245 Times

in

163 Posts

. . .It's subtle, as most tasteful things are. . . Euler spiral. . . .

P.S. Love your sig.

Last edited by conspiratemus1; 11-04-19 at 10:12 AM.

Likes For conspiratemus1:

#50

Banned

Join Date: Aug 2013

Posts: 6,480

Mentioned: 93 Post(s)

Tagged: 0 Thread(s)

Quoted: 1361 Post(s)

Likes: 0

Liked 423 Times

in

282 Posts

As an enthusiast of classic tandem~ I'm most jealous.

Enjoying the pics and experts chiming in. The discovery to learning more of it.

---

Interesting comments of the Timken tapered roller bearings used here. Although aware of them used in bb applications, the positive of having more bearing surface load, its tricky to get a very precise pre-load on small diameter Timken type especially with its axle having less TPI lock nuts.

Then there's the argument of being less efficient for this particular application in a bicycle.

I would think they can take more abuse than ball bearings but that too is widely subjective. Felt dust shields are part of the pro / con.

Perhaps back when, they saturated with a gear oil 140 wt.. Eventually that would gum and cause additional drag.

If mine and these days I would saturate with a low viscosity, high quality brand pure synthetic grease. Disregard the seals.

Enjoying the pics and experts chiming in. The discovery to learning more of it.

---

Interesting comments of the Timken tapered roller bearings used here. Although aware of them used in bb applications, the positive of having more bearing surface load, its tricky to get a very precise pre-load on small diameter Timken type especially with its axle having less TPI lock nuts.

Then there's the argument of being less efficient for this particular application in a bicycle.

I would think they can take more abuse than ball bearings but that too is widely subjective. Felt dust shields are part of the pro / con.

Perhaps back when, they saturated with a gear oil 140 wt.. Eventually that would gum and cause additional drag.

If mine and these days I would saturate with a low viscosity, high quality brand pure synthetic grease. Disregard the seals.