Derailleur destroyed

#26

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,362

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6218 Post(s)

Liked 4,217 Times

in

2,364 Posts

Your vaunted Phil Wood hubs, as far as I'm aware, are the same crappy design as all the other pretenders: undo a locknut or something on the axle, and the cassette body just falls out of the hub. The drive side axle bearing is inside the freehub ratchet bearings, not outside where it should be. This requires a ridiculous amount of over-engineering to compensate for, and I'm not sure even the likes of Phil Wood or Campy has fully compensated for the weakness this introduces..

But what you are missing is that there is another bearing...actually 2...outboard of that central bearing inside the freehub shell. There is a bearing directly next to that central bearing and another one at the end of the axle. Looking at an exploded view of a Campagnolo hub (I don’t work on Campy stuff), it has a similar arrangement. The Shimano hub only has a bearing at the end of the axle in the same place as the outside bearing in the above example. Campagnolo, Phil Wood, White Industries and many other hubs use this 4 bearing arrangement while Shimano only uses 2 bearings. That means that the bearings on all those other hubs have to bear less weight and thus don’t have to work as hard. It also means that the axle is supported better and would be less likely to bend. I’m not saying that Shimano’s hubs bend axles but having more support along the entire axle makes those other axles even less likely to bend.

I don’t see why you think the inboard bearing on the Mavic is in adequate. They are 6001 bearings which are used in a lot of hubs. But, like the other hubs, it uses 2 more bearings in the freehub body.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#27

Senior Member

Join Date: Dec 2009

Location: Melbourne, Oz

Posts: 9,545

Bikes: https://weightweenies.starbike.com/forum/viewtopic.php?f=10&t=152015&p=1404231

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 1528 Post(s)

Liked 718 Times

in

510 Posts

In that case, I think you are giving Shimano much more credit then they deserve.

You don’t seem to understand how Phil Wood or other hubs like it are designed and how they are superior to the exalted Shimano hub. Yes, you undo a locknut with a 5mm Allen wrench and the freehub body comes off. That’s actually a nice feature which greatly simplifies spoke replacement. And, yes, there is a bearing set into the hub there. Shimano doesn’t have a bearing at that point so the axle is unsupported in the middle.

But what you are missing is that there is another bearing...actually 2...outboard of that central bearing inside the freehub shell. There is a bearing directly next to that central bearing and another one at the end of the axle. Looking at an exploded view of a Campagnolo hub (I don’t work on Campy stuff), it has a similar arrangement. The Shimano hub only has a bearing at the end of the axle in the same place as the outside bearing in the above example. Campagnolo, Phil Wood, White Industries and many other hubs use this 4 bearing arrangement while Shimano only uses 2 bearings. That means that the bearings on all those other hubs have to bear less weight and thus don’t have to work as hard. It also means that the axle is supported better and would be less likely to bend. I’m not saying that Shimano’s hubs bend axles but having more support along the entire axle makes those other axles even less likely to bend.

I don’t see why you think the inboard bearing on the Mavic is in adequate. They are 6001 bearings which are used in a lot of hubs. But, like the other hubs, it uses 2 more bearings in the freehub body.

You don’t seem to understand how Phil Wood or other hubs like it are designed and how they are superior to the exalted Shimano hub. Yes, you undo a locknut with a 5mm Allen wrench and the freehub body comes off. That’s actually a nice feature which greatly simplifies spoke replacement. And, yes, there is a bearing set into the hub there. Shimano doesn’t have a bearing at that point so the axle is unsupported in the middle.

But what you are missing is that there is another bearing...actually 2...outboard of that central bearing inside the freehub shell. There is a bearing directly next to that central bearing and another one at the end of the axle. Looking at an exploded view of a Campagnolo hub (I don’t work on Campy stuff), it has a similar arrangement. The Shimano hub only has a bearing at the end of the axle in the same place as the outside bearing in the above example. Campagnolo, Phil Wood, White Industries and many other hubs use this 4 bearing arrangement while Shimano only uses 2 bearings. That means that the bearings on all those other hubs have to bear less weight and thus don’t have to work as hard. It also means that the axle is supported better and would be less likely to bend. I’m not saying that Shimano’s hubs bend axles but having more support along the entire axle makes those other axles even less likely to bend.

I don’t see why you think the inboard bearing on the Mavic is in adequate. They are 6001 bearings which are used in a lot of hubs. But, like the other hubs, it uses 2 more bearings in the freehub body.

How could the outside two bearings on a non Shimano hub do anything to support the wheel? They're for the cassette body, which isn't fixed to the hub - the only contact is via the pawls. On a Shimano hub, the central portion of the cassette body is a structural part of the hub; a stressed member. This member is not stressed on other hubs by all the loads on the wheel; it only supports drive forces. Just follow the load paths.

Last edited by Kimmo; 04-23-20 at 07:03 PM.

#28

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,362

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6218 Post(s)

Liked 4,217 Times

in

2,364 Posts

As to ”shims”, I’m not sure what you mean by that. Cup and cone hubs are adjusted through tightening and loosening the cone.

How could the outside two bearings on a non Shimano hub do anything to support the wheel? They're for the cassette body, which isn't fixed to the hub - the only contact is via the pawls. On a Shimano hub, the central portion of the cassette body is a structural part of the hub; a stressed member. This member is not stressed on other hubs by all the loads on the wheel; it only supports drive forces. Just follow the load paths.

In the Shimano freehub

the freehub spins on bearings as well but the bearings in the freehub body don’t bear weight. The axle passes through the free hub fixing bolt (13 in the illustration above) and the bearings (14) are in the cup with the cone (8) contacting them. They are doing the same thing the single bearing furthest to the right in the Phil Wood picture is doing.

I’m not saying that the Shimano axle is prone to bending but it isn't supported nearly as well as the Phil Wood. If an axle were going to bend, the Shimano one would bend first.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#29

Senior Member

Join Date: Dec 2009

Location: Melbourne, Oz

Posts: 9,545

Bikes: https://weightweenies.starbike.com/forum/viewtopic.php?f=10&t=152015&p=1404231

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 1528 Post(s)

Liked 718 Times

in

510 Posts

I’m not saying that the Shimano axle is prone to bending but it isn't supported nearly as well as the Phil Wood. If an axle were going to bend, the Shimano one would bend first.

#30

Senior Member

Join Date: Dec 2009

Location: Melbourne, Oz

Posts: 9,545

Bikes: https://weightweenies.starbike.com/forum/viewtopic.php?f=10&t=152015&p=1404231

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 1528 Post(s)

Liked 718 Times

in

510 Posts

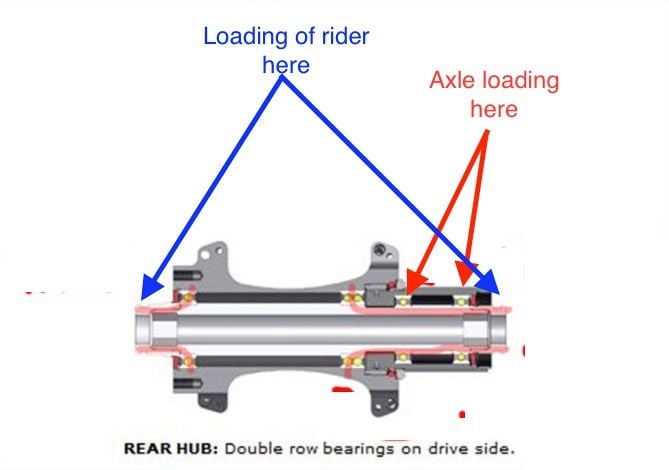

Some brands of hub acknowledge this shortcoming by using a larger drive side axle bearing, or a pair of bearings. Still crap.

#31

Senior Member

Join Date: Apr 2010

Location: Elevation 666m Edmonton Canada

Posts: 2,480

Bikes: 2013 Custom SA5w / Rohloff Tourster

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 1236 Post(s)

Liked 319 Times

in

246 Posts

LOL. My Rohloff14 has 2 bearings on both sides. Finally loosened up after 16,200 miles.

Gets faster and easier every ride. ZERO shifter/ cable service. Goes as fast as the WIND lets me.

There's a guy on the Thorn chat with 100,000 miles on 2 or three of them.

There's also a 6'6" guy on CGOAB who destroyed 3 rims and FOUR defailleur hubs in 6,500 miles. A 40 hole Phil, another 40h, and 2 others. Pawls springs caved in. LOL >> THEN he bought a Rohloff.

Why people think the OP needs derailleurs is a mystery to me.

Gets faster and easier every ride. ZERO shifter/ cable service. Goes as fast as the WIND lets me.

There's a guy on the Thorn chat with 100,000 miles on 2 or three of them.

There's also a 6'6" guy on CGOAB who destroyed 3 rims and FOUR defailleur hubs in 6,500 miles. A 40 hole Phil, another 40h, and 2 others. Pawls springs caved in. LOL >> THEN he bought a Rohloff.

Why people think the OP needs derailleurs is a mystery to me.

Last edited by GamblerGORD53; 04-23-20 at 11:23 PM.

#32

Senior Member

Join Date: Dec 2009

Location: Melbourne, Oz

Posts: 9,545

Bikes: https://weightweenies.starbike.com/forum/viewtopic.php?f=10&t=152015&p=1404231

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 1528 Post(s)

Liked 718 Times

in

510 Posts

Well, derailers are kind of the default, mainly because they're cheap, but also because a lot of folks want at least theoretical efficiency (although judging from what I've seen pass through shops, actual efficiency doesn't seem like a high priority for a lot of commuters).

Likes For Kimmo:

#33

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,362

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6218 Post(s)

Liked 4,217 Times

in

2,364 Posts

Um, that's exactly what I'm saying. Those two bearings' outer races, how are they part of the hub? They're not. They're part of the cassette body, which is separate from the hub. They don't hold the wheel up at all. They have exactly the same job as the corresponding bearings in a Shimano hub. Which you'd know are adjustable via shims, if you'd ever disassembled a Shimano cassette body. I believe there may be a link in my tag.

The Shimano freehub body bolts to the hub shell. The inner part of the freehub body turns with the hub while the outer part turns on its own very, very, very small bearings. A picture of a disassembled freehub body can be found here. Those bearings don’t carry weight. Because the freehub body isn’t in contact with the axle except where the bearings fo the hub contact it at the end.

I see what you were getting at with the shims now but your post was very confusing. You seemed to talking about hubs and not the freehub body. As for taking one apart, I don’t. I treat them like I do freewheels. Servicing one just isn’t worth the effort. They are fairly easily removed and replaced.

No, it is not backwards. Think of it this way. The axle is just a tube. Support the tube on both ends and put weight on it. The center is going to deflect downward because it is surrounded by open space. Now take that same tube and put additional support in the middle and put weight on it. The center won’t defect downward as much. The more support, the less it deflects. Add to that the fact that the axle on the Phill Wood (and most every other cartridge bearing hub) has a wider diameter and you have a stronger axle that is supported better.

That your opinion and it is still wrong.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#34

Senior Member

Join Date: Dec 2009

Location: Melbourne, Oz

Posts: 9,545

Bikes: https://weightweenies.starbike.com/forum/viewtopic.php?f=10&t=152015&p=1404231

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 1528 Post(s)

Liked 718 Times

in

510 Posts

Yeah, nah. I'm obviously gonna have to bust out some diagrams before I'm satisfied I've done everything I can to illustrate my assertion here. Stay tuned

#35

Senior Member

Join Date: Dec 2009

Location: Melbourne, Oz

Posts: 9,545

Bikes: https://weightweenies.starbike.com/forum/viewtopic.php?f=10&t=152015&p=1404231

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 1528 Post(s)

Liked 718 Times

in

510 Posts

Au contraire.

So here's what we're talking about; a hub that comes apart like this (the fact it's a through-axle hub is immaterial).

Are we on the same page? Okay.

Now, I flat-out refuse to be told that there's anything more than the axle (and unintended carnage in the ratchet) preventing this when you land a bunny hop:

In fact, I've even seen this on a through-axle hub in the shop; admittedly it was helped along by the DS axle bearing seizing (crappy sealing on cartridge bearings anyone?), and scoring a line at the point of highest stress on the axle sleeve. The through-axle inside it didn't prevent the failure, interestingly enough.

Shimano freehubs are based on a far better principle, with the exception of the 7800 hub, and sadly it looks like future hubs going forwards, probably largely because folks seem to have a hard time appreciating the inherent superiority of having the DS axle bearing where it should be, robbing Shimano of their due credit.

Might as well start making lighter, nastier hubs.

So here's what we're talking about; a hub that comes apart like this (the fact it's a through-axle hub is immaterial).

Are we on the same page? Okay.

Now, I flat-out refuse to be told that there's anything more than the axle (and unintended carnage in the ratchet) preventing this when you land a bunny hop:

In fact, I've even seen this on a through-axle hub in the shop; admittedly it was helped along by the DS axle bearing seizing (crappy sealing on cartridge bearings anyone?), and scoring a line at the point of highest stress on the axle sleeve. The through-axle inside it didn't prevent the failure, interestingly enough.

Shimano freehubs are based on a far better principle, with the exception of the 7800 hub, and sadly it looks like future hubs going forwards, probably largely because folks seem to have a hard time appreciating the inherent superiority of having the DS axle bearing where it should be, robbing Shimano of their due credit.

Might as well start making lighter, nastier hubs.

Last edited by Kimmo; 04-25-20 at 07:49 AM.

#36

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,362

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6218 Post(s)

Liked 4,217 Times

in

2,364 Posts

In your drawing above, it is clear that the outboard bearings in the hub shell are attached to the axle and support it as well as the hub shell bearing. There would be no reason for the axle to bend no matter what kind of load a human body can put on it. Your drawing is just wrong. If this is a drawing from a website, please cite it so that the rest of us can see the context.

Now look at this drawing of a Shimano hub (part way down the page). The axle isn’t in contact with the hub at any point except at the very ends of the axle. A hard g landing would be much more likely to flex the axle downward than a hub that is supported in 4 places rather than 2.

Shimano freehubs are based on a far better principle, with the exception of the 7800 hub, and sadly it looks like future hubs going forwards, probably largely because folks seem to have a hard time appreciating the inherent superiority of having the DS axle bearing where it should be, robbing Shimano of their due credit.

Might as well start making lighter, nastier hubs.

Might as well start making lighter, nastier hubs.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#37

Senior Member

Au contraire.

So here's what we're talking about; a hub that comes apart like this (the fact it's a through-axle hub is immaterial).

Are we on the same page? Okay.

Now, I flat-out refuse to be told that there's anything more than the axle (and unintended carnage in the ratchet) preventing this when you land a bunny hop:

In fact, I've even seen this on a through-axle hub in the shop; admittedly it was helped along by the DS axle bearing seizing (crappy sealing on cartridge bearings anyone?), and scoring a line at the point of highest stress on the axle sleeve. The through-axle inside it didn't prevent the failure, interestingly enough.

Shimano freehubs are based on a far better principle, with the exception of the 7800 hub, and sadly it looks like future hubs going forwards, probably largely because folks seem to have a hard time appreciating the inherent superiority of having the DS axle bearing where it should be, robbing Shimano of their due credit.

Might as well start making lighter, nastier hubs.

So here's what we're talking about; a hub that comes apart like this (the fact it's a through-axle hub is immaterial).

Are we on the same page? Okay.

Now, I flat-out refuse to be told that there's anything more than the axle (and unintended carnage in the ratchet) preventing this when you land a bunny hop:

In fact, I've even seen this on a through-axle hub in the shop; admittedly it was helped along by the DS axle bearing seizing (crappy sealing on cartridge bearings anyone?), and scoring a line at the point of highest stress on the axle sleeve. The through-axle inside it didn't prevent the failure, interestingly enough.

Shimano freehubs are based on a far better principle, with the exception of the 7800 hub, and sadly it looks like future hubs going forwards, probably largely because folks seem to have a hard time appreciating the inherent superiority of having the DS axle bearing where it should be, robbing Shimano of their due credit.

Might as well start making lighter, nastier hubs.

Back to the issue raised by the OP: the destruction of the rear derailleur probably has little to do with the rear wheel. Based on the dozens of bikes per week I've worked on at my Co-op, it was likely the result of a bent derailleur hanger or bent derailleur. Or both. Root cause: the bike was dropped on its right side. Or perhaps the limit screws weren't adjusted correctly.

Anyway, as to hubs: Kimmo is entirely correct regarding the impact of forces and stresses placed on cassette hubs. There are two classes of rear cassette hubs:

- The Shimano type, in which the freehub is structurally part of the hub shell. The freehub carries stresses from the spokes through to the bearings on the drive side.

- The Campagnolo type, in which the freehub is separate. The freehub does not carry the stresses of the rider and road, but it 'floats' separate from the hub shell. The hub axle is more cantilevered therefore more stressed, and has to be overbuilt relative to the Shimano design.

At least the better quality Campagnolo hubs use the superior cup and cone bearing design. Cartridge bearings are a sub-optimal solution in hubs, used by small-fry manufacterers who cannot afford to tooling to make custom cup and cone parts. Plus cartridge bearings by themselves are poorly sealed. If anything, the rubber ring on cartridge bearings causes moisture to be wicked into the inside of the cart, where it then sits forever to rust out the insides. Overall, Shimano hubs are better sealed.

Attending the first year engineering course: 'Statics and Dynamics' would clear up all of this wrong-headed confusion. Aside: the best bike mechanic I've ever run into had zero hands-on experience in working with bikes. But he had a masters degree in mechanical engineering, and access to a sophisticated machine tools, and years of experience in a fabrication shop. His very first used bike purchase resulted in him undertaking upgrades and overhauls that most pro mechanics would never take on. Outstanding: 'get-it factor'. The worst mechanics I've run into: our local bike flippers that clog up Craigslist with dysfunctional crap. Despite working on bikes every day, they are appallingly ignorant about almost everything to do with bikes.

Likes For Dave Mayer:

#38

Senior Member

Join Date: Dec 2009

Location: Melbourne, Oz

Posts: 9,545

Bikes: https://weightweenies.starbike.com/forum/viewtopic.php?f=10&t=152015&p=1404231

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 1528 Post(s)

Liked 718 Times

in

510 Posts

That was an Easton hub, found with 'freehub cross section' image search. I should've said through-axle style hub; pretty sure it'd have other axle caps. Anyway. Here's another Easton hub.

#39

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,362

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6218 Post(s)

Liked 4,217 Times

in

2,364 Posts

Anyway, as to hubs: Kimmo is entirely correct regarding the impact of forces and stresses placed on cassette hubs. There are two classes of rear cassette hubs:

- The Shimano type, in which the freehub is structurally part of the hub shell. The freehub carries stresses from the spokes through to the bearings on the drive side.

- The Campagnolo type, in which the freehub is separate. The freehub does not carry the stresses of the rider and road, but it 'floats' separate from the hub shell. The hub axle is more cantilevered therefore more stressed, and has to be overbuilt relative to the Shimano design.

I own approximately a dozen (high-end) sets of each. Stuff labelled: Fulcrum, Campagnolo, Fast Forward, Vision, Hope, Zipp, etc. The Campagnolo style is fine, if properly executed. But the overall design is sub-optimal relative to the Shimano design. All things being equal, the Shimano-design hubs should be stronger and ligher. Just because the boutique vendors using the Campagnolo design cheat by using alloy freehubs, and small bearings, they can bring the weights below Shimano. But this decreases strength and longevity.

At least the better quality Campagnolo hubs use the superior cup and cone bearing design. Cartridge bearings are a sub-optimal solution in hubs, used by small-fry manufacterers who cannot afford to tooling to make custom cup and cone parts. Plus cartridge bearings by themselves are poorly sealed. If anything, the rubber ring on cartridge bearings causes moisture to be wicked into the inside of the cart, where it then sits forever to rust out the insides. Overall, Shimano hubs are better sealed.

Your tall tale of water wicking into the inside of the cartridge just doesn’t happen. What is the mechanism? The inside of the bearing is filled with grease...hydrophobic grease. There is no pressure gradient to make the water go where it is unwelcome. It would also show up as a seized bearing. While that can happen, it’s not something that happens all that often in my experience. I’ve had several cartridge bearing hubs and I’ve only replace bearings 3 times. As I’ve stated above, one of my Phil Wood hubs has 25,000 miles on it without maintenance and without any failures nor even any hint of failure. This is something that I hear constantly from people who have no knowledge of cartridge bearings nor how widely ubiquitous their use is in our modern society.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#40

Senior Member

Join Date: Dec 2009

Location: Melbourne, Oz

Posts: 9,545

Bikes: https://weightweenies.starbike.com/forum/viewtopic.php?f=10&t=152015&p=1404231

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 1528 Post(s)

Liked 718 Times

in

510 Posts

Come to think of it, I've wondered in the past if it'd be possible to take Shimano's arrangement and move the ratchet inside the hub flange... that'd leave you with a C-shaped load path between spokes and bearings though, unless you could get it really compact...

Damn ratchets! I want a nanotech solution.

#41

Senior Member

Join Date: Dec 2009

Location: Melbourne, Oz

Posts: 9,545

Bikes: https://weightweenies.starbike.com/forum/viewtopic.php?f=10&t=152015&p=1404231

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 1528 Post(s)

Liked 718 Times

in

510 Posts

While it is true that the freehub is separate from the hub shell in the ”Campagnolo type”, the freehub body doesn’t just float in midair. It ”floats” on the axle and on two more bearings. Those extra bearings aren’t just along for the ride. As I’ve said before, the bearing on the driveside are as attached to the axle as the bearings on the nondriveside and support weight in exactly the same manner.

If you insist on continuing to deny it, show me your alleged load path in a diagram.

This is something that I hear constantly from people who have no knowledge of cartridge bearings nor how widely ubiquitous their use is in our modern society.

#42

Senior Member

Well, I dunno about lighter; It's not just the smaller splines necessitating steel or titanium; the ratchet has to fit inside a 12t, so it pretty much has to be the same bit of metal forming the splines, and I'd bet the inner section of Dura-Ace cassette bodies is steel... and what with oversize axles first, and now disc hubs, there's even less room. Hence Shimano's relatively few points of engagement, the only real Achilles heel of the design.

Come to think of it, I've wondered in the past if it'd be possible to take Shimano's arrangement and move the ratchet inside the hub flange... that'd leave you with a C-shaped load path between spokes and bearings though, unless you could get it really compact...

Damn ratchets! I want a nanotech solution.

Come to think of it, I've wondered in the past if it'd be possible to take Shimano's arrangement and move the ratchet inside the hub flange... that'd leave you with a C-shaped load path between spokes and bearings though, unless you could get it really compact...

Damn ratchets! I want a nanotech solution.

Yes, that is a constraint of the Shimano freehub system: that the ratchet mechanism has to fit inside a freehub body that takes a 12-tooth cog. One could make a stepped-diameter system in which the larger cogs fit on a larger diameter spline, the way Shimano and Sachs and freewheels were constructed. Then the ratchet mechanism would sit inside the larger diameter body. Still, there are millions and millions of Shimano freehub-based (and clones) systems on the road, and failures in the freehubs are very rare. I don't see the small diameter of the ratchet mechanism to be a problem in practice. The only failures I've seen are on bikes that were ridden a gazillion miles in wet dirty conditions, and the freehub simply got filled with crap and seized up. But at our local Co-op, we have a heavy bucket 'o freehubs for $5 each, so the lifespan of your Shimano rear hub should be infinite.

I have taken apart XTR and Dura-Ace titanium freehub bodies down to the little balls - yes, the guts of these are steel. Only the freehub shells are Ti.

As far as points of engagement, I am not fussed by Shimano's 20 or so points. I've ridden on clutch systems in which torque engagement is instantaneous, and I did not see any detectible improvement in my performance or 'ride experience'. I know that some of the small-fry hub vendors like to boast of an increased number of engagement points, but this reminds of the food processor wars of of the 70's, where blenders had to go from 3 speeds to 11 or whatever, in a game of pointless manufacturer one-upmanship. Same issue with the number of pawls in a hub: the small fry manufacturers boast of 3 or 6 or whatever number of pawls, as if it is some kind of arms race. Since only one pawl can transfer pedaling torque at any time, increasing the number of pawls does not increase the 'strength' or power transfer of the hub.

Something to ponder: because the bearings on Shimano hubs are loaded at the ends, the optimum design, this allows a thin axle to be used. On the Campy-style hubs, the axle has to be bigger in order to compensate for more unsupported/cantilevered load. So why should Shimano be required to increase the diameter of their axles, thereby consuming precious space inside the hub?

#43

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,362

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6218 Post(s)

Liked 4,217 Times

in

2,364 Posts

Dude, how?! Bust out a felt-tipped pen and a napkin and take a pic with your phone, and show me how any load from those ratchet bearings gets into the hubshell. Aside perhaps from some negligible percentage under power, from friction between pawls and ratchet. Bending loads on the axle push and pull on the pawls laterally, so it's a merely academic consideration how much that's holding your hub together. Nothing much at all is, aside from being clamped in the frame. These hubs are stupid.

If you insist on continuing to deny it, show me your alleged load path in a diagram.

If you insist on continuing to deny it, show me your alleged load path in a diagram.

That double row bearings isn't all that common in the hubs I've worked on. In fact, I've never seen one.

If the end of the axle were unsupported like in a freewheel (borrowed from Wikipedia)

you might have a point that the axle is prone to bending but the ends of the axle in a cartridge bearing hub are supported and are no more likely to bend than a Shimano hub...something that I have already stipulated above.

An appeal to ubiquity doesn't cut much ice in a sub-optimal world. I'd consider shagged-out cartridge bearings pretty ubiquitous too, based on how many I've come across. If you have a cartridge bearing hub you want to convince me is the tits, you can start out by pointing to the preload adjustment for the angular contact bearings.

As for the preload adjustment, any that is needed is taken care of by the end caps. As there is little need in doing any "adjustment" to the bearings, there is very little adjustment available.

And, finally, I've not seen a bent axle on a Shimano freehub hub. They are far superior to freewheel hubs. But, on the other hand, I've never seen a bent axle on a cartridge bearing hub either.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#44

Senior Member

Join Date: Dec 2009

Location: Melbourne, Oz

Posts: 9,545

Bikes: https://weightweenies.starbike.com/forum/viewtopic.php?f=10&t=152015&p=1404231

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 1528 Post(s)

Liked 718 Times

in

510 Posts

So why should Shimano be required to increase the diameter of their axles, thereby consuming precious space inside the hub?

#45

Senior Member

Join Date: Dec 2009

Location: Melbourne, Oz

Posts: 9,545

Bikes: https://weightweenies.starbike.com/forum/viewtopic.php?f=10&t=152015&p=1404231

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 1528 Post(s)

Liked 718 Times

in

510 Posts

As for the preload adjustment, any that is needed is taken care of by the end caps. As there is little need in doing any "adjustment" to the bearings, there is very little adjustment available.

And, finally, I've not seen a bent axle on a Shimano freehub hub. They are far superior to freewheel hubs. But, on the other hand, I've never seen a bent axle on a cartridge bearing hub either.

And, finally, I've not seen a bent axle on a Shimano freehub hub. They are far superior to freewheel hubs. But, on the other hand, I've never seen a bent axle on a cartridge bearing hub either.

And I just told you I've come across a (through-axle, no less) non Shimano hub (Focus branded) with a broken axle, that looked just like my diagram above, because the axle is the only thing holding the freehub body in place.

#46

Senior Member

The load path is between the spokes and the dropouts; it kinda has to go through the hub shell... Otherwise you wouldn't need a hub shell, would you. I dunno what you're doing with those arrows; it just looks like hand-waving to me. Why can't you draw some lines showing me how forces from/to the spokes get to/from the axle via your magical ratchet bearings? Don't just point at them and make an unsubstantiated assertion.

- Load is directed downwards through the dropouts onto the ends of the axles.

- From there it is transmitted through the axle on each side, to the hub shell and from there to the hub flanges and then the spokes. From the spokes to the rim and from there to the tire. Obvious.

- Here is the problem: with the Campy-style hub, drive-side forces are transmitted through roughly 3cm of cantilevered axle.

- The freehub itself does not support rider weight, it only supports torque which is transferred from the chain to the sprockets to the hub shell, and to the spokes etc.

So that is the fundamental problem with the Campy-style hub: the 3cm of unsupported axle. This is why this axle has to be bulked-up and made larger than equivalent Shimano hubs. It can be made to work well, but an inferior design.

Likes For Dave Mayer: