On Snapping Spokes

#1

Junior Member

Thread Starter

Join Date: Apr 2019

Posts: 104

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 24 Post(s)

Likes: 0

Liked 17 Times

in

12 Posts

On Snapping Spokes

Last year, I broke several rear wheel spokes on my old mountain bike, all at once. I wound up giving that one to a guy at the LBS and buying a used Norco Indie from them in June. All was fine until September, when I started snapping a rear spoke a day. I replaced the wheel with a hand-laced job from a local shop, probably a mid-range thing (I paid $250 CDN). All was fine.

Then Christmas Day came. SNAP!! I took it in and got it repaired at the same shop, they chalked it up to a bum spoke. Yesterday, same deal, a busted rear spoke. I finally just bought some spares, figuring I'll just check tension monthly and be ready to replace them.

Here's the question: why only rear spokes? I've never busted a front spoke, only a rear. I'm a big, fat guy, which probably explains the snapping spokes, but I would have expected fronts to break as often as rears.

Any thoughts?

Then Christmas Day came. SNAP!! I took it in and got it repaired at the same shop, they chalked it up to a bum spoke. Yesterday, same deal, a busted rear spoke. I finally just bought some spares, figuring I'll just check tension monthly and be ready to replace them.

Here's the question: why only rear spokes? I've never busted a front spoke, only a rear. I'm a big, fat guy, which probably explains the snapping spokes, but I would have expected fronts to break as often as rears.

Any thoughts?

#2

Really Old Senior Member

Rear wheels have dish, so different spoke tension on opposite sides.

Is it the NDS spokes? That's usually a sign of the tension being too low .

J bend or elsewhere?

Is it the NDS spokes? That's usually a sign of the tension being too low .

J bend or elsewhere?

Likes For Bill Kapaun:

#3

Senior Member

The rear wheel has uneven tension and bears more weight; broken rear spokes are much more common. To be honest, you'd probably benefit from a seriously overbuilt wheel by a very good wheel builder.

#4

I am potato.

Join Date: Jun 2015

Location: Pacific Northwest

Posts: 3,104

Bikes: Only precision built, custom high performance elitist machines of the highest caliber. 🍆

Mentioned: 28 Post(s)

Tagged: 0 Thread(s)

Quoted: 1782 Post(s)

Liked 1,620 Times

in

926 Posts

You keep breaking spokes because there is not enough of them to support your weight. The constant cycling of tension/relaxing is causing stress at the J-bend.

Higher spoke tension would end the paperclip bending you are doing with every rotation of the wheel.

The trade-off of too high tension would be stress cracking at the nipples &/or the spoke bed.

Seriously. Just get a hand built wheel with 40 or 48, 12 gauge spokes and double wall construction like Velocity Atlas, Deep V, or Chukker and call it a day.

Related: You keep breaking the rear because the rear is where the weight is at & secondly you probably ride like a gorilla. (That's not a sleight on your weight. Some gorillas ride like feathers, some feathers ride like gorillas...It a statement of riding style.)

Higher spoke tension would end the paperclip bending you are doing with every rotation of the wheel.

The trade-off of too high tension would be stress cracking at the nipples &/or the spoke bed.

Seriously. Just get a hand built wheel with 40 or 48, 12 gauge spokes and double wall construction like Velocity Atlas, Deep V, or Chukker and call it a day.

Related: You keep breaking the rear because the rear is where the weight is at & secondly you probably ride like a gorilla. (That's not a sleight on your weight. Some gorillas ride like feathers, some feathers ride like gorillas...It a statement of riding style.)

#7

Junior Member

Thread Starter

Join Date: Apr 2019

Posts: 104

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 24 Post(s)

Likes: 0

Liked 17 Times

in

12 Posts

They're snapping on both sides of the wheel, but always down near the hub.

Of course my $50 Raleigh 3 speed that I ride every day has never done it. It's a rolling collection of problems, but busted spokes aren't one of them.

Of course my $50 Raleigh 3 speed that I ride every day has never done it. It's a rolling collection of problems, but busted spokes aren't one of them.

#8

Senior Member

Join Date: Mar 2008

Posts: 8,688

Mentioned: 46 Post(s)

Tagged: 0 Thread(s)

Quoted: 1074 Post(s)

Liked 295 Times

in

222 Posts

But sure, I bought my first freewheel puller to deal with a broken DS spoke, not to replace the f/w. It does happen.

I’ve sometimes wondered if it’s possible to build a wheel with low enough tension so that the NDS spokes survive b/c of never seeing enough tension to fatigue, while putting the DS spokes right in the fatigue range.

And there’s always the option of the really sloppy build where some spokes simply started out a lot slacker.

As someone already wrote, what breaks spokes is constant bending, the frequent (big) changes in tension that causes metal fatigue. It’s far easier to get all spokes into the ”safe” zone on an IGH or otherwise near symmetrical wheel. For a comparable build quality, no mystery there.

#9

Really Old Senior Member

Breaking at the J bend is typically too low tension.

As the wheel is rotating, the stress is constantly moving from spoke to spoke. If the tension is low, the weight transfer has kind of a "running start" to flex the J.

If tension is higher, it doesn't take as much of a jolt.

Thing of getting hit by a punch or getting a shove.

Rears also take the pedaling stresses. You are basically trying to "unwind" 1/2 the spokes every stroke. (combine that with too low of tension and you may actually start getting a slack spoke with nipples starting to loosen.)

If you mash low gears going uphill, think of the stress.

You may also simply have a wheel without enough spokes for you.

How much do you weigh?

How many spokes?

How many "speeds".

As the wheel is rotating, the stress is constantly moving from spoke to spoke. If the tension is low, the weight transfer has kind of a "running start" to flex the J.

If tension is higher, it doesn't take as much of a jolt.

Thing of getting hit by a punch or getting a shove.

Rears also take the pedaling stresses. You are basically trying to "unwind" 1/2 the spokes every stroke. (combine that with too low of tension and you may actually start getting a slack spoke with nipples starting to loosen.)

If you mash low gears going uphill, think of the stress.

You may also simply have a wheel without enough spokes for you.

How much do you weigh?

How many spokes?

How many "speeds".

#10

Senior Member

Join Date: Apr 2005

Location: Northern CA

Posts: 735

Bikes: Cannondale tandems: '92 Road, '97 Mtn. Mongoose 10.9 Ti, Kelly Deluxe, Tommaso Chorus, Cdale MT2000, Schwinn Deluxe Cruiser, Torker Unicycle, among others.

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 276 Post(s)

Liked 201 Times

in

127 Posts

The theory is clear that the NDS spokes should have it worse.

But sure, I bought my first freewheel puller to deal with a broken DS spoke, not to replace the f/w. It does happen.

I’ve sometimes wondered if it’s possible to build a wheel with low enough tension so that the NDS spokes survive b/c of never seeing enough tension to fatigue, while putting the DS spokes right in the fatigue range.

And there’s always the option of the really sloppy build where some spokes simply started out a lot slacker.

Last IGH I built up had an 8% difference in spoke tension between DS and NDS. Last derailer gear wheel I built had about 60% NDS spoke tension.

As someone already wrote, what breaks spokes is constant bending, the frequent (big) changes in tension that causes metal fatigue. It’s far easier to get all spokes into the ”safe” zone on an IGH or otherwise near symmetrical wheel. For a comparable build quality, no mystery there.

But sure, I bought my first freewheel puller to deal with a broken DS spoke, not to replace the f/w. It does happen.

I’ve sometimes wondered if it’s possible to build a wheel with low enough tension so that the NDS spokes survive b/c of never seeing enough tension to fatigue, while putting the DS spokes right in the fatigue range.

And there’s always the option of the really sloppy build where some spokes simply started out a lot slacker.

Last IGH I built up had an 8% difference in spoke tension between DS and NDS. Last derailer gear wheel I built had about 60% NDS spoke tension.

As someone already wrote, what breaks spokes is constant bending, the frequent (big) changes in tension that causes metal fatigue. It’s far easier to get all spokes into the ”safe” zone on an IGH or otherwise near symmetrical wheel. For a comparable build quality, no mystery there.

So, counter to some people's intuition, high spoke tension is NOT the cause. It's low tension and a dished wheel. And straight-guage spokes. And low spoke count.

Yes, you want a beefier wheel built for your usage. Rear wheels have two major factors reducing their durability:

1. Dish. Half the spokes are doing most of the work. 12 speed hubs have even more dish, worsening the problem.

2. Approximately 60% of your weight is on the rear wheel.

So you want a clydesdale-type rear wheel. In general, you increase rim width/strength first, then spoke count. But you also want THINNER spokes - in the middle, that is. Contrary to intuition, a FATTER spoke will not build a more durable wheel. A butted spoke will. Ideally, you may want to go with a 2.3/1.8/2.0 spoke. This is the "Strong" spoke in the Sapim spoke line. I think DT offers something as well.

So a heavy, wide, strong rim with 36 spokes (if you can find it), and with asymmetrical drilling (to reduce dish), butted 2.3/1.8/2.0 spokes with brass nipples built by a proficient wheel builder who can guarantee very even spoke tension should solve your problems. Locking nipples too (or at the minimum, appropriate thread locking compound and lubrication). No wheel is indestructible, but this is about as close as you can get. This would be a good choice for a clydesdale or tandem.

#11

Senior Member

Join Date: Mar 2008

Posts: 8,688

Mentioned: 46 Post(s)

Tagged: 0 Thread(s)

Quoted: 1074 Post(s)

Liked 295 Times

in

222 Posts

I am NOT questioning the general theory.

I’m speculating in what breaks DS spokes, which usually have considerably higher tension than the NDS spokes.

Either they break b/c of that particular spoke being undertensioned compared to the other DS spokes.

Or there is something else going on that keeps the NDS spokes from breaking.

And I think you’re wrong about ”not enough tension to fatigue”

Consider a spoke alternating between rattling around and barely load-carrying. Would that too fatigue?

Sure, a big proportional change in load is a big fatigue driver.

But what if that ”big proportional change” is between near zero and very little load?

As far as I remember, there is a lower limit to when fatigue can occur as well. If the cyclic load change is small enough, steel doesn’t fatigue.

That’s one of the frequently stated advantages to steel frames & forks. Designed and dimensioned ”right”, they’re expected to last ”forever”.

#12

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,335

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6193 Post(s)

Liked 4,192 Times

in

2,352 Posts

This a theory that I’ve seldom seen in practice. I’ve broken lots of spokes myself and I see dozens per year at my local co-op. I would estimate the number of my broken spokes and the ones at the co-op on the nondrive side to be around 10%. The vast majority occur on the drive side. My hypothesis on how this happens is that the amount of load/unloading of the spoke puts more stress on the driveside spoke because the magnitude of the difference is larger on the driveside. Tension is higher on the driveside so the decease in tension is greater on the driveside than the nondriveside.

Your solution would only result in more broken spokes.

IGH and single speed wheels seldom break spokes like front wheels for the same reason...the tension is nearly equal on both sides. The way to make a rear wheel with much more even tension is to use a off-center rim (OCR). The rim is built with an offset in the spoke bed to the nondrive side. This decreases the tension differences between the two sides from about 80% to about 60%. It’s not like a front wheel but is usually enough to make the wheels stronger.

Additionally, we should build wheels with stronger spokes. Rims get all the glory when it comes to strength but the “glory” is misplaced. The strongest rim around still undergoes the same flattening when the rim reaches the bottom of the wheel and the spoke undergo the same detensioning/retensioning cycle. A thicker head at the elbow withstands fatigue better than thinner heads. If nothing else, a 2.3mm spoke moves less in the hub which also reduces fatigue. Eric Hjertberg thas a really good article that explains my point quite well.

I’ve sometimes wondered if it’s possible to build a wheel with low enough tension so that the NDS spokes survive b/c of never seeing enough tension to fatigue, while putting the DS spokes right in the fatigue range.

And there’s always the option of the really sloppy build where some spokes simply started out a lot slacker.

And there’s always the option of the really sloppy build where some spokes simply started out a lot slacker.

Last IGH I built up had an 8% difference in spoke tension between DS and NDS. Last derailer gear wheel I built had about 60% NDS spoke tension.

As someone already wrote, what breaks spokes is constant bending, the frequent (big) changes in tension that causes metal fatigue. It’s far easier to get all spokes into the ”safe” zone on an IGH or otherwise near symmetrical wheel. For a comparable build quality, no mystery there.

As someone already wrote, what breaks spokes is constant bending, the frequent (big) changes in tension that causes metal fatigue. It’s far easier to get all spokes into the ”safe” zone on an IGH or otherwise near symmetrical wheel. For a comparable build quality, no mystery there.

Additionally, we should build wheels with stronger spokes. Rims get all the glory when it comes to strength but the “glory” is misplaced. The strongest rim around still undergoes the same flattening when the rim reaches the bottom of the wheel and the spoke undergo the same detensioning/retensioning cycle. A thicker head at the elbow withstands fatigue better than thinner heads. If nothing else, a 2.3mm spoke moves less in the hub which also reduces fatigue. Eric Hjertberg thas a really good article that explains my point quite well.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Likes For cyccommute:

#13

Senior Member

Join Date: Apr 2010

Location: Mountain View, CA USA and Golden, CO USA

Posts: 6,341

Bikes: 97 Litespeed, 50-39-30x13-26 10 cogs, Campagnolo Ultrashift, retroreflective rims on SON28/PowerTap hubs

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 550 Post(s)

Liked 325 Times

in

226 Posts

You have about 750 stress cycles per mile from spokes losing tension passing the bottom of the wheel as the rim deflects and unloads them.

Heavier riders increase the magnitude of the cycle by bending the rim farther.

With more weight on the rear wheel it has higher magnitude cycles.

The drive side has higher tension than the non-drive side and therefore average stress making failures there most common.

Regardless, if you're breaking spokes your wheels are not well-built.

As manufactured, spoke elbows have high stress because the entire elbow isn't taken past its elastic limit. If you don't stress relieve them they'll fail. If you do they can last over 300,000 miles provided you don't get anything caught in them or nick them overshifting your chain past the large cog.

You can also have problems at the nipples when they can't pivot enough to point at the hub spoke holes and don't bend the spokes to compensate.

These things usually aren't addressed in machine built wheels, although you can buy a Holland Mechanics machine which stress relieves.

They may or may not be addressed by individual mechanics, You need to build your own wheels or delegate to a one person wheel building operation where the hands that earned its reputation build your wheels; e.g. Peter White.

Few mechanics could build good wheels fast enough to be profitable before the rise of factory wheel sets. Most compromised building bad wheels profitably. This has gotten worse.

Last edited by Drew Eckhardt; 04-06-20 at 08:10 AM.

Likes For Drew Eckhardt:

#14

Senior Member

Join Date: Dec 2010

Location: northern Deep South

Posts: 8,889

Bikes: Fuji Touring, Novara Randonee

Mentioned: 36 Post(s)

Tagged: 0 Thread(s)

Quoted: 2590 Post(s)

Liked 1,921 Times

in

1,205 Posts

I think Drew hit all the high points, but let me re-emphasize them.

Your wheels were not built well. (This is common in machine-built wheels.)

Wheels need to be adequately tensioned and stress-relieved.

Good wheel-builders will build wheels well, with properly tensioned and stress-relieved spokes.

Your wheels were not built well. (This is common in machine-built wheels.)

Wheels need to be adequately tensioned and stress-relieved.

Good wheel-builders will build wheels well, with properly tensioned and stress-relieved spokes.

Likes For trailangel:

#17

CityCycle

Join Date: Feb 2008

Location: Johnstown,Pa

Posts: 117

Bikes: Brand new Cannondale Roadwarrior 3

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I'm a heavy person also, I have broken many spokes on the back wheel, both sides of the wheel so that's not uncommon I would say. I've only broke one spoke on the front wheel and that was back in the 80's ! Just more weight on back wheel pure and simple and the offset of the spokes isn't a plus that's for sure. I've had them break at both ends of the spoke. Learn to repair it yourself is best advice. Also buy a tension meter it's helped me build a very evenly proportioned wheel that needs very little to no truing or only a breakage every so often..

#18

Senior Member

Join Date: Feb 2018

Posts: 1,410

Bikes: 2017 Specialized Allez Sprint Comp

Mentioned: 11 Post(s)

Tagged: 0 Thread(s)

Quoted: 850 Post(s)

Liked 344 Times

in

247 Posts

I imagine that breaking DS spokes has something to do with leading vs trailing spokes. If I recall correctly, trailing spokes go slacker under torque. This means that if a big, strong person with a huge gear (which mountain bikes these days have) puts down serious torque, your DS trailing spokes, along with your NDS, would go slack. This in addition to local rim compression at the contact patch.

28 spokes seems to be the standard for even the lightest people. If you’re big and strong, 32 might not be enough. I’d look into 36. You’re restricted to J bend at that point, probably, but that shouldn’t be a big deal. I’d also probably go with beefier sapim Race/CX-sprint spokes. They’re stiffer so they’re less likely to go slack. I’d also go for the beefiest, deepest rim I can find to reduce local compression (at the risk of causing cracked rims, of course).

28 spokes seems to be the standard for even the lightest people. If you’re big and strong, 32 might not be enough. I’d look into 36. You’re restricted to J bend at that point, probably, but that shouldn’t be a big deal. I’d also probably go with beefier sapim Race/CX-sprint spokes. They’re stiffer so they’re less likely to go slack. I’d also go for the beefiest, deepest rim I can find to reduce local compression (at the risk of causing cracked rims, of course).

#19

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,881

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4783 Post(s)

Liked 3,905 Times

in

2,539 Posts

Some simple math. Typically 55-60% of your weight is onthe rear wheel. With the dish in the rear wheel (the hub is offset to the left to make room for the cassette cogs), the right side spokes are near vertical and have considerably higher tension to oppose the left side spokes, roughly a factor of 2. So 1) front wheels have equal spoke tensions and all the spokes can be laced tit he best tension. THey also see less abuse because the see less weight on them.

Now, rear wheels have a huge imbalance between right and left. The result? Right side spokes have to be near too tight just to keep the left spokes from being too loose. If the spokes are equal diameter left and right, both have to be pushing their respective limits. Too tight - rims crack, hub flanges crack, any shortcomings in the wheel build and spoke heads are likely to pop off. Too loose and the spokes go slack as they pass the bottom of the wheel rotation and your weight is pulling the hub down. This leads to fatigue failure in the same places, spoke heads and at the start of the threads.

You say you are heavy. I suggest having a custom wheel built by a reputable wheelbuilder with heavy spokes on thet right and spokes a full gauge thinner on the left - and have the spokes on both sides "butted", ie thinner n the long middle section than at the ends so you have both more material where they break and more stretch in the middle which allows the spokes to stay "tight" at the bottom of the wheel rotation and not go into fatigue mode very wheel revolution. This wheel will be expensive. But done right, it will give you good service.

Oh, and think about seeing if you can "ride light". All l of us who build wheels know that weight isn't the entire issue. Some riders at a given weight are easy on wheels, other killers on the same wheels, riding the same roads. Whether you hit a road issue (pothole, rock, crack, etc.) and how you manage your weight on the bike when you do hit (we all do, even the most aware of us) matters a whole lot.

Spoked wheels - one of the key inventions that allowed the bikes we ride today to happen. We owe a lot to that, pneumatic tires and the chain. Without these three things, we would still be riding 80 pound high wheelers. (But the inventors of the spoked wheel never dreamed we would, 100 years later, be putting that huge amount of dish in the rear wheel. In fact, they would simply say that wheels built that way were to be considered "bad wheels". Now we have to jump through hoops to make these bad wheels work. Aside: I do half my riding on fix gears which use rear wheels with virtually no dish. I use the same spokes as I use on front wheels and get the same life out of those wheels. They go forever; until I wear out the rim from brake wear.or I've damaged the rim on bumps - bunny hopping not being possible riding fix gears.

Ben

Now, rear wheels have a huge imbalance between right and left. The result? Right side spokes have to be near too tight just to keep the left spokes from being too loose. If the spokes are equal diameter left and right, both have to be pushing their respective limits. Too tight - rims crack, hub flanges crack, any shortcomings in the wheel build and spoke heads are likely to pop off. Too loose and the spokes go slack as they pass the bottom of the wheel rotation and your weight is pulling the hub down. This leads to fatigue failure in the same places, spoke heads and at the start of the threads.

You say you are heavy. I suggest having a custom wheel built by a reputable wheelbuilder with heavy spokes on thet right and spokes a full gauge thinner on the left - and have the spokes on both sides "butted", ie thinner n the long middle section than at the ends so you have both more material where they break and more stretch in the middle which allows the spokes to stay "tight" at the bottom of the wheel rotation and not go into fatigue mode very wheel revolution. This wheel will be expensive. But done right, it will give you good service.

Oh, and think about seeing if you can "ride light". All l of us who build wheels know that weight isn't the entire issue. Some riders at a given weight are easy on wheels, other killers on the same wheels, riding the same roads. Whether you hit a road issue (pothole, rock, crack, etc.) and how you manage your weight on the bike when you do hit (we all do, even the most aware of us) matters a whole lot.

Spoked wheels - one of the key inventions that allowed the bikes we ride today to happen. We owe a lot to that, pneumatic tires and the chain. Without these three things, we would still be riding 80 pound high wheelers. (But the inventors of the spoked wheel never dreamed we would, 100 years later, be putting that huge amount of dish in the rear wheel. In fact, they would simply say that wheels built that way were to be considered "bad wheels". Now we have to jump through hoops to make these bad wheels work. Aside: I do half my riding on fix gears which use rear wheels with virtually no dish. I use the same spokes as I use on front wheels and get the same life out of those wheels. They go forever; until I wear out the rim from brake wear.or I've damaged the rim on bumps - bunny hopping not being possible riding fix gears.

Ben

#20

CityCycle

Join Date: Feb 2008

Location: Johnstown,Pa

Posts: 117

Bikes: Brand new Cannondale Roadwarrior 3

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I imagine that breaking DS spokes has something to do with leading vs trailing spokes. If I recall correctly, trailing spokes go slacker under torque. This means that if a big, strong person with a huge gear (which mountain bikes these days have) puts down serious torque, your DS trailing spokes, along with your NDS, would go slack. This in addition to local rim compression at the contact patch.

28 spokes seems to be the standard for even the lightest people. If you’re big and strong, 32 might not be enough. I’d look into 36. You’re restricted to J bend at that point, probably, but that shouldn’t be a big deal. I’d also probably go with beefier sapim Race/CX-sprint spokes. They’re stiffer so they’re less likely to go slack. I’d also go for the beefiest, deepest rim I can find to reduce local compression (at the risk of causing cracked rims, of course).

28 spokes seems to be the standard for even the lightest people. If you’re big and strong, 32 might not be enough. I’d look into 36. You’re restricted to J bend at that point, probably, but that shouldn’t be a big deal. I’d also probably go with beefier sapim Race/CX-sprint spokes. They’re stiffer so they’re less likely to go slack. I’d also go for the beefiest, deepest rim I can find to reduce local compression (at the risk of causing cracked rims, of course).

I'm always careful to avoid hitting potholes.

#21

Senior Member

Join Date: Apr 2010

Location: Elevation 666m Edmonton Canada

Posts: 2,472

Bikes: 2013 Custom SA5w / Rohloff Tourster

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 1233 Post(s)

Liked 317 Times

in

244 Posts

We need your height/ weight and pics of what bikes you have to really see what is going on. Maybe the spokes are getting stressed sideways when you lean or climb on and off. Or the bike is too small, cheap ones often are.

I don't call them deFAILeurs for nothing. LOL ...Spokes breaking on tour bikes happen to over 60%, in my estimation. One average size guy broke 5 twice, on a LHT. SOME combinations of rim and hubs just do more poorly, IMO. Getting heavy spokes with the new wheel could have worked, but now is rather too late. 2 strikes and yer OUT. IMO.

The OP then answered his own question. Get a BETTER IGH bike.

I assume you don't want to spend thousands for a Rohloff bike so ....Look for a bike with a SA 5 or Nexus 7 or 8.

They are $800 to $1100. Or maybe you can find an old tour bike and replace the back wheel.

If you do build such a wheel, put 2.3/2.0 spokes at least on the drive side. If 35 mm tires, use a Velocity Dyad rim, that has NO goofy EYELETS.

I'm not big, but my custom tour bike rolls at 290/ 300 lbs. 8.000 miles like that, including some crashes too. My Rohloff has 16,500 miles with NO problems, including the shifter and cables. Only broken spoke was caused by my lock. The spokes are just straight 2.0 with locking nipples.

I have a SA dyno drum hub in front, with 24,000 trouble free miles. It has all 2.3/2.0 spokes. MY builds too, I haven't done many either.

There was a huge guy on YT who went on a tour in SE Asia. His LHT had the best derailleur hubs around. He broke 3 rims and 4 rear hubs, the pawls were breaking. THEN he got a Rohloff. LOL. Haven't heard from him the 6 years since.

I don't call them deFAILeurs for nothing. LOL ...Spokes breaking on tour bikes happen to over 60%, in my estimation. One average size guy broke 5 twice, on a LHT. SOME combinations of rim and hubs just do more poorly, IMO. Getting heavy spokes with the new wheel could have worked, but now is rather too late. 2 strikes and yer OUT. IMO.

The OP then answered his own question. Get a BETTER IGH bike.

I assume you don't want to spend thousands for a Rohloff bike so ....Look for a bike with a SA 5 or Nexus 7 or 8.

They are $800 to $1100. Or maybe you can find an old tour bike and replace the back wheel.

If you do build such a wheel, put 2.3/2.0 spokes at least on the drive side. If 35 mm tires, use a Velocity Dyad rim, that has NO goofy EYELETS.

I'm not big, but my custom tour bike rolls at 290/ 300 lbs. 8.000 miles like that, including some crashes too. My Rohloff has 16,500 miles with NO problems, including the shifter and cables. Only broken spoke was caused by my lock. The spokes are just straight 2.0 with locking nipples.

I have a SA dyno drum hub in front, with 24,000 trouble free miles. It has all 2.3/2.0 spokes. MY builds too, I haven't done many either.

There was a huge guy on YT who went on a tour in SE Asia. His LHT had the best derailleur hubs around. He broke 3 rims and 4 rear hubs, the pawls were breaking. THEN he got a Rohloff. LOL. Haven't heard from him the 6 years since.

Last edited by GamblerGORD53; 04-06-20 at 03:00 PM.

#22

Senior Member

36 double-butted spokes should solve your problems. I'm not a pro builder I do it because I enjoy the work. I have built wheel for 275 pounders and they have held up.

#23

Senior Member

Join Date: Apr 2005

Location: Northern CA

Posts: 735

Bikes: Cannondale tandems: '92 Road, '97 Mtn. Mongoose 10.9 Ti, Kelly Deluxe, Tommaso Chorus, Cdale MT2000, Schwinn Deluxe Cruiser, Torker Unicycle, among others.

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 276 Post(s)

Liked 201 Times

in

127 Posts

One thing failed to be mentioned is the fact that DS spokes also suffer all manner of abuse from the chain. What percentage of wheels in use have ZERO damage to DS spokes? I don't think it's that high. In other words, the damage caused by the chain to the DS spokes is also a factor in spoke failure on the DS. Stress risers caused by chain damage account for a significant percentage of DS spoke failures.

In my 40 years of riding, I've replaced probably almost half of my broken spokes on the NDS. Majority on DS, but not my much. And in the shop I was always surprised just how many NDS spoke failures I saw. Given the majority of the loads and stresses are taken by the DS spokes, I simply always assumed they'd always be the ones failing. But this wasn't the case.

In order of effectiveness (according to Wheelsmith many years ago, rim width was the biggest factor) in my book:

(Hub type - usually not an option. But a dishless wheel for the rear is ideal, but often impossible, given today's "more and more cogs" designs.)

Rim width

Rim strength, weight and type (offset spoke holes)

Spoke count

Spoke type (double or triple butted)

(And this assumes the wheels are built by an experienced builder who uses a tension meter and knows how to fully stress-relieve the wheel and spokes. Brass nipples, preferably with locking compound and/or thread prep.)

In my 40 years of riding, I've replaced probably almost half of my broken spokes on the NDS. Majority on DS, but not my much. And in the shop I was always surprised just how many NDS spoke failures I saw. Given the majority of the loads and stresses are taken by the DS spokes, I simply always assumed they'd always be the ones failing. But this wasn't the case.

In order of effectiveness (according to Wheelsmith many years ago, rim width was the biggest factor) in my book:

(Hub type - usually not an option. But a dishless wheel for the rear is ideal, but often impossible, given today's "more and more cogs" designs.)

Rim width

Rim strength, weight and type (offset spoke holes)

Spoke count

Spoke type (double or triple butted)

(And this assumes the wheels are built by an experienced builder who uses a tension meter and knows how to fully stress-relieve the wheel and spokes. Brass nipples, preferably with locking compound and/or thread prep.)

#24

CityCycle

Join Date: Feb 2008

Location: Johnstown,Pa

Posts: 117

Bikes: Brand new Cannondale Roadwarrior 3

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

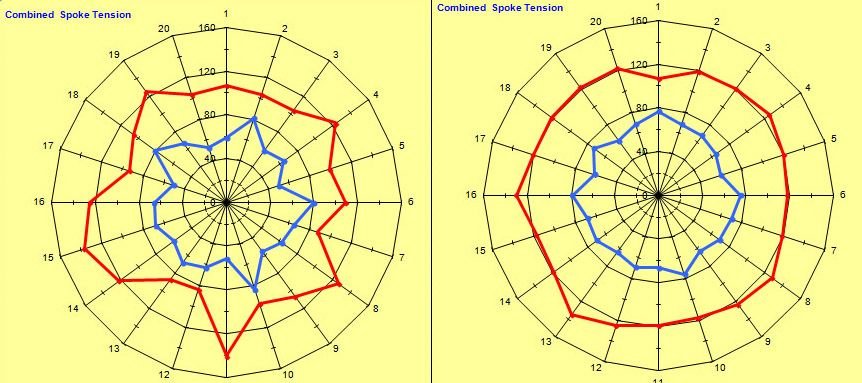

I had a lot fun with my tension meter and taking a wheel with uneven tension (left) and making it one well within limits (right) I could never get them perfect but got almost perfect performance. I got technical, even waiting 10 seconds on each spoke for the meter to settle down and achieve a consistent reading. The meter takes the guess work out it and one can practically turn out strong wheels like an experienced wheel building expert

#25

Clark W. Griswold

Join Date: Mar 2014

Location: ,location, location

Posts: 13,446

Bikes: Foundry Chilkoot Ti W/Ultegra Di2, Salsa Timberjack Ti, Cinelli Mash Work RandoCross Fun Time Machine, 1x9 XT Parts Hybrid, Co-Motion Cascadia, Specialized Langster, Phil Wood Apple VeloXS Frame (w/DA 7400), R+M Supercharger2 Rohloff, Habanero Ti 26

Mentioned: 54 Post(s)

Tagged: 0 Thread(s)

Quoted: 4323 Post(s)

Liked 3,945 Times

in

2,638 Posts

I am of a larger size and I don't break spokes, my key is high quality components built by someone who has built or builds a lot of wheels. I think at this point all of my wheels are 32h and many are laced with Sapim Strong or Force Spokes and Brass Secure Lock Nipples on good well known rims (Velocity and H+Son as well as some WTB rims) with quality hubs (White Industries, Phil Wood, Paul) . I have a wheelset that is using Phil Wood Spokes and Nipples but the bike is from Phil Wood back in 1994 so it was only appropriate. I don't know the conversion rate for loonies but I cannot imagine it is worth twice a much or something so my guess is the wheel you have was not hand built or it was using the cheapest parts with little to no labor charge. Usually a wheel at the price is going to be machine built from a distributor and some of those wheels can be mediocre or even marginally good but when you are talking heavier riders or people who put a lot of stress on wheels they don't tend to hold up as well.

If you are looking for something durable use a quality hub something with a steel or titanium freehub (assuming a cassette wheel) and ideally with easily serviceable bearings in 32 or 36h with high flanges if possible. Stick with good strong spokes and nipples like the ones mentioned above or DT Swiss Apline III and a good rim that can handle heavier duty spokes and good high tension. One big thing to remember is the system has to be able to work together so you can drill a lightweight aluminum rim for 36h but it probably won't handle big thick spokes well and lightweight hubs are the same deal.

If I were building a really bombproof rim brake wheel I would probably do a 36h White Industries MI5 hub laced to a Velocity NoBS rim (or Atlas if I wanted it to look prettier and lose a little strength) with Sapim Strong spokes and brass Secure Lock Nipples laced 3X. For disc I would do the same but WI CLD hubs. If I wanted something even stronger I might switch everything to 40h which I can get with all those components minus the CLD disc hubs. Also I would have them made by someone like Bill Mould or Peter J. White or another long time wheel builder who knows their stuff. I don't know who is up in Canadia on the wheel building side but I am sure someone has some good skills and has been doing it a while or has that as their main focus.

A handbuilt wheel by a competent wheel builder should last a long long long time without issue and if there is an issue that wheel builder should stand behind their product. The same cannot really be said for a machine that is cranking out tons of wheels a day and probably those wheels aren't checked by a human. I know most shops sadly don't always check over the wheels before they go out. Not a jab against shops at all because that takes time and most of these wheels are decent enough and have few problems but it would be nice if we had the time.

If you are looking for something durable use a quality hub something with a steel or titanium freehub (assuming a cassette wheel) and ideally with easily serviceable bearings in 32 or 36h with high flanges if possible. Stick with good strong spokes and nipples like the ones mentioned above or DT Swiss Apline III and a good rim that can handle heavier duty spokes and good high tension. One big thing to remember is the system has to be able to work together so you can drill a lightweight aluminum rim for 36h but it probably won't handle big thick spokes well and lightweight hubs are the same deal.

If I were building a really bombproof rim brake wheel I would probably do a 36h White Industries MI5 hub laced to a Velocity NoBS rim (or Atlas if I wanted it to look prettier and lose a little strength) with Sapim Strong spokes and brass Secure Lock Nipples laced 3X. For disc I would do the same but WI CLD hubs. If I wanted something even stronger I might switch everything to 40h which I can get with all those components minus the CLD disc hubs. Also I would have them made by someone like Bill Mould or Peter J. White or another long time wheel builder who knows their stuff. I don't know who is up in Canadia on the wheel building side but I am sure someone has some good skills and has been doing it a while or has that as their main focus.

A handbuilt wheel by a competent wheel builder should last a long long long time without issue and if there is an issue that wheel builder should stand behind their product. The same cannot really be said for a machine that is cranking out tons of wheels a day and probably those wheels aren't checked by a human. I know most shops sadly don't always check over the wheels before they go out. Not a jab against shops at all because that takes time and most of these wheels are decent enough and have few problems but it would be nice if we had the time.