(Two) Peugeot PR-10 from the 70's

#26

Full Member

Thread Starter

Join Date: Oct 2017

Location: Rotterdam, The Netherlands

Posts: 361

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 157 Post(s)

Liked 113 Times

in

64 Posts

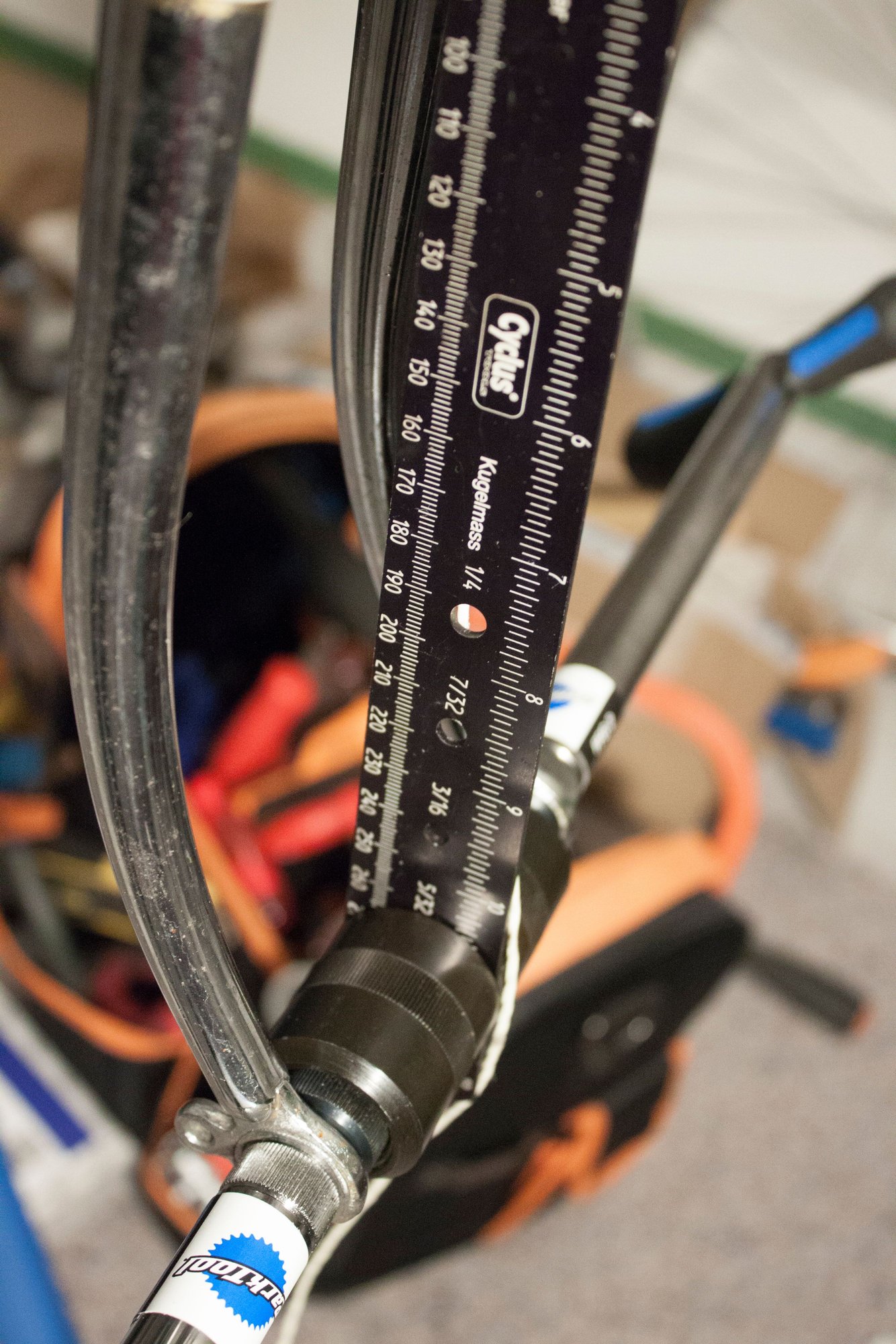

I just used a ruler which I clamped between the bushings to see where the center of the wheel will end up. Next to that, I used a string as a reference. It seems a bit off indeed! Gonna try to fix the alignment tomorrow and see if it helps.

The alignment is slightly off

#27

Friendship is Magic

Join Date: Nov 2010

Location: Sacramento, CA

Posts: 22,983

Bikes: old ones

Mentioned: 304 Post(s)

Tagged: 0 Thread(s)

Quoted: 26382 Post(s)

Liked 10,359 Times

in

7,195 Posts

...the simplest fix is to take a round file of the appropriate size and file down the interior bottom of the fork end that is high (when you look at the fork upside down...which is how the fork should be positioned for this operation.) Go slowly, and recheck by inserting the wheel often until the rim is equidistant from each leg. There is a way to do this by changing the curve on one fork leg, but it's something youi probably don't want to attempt without someone present who has done it before.

#28

Senior Member

The French Standard for the headset crown race is 27.0mm ID. Some Japanese headsets are/were made in that diameter but most non French headsets have a 26.4mm or 26.5mm ID.

All Campagnolo headsets have a 26.4mm ID... But I think the NJS Keiren track racing standard is 27.0mm so Campy maybe makes some special headsets for that market???

verktyg

All Campagnolo headsets have a 26.4mm ID... But I think the NJS Keiren track racing standard is 27.0mm so Campy maybe makes some special headsets for that market???

verktyg

For anyone wanting to fit a new crown race to 27.0, Tange Levin headsets can be bought for that dimension. If someone wanted to, could use just the crown race, lower cup, and bearings and few observers would be the wiser as the Tange Levin is a pretty nice looking headset.

#29

Senior Member

If the fork in the picture with the string has the steerer positioned vertically, and if the fork crown is properly positioned with the respect to the steerer and if the fork ends are properly spaced and aligned square with each other, then both fork ends need to move to the right (to the left side of the bike with the fork installed.) Look at this thread for a discussion along with a couple photos of the "proper" tool to use to evaluate the fork's alignment. Essentially, you have to locate the positions of the two fork ends in space with respect to the steerer and then reposition them, by bending the fork blades, so everything is spaced properly and symmetrically. If you look at the photos in that thread, you can see what the tool does and you may be able to accomplish the same thing without it.

Of course I don't know for sure, but it appears that fork got somehow bent on one or both sides resulting in the distance between the dropouts being 90 mm. Then, it was bent again when the spacing was corrected. The result is that the blades appear to be improperly bent. The thing to do, in my opinion, is to get them bent back rather than to start removing metal -- which is a one way operation.

Of course I don't know for sure, but it appears that fork got somehow bent on one or both sides resulting in the distance between the dropouts being 90 mm. Then, it was bent again when the spacing was corrected. The result is that the blades appear to be improperly bent. The thing to do, in my opinion, is to get them bent back rather than to start removing metal -- which is a one way operation.

#30

PM me your cotters

Join Date: Jun 2015

Location: ATL

Posts: 3,241

Mentioned: 80 Post(s)

Tagged: 0 Thread(s)

Quoted: 1137 Post(s)

Liked 588 Times

in

420 Posts

Hmm, it's actually hard to tell how perfect the alignment is by using just the tool itself. Or maybe I don't use the tool correctly.

I just used a ruler which I clamped between the bushings to see where the center of the wheel will end up. Next to that, I used a string as a reference. It seems a bit off indeed! Gonna try to fix the alignment tomorrow and see if it helps.

I just used a ruler which I clamped between the bushings to see where the center of the wheel will end up. Next to that, I used a string as a reference. It seems a bit off indeed! Gonna try to fix the alignment tomorrow and see if it helps.

I'll attach instructions from my FFG below, but what I'd suggest is this: Check their repair page out and see if anything jumps out which you didn't already know: https://www.parktool.com/blog/repair...pout-alignment

Specifically pay attention to how they handle the tool when bending. I swear they had a video for it also, but I just can't seem to find it!

Here are my instructions, if it helps. If you need me to scan to PDF and email you a copy, LMK, I'm happy to do so. (PS: Some folks suggest bending slightly past where you should, like +5%, just to account for snap-back of steel. Not sure if it applies for fork-ends, but for steel in general...)

__________________

███████████████

███████████████

#31

Full Member

Thread Starter

Join Date: Oct 2017

Location: Rotterdam, The Netherlands

Posts: 361

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 157 Post(s)

Liked 113 Times

in

64 Posts

...the simplest fix is to take a round file of the appropriate size and file down the interior bottom of the fork end that is high (when you look at the fork upside down...which is how the fork should be positioned for this operation.) Go slowly, and recheck by inserting the wheel often until the rim is equidistant from each leg. There is a way to do this by changing the curve on one fork leg, but it's something youi probably don't want to attempt without someone present who has done it before.

#32

Full Member

Thread Starter

Join Date: Oct 2017

Location: Rotterdam, The Netherlands

Posts: 361

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 157 Post(s)

Liked 113 Times

in

64 Posts

What you did is exactly what I was going to ask you to do: Pinch a flat edge between the two ends and run a string. Bingo. And you see, it's not quite straight. There's your problem in a whole.

I'll attach instructions from my FFG below, but what I'd suggest is this: Check their repair page out and see if anything jumps out which you didn't already know: https://www.parktool.com/blog/repair...pout-alignment

Specifically pay attention to how they handle the tool when bending. I swear they had a video for it also, but I just can't seem to find it!

Here are my instructions, if it helps. If you need me to scan to PDF and email you a copy, LMK, I'm happy to do so. (PS: Some folks suggest bending slightly past where you should, like +5%, just to account for snap-back of steel. Not sure if it applies for fork-ends, but for steel in general...)

I'll attach instructions from my FFG below, but what I'd suggest is this: Check their repair page out and see if anything jumps out which you didn't already know: https://www.parktool.com/blog/repair...pout-alignment

Specifically pay attention to how they handle the tool when bending. I swear they had a video for it also, but I just can't seem to find it!

Here are my instructions, if it helps. If you need me to scan to PDF and email you a copy, LMK, I'm happy to do so. (PS: Some folks suggest bending slightly past where you should, like +5%, just to account for snap-back of steel. Not sure if it applies for fork-ends, but for steel in general...)

I am gonna correct the fork ends and see if it helps.

might be a good idea to check the dropouts with a ruler as well.

Thanks for the link, anyway!

The website provides better instructions for sure but I wonder how precise the method is when you just judge by the gap between the bushings.

I have instructions for FFG-2 but they look bit different than yours

#33

Full Member

Thread Starter

Join Date: Oct 2017

Location: Rotterdam, The Netherlands

Posts: 361

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 157 Post(s)

Liked 113 Times

in

64 Posts

If the fork in the picture with the string has the steerer positioned vertically, and if the fork crown is properly positioned with the respect to the steerer and if the fork ends are properly spaced and aligned square with each other, then both fork ends need to move to the right (to the left side of the bike with the fork installed.) Look at this thread for a discussion along with a couple photos of the "proper" tool to use to evaluate the fork's alignment. Essentially, you have to locate the positions of the two fork ends in space with respect to the steerer and then reposition them, by bending the fork blades, so everything is spaced properly and symmetrically. If you look at the photos in that thread, you can see what the tool does and you may be able to accomplish the same thing without it.

Of course I don't know for sure, but it appears that fork got somehow bent on one or both sides resulting in the distance between the dropouts being 90 mm. Then, it was bent again when the spacing was corrected. The result is that the blades appear to be improperly bent. The thing to do, in my opinion, is to get them bent back rather than to start removing metal -- which is a one way operation.

Of course I don't know for sure, but it appears that fork got somehow bent on one or both sides resulting in the distance between the dropouts being 90 mm. Then, it was bent again when the spacing was corrected. The result is that the blades appear to be improperly bent. The thing to do, in my opinion, is to get them bent back rather than to start removing metal -- which is a one way operation.

The thing is that originally the wheel was perfectly centered in the fork, at least as far as I remember.

Why it was spaced to 90mm is another question..

#34

Full Member

Thread Starter

Join Date: Oct 2017

Location: Rotterdam, The Netherlands

Posts: 361

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 157 Post(s)

Liked 113 Times

in

64 Posts

I have three French bikes : a PR10 very much like the white one, a MB Grand Record from 77, and a 70s contract B Carre frame that I recently bought from a member. I've not removed the crown race on either the PR10 or the MB GR, but the headset on the Carre was metric Campagnolo (sort of) so the fork was machined for 26.4 or so. I'll bet that the fork with the DA headset was machined to match the headset when it was installed. Aren't there tools for doing just that thing?

I might have a picture of it somewhere.

Anyway, I had to ream/face it myself so that the crown race could be seated nicely.

#35

Friendship is Magic

Join Date: Nov 2010

Location: Sacramento, CA

Posts: 22,983

Bikes: old ones

Mentioned: 304 Post(s)

Tagged: 0 Thread(s)

Quoted: 26382 Post(s)

Liked 10,359 Times

in

7,195 Posts

From what I recall, 92mm was another common OLD distance in ancient times.

Regardless, you do need to get some idea off whether the fork ends are equidistant from the centerline before proceeding with your fix.

#36

Full Member

Thread Starter

Join Date: Oct 2017

Location: Rotterdam, The Netherlands

Posts: 361

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 157 Post(s)

Liked 113 Times

in

64 Posts

Well, I've tried aligning the fork ends once again but every time I get the same result. Which does make sense because I haven't changed the position of the fork ends relatively to each other, right?

So the fork blades are off, aren't they?

Here is what Jobst Brandt recommends:

"If the fork is only bent to the side, the correction must be to the side to which the rider must lean when riding no-hands. This bend can be done carefully by bending one blade at a time.

Lay the bicycle on its side, front wheel removed. Place the rubber-soled foot inside the crown of the fork and pull the upper blade until the gap at the fork end increases by a couple of millimeters. This should be measured. With the foot in the same place, pull the other fork blade until the original spacing is restored. Ride the bicycle and assess the difference. Repeat if necessary. This must be done with a strong arm and a bit of skill but it is simple."

Doesn't seem like a very precise method to me, but OK..the idea is quite simple though

Has anyone tried using Park Tool Frame and Fork Straightener FFS-2? It seems to provide more control over bending process.

My LBS doesn't really have a fork jig so I can't really rely on them

So the fork blades are off, aren't they?

Here is what Jobst Brandt recommends:

"If the fork is only bent to the side, the correction must be to the side to which the rider must lean when riding no-hands. This bend can be done carefully by bending one blade at a time.

Lay the bicycle on its side, front wheel removed. Place the rubber-soled foot inside the crown of the fork and pull the upper blade until the gap at the fork end increases by a couple of millimeters. This should be measured. With the foot in the same place, pull the other fork blade until the original spacing is restored. Ride the bicycle and assess the difference. Repeat if necessary. This must be done with a strong arm and a bit of skill but it is simple."

Doesn't seem like a very precise method to me, but OK..the idea is quite simple though

Has anyone tried using Park Tool Frame and Fork Straightener FFS-2? It seems to provide more control over bending process.

My LBS doesn't really have a fork jig so I can't really rely on them

#37

Senior Member

Join Date: Aug 2013

Posts: 2,321

Mentioned: 35 Post(s)

Tagged: 0 Thread(s)

Quoted: 767 Post(s)

Liked 1,898 Times

in

889 Posts

I have done the method that Jobst Brandt explains successfully a couple of times. Obviously, go slow - a little at a time. It does work.

I would not take a file to the forkend.

I would not take a file to the forkend.

#38

PM me your cotters

Join Date: Jun 2015

Location: ATL

Posts: 3,241

Mentioned: 80 Post(s)

Tagged: 0 Thread(s)

Quoted: 1137 Post(s)

Liked 588 Times

in

420 Posts

Has anyone tried using Park Tool Frame and Fork Straightener FFS-2? It seems to provide more control over bending process.

My LBS doesn't really have a fork jig so I can't really rely on them

My LBS doesn't really have a fork jig so I can't really rely on them

The FFS-2 is extremely useful to bend darn near anything. But without the FT-4 or a similar jig you make or careful and precise stringing (at least), it's difficult to impossible to figure out where the blades are out of whack, thus where to start your bending, and getting the leverage in the exact place going the correct direction is a challenge. I would liken it to trying to straighten a bent rod, which is easy enough to get 90% of the way there but you'll lose your damn mind trying to get that last 10% perfectly straight.

With the test side-impact fork I played with after the FT-4 arrived - which a car took the front wheel of this bike under it, both fork blades swooped over equally like (( this - it was really difficult trying to make sense of exactly where to bend and how much, even with the FT-4. I *did* manage to straighten the tines, but with a fair amount of playing, I haven't gotten everything as square as it should be.

Before you proceed, I would probably check in with a seasoned frame guy like @gugie because he may have some sage advice to share in this case. Thing I would say is, if you can find someone who has a tool like the Park FT-4, in a matter of 60 seconds you'd know if the blades are actually out of whack, or if it's just the fork-ends, then massage the correct bits into place.

__________________

███████████████

███████████████

#39

Friendship is Magic

Join Date: Nov 2010

Location: Sacramento, CA

Posts: 22,983

Bikes: old ones

Mentioned: 304 Post(s)

Tagged: 0 Thread(s)

Quoted: 26382 Post(s)

Liked 10,359 Times

in

7,195 Posts

Here is what Jobst Brandt recommends:

"If the fork is only bent to the side, the correction must be to the side to which the rider must lean when riding no-hands. This bend can be done carefully by bending one blade at a time.

Lay the bicycle on its side, front wheel removed. Place the rubber-soled foot inside the crown of the fork and pull the upper blade until the gap at the fork end increases by a couple of millimeters. This should be measured. With the foot in the same place, pull the other fork blade until the original spacing is restored. Ride the bicycle and assess the difference. Repeat if necessary. This must be done with a strong arm and a bit of skill but it is simple."

Doesn't seem like a very precise method to me, but OK..the idea is quite simple though

Has anyone tried using Park Tool Frame and Fork Straightener FFS-2? It seems to provide more control over bending process.

My LBS doesn't really have a fork jig so I can't really rely on them

"If the fork is only bent to the side, the correction must be to the side to which the rider must lean when riding no-hands. This bend can be done carefully by bending one blade at a time.

Lay the bicycle on its side, front wheel removed. Place the rubber-soled foot inside the crown of the fork and pull the upper blade until the gap at the fork end increases by a couple of millimeters. This should be measured. With the foot in the same place, pull the other fork blade until the original spacing is restored. Ride the bicycle and assess the difference. Repeat if necessary. This must be done with a strong arm and a bit of skill but it is simple."

Doesn't seem like a very precise method to me, but OK..the idea is quite simple though

Has anyone tried using Park Tool Frame and Fork Straightener FFS-2? It seems to provide more control over bending process.

My LBS doesn't really have a fork jig so I can't really rely on them

I'm not making this up: fixing a fork like yours is a process that requires that you first ascertain whither the fork ends are equidistant from the centerline.

If you don't have access to a fork jig, you can still do it using your basic straight edge, and a measuring caliper. It just takes a lot longer if you actually do need to re-position the fork blades.

If you Google up some images of either the VAR or Park fork alignment jig, you'll quickly see that all it is is a solid clamp for the steerer, and a long arm that drops down the centerline of the fork past the crown. The arm has a little adjustable rod thingie on the end of it, so you can slide it up and down the length to catch the fork ends of whatever fork you're working on. So you do need some kind of solid clamping vise for the steerer, like the pipe jaws of a bench vise. Then you adjust the fork in that clamp so the crown is level (you can set a small bubble level on it). Then you need to drop a straight centerline along the steerer and across the center of the crown that goes all the way past the fork ends. Measure how far off from that line each fork end sits (do it near the top of the fork end, where it inserts into the fork leg.) If it's pretty close to on center, then pulling on the fork legs is not what you need to do.

On a lot of forks, you can often bend the position of the legs enough for your purposes by just grabbing onto them with both hands, and either pushing or pulling. The Park straightener does make the job easier, and with some steel forks, you can't get enough movement without it. Whatever you do, don't yank around too much on the fork ends themselves, because they can break off where they are brazed into the fork blade. You just want to move the blades, and then when you've got them properlypositioned, use your alignment tools to get them parallel. Don't bend the leg in or out using the alignment tool in the fork end, because eventually, you will discover this the hard way.

It's worth looking around for womeone near you who has an old alignment jig. makes the process a lot less worrisome.

#40

Friendship is Magic

Join Date: Nov 2010

Location: Sacramento, CA

Posts: 22,983

Bikes: old ones

Mentioned: 304 Post(s)

Tagged: 0 Thread(s)

Quoted: 26382 Post(s)

Liked 10,359 Times

in

7,195 Posts

.

...I know I will never convince the "never file a fork end" guys that sometimes this is the most efficacious method of repair. I won't even try.

...I know I will never convince the "never file a fork end" guys that sometimes this is the most efficacious method of repair. I won't even try.

#41

PM me your cotters

Join Date: Jun 2015

Location: ATL

Posts: 3,241

Mentioned: 80 Post(s)

Tagged: 0 Thread(s)

Quoted: 1137 Post(s)

Liked 588 Times

in

420 Posts

If you Google up some images of either the VAR or Park fork alignment jig, you'll quickly see that all it is is a solid clamp for the steerer, and a long arm that drops down the centerline of the fork past the crown. The arm has a little adjustable rod thingie on the end of it, so you can slide it up and down the length to catch the fork ends of whatever fork you're working on.

__________________

███████████████

███████████████

#42

Bike Butcher of Portland

Join Date: Jul 2014

Location: Portland, OR

Posts: 11,630

Bikes: It's complicated.

Mentioned: 1299 Post(s)

Tagged: 0 Thread(s)

Quoted: 4677 Post(s)

Liked 5,790 Times

in

2,279 Posts

I recently got a great deal on an FT-4 from a listing at CABE by a member also on BF. After, figured I'd use the money I saved to get a new FFS-2 of eBay from someone clearing out old inventory at about 20% off MSRP. Already had the FFG so I was good to go there. Here's what I'll say....

The FFS-2 is extremely useful to bend darn near anything. But without the FT-4 or a similar jig you make or careful and precise stringing (at least), it's difficult to impossible to figure out where the blades are out of whack, thus where to start your bending, and getting the leverage in the exact place going the correct direction is a challenge. I would liken it to trying to straighten a bent rod, which is easy enough to get 90% of the way there but you'll lose your damn mind trying to get that last 10% perfectly straight.

With the test side-impact fork I played with after the FT-4 arrived - which a car took the front wheel of this bike under it, both fork blades swooped over equally like (( this - it was really difficult trying to make sense of exactly where to bend and how much, even with the FT-4. I *did* manage to straighten the tines, but with a fair amount of playing, I haven't gotten everything as square as it should be.

Before you proceed, I would probably check in with a seasoned frame guy like @gugie because he may have some sage advice to share in this case. Thing I would say is, if you can find someone who has a tool like the Park FT-4, in a matter of 60 seconds you'd know if the blades are actually out of whack, or if it's just the fork-ends, then massage the correct bits into place.

The FFS-2 is extremely useful to bend darn near anything. But without the FT-4 or a similar jig you make or careful and precise stringing (at least), it's difficult to impossible to figure out where the blades are out of whack, thus where to start your bending, and getting the leverage in the exact place going the correct direction is a challenge. I would liken it to trying to straighten a bent rod, which is easy enough to get 90% of the way there but you'll lose your damn mind trying to get that last 10% perfectly straight.

With the test side-impact fork I played with after the FT-4 arrived - which a car took the front wheel of this bike under it, both fork blades swooped over equally like (( this - it was really difficult trying to make sense of exactly where to bend and how much, even with the FT-4. I *did* manage to straighten the tines, but with a fair amount of playing, I haven't gotten everything as square as it should be.

Before you proceed, I would probably check in with a seasoned frame guy like @gugie because he may have some sage advice to share in this case. Thing I would say is, if you can find someone who has a tool like the Park FT-4, in a matter of 60 seconds you'd know if the blades are actually out of whack, or if it's just the fork-ends, then massage the correct bits into place.

Based on everything I've read on this thread, I can tell you that an FFS-2 probably will not help you fix this. If what I read is correct, the problem is that the distance from the fork crown to the dropout is uneven from one side to another. 3alarmer is correct, filing down the dropout is one way to fix this, but, based on the picture, that would be a lot of filing. The FFS-2 will help give you leverage to bend the blades and thus center the dropout faces. Used in the other plane it can get the tips lined up, but it doesn't do much to change the distance from the fork crown to the dropout.

The best way to do it his to add or subtract curvature to the bottom of the blade, but you need a special mandrel for this, but even then, I know of no commercially available tool that I'd trust to do this, as you need to use the steerer for leverage - putting a good amount of force on the fork crown/blade interface. Maybe it's ok, maybe not, but I made my own fork reraker, which touches the fork near the dropout and up on the blade near the fork crown - keeping all the forces on the blade, and away from joints.

I've explained this in my Flickr album Fork repair - cold setting - advanced version for more details. More on the Babe Ruth of fork rerakers.

__________________

If someone tells you that you have enough bicycles and you don't need any more, stop talking to them. You don't need that kind of negativity in your life.

If someone tells you that you have enough bicycles and you don't need any more, stop talking to them. You don't need that kind of negativity in your life.

Last edited by gugie; 01-27-20 at 06:43 PM.

Likes For gugie:

#43

Senior Member

Has anyone tried using Park Tool Frame and Fork Straightener FFS-2? It seems to provide more control over bending process.

My LBS doesn't really have a fork jig so I can't really rely on them

I wouldn't feel comfortable straightening a fork without a jig personally.

This is for general straightening. For the specific problem of unequal length to the dropout ends, I concur with everything gugie just said ^^^. If the difference is only 2 mm or so, filing is a bit of a hack but might be prudent.

Last edited by Salamandrine; 01-27-20 at 07:18 PM.

#44

Full Member

Thread Starter

Join Date: Oct 2017

Location: Rotterdam, The Netherlands

Posts: 361

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 157 Post(s)

Liked 113 Times

in

64 Posts

Thanks for replies, everyone! A lot of useful information here.

It seems that I found a place where they will be happy to straighten the fork for me. Will report once it's done.

It seems that I found a place where they will be happy to straighten the fork for me. Will report once it's done.

#45

Full Member

Thread Starter

Join Date: Oct 2017

Location: Rotterdam, The Netherlands

Posts: 361

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 157 Post(s)

Liked 113 Times

in

64 Posts

Took the fork to a bike shop in Amsterdam yesterday. Ones the fork was clamped in the jig, it became clear that the blades were off laterally. After 5 minutes, it was straight again

Likes For alexnagui:

#48

Full Member

Thread Starter

Join Date: Oct 2017

Location: Rotterdam, The Netherlands

Posts: 361

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 157 Post(s)

Liked 113 Times

in

64 Posts

The white PR-10 is done!! It ended up being a mix of French, Japanese and Italian components but who cares. I hope it will be a nice bike to ride. I still have to take it to a shakedown ride but the weather doesn't look too promising.

Likes For alexnagui:

#49

Full Member

Thread Starter

Join Date: Oct 2017

Location: Rotterdam, The Netherlands

Posts: 361

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 157 Post(s)

Liked 113 Times

in

64 Posts

And the specs:

- Simplex SLJ SX660 rear derailleur

- Campagnolo NR front derailleur

- Simplex Retrofriction shifters

- Stronglight 49D with 53/42 rings

- Shimano 5sp 14-24 freewheel

- Shimano Dura Ace headset

- Shimano Dura Ace brakes with Shimano 600 brake levers

- MKS Road Vx quill pedals with toe clips and straps

- SR stem with Atax Philippe bars

- Campagnolo NR seatpost

- Ideale 39 saddle

- Normandy high flange hubs

- Tioga Proline S 700x26C tires

#50

Senior Member

Join Date: May 2011

Location: Seattle WA

Posts: 2,841

Bikes: 2009 Handsome Devil, 1987 Trek 520 Cirrus, 1978 Motobecane Grand Touring, 1987 Nishiki Cresta GT, 1989 Specialized Allez Former bikes; 1986 Miyata Trail Runner, 1979 Miyata 912, 2011 VO Rando, 1999 Cannondale R800, 1986 Schwinn Passage

Mentioned: 72 Post(s)

Tagged: 0 Thread(s)

Quoted: 796 Post(s)

Liked 522 Times

in

367 Posts

So for this bike you can start your day with French press, a bit of green tea for mid-day and a nice Moka Pot expresso to finish the day  Nicely done OP

Nicely done OP

Nicely done OP

Nicely done OP