Upgrading Campagnolo Zonda Front/Rear Hubs to USB

#1

Newbie

Thread Starter

Join Date: Apr 2022

Posts: 18

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 8 Post(s)

Liked 0 Times

in

0 Posts

Upgrading Campagnolo Zonda Front/Rear Hubs to USB

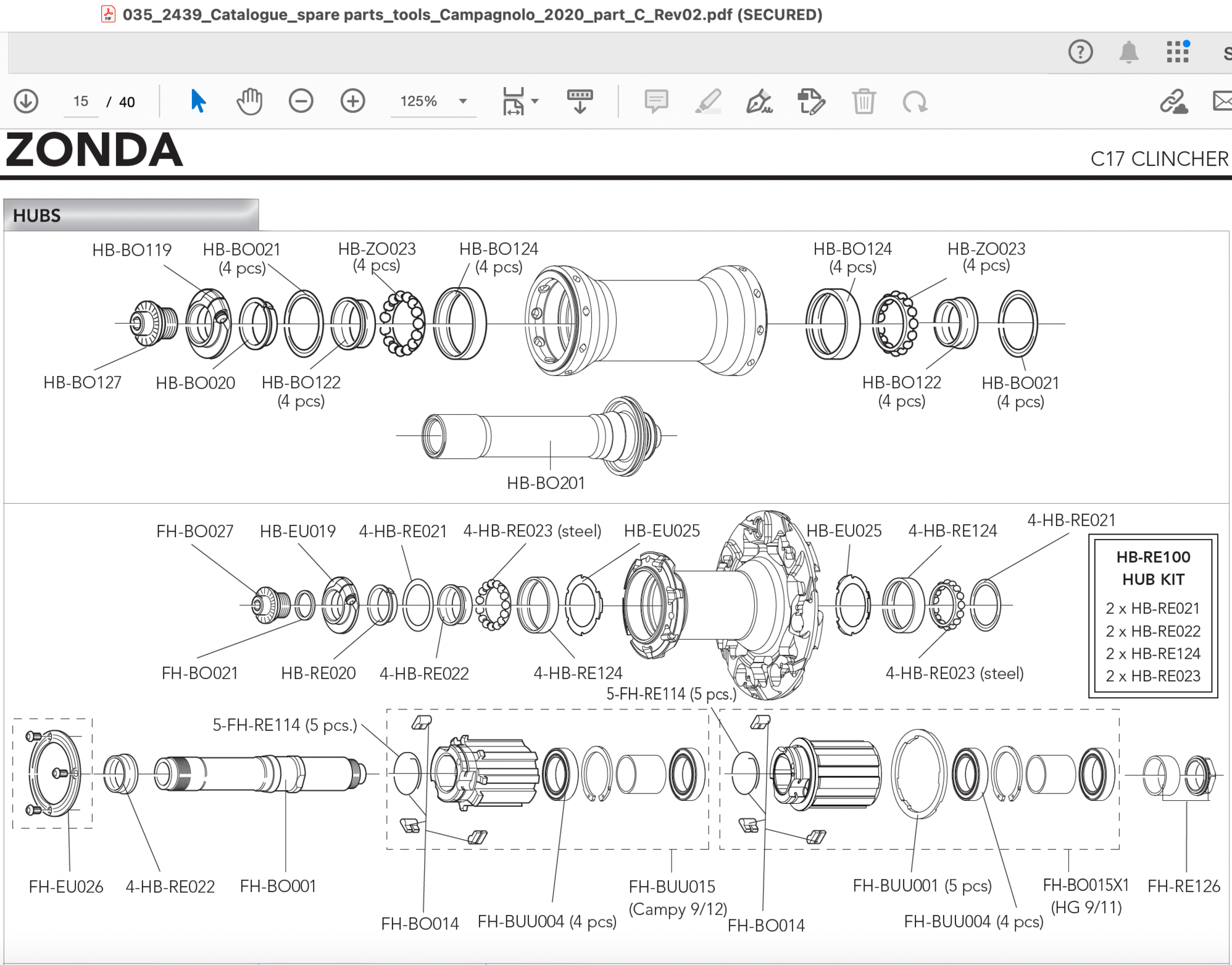

My Wheelset: Campagnolo Zonda C17 Clincher purchased in April 2022

Plan to replace the steel bearings in both hubs with USB ceramic bearings.

Was told there are dedicated kits for front and rear hubs. Each kit comes with a full set of caged bearings, seals, cones and cups.

And that both kits below will work on a Zonda C17 clincher with rim brakes. Can anyone confirm?

1. USB HB-SH100 (Rear Hub)

2. USB HB-SH200 (Front Hub)

Does anyone know the axle diameter (mm) of the Zonda front and rear hubs? Are both same or different?

Also, both the rear and front bearings in Zonda have 15 beads...is that correct?

Plan to replace the steel bearings in both hubs with USB ceramic bearings.

Was told there are dedicated kits for front and rear hubs. Each kit comes with a full set of caged bearings, seals, cones and cups.

And that both kits below will work on a Zonda C17 clincher with rim brakes. Can anyone confirm?

1. USB HB-SH100 (Rear Hub)

2. USB HB-SH200 (Front Hub)

Does anyone know the axle diameter (mm) of the Zonda front and rear hubs? Are both same or different?

Also, both the rear and front bearings in Zonda have 15 beads...is that correct?

Last edited by Fidler; 04-21-24 at 12:20 PM.

#2

Full Member

Yes, you can use those two kits to do the upgrade that you want to do.

A couple of things to be aware of:

1. Important - the front hub does not dismantle the same as older Campagnolo front hubs of similar - but older - design. Please see the video here:

https://support.campagnolo.com/UK/en...al_ultra_mille

2. When extracting the bearing surfaces, you will need two different tools for front and rear because the bearing surfaces are different diameters, 28mm in the front, 30mm in the back. The tools to use are from Cyclus, 720112 & 720882. There is an tool part number error on the Cyclus website.

3. When pressing the new bearing surfaces in, the press tool from Cyclus now includes drifts for both the 28mm OD surfaces, and the 30mm. Part numbers is Cyclus 720113.

I would strongly advise using the correct tools. Whilst there are "workarounds", the hub shells cannot be replaced as spare parts and having them repaired if bearing surface removal or refitting damages them is expensive and not always possible (at Velotech we have done this for shops who have tried to cut corners on the tools, several times). "Walking" the bearing surfaces out and knocking them back in with a hammer and drift both have a high potential to damage the hub shell.

A couple of things to be aware of:

1. Important - the front hub does not dismantle the same as older Campagnolo front hubs of similar - but older - design. Please see the video here:

https://support.campagnolo.com/UK/en...al_ultra_mille

2. When extracting the bearing surfaces, you will need two different tools for front and rear because the bearing surfaces are different diameters, 28mm in the front, 30mm in the back. The tools to use are from Cyclus, 720112 & 720882. There is an tool part number error on the Cyclus website.

3. When pressing the new bearing surfaces in, the press tool from Cyclus now includes drifts for both the 28mm OD surfaces, and the 30mm. Part numbers is Cyclus 720113.

I would strongly advise using the correct tools. Whilst there are "workarounds", the hub shells cannot be replaced as spare parts and having them repaired if bearing surface removal or refitting damages them is expensive and not always possible (at Velotech we have done this for shops who have tried to cut corners on the tools, several times). "Walking" the bearing surfaces out and knocking them back in with a hammer and drift both have a high potential to damage the hub shell.

Likes For gfk_velo:

#3

Newbie

Thread Starter

Join Date: Apr 2022

Posts: 18

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 8 Post(s)

Liked 0 Times

in

0 Posts

gfk_velo your help and professional expertise is greatly appreciated. Thanks!

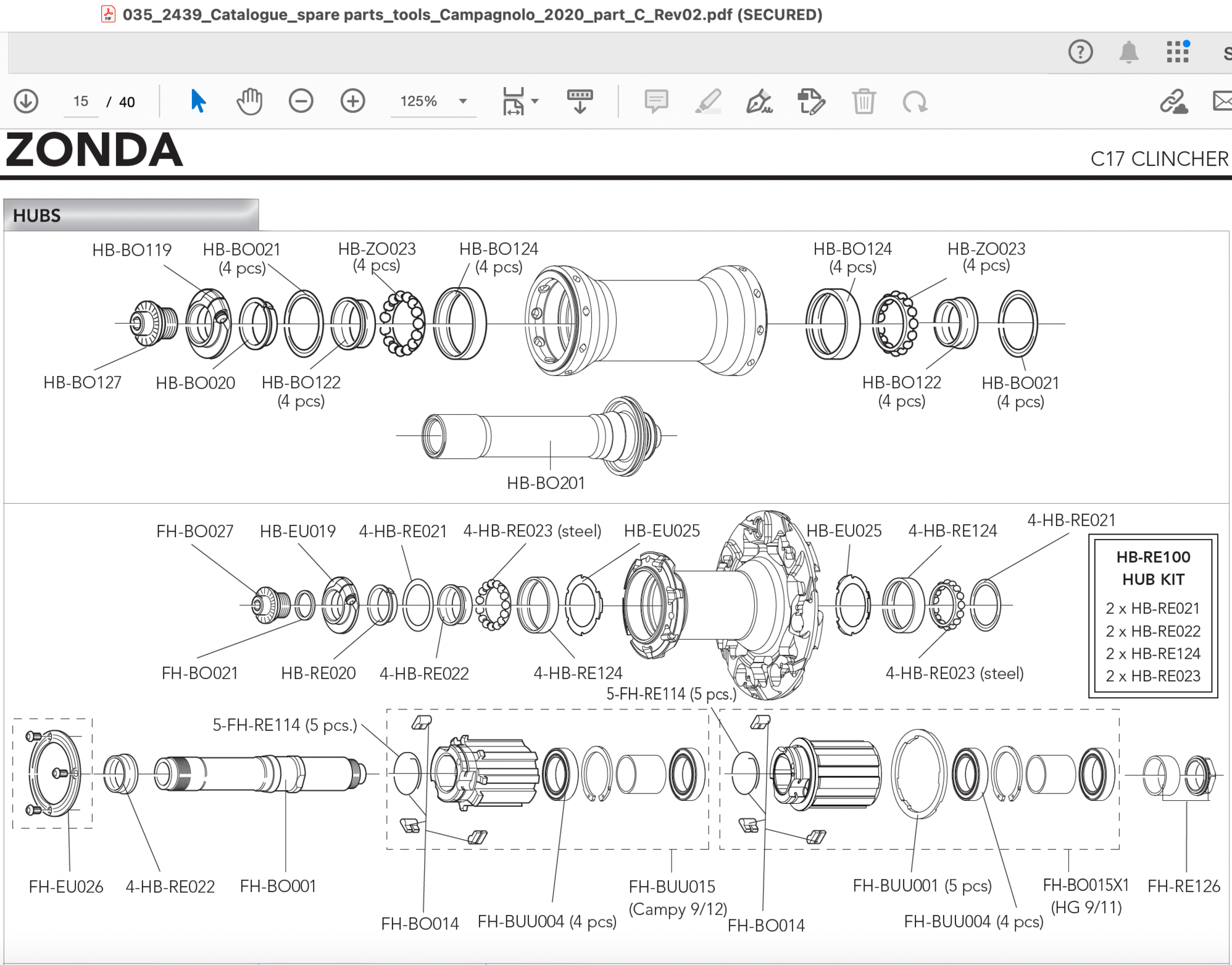

If I wanted to upgrade to the CULT bearings, would these be the Kits I should purchase?

They will be 100% compatible?

These are still for the Zonda C17 Clincher from 2022.

1. HB-HY100 (Rear Hub) – CULT

2. HB-BO100 (Front Hub) – CULT

If I wanted to upgrade to the CULT bearings, would these be the Kits I should purchase?

They will be 100% compatible?

These are still for the Zonda C17 Clincher from 2022.

1. HB-HY100 (Rear Hub) – CULT

2. HB-BO100 (Front Hub) – CULT

Last edited by Fidler; 04-23-24 at 12:07 PM.

#5

Newbie

Thread Starter

Join Date: Apr 2022

Posts: 18

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 8 Post(s)

Liked 0 Times

in

0 Posts

Update:

Replacing rear hub bearings to CULT was a breeze.

Ran into problems with dis-assembling front wheel hub.

Only one side opens up freely...the other side simply won't budge. Googled extensively to research.

Apparently, some have destroyed their front axle to get it out by using brute force.

There's a mechanic somewhere in Thailand who actually made his own jig to get around the problem.

Perhaps this may help a few who have run into issues opening up the front hub. Good tutorial.

I may have to find a machine shop to construct a jig as shown.

gfk_velo any idea what material it should be made from? Steel or Aluminium?

Replacing rear hub bearings to CULT was a breeze.

Ran into problems with dis-assembling front wheel hub.

Only one side opens up freely...the other side simply won't budge. Googled extensively to research.

Apparently, some have destroyed their front axle to get it out by using brute force.

There's a mechanic somewhere in Thailand who actually made his own jig to get around the problem.

Perhaps this may help a few who have run into issues opening up the front hub. Good tutorial.

I may have to find a machine shop to construct a jig as shown.

gfk_velo any idea what material it should be made from? Steel or Aluminium?

Last edited by Fidler; 05-16-24 at 01:48 AM.

#6

Full Member

Update:

Replacing rear hub bearings to CULT was a breeze.

Ran into problems with dis-assembling front wheel hub.

Only one side opens up freely...the other side simply won't budge. Googled extensively to research.

Apparently, some have destroyed their front axle to get it out by using brute force.

There's a mechanic somewhere in Thailand who actually made his own jig to get around the problem.

Perhaps this may help a few who have run into issues opening up the front hub. Good tutorial.

I may have to find a machine shop to construct a jig as shown.

gfk_velo any idea what material it should be made from? Steel or Aluminium?

https://youtu.be/GrUJCeqHWQA?si=J2Vw2HuwJTvRLnio

Replacing rear hub bearings to CULT was a breeze.

Ran into problems with dis-assembling front wheel hub.

Only one side opens up freely...the other side simply won't budge. Googled extensively to research.

Apparently, some have destroyed their front axle to get it out by using brute force.

There's a mechanic somewhere in Thailand who actually made his own jig to get around the problem.

Perhaps this may help a few who have run into issues opening up the front hub. Good tutorial.

I may have to find a machine shop to construct a jig as shown.

gfk_velo any idea what material it should be made from? Steel or Aluminium?

https://youtu.be/GrUJCeqHWQA?si=J2Vw2HuwJTvRLnio

I'll drop a post later with full notes!

Last edited by gfk_velo; 05-20-24 at 02:12 PM.

#7

Full Member

Update:

Replacing rear hub bearings to CULT was a breeze.

Ran into problems with dis-assembling front wheel hub.

Only one side opens up freely...the other side simply won't budge. Googled extensively to research.

Apparently, some have destroyed their front axle to get it out by using brute force.

There's a mechanic somewhere in Thailand who actually made his own jig to get around the problem.

Perhaps this may help a few who have run into issues opening up the front hub. Good tutorial.

I may have to find a machine shop to construct a jig as shown.

gfk_velo any idea what material it should be made from? Steel or Aluminium?

https://youtu.be/GrUJCeqHWQA?si=J2Vw2HuwJTvRLnio

Replacing rear hub bearings to CULT was a breeze.

Ran into problems with dis-assembling front wheel hub.

Only one side opens up freely...the other side simply won't budge. Googled extensively to research.

Apparently, some have destroyed their front axle to get it out by using brute force.

There's a mechanic somewhere in Thailand who actually made his own jig to get around the problem.

Perhaps this may help a few who have run into issues opening up the front hub. Good tutorial.

I may have to find a machine shop to construct a jig as shown.

gfk_velo any idea what material it should be made from? Steel or Aluminium?

https://youtu.be/GrUJCeqHWQA?si=J2Vw2HuwJTvRLnio

This is only a problem if the person carrying out the maintenance doesn't follow the instructions that Campagnolo provide for these wheels.

There is normally a Campagnolo video on their website (that part of it is down whilst they are updating the relevant section at present - 20.05.24) which explains - and which I signposted right at the top of the thread - however, in it's absence:

1. If you haven't already used a 5mm allen key in both ends of the axle and tried turning them counter to one another.

First - don't, as such. The newer hubs (which have two spanner flats just inboard of the axle end on the non-adjuster side), don't open like the old ones.

I noted that the top of this thread where I also suggested the correct tool to use.

Instead ...

1.1 Release the preload collar pinch bolt.

1.2 Fit a 14mm spanner max 6mm "thick" onto the flats, insert a 5mm allen key aligned with the spanner (so that you can hold both together) into the cap on the side with the spanner flat (so both tool are on the same side of the hub). This is not always necessary so long as you have done step 1.1 but I would very strongly advise it.

1.3 holding the two tools together, *then* insert a 5mm spanner ito the preload cap side and turn it anti-clockwise so that the torque on the other side is being taken up by both the 14mm spanner and the allen key together.

1.4 Unscrew the cap from the preload adjuster side - you can then unscrew the preload adjuster.

2. If you have already accidentally unscrewed the cap from the side with 2 spanner flats by trying to open the hub the "old" way.

2.1 Don't be tempted to try and use a spanner on the spanner flats straight away - the axle is too thin to support the load and you will damage the axle. Instead, apply a small amout of Loctite 222 or Wurth Blue threadlocker to the end cap and screw it back in. Hold the axle still with a 14mm spanner no more than 6mm "thick", and once the cap is fully in and finger tight, insert a 5mm key into the cap and nip it hard into place, holding the axle still with the spanner (the spanner flats are now supported because the cap is screwed into the material inside them). We suggest a torque of 8nm.

2.2 allow the Loctite / Threadlocker to cure - see Loctite's / Wurth's handling instructions.

2.3 follow the instructions above, 1.1 - 1.4, once the Loctite / Threadlocker curing process has completed.

It is very important that the pinchbolt on the preload adjuster is undone - although the torque is comparatively low, the preload adjuster compresses the axle enough that it will hold the cap on that side of the axle, preventing it from unscrewing easily, so causing a simple insertion of two 5mm allen keys to undo the "non-adjuster" side cap. This is a consequence of having changed some of the key dimensions as well as the design of the axle, to reduce the bearing size & the overall weight of post 2017 model year QR front wheels.