I want a robust rear wheel for touring

#51

Senior Member

Join Date: Mar 2010

Posts: 1,659

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 1248 Post(s)

Liked 1,323 Times

in

674 Posts

The relevant information would be what is happening currently in the sport not stories from the past. Gravel racing and adventure riding is extremely demanding on wheel sets and by a vast majority it is being performed on wheels with 28 or 24 spokes. Last of your worries is spoke breakage on tour.

Also replacing a spoke is ridiculously simple and a minor issue. Probably quicker to repair than a flat tire.

Also replacing a spoke is ridiculously simple and a minor issue. Probably quicker to repair than a flat tire.

#52

Junior Member

Join Date: Sep 2018

Posts: 78

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 24 Post(s)

Likes: 0

Liked 23 Times

in

18 Posts

Never had a wheel fail before but last year I was beginning to stew about the same thing and one day when i was about 40 km from home I hear PING PING. No bike shops anywhere near me. I made it until a block from my house and then PING, and my wheel potato chipped. I was lucky to get home.

I had to get an off the shelf wheel because i was leaving on a tour a few days later and my local shop recommended a Wheel Shop wheel with 36 hole alexrims dm-18. They look very robust and I bought another rim to have built up on a dynamo hub. Shop guy told me they were designed for mountain bikes and they look it. If you have a shop near by with a competent mechanic you can have them test the tension and adjust if necessary.

of course, if you want to really put it out of your mind, it seems the velocity rims are the cats whiskers. Crazy expensive in Canada so I haven't used them.

With touring, I think there is something to be said for paying for peace of mind. In a small number of relatively short tours, I've had failures I've never experienced in over 30 years of non touring biking.

I had to get an off the shelf wheel because i was leaving on a tour a few days later and my local shop recommended a Wheel Shop wheel with 36 hole alexrims dm-18. They look very robust and I bought another rim to have built up on a dynamo hub. Shop guy told me they were designed for mountain bikes and they look it. If you have a shop near by with a competent mechanic you can have them test the tension and adjust if necessary.

of course, if you want to really put it out of your mind, it seems the velocity rims are the cats whiskers. Crazy expensive in Canada so I haven't used them.

With touring, I think there is something to be said for paying for peace of mind. In a small number of relatively short tours, I've had failures I've never experienced in over 30 years of non touring biking.

#53

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,366

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,220 Times

in

2,367 Posts

I know you don't believe in the rim vertical stiffness being a factor in wheel durability in terms of spoke breakages. However even though spokes have advanced in recent years, the larger advancements have been made in the rim department. Especially high profile carbon rims combine several factors which allow for a wheel to remain intact with lower spoke counts.

1) Tighter spoke spacing on the rim. As we know, the more spread out the spokes are, the larger the responsibility of a single spoke to handle riding loads. With high profile rims the spacing narrows as the radius of the rim edge gets smaller.

2) Shorter spokes. A shorter spoke is typically a stronger one as long as the bracing angles aren't excessive.

3) better bracing angles. As the rim spoke bed gets closer to the hub, especially the drive side spoke bracing angles get less vertical and thus help with side loading situations such as cornering or rough roads.

4) Exponentially less rim deformation. A rim will deform once load is applied, either from the top of the rim or the bottom. Personally I suspect the main deformation happens at the top as the hub is pushed down. Some hypothesize that the deformation happens at the bottom where the groung is pushing against the rim. I however don't think that actually has a significant effect as there's a pneumatic tire between the rim and the ground. I don't believe the tire actually does a lot of pushing against a single point but rather spreads out the load. But in any case the rim does deform the cause a drop in tension at the bottom spokes. If you add to the rim height the geometry of the rim fights against that deformation. In tubes geometry trumps wall thickness.

If we compare a 26" wheel with a 20mm rim height and a 28" wheel with a 50mm rim height (common carbon rim height), we can see that the two wheels have almost the same spoke length AND spoke spacing. So that in turn means that purely from a spoke spacing, length and bracing angle point of view the wheels should be as durable. However the 28" wheel has the added advantage of a massively stiffer rim meaning less deformation.

If both wheels have 28 spokes, they equal the spoke spacing of a 28" wheel with 32 spokes, which is actually adequate for touring these days.

It's pretty safe to say then, that a modern high profile carbon wheel can be as strong or even stronger than a 26" touring wheel AND as strong or stronger than a 28" touring wheel with a higher spoke count.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#54

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,366

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,220 Times

in

2,367 Posts

The relevant information would be what is happening currently in the sport not stories from the past. Gravel racing and adventure riding is extremely demanding on wheel sets and by a vast majority it is being performed on wheels with 28 or 24 spokes. Last of your worries is spoke breakage on tour.

What someone does or doesn’t in a racing situation has little impact on the rest of us. Someone who is racing isn’t making a bike last more than a season at best. Spoke breakage on tour is a thing. It happens and, as I said above, it is only behind flats in terms of frequency. It’s something that comes up over and over and over again in these forums. Saying it “doesn’t happen” is simply not accepting reality.

Also replacing a spoke is ridiculously simple and a minor issue. Probably quicker to repair than a flat tire.

Of course, the job is easier if you design and build to avoid the problem to begin with.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Last edited by cyccommute; 07-14-23 at 11:05 PM.

#55

Senior Member

Join Date: Mar 2010

Posts: 1,659

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 1248 Post(s)

Liked 1,323 Times

in

674 Posts

There is nothing but “stories in the past”. We can’t see into the future. People go on their (and others) experiences so that they can learn how to avoid the pitfalls. That’s what the whole “failing to learn from the past…yada, yada, yada” is all about. You can reinvent the wheel all the time or you can work on what other people have experience. Reinventing the wheel is just too difficult and gets you nowhere.

What someone does or doesn’t in a racing situation has little impact on the rest of us. Someone who is racing isn’t making a bike last more than a season at best. Spoke breakage on tour is a thing. It happens and, as I said above, it is only behind flats in terms of frequency. It’s something that comes up over and over and over again in these forums. Saying it “doesn’t happen” is simply not accepting reality.

At home, in a shop, yes. On the side of the road, no. It has never been simple nor minor nor, for that matter, quicker than repairing a flat tire. Thankfully, the days of freewheels are long gone but just getting a cassette off on the side of the road is a difficult task. Tools that are small enough to carry are difficult to use. No one really wants to carry the tools that are large enough to make the job easier. I’m certainly not carrying a chain whip, a lock ring tool and a large adjustable wrench on tour.

Of course, the job is easier if you design and build to avoid the problem to begin with.

What someone does or doesn’t in a racing situation has little impact on the rest of us. Someone who is racing isn’t making a bike last more than a season at best. Spoke breakage on tour is a thing. It happens and, as I said above, it is only behind flats in terms of frequency. It’s something that comes up over and over and over again in these forums. Saying it “doesn’t happen” is simply not accepting reality.

At home, in a shop, yes. On the side of the road, no. It has never been simple nor minor nor, for that matter, quicker than repairing a flat tire. Thankfully, the days of freewheels are long gone but just getting a cassette off on the side of the road is a difficult task. Tools that are small enough to carry are difficult to use. No one really wants to carry the tools that are large enough to make the job easier. I’m certainly not carrying a chain whip, a lock ring tool and a large adjustable wrench on tour.

Of course, the job is easier if you design and build to avoid the problem to begin with.

No tools needed I use DT Swiss hubs exclusively for touring and adventure riding. Cassette just pulls off.

#56

Senior Member

There's also the problem of having very little supply for actual touring components. Of the big three only Shimano offers touring labeled components and their opinion seems to be that touring is a flat bar activity. So it's no wonder that the smaller carbon rim manufacturers (or bigger ones) aren't jumping at the opportunity to sell a handful of rims to a few tourists willing to try them out

The price isn't right either. You can easily spend 5k€ to modestly deck out a touring rig and if you want all the bells and whistles 10k€ isn't an impossible proposition. Adding to that 400€ in rims when you can get indestructible Rydes for 20€ a pop isn't a good value.

None of the above doesn't mean carbon wouldn't be a better material though. You can get higher profile rims with higher spoke tension tolerances and in some cases custom spoke drillings. But in touring you're only really buying durability as the aerodynamics or weight savings don't really matter and you can get durability for cheaper.

Something you also get in higher spoke count wheels. Even with high profile rims, the spacing for a 24 count wheel is going to be wider than the spacing for a 36 spoke count wheel of lower profile. It would be wider than the spacing for a 32 spoke count wheel which is still somewhat questionable as a wheel for a loaded touring bike.

Yes. And that is one of the failings of a 622mm rim. We’d be better off with 559mm rims but that ship has sailed. And, again, more shorter spokes are better than fewer shorter spokes. Less stress on the individual spoke and on the rim.

But, again, more spokes under the same bracing angles would lower the stress and fatigue on the spokes.

Rim deformation happens and it is measurable. The tire actually reduces spoke tension when it is inflated by a substantial amount. A taller rim resists deformation somewhat but I would say it is only minimal and, sounding like a broken record here, more spokes, less tension change. Less tension change, less spoke fatigue. Less spoke fatigue, less likelihood of broken spokes.

No, we can’t “see” that the two wheels have the same spoke length and spacing. You’ve only written that. Back up your claim with measurements and something we can really “see”.

The question raised is about using 32 spokes for touring and whether it is “adequate”. 32 spoke isn’t necessarily adequate. People seem to think that something has fundamentally changed in touring (and bike riding in general) but spoke breakage is still the second most common type of equipment failure in touring (and general bicycling) behind flats.

If they were used there. Not all that many people are using carbon rims in general.

#57

Senior Member

Never had a wheel fail before but last year I was beginning to stew about the same thing and one day when i was about 40 km from home I hear PING PING. No bike shops anywhere near me. I made it until a block from my house and then PING, and my wheel potato chipped. I was lucky to get home.

I had to get an off the shelf wheel because i was leaving on a tour a few days later and my local shop recommended a Wheel Shop wheel with 36 hole alexrims dm-18. They look very robust and I bought another rim to have built up on a dynamo hub. Shop guy told me they were designed for mountain bikes and they look it. If you have a shop near by with a competent mechanic you can have them test the tension and adjust if necessary.

of course, if you want to really put it out of your mind, it seems the velocity rims are the cats whiskers. Crazy expensive in Canada so I haven't used them.

With touring, I think there is something to be said for paying for peace of mind. In a small number of relatively short tours, I've had failures I've never experienced in over 30 years of non touring biking.

I had to get an off the shelf wheel because i was leaving on a tour a few days later and my local shop recommended a Wheel Shop wheel with 36 hole alexrims dm-18. They look very robust and I bought another rim to have built up on a dynamo hub. Shop guy told me they were designed for mountain bikes and they look it. If you have a shop near by with a competent mechanic you can have them test the tension and adjust if necessary.

of course, if you want to really put it out of your mind, it seems the velocity rims are the cats whiskers. Crazy expensive in Canada so I haven't used them.

With touring, I think there is something to be said for paying for peace of mind. In a small number of relatively short tours, I've had failures I've never experienced in over 30 years of non touring biking.

Getting ones wheels checked for spoke tension by an experienced mechanic and keeping the wheel in good shape spoke tension wise generally means that wheels will stay rather true and robust for years of use, and all of us with this experience supports this claim.

Touring is always going to put more weight and stress on wheels, so even more reason to make sure that your wheels are well taken care of to start with, but a wheel that is ok for riding unloaded will be stressed more with panniers on, and this certainly sounds like what you've experienced.

Likes For djb:

#58

Junior Member

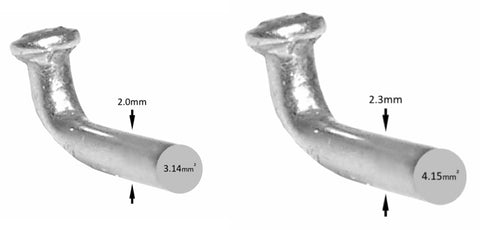

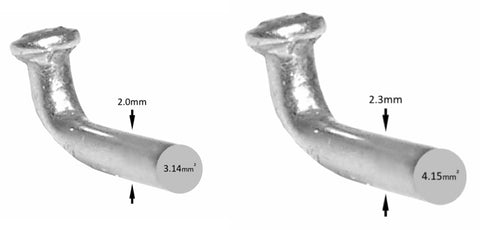

Having a tendency toward heavier loading, and having had experience of multiple pinged and loose spokes (once so bad that I feared and avoided high speed descent), I now spec 2.2mm spokes instead of 2mm spokes on my 32 spoke rear wheels. It seems 2.2mm spokes are generally compatible with rims/hubs fitted with 2mm spokes.

#59

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,366

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,220 Times

in

2,367 Posts

Point being if the wheels can handle racing under extreme conditions it can definitely handle my usage. The only spokes I have ever broken have been on legacy type 32 and 36 spoke wheels. Modern high tension wheels are way more reliable and have virtually eliminated spoke breakage.

How old were the legacy 32 and 36 spoke wheels that you broke spokes on? In my experience spoke breakage takes at least a little bit of time to manifest. It’s not like spokes break on the first ride after a build.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#60

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,366

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,220 Times

in

2,367 Posts

admittedly not many. Tourists seem to be a retro grouchy bunch (I know I beginning to be) so new fangled stuff like carbon rims aren't embraced that readily and thus there isn't demand.

There's also the problem of having very little supply for actual touring components. Of the big three only Shimano offers touring labeled components and their opinion seems to be that touring is a flat bar activity. So it's no wonder that the smaller carbon rim manufacturers (or bigger ones) aren't jumping at the opportunity to sell a handful of rims to a few tourists willing to try them out

The price isn't right either. You can easily spend 5k€ to modestly deck out a touring rig and if you want all the bells and whistles 10k€ isn't an impossible proposition. Adding to that 400€ in rims when you can get indestructible Rydes for 20€ a pop isn't a good value.

None of the above doesn't mean carbon wouldn't be a better material though. You can get higher profile rims with higher spoke tension tolerances and in some cases custom spoke drillings. But in touring you're only really buying durability as the aerodynamics or weight savings don't really matter and you can get durability for cheaper.

There's also the problem of having very little supply for actual touring components. Of the big three only Shimano offers touring labeled components and their opinion seems to be that touring is a flat bar activity. So it's no wonder that the smaller carbon rim manufacturers (or bigger ones) aren't jumping at the opportunity to sell a handful of rims to a few tourists willing to try them out

The price isn't right either. You can easily spend 5k€ to modestly deck out a touring rig and if you want all the bells and whistles 10k€ isn't an impossible proposition. Adding to that 400€ in rims when you can get indestructible Rydes for 20€ a pop isn't a good value.

None of the above doesn't mean carbon wouldn't be a better material though. You can get higher profile rims with higher spoke tension tolerances and in some cases custom spoke drillings. But in touring you're only really buying durability as the aerodynamics or weight savings don't really matter and you can get durability for cheaper.

Yet with 28 spokes you already get the same spacing as 32 spoke lower profile. And with 32 spokes you get same spacing as with 36 etc.

Well, kinda. 559mm would mean some ridiculously long head tubes for the likes of me so I actually prefer the 622mm size. But there should be more proportional wheel sizing as smaller people would fare better with smaller wheels.

I will most certainly agree that smaller wheels would be advantageous to smaller people. 40+ years of trying to find bikes that fit the pixie in my life has somewhat radicalized me. But that is a different topic.

True, but at some point you're just adding weight without adding strength. 48 spokes or even 40 these days with triple butted spokes and stiff rims is overkill.

The strength of the wheel comes from spokes which is why we have high spoke count wheels for high load applications. Granted going to a 48 spoke wheel and triple butted spokes would not be necessary except in a loaded tandem with two large people on it. I’m not necessarily advocating for that number of spokes. Actually, a 32 spoke wheel with triple butted spokes would be as strong as (at least) a 36 spoke wheel with straight or double butted spokes.

And the addition of triple butted spokes don’t diminish the strength of the wheel nor do that add that much weight. Ric Hjertberg states in his “Cracking the Code” post that using triple butted over double butted spokes adds 7g per wheel. Not per spoke, per wheel! There’s no penalty for going to a triple butted spoke.

Additionally, the spoke fits into the hub better. Hubs are drilled to 2.6mm so that the threads that are rolled onto the spoke can pass through the spoke hole. When using a 2.0mm spoke, that leaves 0.6mm of slop in the fit of the spoke into the hub. When the spoke detensions, the spoke can move around in the hole which adds fatigue to the head. Granted, the movement isn’t much, but it is there. With a 2.3mm spoke, there is less room to move which puts less stress on an already stronger head. A stronger spoke makes for a longer lasting wheel, especially under demanding conditions.

I'm going to have disagree here. A 20mm rim and 50mm rim are going to be night and day in how easily they deform. Tube shape has a massive effect on the tube stiffness, which is why we can easily make stiffer aluminum frames than steel frames even though steel is three times stiffer as a material. Aluminum is easier to shape into massive tube shapes without adding excessive weight. Kinda the same with aluminum and carbon rims.

It really is if the wheel is built properly with the proper components. My front wheel is only 32 spoke, but it handles most the braking. On our last tour it handled loads of around 400lbs coming down gravel roads without any difficulty

By the way, I really wish people would stop with the “properly built” thing. Everyone seems to think that wheels are thrown together willy hilly and that anyone who advocates for using better components is an incompetent builder. How about we start with the assumption that the wheels are build “properly”. Even OEM wheels on all but the BSOs you find at HellMart are “properly built” from the stand point of being tensioned and laced properly. Even machine built wheels can provide years of service under “average” conditions with little to no maintenance. Touring falls outside of that “average” condition and requires a little more consideration.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#61

Junior Member

Not sure I agree with the suggestion that broken spokes are no longer a problem. Granted I'm heavier than average at 105kg but I have broken a couple of spokes on hand built wheels in the past year. Those were on LX17 rims, not super light.

A regular on CTC forums said this

"

I see broken wheels every day; most of them are rear wheels and the usual reason they have broken is largely because of the dish/narrow flange spacing. We live in a crazy world where front wheels almost invariably see smaller service loads and yet are often built more strongly than rear wheels. It is a doubly crazy world because folk that happen not to break wheels say things like "there is no widespread problem" when it is perfectly evident to everyone else there is exactly that."

https://forum.cyclinguk.org/viewtopi...eels+strongest

As it happens my touring wheels don't break spokes because I chose seriously tough and heavy rims Ryde Sputnik.745g

Hand built at Spa Cycles. Very cheap. Unlikely to let you down.

A regular on CTC forums said this

"

I see broken wheels every day; most of them are rear wheels and the usual reason they have broken is largely because of the dish/narrow flange spacing. We live in a crazy world where front wheels almost invariably see smaller service loads and yet are often built more strongly than rear wheels. It is a doubly crazy world because folk that happen not to break wheels say things like "there is no widespread problem" when it is perfectly evident to everyone else there is exactly that."

https://forum.cyclinguk.org/viewtopi...eels+strongest

As it happens my touring wheels don't break spokes because I chose seriously tough and heavy rims Ryde Sputnik.745g

Hand built at Spa Cycles. Very cheap. Unlikely to let you down.

Last edited by irc; 07-16-23 at 10:29 AM. Reason: update

Likes For irc:

#62

Senior Member

Join Date: Aug 2010

Location: Madison, WI

Posts: 11,211

Bikes: 1961 Ideor, 1966 Perfekt 3 Speed AB Hub, 1994 Bridgestone MB-6, 2006 Airnimal Joey, 2009 Thorn Sherpa, 2013 Thorn Nomad MkII, 2015 VO Pass Hunter, 2017 Lynskey Backroad, 2017 Raleigh Gran Prix, 1980s Bianchi Mixte on a trainer. Others are now gone.

Mentioned: 48 Post(s)

Tagged: 0 Thread(s)

Quoted: 3461 Post(s)

Liked 1,467 Times

in

1,144 Posts

...

When I built up my light touring bike (Lynskey Backroad) in 2017, I wanted 36 spoke front and rear. But the dynohub I wanted was out of stock on 36 spoke, was on sale in 32. I decided that front wheels carry a lot less weight so I went with 32 in front and 36 in back. I am happy with that decision. Decades ago, a lot of utility bikes were built with more spokes on rear wheels than the front, so there is precedent. And I do not carry a lot on that bike, I have heavier duty bikes for that.

...

When I built up my light touring bike (Lynskey Backroad) in 2017, I wanted 36 spoke front and rear. But the dynohub I wanted was out of stock on 36 spoke, was on sale in 32. I decided that front wheels carry a lot less weight so I went with 32 in front and 36 in back. I am happy with that decision. Decades ago, a lot of utility bikes were built with more spokes on rear wheels than the front, so there is precedent. And I do not carry a lot on that bike, I have heavier duty bikes for that.

...

And since rear wheels on derailleur bikes are dished, drive side spokes are tensioned greater than non-drive side, that makes the situation worse. That excludes tandems and Co-Motion Americano model. And there is a Velocity rim that can solve this, but that is a lighter duty rim, for my light touring bike I used Velocity Dyads that are more robust.

#63

Banned

There is a wide range of spokes available and they vary in strength. Often a tempered spoke is going to be more brittle and can break at the section at the spoke hole in the hub. Best to use the best spokes you can buy when lacing the wheels. 3-Cross are strong but 4-cross lacing is even stronger although it requires longer spokes. A friend who weighs about 240 lbs was frequently breaking spokes but I convinced him to go to 4-cross lacing and he never broke another spoke.

On long tours I always take two extra spokes that I tape to the pump or top tube of the frame and carried a spoke wrench in my kit. If the rim is not damaged when the spoke breaks the fix to put in a new spoke and retrue the wheel is a 1-hour repair at most.

My tour riding has mostly been with 23mm sewup tires but with bikes now able to support tires up to 38mm wide there is greater shock dissipation and less likelihood of a broken spoke with wide clincher tires that have a much greater volume and can support a load at a lower tire PSI.

Road bikes can be rated by their manufacturers for a total load of 275 lbs up to 330 lbs and I suspect that the difference is in the wheels and tires provided. A 250 lb rider with a tour load of 25 lbs is far more likely to have a spoke fail than a 150 lb rider with a 15 lb tour load. That 165 lb total load is what my bike had to manage and the rest was up to me to look ahead and avoid pot holes and grates and other obstacles on the road.

On long tours I always take two extra spokes that I tape to the pump or top tube of the frame and carried a spoke wrench in my kit. If the rim is not damaged when the spoke breaks the fix to put in a new spoke and retrue the wheel is a 1-hour repair at most.

My tour riding has mostly been with 23mm sewup tires but with bikes now able to support tires up to 38mm wide there is greater shock dissipation and less likelihood of a broken spoke with wide clincher tires that have a much greater volume and can support a load at a lower tire PSI.

Road bikes can be rated by their manufacturers for a total load of 275 lbs up to 330 lbs and I suspect that the difference is in the wheels and tires provided. A 250 lb rider with a tour load of 25 lbs is far more likely to have a spoke fail than a 150 lb rider with a 15 lb tour load. That 165 lb total load is what my bike had to manage and the rest was up to me to look ahead and avoid pot holes and grates and other obstacles on the road.

Last edited by Calsun; 07-16-23 at 12:52 PM.

#64

Junior Member

Join Date: Sep 2018

Posts: 78

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 24 Post(s)

Likes: 0

Liked 23 Times

in

18 Posts

the thing is this story will scare the beejesus out of the poor guy who is fretting about his wheels here, but lets be honest, your wheel was not in good shape spoke tension wise if you broke multiple spokes and the thing tacoed. It must have been so unbalanced spoke tension wise or whatever that it was quite the sick puppy.

Getting ones wheels checked for spoke tension by an experienced mechanic and keeping the wheel in good shape spoke tension wise generally means that wheels will stay rather true and robust for years of use, and all of us with this experience supports this claim.

Touring is always going to put more weight and stress on wheels, so even more reason to make sure that your wheels are well taken care of to start with, but a wheel that is ok for riding unloaded will be stressed more with panniers on, and this certainly sounds like what you've experienced.

Getting ones wheels checked for spoke tension by an experienced mechanic and keeping the wheel in good shape spoke tension wise generally means that wheels will stay rather true and robust for years of use, and all of us with this experience supports this claim.

Touring is always going to put more weight and stress on wheels, so even more reason to make sure that your wheels are well taken care of to start with, but a wheel that is ok for riding unloaded will be stressed more with panniers on, and this certainly sounds like what you've experienced.

After several unexpected and never before experienced failures I’ve come to the conclusion that it makes more sense to configure the bike to reduce the probability of failure. I’d much rather take on extra weight and have the wheel operate within its tolerances.

#65

Senior Member

You are most likely correct about the state of the wheel. I had never had it looked at or even done the squeeze test on the spokes. Lesson learned.

After several unexpected and never before experienced failures I’ve come to the conclusion that it makes more sense to configure the bike to reduce the probability of failure. I’d much rather take on extra weight and have the wheel operate within its tolerances.

After several unexpected and never before experienced failures I’ve come to the conclusion that it makes more sense to configure the bike to reduce the probability of failure. I’d much rather take on extra weight and have the wheel operate within its tolerances.

#66

Senior Member

Join Date: Apr 2013

Posts: 1,173

Bikes: Surly Disk Trucker, 2014 w/Brooks Flyer Special saddle, Tubus racks - Duo front/Logo Evo rear, 2019 Dahon Mariner D8, Both bikes share Ortlieb Packer Plus series panniers, Garmin Edge 1000

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 405 Post(s)

Liked 115 Times

in

99 Posts

I have been on three tours with my 32-spoke rear wheel (on a Windsor Tourist) but can't stop worrying about it when riding fully loaded. I'm concerned about breaking a spoke. I think I would like to upgrade to a more robust touring-specific rear wheel (I guess with 36 spokes) but am not sure how to go about ordering one. The bike is 700 x 38 with disc brakes. Any recommendations about how to find and order a suitable wheel?

I will 2nd the point of "spoke tension" being paramount in wheel strength. I would say staying on the lighter end of the spectrum of spoke tension is best. That way you have some flex when you hit bumps. Yes, a flexing rim is not going to stay as true. However, on a tour I would much rather have some lack of true'ness in the wheels not spinning perfectly than to have banjo-string tight spokes popping on bumps.

To date I have never broken a spoke while riding. The only broken spokes I have had were when I got my bike jammed under the side of my truck in a tight garage with no way to get out but driving forward again which meant running over the front wheel. Aside from that incident, I have not had any broken spokes on my regular bikes. Ever.

That is not to say a spoke can't break.

When I was on my Ohio to Erie trip a few years ago I don't think I had any spare spokes with me, actually. I do need to change that and get some. When I rebuilt my front wheel I got way more spokes than I needed. Seems to me they came in a box of 100? So I have plenty of spares for that. However, they are not the same spokes as either side of my rear wheel. So that means I have 3 sizes of spokes I would need to match.

As others have suggested - if you want to change things up go to a 36 spoke wheel and call it good. Keep the spoke tension easy and you should be OK. The spokes at the top are actually what are stressed the most - spokes have next to no compressive strength, but are very strong in tension. With the equal tension around the wheel that is what keeps it both round and strong - the forces are transferred around the rim and distributed to many spokes.

On my Ohio to Erie trip I easily had 200lbs of gear at times. You can see pictures in the following thread.

https://www.bikeforums.net/touring/1...-rain-row.html

There are also 2 video links in the thread below that I did. The 1st video is an outline, mostly, of the gear. You can check the timestamps in the description to see the different categories. Pictures are at the end.

https://www.bikeforums.net/touring/1...trip-pics.html

#67

Senior Member

Join Date: Aug 2010

Location: Madison, WI

Posts: 11,211

Bikes: 1961 Ideor, 1966 Perfekt 3 Speed AB Hub, 1994 Bridgestone MB-6, 2006 Airnimal Joey, 2009 Thorn Sherpa, 2013 Thorn Nomad MkII, 2015 VO Pass Hunter, 2017 Lynskey Backroad, 2017 Raleigh Gran Prix, 1980s Bianchi Mixte on a trainer. Others are now gone.

Mentioned: 48 Post(s)

Tagged: 0 Thread(s)

Quoted: 3461 Post(s)

Liked 1,467 Times

in

1,144 Posts

...

When I was on my Ohio to Erie trip a few years ago I don't think I had any spare spokes with me, actually. I do need to change that and get some. When I rebuilt my front wheel I got way more spokes than I needed. Seems to me they came in a box of 100? So I have plenty of spares for that. However, they are not the same spokes as either side of my rear wheel. So that means I have 3 sizes of spokes I would need to match.

As others have suggested - if you want to change things up go to a 36 spoke wheel and call it good. Keep the spoke tension easy and you should be OK. The spokes at the top are actually what are stressed the most - spokes have next to no compressive strength, but are very strong in tension. With the equal tension around the wheel that is what keeps it both round and strong - the forces are transferred around the rim and distributed to many spokes.

On my Ohio to Erie trip I easily had 200lbs of gear at times. You can see pictures in the following thread.

https://www.bikeforums.net/touring/1...-rain-row.html

...

When I was on my Ohio to Erie trip a few years ago I don't think I had any spare spokes with me, actually. I do need to change that and get some. When I rebuilt my front wheel I got way more spokes than I needed. Seems to me they came in a box of 100? So I have plenty of spares for that. However, they are not the same spokes as either side of my rear wheel. So that means I have 3 sizes of spokes I would need to match.

As others have suggested - if you want to change things up go to a 36 spoke wheel and call it good. Keep the spoke tension easy and you should be OK. The spokes at the top are actually what are stressed the most - spokes have next to no compressive strength, but are very strong in tension. With the equal tension around the wheel that is what keeps it both round and strong - the forces are transferred around the rim and distributed to many spokes.

On my Ohio to Erie trip I easily had 200lbs of gear at times. You can see pictures in the following thread.

https://www.bikeforums.net/touring/1...-rain-row.html

...

For that load, I am surprised you have not had any wheel failures, especially if you are intentionally keeping your spokes under-tensioned. For that load, you could certainly use tandem strength wheels.

#68

Senior Member

Join Date: Apr 2013

Posts: 1,173

Bikes: Surly Disk Trucker, 2014 w/Brooks Flyer Special saddle, Tubus racks - Duo front/Logo Evo rear, 2019 Dahon Mariner D8, Both bikes share Ortlieb Packer Plus series panniers, Garmin Edge 1000

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 405 Post(s)

Liked 115 Times

in

99 Posts

What I eventually figured was the bead had stretched.

The tires were the originals at that time - from 2014. So before the trip I put on a new pair of tires and the old tire that didn't thump I had along as a spare.

Aside from that I have not had any other wheel or tire issues, outside of the occasional flat. I got a bit of glass in one of my tires on that trip that stumped me for a day. I fixed the flat trail side one day as I ended up on the rim and couldn't continue on. At that time I did a quick check of the tire for obvious stuff poking through, put a new tube in, and called it good. The next morning the tire was flat again. I was close to a park of sorts so I stayed there after breakfast and dug in to the tire. That's when I found the glass bit. Between that and patching tubes that morning I lost a good bit of time, but that was a critical thing that needed done.

On tour the same would go for spokes - if one breaks you can't just tie it up and keep on keepin' on. One missing spoke will increase the load shared by the others and you'll end up stressing more = easier to break another. If you are at the end of your day and almost to your stop for the night that is one thing, but if you are trying to make it through 20 miles - forget it.

#69

Senior Member

I feel it needa to be said but modern spokes won't break from tension but lack thereof, unless you wildly over tension them but even in that case the rim or hub are more likely to give first. A 1,8mm cross section spoke can withstand 180kgf. If said spoke is tensioned to 120kgf there's still 60kgf in reserve and the initial tension of a spoke is very close to the peak tension it'll ever experience. The wheel system is exceedingly good at spreading out the tension so with even a 150kgf load per wheel the maximum spoke tension for said wheel only goes up to around 126kgf with a 36 spoke wheel.

Likes For elcruxio:

#70

Senior Member

Join Date: Dec 2010

Location: northern Deep South

Posts: 8,904

Bikes: Fuji Touring, Novara Randonee

Mentioned: 36 Post(s)

Tagged: 0 Thread(s)

Quoted: 2604 Post(s)

Liked 1,933 Times

in

1,213 Posts

I will 2nd the point of "spoke tension" being paramount in wheel strength. I would say staying on the lighter end of the spectrum of spoke tension is best. That way you have some flex when you hit bumps. Yes, a flexing rim is not going to stay as true. However, on a tour I would much rather have some lack of true'ness in the wheels not spinning perfectly than to have banjo-string tight spokes popping on bumps.

To date I have never broken a spoke while riding.

As others have suggested - if you want to change things up go to a 36 spoke wheel and call it good. Keep the spoke tension easy and you should be OK. The spokes at the top are actually what are stressed the most - spokes have next to no compressive strength, but are very strong in tension. With the equal tension around the wheel that is what keeps it both round and strong - the forces are transferred around the rim and distributed to many spokes.

To date I have never broken a spoke while riding.

As others have suggested - if you want to change things up go to a 36 spoke wheel and call it good. Keep the spoke tension easy and you should be OK. The spokes at the top are actually what are stressed the most - spokes have next to no compressive strength, but are very strong in tension. With the equal tension around the wheel that is what keeps it both round and strong - the forces are transferred around the rim and distributed to many spokes.

I believe you're misunderstanding how spokes fail, though, and this is leading to some bad advice. What kills most spokes is not overstressing, it's stress cycling. So rim flexure at the bottom may force the spoke at the top of the wheel to pick up its load (along with the other spokes above the horizontal), that's a minimal overstressing -- 4% on a 24 spoke wheel even if the vertical load wasn't shared among all 12 of the upper spokes. But as the undertensioned wheel rolls along, each spoke, particularly on the rear NDS, can be destressed (nearly or completely) and restressed with each wheel revolution. That stress cycling will eventually lead to small fractures that'll grow until the spoke fails catastrophically (in the engineering sense). The failure will occur at the maximum stress and stress cycling point, usually at the spoke head but sometimes at the root of the thread.

So how to reduce/prevent spoke failure? The answer is high, balanced spoke tension. Make sure the wheel tension is balanced, so no spoke has lower tension that'll go through the stress cycling. And tension the wheel as high as the rim will allow. That means each spoke will be tensioned well above null stress when it rolls through the bottom of the revolution; perhaps paradoxically, a spoke cycled between 75% and 25% of its plastic yield doesn't fail the way a spoke cycled between 50% and 0% does.

Likes For pdlamb:

#71

Senior Member

#72

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,366

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,220 Times

in

2,367 Posts

Industry practice. Racing teams don’t use wheels for season after season if they have a sponsor. The sponsors want to showcase their products so the racers get new gear frequently. The parts may be used hard during the season but they aren’t used all that long. They certainly aren’t going to be using 10 to 20 year old wheels with 10,000 to 25,000 miles on them.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Last edited by cyccommute; 07-17-23 at 05:00 PM.

#73

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,366

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,220 Times

in

2,367 Posts

Lots of good posts thus far. Good discussion.

I will 2nd the point of "spoke tension" being paramount in wheel strength. I would say staying on the lighter end of the spectrum of spoke tension is best. That way you have some flex when you hit bumps. Yes, a flexing rim is not going to stay as true. However, on a tour I would much rather have some lack of true'ness in the wheels not spinning perfectly than to have banjo-string tight spokes popping on bumps.

I will 2nd the point of "spoke tension" being paramount in wheel strength. I would say staying on the lighter end of the spectrum of spoke tension is best. That way you have some flex when you hit bumps. Yes, a flexing rim is not going to stay as true. However, on a tour I would much rather have some lack of true'ness in the wheels not spinning perfectly than to have banjo-string tight spokes popping on bumps.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#74

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,366

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,220 Times

in

2,367 Posts

I feel it needa to be said but modern spokes won't break from tension but lack thereof, unless you wildly over tension them but even in that case the rim or hub are more likely to give first. A 1,8mm cross section spoke can withstand 180kgf. If said spoke is tensioned to 120kgf there's still 60kgf in reserve and the initial tension of a spoke is very close to the peak tension it'll ever experience. The wheel system is exceedingly good at spreading out the tension so with even a 150kgf load per wheel the maximum spoke tension for said wheel only goes up to around 126kgf with a 36 spoke wheel.

spoke’s fatigue resistance is proportional NOT to its diameter but to its cross sectional area.

32% greater cross section area through the J-bend. 32% longer lasting.

32% greater cross section area through the J-bend. 32% longer lasting.

That’s a whopping 32% increase for a paltry 7g/wheel. Equivalent to adding 10 spokes to the wheel. Experience shows this one feature can nearly eliminate spoke breakage. Combine with larger tires and you have a solution for every under-built, over-used, or over-loaded wheel.

32% greater cross section area through the J-bend. 32% longer lasting.

32% greater cross section area through the J-bend. 32% longer lasting.That’s a whopping 32% increase for a paltry 7g/wheel. Equivalent to adding 10 spokes to the wheel. Experience shows this one feature can nearly eliminate spoke breakage. Combine with larger tires and you have a solution for every under-built, over-used, or over-loaded wheel.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#75

Senior Member

It isn’t.

Every spoke on every revolution…around 250 rpm at 20 mph…undergoes a tension cycle of decrease/increase as the spoke passes over the contact patch. Modern spokes do indeed break because of tension changes. Every rim…including those high cross section rims you’ve discussed above…undergo deformation when loaded. Cycle the tension enough and the head will fatigue and fail. That’s the whole point of using triple butted spokes as this quote from Ric Hjertberg points out

That's actually one of the potential benefits of rope spokes, because rope doesn't suffer from the same tension cycle limitations.