Torque arm does not fit on bionx axle. Still go ahead?

#1

Senior Member

Thread Starter

Torque arm does not fit on bionx axle. Still go ahead?

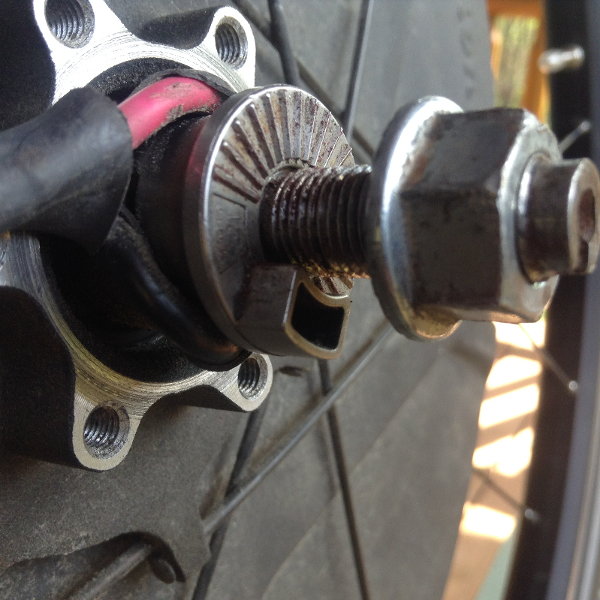

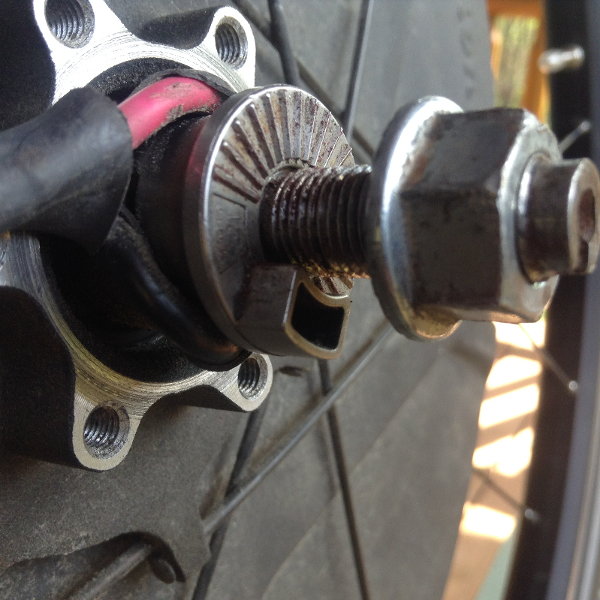

Bought a torque arm to install on a bionx axle. It doesn't appear to fit on the axle. Should I still try to install it? Would it make any sense?

#2

Senior Member

??? BionX never required or manufactured a "torque arm" for their products. Torqueing the axle nuts to 30#-ft is adequate. Do you mean "torque reaction collar"?

#3

Senior Member

Thread Starter

??? BionX never required or manufactured a "torque arm" for their products. Torqueing the axle nuts to 30#-ft is adequate. Do you mean "torque reaction collar"?

#4

Senior Member

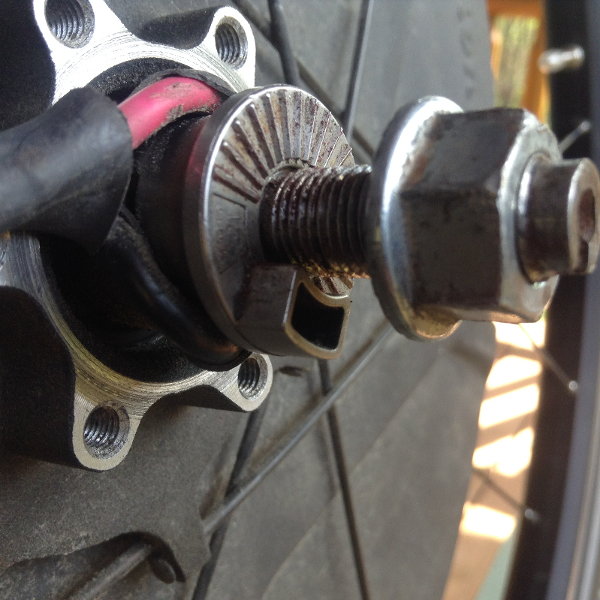

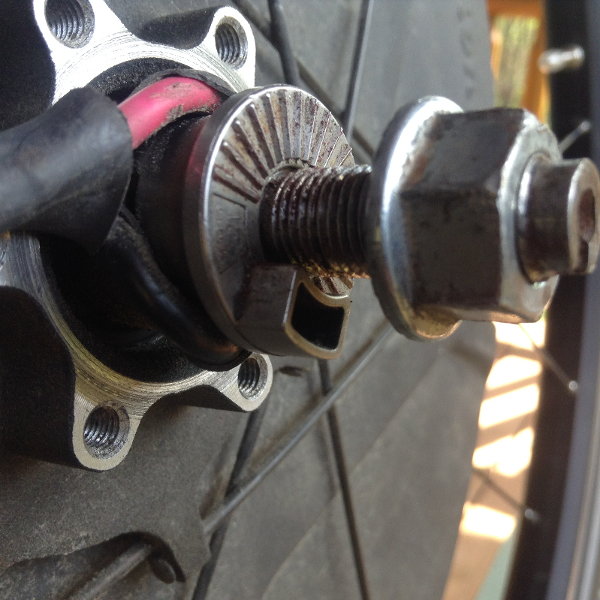

No, that makes no sense at all. That appears to be a D series motor. Did you acquire a V3 torque reaction collar as discussed at previous thread to match your dopout angle? If unavailable to fit your frame you're out of luck...

https://www.bikeforums.net/22855947-post4.html

It has splines to engage with the interior of the hub to make the torque sensor work properly and to maintain the plumb axle notch. Use conventional nuts on the exterior as specified by the mfr properly torqued.

peg aligned with dropout opening with axle notch at 6 o'clock on D500

https://www.bikeforums.net/22855947-post4.html

It has splines to engage with the interior of the hub to make the torque sensor work properly and to maintain the plumb axle notch. Use conventional nuts on the exterior as specified by the mfr properly torqued.

peg aligned with dropout opening with axle notch at 6 o'clock on D500

Last edited by BobG; 05-13-23 at 06:53 PM. Reason: add photo

#5

Senior Member

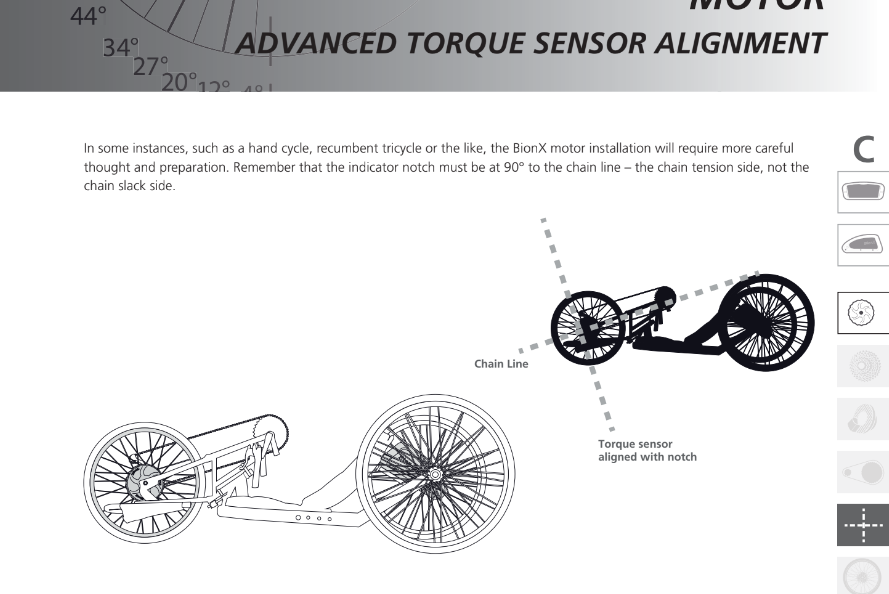

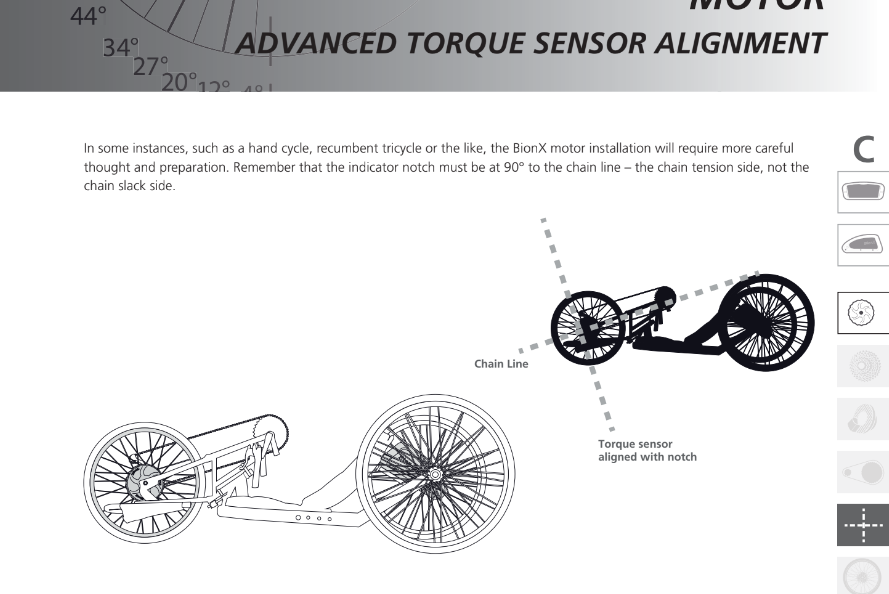

Correction ... The axle notch will usually need to be plumb on a conventional bike. If your recumbent has a sloping chain line you will need a torque reaction collar that places the notch perpendicular to the tug of the chain.

#6

Senior Member

Thread Starter

No, that makes no sense at all. That appears to be a D series motor. Did you acquire a V3 torque reaction collar as discussed at previous thread to match your dopout angle? If unavailable to fit your frame you're out of luck...

https://www.bikeforums.net/22855947-post4.html

It has splines to engage with the interior of the hub to make the torque sensor work properly and to maintain the plumb axle notch. Use conventional nuts on the exterior as specified by the mfr properly torqued.

peg aligned with dropout opening with axle notch at 6 o'clock on D500

https://www.bikeforums.net/22855947-post4.html

It has splines to engage with the interior of the hub to make the torque sensor work properly and to maintain the plumb axle notch. Use conventional nuts on the exterior as specified by the mfr properly torqued.

peg aligned with dropout opening with axle notch at 6 o'clock on D500