Comparing strengths of alternative hinges, Qix, Visc, Birdy, IVE, Spin

#51

Senior Member

Ok...

Got it. You can also just get a single crankset with the chainline squarely in the middle of the cogset. That would be the simplest solution (one that i myself use), no?

I want to change to 46/28 chainrings which is only possible using a triple crank as a double. Because of the jump in the chainrings I have to be careful about chain rubbing and dropping with the chain line. I will use 11-28 cassette and want to cross as much as possible since the 2 chainrings are only overlapping by around a third. I have a choice of getting a new JIS crank or switching to hollowtech 2. But Hollowtech is fixed with the chain line and cannot be adjusted, while JIS can be adjusted with the axle length. Also JIS would be 110/74 BCD while Hollowtech is 130/74 BCD, so I have to choose the correct size of chainring.

My current bike is dual drive with 135mm dropout. The middle of the cassette is around 45mm and single chainring at 48mm on the outside position of a double crank. The chain would drop if I used the largest cog. If I moved the chainring to the inside position then the chain would rub on the smaller cogs. I solved this by using a narrow wide chainring.

So with the vector, if the dropout is 135mm, then I assume the Hollowtech crank will not work well. Because the inner position ring will be at around 41mm and middle position at 46mm. The inner ring may be to far in to use the smallest few cogs. A 130mm dropout would move the cassette 2.5mm inward.

My current bike is dual drive with 135mm dropout. The middle of the cassette is around 45mm and single chainring at 48mm on the outside position of a double crank. The chain would drop if I used the largest cog. If I moved the chainring to the inside position then the chain would rub on the smaller cogs. I solved this by using a narrow wide chainring.

So with the vector, if the dropout is 135mm, then I assume the Hollowtech crank will not work well. Because the inner position ring will be at around 41mm and middle position at 46mm. The inner ring may be to far in to use the smallest few cogs. A 130mm dropout would move the cassette 2.5mm inward.

#52

Senior Member

Thread Starter

Join Date: Jan 2017

Posts: 1,064

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 350 Post(s)

Likes: 0

Liked 122 Times

in

90 Posts

I want to be able to have a larger gear range with a double chainring set. A single chainring is limited. With 11-28T 10 speed cassette and 46/28T chainrings, gear inches would be around 19-78" (with 406 1.75"tires, or x2.5% with Big Apples). It would provide 418% range with 15 unique steps. I would prefer 48/28T or 48/30T to increase the high to 81", but I've been told I won't find a 48T middle, unless someone knows of one?

For 5 bolt, 28T only commonly comes in 74 BCD, which can only be found on a triple crank in combination with 110 or 130 BCD, except for some really special and expensive models, like $300-400. The largest middle ring I could find is 46T in 110 or 130 BCD but only from 1 or 2 suppliers like TA Zephyr or Alize and Spa Cycles. I've been told that I can't use the more commonly available 46T or 48T outer ring for the middle position on a triple crank because the inner side without counterbored holes will make the bolt heads stick out and hit the chain when the chain is on the inner ring. Otherwise I would have wanted to go for the 48T. Or is there some solution for getting an outer into the middle position?

For 5 bolt, 28T only commonly comes in 74 BCD, which can only be found on a triple crank in combination with 110 or 130 BCD, except for some really special and expensive models, like $300-400. The largest middle ring I could find is 46T in 110 or 130 BCD but only from 1 or 2 suppliers like TA Zephyr or Alize and Spa Cycles. I've been told that I can't use the more commonly available 46T or 48T outer ring for the middle position on a triple crank because the inner side without counterbored holes will make the bolt heads stick out and hit the chain when the chain is on the inner ring. Otherwise I would have wanted to go for the 48T. Or is there some solution for getting an outer into the middle position?

#53

Senior Member

Did you not say you are using SRAM DualDrive?

If not, I'd go with a 50/34 crankset with an 11-34T cogset. KISS.

I want to be able to have a larger gear range with a double chainring set. A single chainring is limited. With 11-28T 10 speed cassette and 46/28T chainrings, gear inches would be around 19-78" (with 406 1.75"tires, or x2.5% with Big Apples). It would provide 418% range with 15 unique steps. I would prefer 48/28T or 48/30T to increase the high to 81", but I've been told I won't find a 48T middle, unless someone knows of one?

For 5 bolt, 28T only commonly comes in 74 BCD, which can only be found on a triple crank in combination with 110 or 130 BCD, except for some really special and expensive models, like $300-400. The largest middle ring I could find is 46T in 110 or 130 BCD but only from 1 or 2 suppliers like TA Zephyr or Alize and Spa Cycles. I've been told that I can't use the more commonly available 46T or 48T outer ring for the middle position on a triple crank because the inner side without counterbored holes will make the bolt heads stick out and hit the chain when the chain is on the inner ring. Otherwise I would have wanted to go for the 48T. Or is there some solution for getting an outer into the middle position?

For 5 bolt, 28T only commonly comes in 74 BCD, which can only be found on a triple crank in combination with 110 or 130 BCD, except for some really special and expensive models, like $300-400. The largest middle ring I could find is 46T in 110 or 130 BCD but only from 1 or 2 suppliers like TA Zephyr or Alize and Spa Cycles. I've been told that I can't use the more commonly available 46T or 48T outer ring for the middle position on a triple crank because the inner side without counterbored holes will make the bolt heads stick out and hit the chain when the chain is on the inner ring. Otherwise I would have wanted to go for the 48T. Or is there some solution for getting an outer into the middle position?

#54

**thusi*st

Dahon's warranty on the frame may be lost, but even so, Nomadic's warranty will stand. I have had no problem with this modification and have had it in real world testing for over 2 years. It is a common thread here to modify and make bikes better and for me this makes the bike better in several ways.

Removing the front and rear wheels does work but it exposes the dropout spans to damage (needs to be braced) and exposes the Derailleur hanger more than is the case with the wheels in place.

For me, I can go both ways. I hate getting my hands greasy in a hotel room when I unpack my bike, and reassembling needs much more time when I start taking both the derailleur and the rear wheel off.

Splitting the frame is fast and effective for me, and I get a bigger 20" bike w/ lots of gears with the Visc D18.

Of course, a Curl fits in a suitcase without disassembly. 3 or 8 Speeds and smaller wheels to make that happen.

Removing the front and rear wheels does work but it exposes the dropout spans to damage (needs to be braced) and exposes the Derailleur hanger more than is the case with the wheels in place.

For me, I can go both ways. I hate getting my hands greasy in a hotel room when I unpack my bike, and reassembling needs much more time when I start taking both the derailleur and the rear wheel off.

Splitting the frame is fast and effective for me, and I get a bigger 20" bike w/ lots of gears with the Visc D18.

Of course, a Curl fits in a suitcase without disassembly. 3 or 8 Speeds and smaller wheels to make that happen.

Last edited by L Arnold; 02-21-18 at 07:04 PM.

#55

**thusi*st

From your post

Most of these subjects are solved in a different direction with this setup.

Using the Nuvinci N360 Rear CVT yields 360% gear Range

Using t he Patterson 2 Speed Front Crank expands that by a factor of 1.6 (160%)

This bike now has 576% Gear Range which may be even wider than a Rohloff and much faster to find the range.

I set it up to expand equally above and below the Standard Nuvinci (single front chain ring) setup.

The Gates belt, as discussed elsewhere, has its own benefits as well.

I'm building a limited number of these available if folks want a really cool ride. This one is the first one I've done in this configuration. (*The correct Belt Tensioner is not shown but is also in the build)

But, all that said, I really like Tom's spreads. I have similar ones I have popped through on this project.

Tom asks good questions as to hinges. In the Dahon range I like the Visc with the compression bar and the the Mu Hinge as well. Visc seems better for big loads. Mu is super elegant and easy to work. But that is an aside to the cool tranny set up on this bike.

Most of these subjects are solved in a different direction with this setup.

Using the Nuvinci N360 Rear CVT yields 360% gear Range

Using t he Patterson 2 Speed Front Crank expands that by a factor of 1.6 (160%)

This bike now has 576% Gear Range which may be even wider than a Rohloff and much faster to find the range.

I set it up to expand equally above and below the Standard Nuvinci (single front chain ring) setup.

The Gates belt, as discussed elsewhere, has its own benefits as well.

I'm building a limited number of these available if folks want a really cool ride. This one is the first one I've done in this configuration. (*The correct Belt Tensioner is not shown but is also in the build)

But, all that said, I really like Tom's spreads. I have similar ones I have popped through on this project.

Tom asks good questions as to hinges. In the Dahon range I like the Visc with the compression bar and the the Mu Hinge as well. Visc seems better for big loads. Mu is super elegant and easy to work. But that is an aside to the cool tranny set up on this bike.

#56

**thusi*st

I want to change to 46/28 chainrings which is only possible using a triple crank as a double. Because of the jump in the chainrings I have to be careful about chain rubbing and dropping with the chain line. I will use 11-28 cassette and want to cross as much as possible since the 2 chainrings are only overlapping by around a third. I have a choice of getting a new JIS crank or switching to hollowtech 2. But Hollowtech is fixed with the chain line and cannot be adjusted, while JIS can be adjusted with the axle length. Also JIS would be 110/74 BCD while Hollowtech is 130/74 BCD, so I have to choose the correct size of chainring.

My current bike is dual drive with 135mm dropout. The middle of the cassette is around 45mm and single chainring at 48mm on the outside position of a double crank. The chain would drop if I used the largest cog. If I moved the chainring to the inside position then the chain would rub on the smaller cogs. I solved this by using a narrow wide chainring.

So with the vector, if the dropout is 135mm, then I assume the Hollowtech crank will not work well. Because the inner position ring will be at around 41mm and middle position at 46mm. The inner ring may be to far in to use the smallest few cogs. A 130mm dropout would move the cassette 2.5mm inward.

My current bike is dual drive with 135mm dropout. The middle of the cassette is around 45mm and single chainring at 48mm on the outside position of a double crank. The chain would drop if I used the largest cog. If I moved the chainring to the inside position then the chain would rub on the smaller cogs. I solved this by using a narrow wide chainring.

So with the vector, if the dropout is 135mm, then I assume the Hollowtech crank will not work well. Because the inner position ring will be at around 41mm and middle position at 46mm. The inner ring may be to far in to use the smallest few cogs. A 130mm dropout would move the cassette 2.5mm inward.

It has a 28 T Chainwheel, which in Overdrive mode turns into a 45 T equivalent wheel. It will work with derailleur or IHG.

#57

Senior Member

Thread Starter

Join Date: Jan 2017

Posts: 1,064

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 350 Post(s)

Likes: 0

Liked 122 Times

in

90 Posts

Is there any reason why dahon bikes don't have models with triple chainring? Are there space issues with the thick tubes in the vector and mu? If not then I assume it's possible?

#59

Senior Member

Triples require long-cage RD which will come perilously close to the ground on wheels smaller than ISO451.

#60

Senior Member

#61

**thusi*st

It is true that wide spreads on Chainrings can create higher chain cross angles which are further increased by the short spans between sprockets (front to back) on most folding bikes.

Last edited by L Arnold; 02-22-18 at 11:10 PM. Reason: Spelling

#62

Senior Member

Thread Starter

Join Date: Jan 2017

Posts: 1,064

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 350 Post(s)

Likes: 0

Liked 122 Times

in

90 Posts

How much flex is normal on a dahon aluminum frame hinge when you put your finger on the crack at the bottom of the hinge and press down on it?

On 2 display models, vector and vigor with the same v clamp as the Mu, I can feel the crack pinching my skin very lightly as it expands and contracts. Is it normal? The clamp was not tight on the vigor when I first opened it, just barely the limit. I tightened it but I don't know if that made a difference. The vector clamp was tighter and the flex seemed smaller than on the vigor.

The shop guy said he thought it was normal.

I went to the shop 3 hours away to look at the vector p20 and brought big Ben plus 2.15" tires to see if they would fit but they don't. I was able to fit them on the vigor d9 with only 5mm of clearance to the joint in the rear fork. I would have to cut the edges of the fender to get it in. The final clearance is maybe 2-3mm at the front part of the rear tire.

Both frames look almost the same except the vigor chainstay around the rear fork is "crimped" to give it a few more millimeters of tire clearance while the vector has straight tubes that restrict tire space. It only had about 40mm. The rims were also small at 17mm. The vigor rims were around 20 or 21mm. The distance from the handlebar to the seatpost on the vector was 40mm shorter than on my speed tr, vigor was 50mm shorter. The difference between the vigor and vector was the tilt angle of the handle post but I don't know if that's because of the post or the angle of the fork.

They did not have any other dahon bikes with v clamp hinges like the Mu so I ended up buying the vigor d9. It was 700€ but I took off the tires, cassette, crank, pedals, derailleur, shifter, grips, seat post, and saddle for them to keep for a 100€ discount for a final price of 600€. It was also the display model and the last one in stock.

When I install the drivetrain, the FD cable will have to be external while the others are internal, unless I try to remove the small amount of aluminum material between the brake and RD cable housings where it goes through the frame and see if I can squeeze a third in between.

I'm just worried about the hinge flex, in case the display model was ridden with the clamp not very tight.

The Vector P20 is the blue/black color, I think the only year it came out was 2014. The one that doesn't fit 2" tires. I don't even know if it will fit 1.75. Original was 1.1".

The Vigor D9 that I saw and got was I think the first series, maybe 2015?

Dahon.com has 3 different pages for the model, blank, 2, 3. It was the blank numbered page, the silvery polished one.

This page is missing geometry information, while the 2 newer ones do have info.

https://dahon.com/bikes/vigor-d9/

The high polished handlepost will probably bother me when it's sunny. I might spray paint the back side black, maybe even the top side of the top tube which is also highly polished. I have a bead-blasted handlepost on my old Speed TR and that was really reflective in the sun. This is probably why the newer models switched to black handlepost and bars.

Also, after looking at some videos and photos of the Mu D10, some come with 2.1" tires with fenders attached in case anyone is looking for a frame that can fit larger tires. One of the reasons why it can fit large tires is because it has no chainstay tubes, and also the little tab behind the seatpost tube is further forward. On the Vigor D9, this tab is welded between the chainstays and further back, which is what's causing the clearance problems. There are some older Mu D10's at other stores but they were 5 hours away and I didn't want to go that far.

On 2 display models, vector and vigor with the same v clamp as the Mu, I can feel the crack pinching my skin very lightly as it expands and contracts. Is it normal? The clamp was not tight on the vigor when I first opened it, just barely the limit. I tightened it but I don't know if that made a difference. The vector clamp was tighter and the flex seemed smaller than on the vigor.

The shop guy said he thought it was normal.

I went to the shop 3 hours away to look at the vector p20 and brought big Ben plus 2.15" tires to see if they would fit but they don't. I was able to fit them on the vigor d9 with only 5mm of clearance to the joint in the rear fork. I would have to cut the edges of the fender to get it in. The final clearance is maybe 2-3mm at the front part of the rear tire.

Both frames look almost the same except the vigor chainstay around the rear fork is "crimped" to give it a few more millimeters of tire clearance while the vector has straight tubes that restrict tire space. It only had about 40mm. The rims were also small at 17mm. The vigor rims were around 20 or 21mm. The distance from the handlebar to the seatpost on the vector was 40mm shorter than on my speed tr, vigor was 50mm shorter. The difference between the vigor and vector was the tilt angle of the handle post but I don't know if that's because of the post or the angle of the fork.

They did not have any other dahon bikes with v clamp hinges like the Mu so I ended up buying the vigor d9. It was 700€ but I took off the tires, cassette, crank, pedals, derailleur, shifter, grips, seat post, and saddle for them to keep for a 100€ discount for a final price of 600€. It was also the display model and the last one in stock.

When I install the drivetrain, the FD cable will have to be external while the others are internal, unless I try to remove the small amount of aluminum material between the brake and RD cable housings where it goes through the frame and see if I can squeeze a third in between.

I'm just worried about the hinge flex, in case the display model was ridden with the clamp not very tight.

The Vector P20 is the blue/black color, I think the only year it came out was 2014. The one that doesn't fit 2" tires. I don't even know if it will fit 1.75. Original was 1.1".

The Vigor D9 that I saw and got was I think the first series, maybe 2015?

Dahon.com has 3 different pages for the model, blank, 2, 3. It was the blank numbered page, the silvery polished one.

This page is missing geometry information, while the 2 newer ones do have info.

https://dahon.com/bikes/vigor-d9/

The high polished handlepost will probably bother me when it's sunny. I might spray paint the back side black, maybe even the top side of the top tube which is also highly polished. I have a bead-blasted handlepost on my old Speed TR and that was really reflective in the sun. This is probably why the newer models switched to black handlepost and bars.

Also, after looking at some videos and photos of the Mu D10, some come with 2.1" tires with fenders attached in case anyone is looking for a frame that can fit larger tires. One of the reasons why it can fit large tires is because it has no chainstay tubes, and also the little tab behind the seatpost tube is further forward. On the Vigor D9, this tab is welded between the chainstays and further back, which is what's causing the clearance problems. There are some older Mu D10's at other stores but they were 5 hours away and I didn't want to go that far.

Last edited by tomtomtom123; 02-23-18 at 04:10 PM.

#63

**thusi*st

Glad you picked up the bike. The hinges can nomrally be tightened some. You could consider a small foam or rubber shim if you wanted to "tighten" things a bit more, such as if you have a sqeak. Of course some grease-less lubricant in the hinge pin is a good idea sometimes as well.

I look forward to seeing your build when you get done with it Tom.

I look forward to seeing your build when you get done with it Tom.

#64

Senior Member

Thread Starter

Join Date: Jan 2017

Posts: 1,064

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 350 Post(s)

Likes: 0

Liked 122 Times

in

90 Posts

It's the first time I've got a V-clamp hinge so I decided to take a closer look at it. The 2 halves are only in contact at the 2 pairs of teeth on the right side that are held together with the shiny V plate. The rest of the hinge face, like the top and bottom, are not in contact.

When I press down on the bike with the hinge closed, I measure the gap at the bottom of the hinge increases approximately from 1.6 to 1.8mm, so +0.2mm flex. Is this a normal amount of flex?

Taking off the V plate, when the hinge is at rest with no load, the top teeth have a 0.15mm gap when the bottom teeth are in contact. If I press down on the hinge, or press from the side, the gap does not close. But if I twist by pulling on the seatpost with a small force, then both pairs of teeth will close. But the gap at the bottom of the hinge will increase. Is this gap in the top pair of teeth OK, or something that is best to be reduced? Like removing 0.15mm of material from the bottom pair of teeth, so that both pairs touch at the same time?

Diagrams attached below:

I will most likely pick the Shimano RD-4700-GS rear derailleur because it has a 41 chain capacity, while equivalent SRAM derailleurs only have 35. The FD-4700 front derailleur is designed for smaller chainrings, so I think it will work better. I should be able to get around 450% range from 18-81 gear inches with 11-30T cassette (custom arrangement 11, 12, 13, 14, 15, 17, 19, 21, 24, 30) and 46/28T chainrings. Chain wrap is 39. The 24 to 30 jump drops 25% for lowest gear. The 18 teeth gap between the double chainring might have problems, as the max capacity of the FD is 16, but I'll test it with a chain catcher.

When I press down on the bike with the hinge closed, I measure the gap at the bottom of the hinge increases approximately from 1.6 to 1.8mm, so +0.2mm flex. Is this a normal amount of flex?

Taking off the V plate, when the hinge is at rest with no load, the top teeth have a 0.15mm gap when the bottom teeth are in contact. If I press down on the hinge, or press from the side, the gap does not close. But if I twist by pulling on the seatpost with a small force, then both pairs of teeth will close. But the gap at the bottom of the hinge will increase. Is this gap in the top pair of teeth OK, or something that is best to be reduced? Like removing 0.15mm of material from the bottom pair of teeth, so that both pairs touch at the same time?

Diagrams attached below:

I will most likely pick the Shimano RD-4700-GS rear derailleur because it has a 41 chain capacity, while equivalent SRAM derailleurs only have 35. The FD-4700 front derailleur is designed for smaller chainrings, so I think it will work better. I should be able to get around 450% range from 18-81 gear inches with 11-30T cassette (custom arrangement 11, 12, 13, 14, 15, 17, 19, 21, 24, 30) and 46/28T chainrings. Chain wrap is 39. The 24 to 30 jump drops 25% for lowest gear. The 18 teeth gap between the double chainring might have problems, as the max capacity of the FD is 16, but I'll test it with a chain catcher.

Last edited by tomtomtom123; 02-25-18 at 06:44 PM.

#65

Senior Member

Join Date: Sep 2004

Location: Chicago area

Posts: 2,551

Bikes: Airborne "Carpe Diem", Motobecane "Mirage", Trek 6000, Strida 2, Dahon "Helios XL", Dahon "Mu XL", Tern "Verge S11i"

Mentioned: 23 Post(s)

Tagged: 0 Thread(s)

Quoted: 980 Post(s)

Liked 582 Times

in

399 Posts

I have two Dahons (Helios XL and Mu XL) and a Tern (Verge S11i), and their joints are rock-solid when closed.

Steve

EDIT: Neither of my Dahons has the same latch as yours. I still think there should be no detectable play.

#66

Senior Member

Thread Starter

Join Date: Jan 2017

Posts: 1,064

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 350 Post(s)

Likes: 0

Liked 122 Times

in

90 Posts

The Shimano RD-4700-GS is a mid cage (SS is short, GS is mid, SGS is long) with the 41 chain wrap capacity. Shimano and SRAM mid cages are supposedly the same length. The SRAM mid cage usually only go to 35, but I don't know why. Some Dahon bikes come with mid cage so I don't think it will be a problem.

I did try tightening the lever but it did not seem to change much. I felt that the gap may have been smaller, but I could not measure the difference with accuracy. I loosened it back to just enough strength to close with one hand.

I also tried adding 0.2mm of paper to the top pair of teeth but that didn't make a difference either, probably because paper compresses (I don't have other material that might work), or the gap in the teeth is not the problem. It's possible that when the lever is closed, that the V-plate pulls the gap closed, but since the plate blocks my view when closed, I can't see it.

The Mu XL should have the same style of clamp. The edges around the faces may have a different shape than the Vigor, but the V-plate and lever should be the same.

I haven't ridden it yet since I took it home without a drivetrain.

I did try tightening the lever but it did not seem to change much. I felt that the gap may have been smaller, but I could not measure the difference with accuracy. I loosened it back to just enough strength to close with one hand.

I also tried adding 0.2mm of paper to the top pair of teeth but that didn't make a difference either, probably because paper compresses (I don't have other material that might work), or the gap in the teeth is not the problem. It's possible that when the lever is closed, that the V-plate pulls the gap closed, but since the plate blocks my view when closed, I can't see it.

The Mu XL should have the same style of clamp. The edges around the faces may have a different shape than the Vigor, but the V-plate and lever should be the same.

I haven't ridden it yet since I took it home without a drivetrain.

#68

Senior Member

Thread Starter

Join Date: Jan 2017

Posts: 1,064

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 350 Post(s)

Likes: 0

Liked 122 Times

in

90 Posts

I'm still waiting for the front derailleur adapter to arrive before I can assemble the drive train. I ordered one from a seller who said it would arrive in 3-5 days, but tracking doesn't show any movement.

I couldn't figure out a good way to route the FD cable because there is a plate welded between the chainstays, so I bought a pair of Avid Rollamajig which can change the cable direction by 90 degrees. Then I don't have to wrap the cable around the BB shell.

I measured the cage length of the Shimano RD-4700 and RD-5700, both are 86mm long. My old Dahon bike came a SRAM X7 derailleur 77mm long. But since I'm using larger tires (+7mm height), and largest 30T cog instead of 32T (+4mm height), I think they should be ok. The RD-4700 has a newer, longer pull ratio, easier shifting, so I might go with that. I'm going for 46/28T chainrings, and the FD-4700 front derailleur is shorter for smaller chainrings (max 52T). I did not see the FD-5700 but it's max chainring is 56T so I assume it's longer and the tail might hit the chainstay or rub on the chain because of the short chainstay of the Dahon bikes.

Shifting is not the same method though. Trim is on opposite sides in the 2 systems. Diagram below. The FD-4700 system with the trim on the outside makes more sense with using a double chainring with a large gap like 46/28T. If instead using the other system with the trim on the inside, then changing chainrings would require pressing both trigger levers immediately after the other to trim inward, since you have to move the chain to the opposite side of the rear cassette.

In the meantime, I was able to install the 2.15" tires and 60mm fenders. I had to cut notches into the fender to get through the forks, chainstays, and seatstays. The fender is a sheet of aluminum encased in plastic, and it was easy to cut with a pair of wire cutters and cleaning up with a box cutter blade. There is only 3.5mm of clearance between the tire and the fender at the screw shown in the photo. A normal screw head would rub against the tire. I had an ultra low head screw lying around so I used this. It has a 1mm head height. I think you can only find these screws from Japan, which you can buy from Misumi online with a business account. This problem is only on Dahon bikes without enough clearance for wide tires. The frame I bought is a Vigor, similar to the Vector. I think the Mu D10 comes standard with 2.10" tires and wide fenders.

I bought some 0.1, 0.15, 0.20mm sheets of metal to try to close the gap in the hinge teeth, but I couldn't get it to work, so I shone a light into the hinge to have a closer look. The gap isn't parallel, both pairs of teeth have gaps that get wider away from the center. Here is a photo. The top pair of teeth start from 0.05mm to more than 0.20mm (probably 0.25mm). The bottom pair of teeth start from 0 to more than 0.10mm (probably 0.15mm). Pressing the hinge together from the side very lightly closes the top gap by about 0.05mm, but the very bottom probably gets wider by the same amount.

I sent the owner of the shop a quick email 2 weeks ago the day after I bought the bike, about what I could do to minimize the gap, but he never replied.

Any ideas what I can do?

Since the surfaces aren't parallel but the bottom is touching at a small point, the bottom pair of teeth could be sanded down by 0.15mm until they touch along their entire length. Then add a 0.10mm shim to the bottom. The top pair of teeth would then get closer by 0.05mm, and sand this down until the gap is a uniform 0.20mm and add a piece of 0.20mm sheet metal to the top.

I calculated that a 0.15 - 0.20mm change in the hinge gap would move the front and rear wheel alignment by 1.5 - 2mm. But it would be impossible to know if there is a misalignment currently as it is now, or if sanding down the surface would correct or introduce some.

I couldn't figure out a good way to route the FD cable because there is a plate welded between the chainstays, so I bought a pair of Avid Rollamajig which can change the cable direction by 90 degrees. Then I don't have to wrap the cable around the BB shell.

I measured the cage length of the Shimano RD-4700 and RD-5700, both are 86mm long. My old Dahon bike came a SRAM X7 derailleur 77mm long. But since I'm using larger tires (+7mm height), and largest 30T cog instead of 32T (+4mm height), I think they should be ok. The RD-4700 has a newer, longer pull ratio, easier shifting, so I might go with that. I'm going for 46/28T chainrings, and the FD-4700 front derailleur is shorter for smaller chainrings (max 52T). I did not see the FD-5700 but it's max chainring is 56T so I assume it's longer and the tail might hit the chainstay or rub on the chain because of the short chainstay of the Dahon bikes.

Shifting is not the same method though. Trim is on opposite sides in the 2 systems. Diagram below. The FD-4700 system with the trim on the outside makes more sense with using a double chainring with a large gap like 46/28T. If instead using the other system with the trim on the inside, then changing chainrings would require pressing both trigger levers immediately after the other to trim inward, since you have to move the chain to the opposite side of the rear cassette.

In the meantime, I was able to install the 2.15" tires and 60mm fenders. I had to cut notches into the fender to get through the forks, chainstays, and seatstays. The fender is a sheet of aluminum encased in plastic, and it was easy to cut with a pair of wire cutters and cleaning up with a box cutter blade. There is only 3.5mm of clearance between the tire and the fender at the screw shown in the photo. A normal screw head would rub against the tire. I had an ultra low head screw lying around so I used this. It has a 1mm head height. I think you can only find these screws from Japan, which you can buy from Misumi online with a business account. This problem is only on Dahon bikes without enough clearance for wide tires. The frame I bought is a Vigor, similar to the Vector. I think the Mu D10 comes standard with 2.10" tires and wide fenders.

I bought some 0.1, 0.15, 0.20mm sheets of metal to try to close the gap in the hinge teeth, but I couldn't get it to work, so I shone a light into the hinge to have a closer look. The gap isn't parallel, both pairs of teeth have gaps that get wider away from the center. Here is a photo. The top pair of teeth start from 0.05mm to more than 0.20mm (probably 0.25mm). The bottom pair of teeth start from 0 to more than 0.10mm (probably 0.15mm). Pressing the hinge together from the side very lightly closes the top gap by about 0.05mm, but the very bottom probably gets wider by the same amount.

I sent the owner of the shop a quick email 2 weeks ago the day after I bought the bike, about what I could do to minimize the gap, but he never replied.

Any ideas what I can do?

Since the surfaces aren't parallel but the bottom is touching at a small point, the bottom pair of teeth could be sanded down by 0.15mm until they touch along their entire length. Then add a 0.10mm shim to the bottom. The top pair of teeth would then get closer by 0.05mm, and sand this down until the gap is a uniform 0.20mm and add a piece of 0.20mm sheet metal to the top.

I calculated that a 0.15 - 0.20mm change in the hinge gap would move the front and rear wheel alignment by 1.5 - 2mm. But it would be impossible to know if there is a misalignment currently as it is now, or if sanding down the surface would correct or introduce some.

Last edited by tomtomtom123; 03-09-18 at 05:27 PM.

#69

Senior Member

Thread Starter

Join Date: Jan 2017

Posts: 1,064

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 350 Post(s)

Likes: 0

Liked 122 Times

in

90 Posts

I discovered something new today. On the V-clamp, the V-plate has a 13mm wide block in the middle that slips into the central slot between the 2 pairs of teeth, spreading the teeth apart, so the teeth don't actually touch when the hinge is locked. The teeth have 0.4 and 0.6mm gaps when the central slot is opened to 13.0mm.

So then the only points of contact when locked is the outside surface of the teeth against the V-plate, and the 13mm block on the V-plate against the central slot between the teeth.

If anyone has a V-clamp can they confirm this is how theirs works too?

If this is normal, then it kind of allows for some movement. I wonder if it's worth shimming the gap to minimize it to 0.1mm, but not closing the gap completely so that the 13mm block on the V-plate is still the contact point.

So then the only points of contact when locked is the outside surface of the teeth against the V-plate, and the 13mm block on the V-plate against the central slot between the teeth.

If anyone has a V-clamp can they confirm this is how theirs works too?

If this is normal, then it kind of allows for some movement. I wonder if it's worth shimming the gap to minimize it to 0.1mm, but not closing the gap completely so that the 13mm block on the V-plate is still the contact point.

#70

Junior Member

Join Date: Dec 2012

Location: Singapore

Posts: 6

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I discovered something new today. On the V-clamp, the V-plate has a 13mm wide block in the middle that slips into the central slot between the 2 pairs of teeth, spreading the teeth apart, so the teeth don't actually touch when the hinge is locked. The teeth have 0.4 and 0.6mm gaps when the central slot is opened to 13.0mm.

So then the only points of contact when locked is the outside surface of the teeth against the V-plate, and the 13mm block on the V-plate against the central slot between the teeth.

If anyone has a V-clamp can they confirm this is how theirs works too?

If this is normal, then it kind of allows for some movement. I wonder if it's worth shimming the gap to minimize it to 0.1mm, but not closing the gap completely so that the 13mm block on the V-plate is still the contact point.

So then the only points of contact when locked is the outside surface of the teeth against the V-plate, and the 13mm block on the V-plate against the central slot between the teeth.

If anyone has a V-clamp can they confirm this is how theirs works too?

If this is normal, then it kind of allows for some movement. I wonder if it's worth shimming the gap to minimize it to 0.1mm, but not closing the gap completely so that the 13mm block on the V-plate is still the contact point.

#71

Senior Member

Thread Starter

Join Date: Jan 2017

Posts: 1,064

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 350 Post(s)

Likes: 0

Liked 122 Times

in

90 Posts

Maybe the gap in the teeth gives some preload onto the V-plate when they're compressed, and allows for the pin on the opposite side to self center itself. But having the main contact point in the center instead of at the top and bottom might be susceptible to see-sawing and torsion.

I filed down the insides of the teeth so that the surfaces are close to parallel. I will shim them but leave a little less than 0.1mm gap so that the center block/slot is still the only contact point when at rest so it will still operate "as designed". I'll test it afterward to see if the shims reduce the flex that I'm feeling.

There is a very small variation in the sides of the center slot, of around 0.05mm from its top to the bottom. The spacer block that I made can rotate laterally inside of the slot. I've tried turning the block 180 degrees and it can still rotate from the same pivot point, which means the sides of the center slot are not parallel, and the sides will see-saw a little bit on the block of the V-plate. But I'm not going to touch it.

I filed down the insides of the teeth so that the surfaces are close to parallel. I will shim them but leave a little less than 0.1mm gap so that the center block/slot is still the only contact point when at rest so it will still operate "as designed". I'll test it afterward to see if the shims reduce the flex that I'm feeling.

There is a very small variation in the sides of the center slot, of around 0.05mm from its top to the bottom. The spacer block that I made can rotate laterally inside of the slot. I've tried turning the block 180 degrees and it can still rotate from the same pivot point, which means the sides of the center slot are not parallel, and the sides will see-saw a little bit on the block of the V-plate. But I'm not going to touch it.

#72

Junior Member

Join Date: Dec 2012

Location: Singapore

Posts: 6

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

From an engineering point, there is no benefit to make the hinge contact at the center bock. The hinge main loading is by bending and torsion. Thus having the top and bottom lip touch would reduce material stress significantly. The v-clamp block is self aligning after clamping (see how brompton hinge work). In this hinge design, the v-clamp lips handle majority of the bending loads and the pin in the hinge handle the torsion frame loading.

If i figured this out earlier, i would have dremel the 13mm slot to approximate 15mm slot so the v clamp block is not restricted. This way there will be proper v-clamp self-aligning and provide actual useful clamping force.

If i figured this out earlier, i would have dremel the 13mm slot to approximate 15mm slot so the v clamp block is not restricted. This way there will be proper v-clamp self-aligning and provide actual useful clamping force.

#73

Senior Member

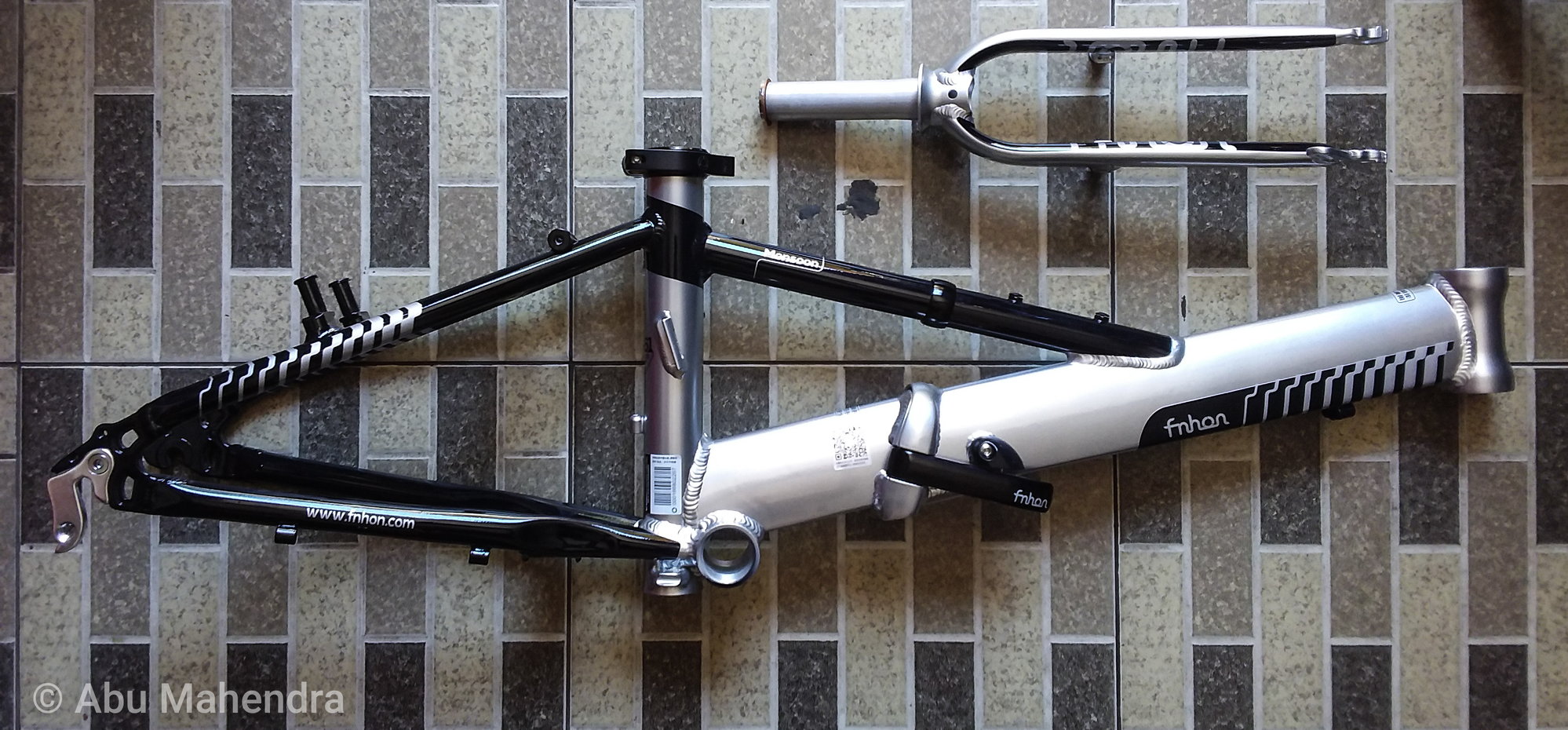

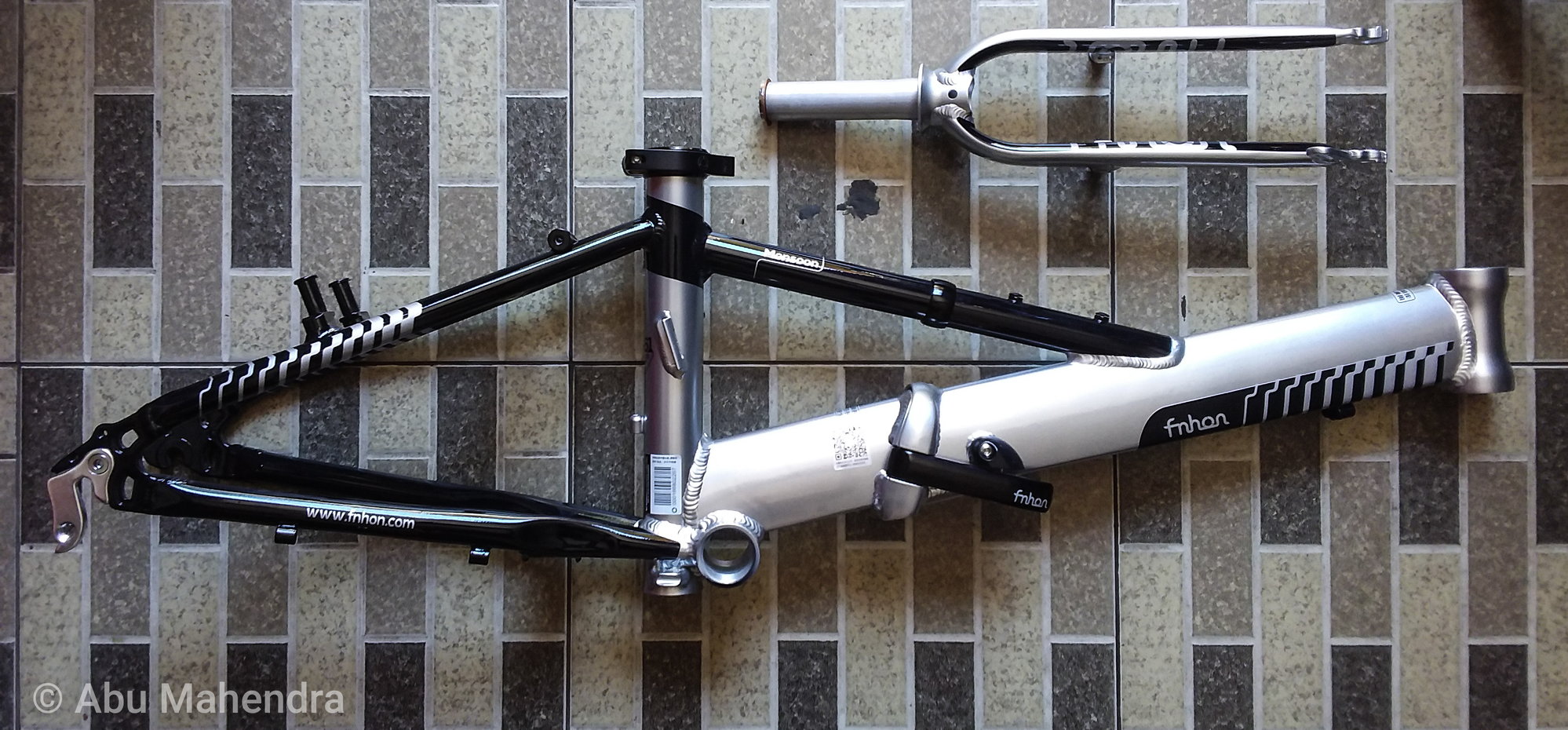

I am about to buy this FnHon Monsoon(Y2020) frameset for $250. Will report on it later...

Btw, I've now put about 1,200km, including a lightly loaded tour of 900km, on the FSIR, and have faced no issues with the bike.

Btw, I've now put about 1,200km, including a lightly loaded tour of 900km, on the FSIR, and have faced no issues with the bike.

I bought my Speed TR in Taiwan, and after 10 months the hinge no longer closed flat and would rock back and forth. The 2 sides are convex, curving away from each other. I did not do a deep inspection of the hinge until 10 months later when I started to notice the problem, so I don't know if the curved sides were like this when the bike was delivered, or if the hinge got damaged during travel and worn down. But the amount of curvature made me suspect a defect.

At about 9 months, I flew to Tasmania with it folded in an original Dahon box. But when I took the bike out of the box, the hinge latch was completely bent out of shape and would not close. I went to a Dahon dealer in Hobart who replaced the latch. But later, I noticed that the bike would flex at the hinge, and no matter how tight I made the latch, the 2 halves would still rock back and forth. I returned to the dealer and he tried to remove the left side pin but couldn't figure out how to get it out. His only solution was to add a piece of inner tube which dampen about 80% the movement. He said I would need warranty service from Dahon in Taiwan, but I wasn't going back there.

Several years later the movement in the hinge has gotten worse since Tasmania. Today, I did an inspection, and the latch has cracked and the components inside of it have bent due to the increased tension required to compress the piece of rubber tube, so I'm not going to ride it anymore.

I recorded the movement in a video here:

https://www.youtube.com/watch?v=choJcvBszMQ

Bent latch from flight:

So that's why I'm interested in a new bike with an alternative hinge design. The Visc has the floating top tube that takes most of the compression off of the main hinge. But like the video that dahoneezz posted, if the top tube gets bent or misaligned, it no longer performs its function. And also like the standard hinge, if the left side pin starts to get bent out of shape, it will introduce play that can't be removed. With the Visc, if the top tube fails, then the hinge will experience worse stress because it's located closer to the BB than on standard Dahon bikes.

The Qix solves some of these issues with the left vs right side play, but if the horizontal pin starts to wear, you'll get vertical play in the bottom of the hinge.

The Qix is available shipped for 650 € but I still have to travel 6 hours to see a demo. It seems there are no more stock of Visc D/P18 in Europe. Some old listings have it for 700-900 €.

I think a better Dahon hinge would be, a compression top tube like on the Visc, combined with a vertical fold like on the Qix for symmetric loading on the pin, and a tension cable below. It would be stronger, but ugly.

At about 9 months, I flew to Tasmania with it folded in an original Dahon box. But when I took the bike out of the box, the hinge latch was completely bent out of shape and would not close. I went to a Dahon dealer in Hobart who replaced the latch. But later, I noticed that the bike would flex at the hinge, and no matter how tight I made the latch, the 2 halves would still rock back and forth. I returned to the dealer and he tried to remove the left side pin but couldn't figure out how to get it out. His only solution was to add a piece of inner tube which dampen about 80% the movement. He said I would need warranty service from Dahon in Taiwan, but I wasn't going back there.

Several years later the movement in the hinge has gotten worse since Tasmania. Today, I did an inspection, and the latch has cracked and the components inside of it have bent due to the increased tension required to compress the piece of rubber tube, so I'm not going to ride it anymore.

I recorded the movement in a video here:

https://www.youtube.com/watch?v=choJcvBszMQ

Bent latch from flight:

So that's why I'm interested in a new bike with an alternative hinge design. The Visc has the floating top tube that takes most of the compression off of the main hinge. But like the video that dahoneezz posted, if the top tube gets bent or misaligned, it no longer performs its function. And also like the standard hinge, if the left side pin starts to get bent out of shape, it will introduce play that can't be removed. With the Visc, if the top tube fails, then the hinge will experience worse stress because it's located closer to the BB than on standard Dahon bikes.

The Qix solves some of these issues with the left vs right side play, but if the horizontal pin starts to wear, you'll get vertical play in the bottom of the hinge.

The Qix is available shipped for 650 € but I still have to travel 6 hours to see a demo. It seems there are no more stock of Visc D/P18 in Europe. Some old listings have it for 700-900 €.

I think a better Dahon hinge would be, a compression top tube like on the Visc, combined with a vertical fold like on the Qix for symmetric loading on the pin, and a tension cable below. It would be stronger, but ugly.

#74

Senior Member

Right. The FnHon Monsoon Y1818 for 355 wheels, and the Y2020 for 406/451 wheels. Both can be had in frameset only for under $250. This a Y1818 in gold color being sold here.

There is a similar one called Fnhon Monsoon YA1818. It also looks like the Dahon Presto. Has 18" 355 wheels. 9kg. Common configuration is 11-32T 9 speed cassette with double 53/39T chainring. Only available from Taobao. But needs a freight forwarder.

There are a series of detail photos here:

https://item.taobao.com/item.htm?id=542287629178

Available also from here:

https://item.taobao.com/item.htm?id=42865227153

Monsoon18 - 18 - fnhon??

After further searching, the Visc doesn't seem to be available anywhere around here.

There are a series of detail photos here:

https://item.taobao.com/item.htm?id=542287629178

Available also from here:

https://item.taobao.com/item.htm?id=42865227153

Monsoon18 - 18 - fnhon??

After further searching, the Visc doesn't seem to be available anywhere around here.

#75

Senior Member

Thread Starter

Join Date: Jan 2017

Posts: 1,064

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 350 Post(s)

Likes: 0

Liked 122 Times

in

90 Posts

I'm curious about these 2 frames. Please show the result of your build when you're done.

On the Dahon Vigor D9, I have 46/26 double front 74/110mm BCD. This gives a very wide gear range. Rear with 10 speed cassette, 11-30T with custom combination of cogs (11,12,13,14,15,17,19,21,24,30). With 406x2.1" tires. This gave me 17-83 gear inches. I might drop the 24T and 30T cog to 25T and 32T, and the chainrings to 44/24 to get a lower range. I rarely use the highest gear anyway.

If you used this same gearing on your FnHon 18" frame with 1.75" tires, you would have 14% lowered range.

The chainring jump is 20T, which I found is the limit for smooth shifting, with a chain catcher attached which prevents any dropping. I think a 22T jump might have problems with upshifting. With 20T, you might have to bend the FD cage a little bit to get it wider. I found the easiest way was to clamp an adjustable wrench to a table, split the FD cage plate in it, and use a 2nd wrench to bend the plate.

Also with a 20T jump, the max spacing of the chainring I could use was 8mm and I could only use up to 7th gear on the inner chainring. If I went over this spacing between chainrings, the gap was too large and I could not upshift. If it was 18T jump, I could increase the spacing to 8.2-8.4mm and use 8th gear on the inner chainring.

In order to use 24 or 26T inner chainring with a double setup, you will need to use either a triple crank 74/110 or 74/130 with 165-170 Q-factor and the middle position becomes your new outer with a max size of 46T, or a special double crank from Sugino (OX series) if you want a narrower 146-148mm Q-factor (similar to inner and middle position, no outer). One problem with a triple crank is that the inner position is a bit too close to the oversized seat tube. The Sugino double crank has the inner chainring spaced further out by 2mm, to reduce clearance problems with the FD cage. I also used the narrower Shimano hollowtech mountain BB with the road plastic sheath, which allowed me to add a spacer and shift the Sugino crank 1mm further to the right.

If you want larger than 46T for the middle position, I think Sugino has 48,50,52 in 110 BCD, but you have to make sure that it's the model with countersink holes on the inside surface. PE110S usually has countersink on both sides. It's $100, but I think there is a shop going out of business in the UK that has old stock for $30-40.

On the Dahon Vigor D9, I have 46/26 double front 74/110mm BCD. This gives a very wide gear range. Rear with 10 speed cassette, 11-30T with custom combination of cogs (11,12,13,14,15,17,19,21,24,30). With 406x2.1" tires. This gave me 17-83 gear inches. I might drop the 24T and 30T cog to 25T and 32T, and the chainrings to 44/24 to get a lower range. I rarely use the highest gear anyway.

If you used this same gearing on your FnHon 18" frame with 1.75" tires, you would have 14% lowered range.

The chainring jump is 20T, which I found is the limit for smooth shifting, with a chain catcher attached which prevents any dropping. I think a 22T jump might have problems with upshifting. With 20T, you might have to bend the FD cage a little bit to get it wider. I found the easiest way was to clamp an adjustable wrench to a table, split the FD cage plate in it, and use a 2nd wrench to bend the plate.

Also with a 20T jump, the max spacing of the chainring I could use was 8mm and I could only use up to 7th gear on the inner chainring. If I went over this spacing between chainrings, the gap was too large and I could not upshift. If it was 18T jump, I could increase the spacing to 8.2-8.4mm and use 8th gear on the inner chainring.

In order to use 24 or 26T inner chainring with a double setup, you will need to use either a triple crank 74/110 or 74/130 with 165-170 Q-factor and the middle position becomes your new outer with a max size of 46T, or a special double crank from Sugino (OX series) if you want a narrower 146-148mm Q-factor (similar to inner and middle position, no outer). One problem with a triple crank is that the inner position is a bit too close to the oversized seat tube. The Sugino double crank has the inner chainring spaced further out by 2mm, to reduce clearance problems with the FD cage. I also used the narrower Shimano hollowtech mountain BB with the road plastic sheath, which allowed me to add a spacer and shift the Sugino crank 1mm further to the right.

If you want larger than 46T for the middle position, I think Sugino has 48,50,52 in 110 BCD, but you have to make sure that it's the model with countersink holes on the inside surface. PE110S usually has countersink on both sides. It's $100, but I think there is a shop going out of business in the UK that has old stock for $30-40.