Seat//Head tube coplanarity

#26

Member

Thread Starter

Join Date: Jul 2019

Posts: 26

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 10 Post(s)

Liked 0 Times

in

0 Posts

Next there's the question as to how this 15mm was measured. If it's with a fork in situ then the fork must be checked. I certainly have seen many production forks that are rather bad in their blade length equaliness as well as the dropouts (or drop throughs

) that are not centered WRT the steerer. If the 15mm was a calculated amount based on an angular HT offness please explain your method to come to this angle.

) that are not centered WRT the steerer. If the 15mm was a calculated amount based on an angular HT offness please explain your method to come to this angle.Not trying to say you can't measure or don't understand this stuff but a number stated with little/no backround as to where it was derived from isn't a full story.

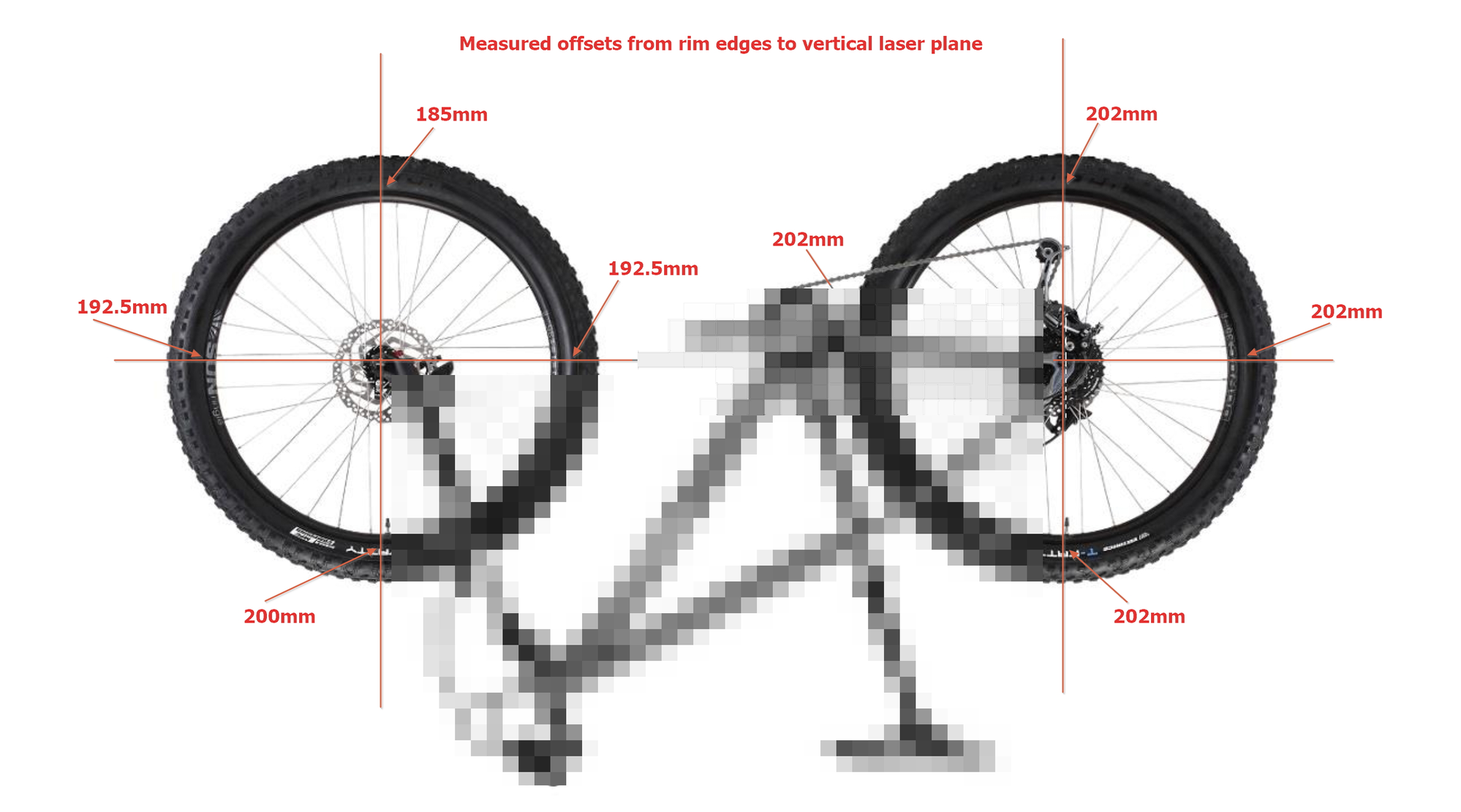

Wheel misalignment is clearly visible just by visual inspection.

More accurate measurement using 2 straight edges.

Wheel rims are 600mm dia, which gives an angle error of ~1.4°

Measurements are all on the second bike; the first one was slightly worse visually.

#27

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,084

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4205 Post(s)

Liked 3,863 Times

in

2,311 Posts

That photo sure shows a poor alignment. More then what I would expect the tires' wobbliness to contribute (another poor gage, inflated tires sides).

I have no skin in this situation. Just a lot of experience in doing this stuff through many years and with many methods. My goal in staying with this thread is for education, not verifying a condition. Since I can't put my hands, eyes and tools I have in play I have no true confirmations to offer. The OP has done a lot of home/sort of good attempts at finding the cause and I suspect the initial opinion of a twisted main triangle would be confirmed with proper assessment/alignment checks. But with all the stuff provided there's assumptions being made and a reliance on gages (tires and forks to name two) that are not always consistent or straight limit conclusions. It is these traps that I speak to.

There are so many false "understandings" to alignment and handling issues that flood the consumer social forums (and the bike shops). It is reasonable that bike companies (note my shift to "companies" as they are often not the manufacturers yet are the "buck stops here" point) can't tell the experience or methods for any one claim of misalignment most of the time. The OP has gone far beyond this level though and I feel that the frame in question is likely twisted in it's main triangle. We just can't say with complete confidence unless we do the work.

Not much more I can add except to repeat that the replacement frame should be checked out by a qualified person before being built up. Please let us know who things work out. Andy

I have no skin in this situation. Just a lot of experience in doing this stuff through many years and with many methods. My goal in staying with this thread is for education, not verifying a condition. Since I can't put my hands, eyes and tools I have in play I have no true confirmations to offer. The OP has done a lot of home/sort of good attempts at finding the cause and I suspect the initial opinion of a twisted main triangle would be confirmed with proper assessment/alignment checks. But with all the stuff provided there's assumptions being made and a reliance on gages (tires and forks to name two) that are not always consistent or straight limit conclusions. It is these traps that I speak to.

There are so many false "understandings" to alignment and handling issues that flood the consumer social forums (and the bike shops). It is reasonable that bike companies (note my shift to "companies" as they are often not the manufacturers yet are the "buck stops here" point) can't tell the experience or methods for any one claim of misalignment most of the time. The OP has gone far beyond this level though and I feel that the frame in question is likely twisted in it's main triangle. We just can't say with complete confidence unless we do the work.

Not much more I can add except to repeat that the replacement frame should be checked out by a qualified person before being built up. Please let us know who things work out. Andy

__________________

AndrewRStewart

AndrewRStewart

#28

Member

Thread Starter

Join Date: Jul 2019

Posts: 26

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 10 Post(s)

Liked 0 Times

in

0 Posts

That photo sure shows a poor alignment. More then what I would expect the tires' wobbliness to contribute (another poor gage, inflated tires sides).

I have no skin in this situation. Just a lot of experience in doing this stuff through many years and with many methods. My goal in staying with this thread is for education, not verifying a condition. Since I can't put my hands, eyes and tools I have in play I have no true confirmations to offer. The OP has done a lot of home/sort of good attempts at finding the cause and I suspect the initial opinion of a twisted main triangle would be confirmed with proper assessment/alignment checks. But with all the stuff provided there's assumptions being made and a reliance on gages (tires and forks to name two) that are not always consistent or straight limit conclusions. It is these traps that I speak to.

There are so many false "understandings" to alignment and handling issues that flood the consumer social forums (and the bike shops). It is reasonable that bike companies (note my shift to "companies" as they are often not the manufacturers yet are the "buck stops here" point) can't tell the experience or methods for any one claim of misalignment most of the time. The OP has gone far beyond this level though and I feel that the frame in question is likely twisted in it's main triangle. We just can't say with complete confidence unless we do the work.

Not much more I can add except to repeat that the replacement frame should be checked out by a qualified person before being built up. Please let us know who things work out. Andy

I have no skin in this situation. Just a lot of experience in doing this stuff through many years and with many methods. My goal in staying with this thread is for education, not verifying a condition. Since I can't put my hands, eyes and tools I have in play I have no true confirmations to offer. The OP has done a lot of home/sort of good attempts at finding the cause and I suspect the initial opinion of a twisted main triangle would be confirmed with proper assessment/alignment checks. But with all the stuff provided there's assumptions being made and a reliance on gages (tires and forks to name two) that are not always consistent or straight limit conclusions. It is these traps that I speak to.

There are so many false "understandings" to alignment and handling issues that flood the consumer social forums (and the bike shops). It is reasonable that bike companies (note my shift to "companies" as they are often not the manufacturers yet are the "buck stops here" point) can't tell the experience or methods for any one claim of misalignment most of the time. The OP has gone far beyond this level though and I feel that the frame in question is likely twisted in it's main triangle. We just can't say with complete confidence unless we do the work.

Not much more I can add except to repeat that the replacement frame should be checked out by a qualified person before being built up. Please let us know who things work out. Andy

Likewise I can also confirm the same visual result with the fork reversed 180°, which pretty much eliminates the fork as a significant contributor to the issue.

Th other thing that I notice on close inspection is that the final boring for the head tube bearings are not concentric with the head tube body, and in fact may contribute (albeit slightly) to the issue rather than alleviate it. There is a variation between the flanges and the body of the tube, probably less than 0.5mm but visible (and easy to feel).

When you look into it, the scale of frame production is vast, with I think 3 factories producing something like 80% of the world's frames; very few brands build their own, and none of the budget brands will.

These frames are generally manufactured by tack welding in a jig, then full welding, followed by heat treatment. Then the frames are aligned physically on a table to fairly loose tolerances. The final step is to bore the HT bearing seats, BB, seatpost and through holes, which again are done holding the frame in a specific fitment. I would be very surprised if the final machining step doesn't achieve tolerances better than most frame builders can achieve without this equipment. In the case of this frame, both the alignment and subsequent machining have made the problem worse, and both are dependent on the correct fitment being used.

And clearly there weren't any subsequent inspections either. Even the LBS didn't know what they were looking for, despite being forewarned.

#29

Member

Thread Starter

Join Date: Jul 2019

Posts: 26

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 10 Post(s)

Liked 0 Times

in

0 Posts

Bust open the piggy bank and purchase the ISO standard. A quick google search suggests it's about safety standards, not about alignment. And while yes alignment can affect control of the bike I doubt that's what the standard focuses on. The only way to know for sure is to read the standard though.

And BTW, your posts ARE confusing. It's clear that you have an ulterior motive for this thread. Why not just come out and say it?

And BTW, your posts ARE confusing. It's clear that you have an ulterior motive for this thread. Why not just come out and say it?

#30

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,084

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4205 Post(s)

Liked 3,863 Times

in

2,311 Posts

I'm pretty sure I've allowed for tire tolerances by first checking the sidewalls spin true, and then also doing the final measurement to the rim edges.

Likewise I can also confirm the same visual result with the fork reversed 180°, which pretty much eliminates the fork as a significant contributor to the issue.

Th other thing that I notice on close inspection is that the final boring for the head tube bearings are not concentric with the head tube body, and in fact may contribute (albeit slightly) to the issue rather than alleviate it. There is a variation between the flanges and the body of the tube, probably less than 0.5mm but visible (and easy to feel).

When you look into it, the scale of frame production is vast, with I think 3 factories producing something like 80% of the world's frames; very few brands build their own, and none of the budget brands will.

These frames are generally manufactured by tack welding in a jig, then full welding, followed by heat treatment. Then the frames are aligned physically on a table to fairly loose tolerances. The final step is to bore the HT bearing seats, BB, seatpost and through holes, which again are done holding the frame in a specific fitment. I would be very surprised if the final machining step doesn't achieve tolerances better than most frame builders can achieve without this equipment. In the case of this frame, both the alignment and subsequent machining have made the problem worse, and both are dependent on the correct fitment being used.

And clearly there weren't any subsequent inspections either. Even the LBS didn't know what they were looking for, despite being forewarned.

Likewise I can also confirm the same visual result with the fork reversed 180°, which pretty much eliminates the fork as a significant contributor to the issue.

Th other thing that I notice on close inspection is that the final boring for the head tube bearings are not concentric with the head tube body, and in fact may contribute (albeit slightly) to the issue rather than alleviate it. There is a variation between the flanges and the body of the tube, probably less than 0.5mm but visible (and easy to feel).

When you look into it, the scale of frame production is vast, with I think 3 factories producing something like 80% of the world's frames; very few brands build their own, and none of the budget brands will.

These frames are generally manufactured by tack welding in a jig, then full welding, followed by heat treatment. Then the frames are aligned physically on a table to fairly loose tolerances. The final step is to bore the HT bearing seats, BB, seatpost and through holes, which again are done holding the frame in a specific fitment. I would be very surprised if the final machining step doesn't achieve tolerances better than most frame builders can achieve without this equipment. In the case of this frame, both the alignment and subsequent machining have made the problem worse, and both are dependent on the correct fitment being used.

And clearly there weren't any subsequent inspections either. Even the LBS didn't know what they were looking for, despite being forewarned.

Re bolded- Most head tube reaming is located by the average of the circumfrence. Pretty much all after joining (weld or braze) head tubes suffer from some distortion. The heat being applied much more on the top tube/down tube side of the head tube will cause the HT to ovalize some (as well as bow like a banana which is another reason for newbies to use thicker walled tubes early on). When the reamer cutter enters the HT it will follow the path of least resistance. This, nearly always, means that some portion of the inside of the HT will see more removal then another portion will.

Additionally a well designed build sequence will have the HT reamed before the final alignment check to account for this slight off center fitting of the steerer/fork. So to with the BB shell facing and chasing. I have not seen many set ups which hold the frame in position then use the cutting as a way to produce alignment. can you link to such a system? I guess that with the through axle stuff this is quite possible and perhaps "the way" to insure wheel alignment. But for the smaller production shops I highly doubt this is how things are done.

Which brings us back to my earlier question as to you're frame's origin. Was it made in a high volume factory? Your comment about 3 factories might be true is one includes all the bikes that we here typically don't consider "worthy" of our riding. But when describing the enthusiast's stuff I suspect that 80% is rather high. Andy

__________________

AndrewRStewart

AndrewRStewart

Last edited by Andrew R Stewart; 10-01-19 at 08:51 AM.

#31

Member

Thread Starter

Join Date: Jul 2019

Posts: 26

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 10 Post(s)

Liked 0 Times

in

0 Posts

I thought I'd been reasonably clear with the description of how these frames are built, the final accuracy is achieved by boring, not reaming. There are several really interesting videos on YouTube that show the vast scale of this kind of production, and at scale CNC machining and complex jig investment becomes economic.

For example, Fuji-Ta/Battle produce over 12 million frames annually;

The manufacturer is producing a replacement frame, and air freighting it to me; I expect to receive it in the next couple of weeks. I'm not confident it will be better, but hopeful that it will be. I'll update when I know more.

For example, Fuji-Ta/Battle produce over 12 million frames annually;

The manufacturer is producing a replacement frame, and air freighting it to me; I expect to receive it in the next couple of weeks. I'm not confident it will be better, but hopeful that it will be. I'll update when I know more.

#32

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,397

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,698 Times

in

2,518 Posts

Sounds like a good outcome. I'm closing this thread now