Carbon Fork Crack Diagnosis

#76

Senior Member

Join Date: Apr 2007

Posts: 6,763

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 1109 Post(s)

Liked 1,200 Times

in

760 Posts

Since I've seen multi-year Lazarus threads resurrected herein, I don't think you have to worry. You can find this thread and reply to it by searching for a word you know is in the thread, let's say Lazarus. Or just search for threads that you've started.

#77

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,399

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,699 Times

in

2,519 Posts

We don't automatically close threads. Any thread that gets closed has generally been discussed by the mod staff, unless a mod thinks it's irredeemable.

I think it's cosmetic. There is probably a relatively thick layer of some finish on top of the carbon and then this fork was painted. Carbon generally doesn't fail on the surface. The fibers come loose from the matrix (which seems to me is a ductile material that can fail in fatigue just like any other) and then start snapping one by one. If they are sheared through external contact, then all bets are off. But that may or may not set off a failure process where more and more fibers snap. They wouldn't fail due to being next to a flaw like a notch sensitive material. The fact that it's bonded to an aluminum crown changes things a little.

I think it's cosmetic. There is probably a relatively thick layer of some finish on top of the carbon and then this fork was painted. Carbon generally doesn't fail on the surface. The fibers come loose from the matrix (which seems to me is a ductile material that can fail in fatigue just like any other) and then start snapping one by one. If they are sheared through external contact, then all bets are off. But that may or may not set off a failure process where more and more fibers snap. They wouldn't fail due to being next to a flaw like a notch sensitive material. The fact that it's bonded to an aluminum crown changes things a little.

#78

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,817

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 839 Post(s)

Liked 1,258 Times

in

663 Posts

while carbon "may not generally fail on the surface" as you say, I would not want to bet my safety on a fork that had a possible crack, delamination or other latent defect.

what we don't know is the trauma or damage that may have occurred before the OP posted it here.

Carbon seems to be a less forgiving material than steel or even aluminum. A fork is a critical item and if it fails, you are likely going down

all we can really do is make decisions for ourselves on what risks we're willing to take.

having said that I've had a steel fork on a high quality bike fail.

but what do I know.

/markp

what we don't know is the trauma or damage that may have occurred before the OP posted it here.

Carbon seems to be a less forgiving material than steel or even aluminum. A fork is a critical item and if it fails, you are likely going down

all we can really do is make decisions for ourselves on what risks we're willing to take.

having said that I've had a steel fork on a high quality bike fail.

but what do I know.

/markp

#79

Senior Member

Carbon does fail on the surface. Below you can see my steerer after a very tough frontal hit. Tacoed front wheel and other damages, but the fork and the frame were still like new on surface, not even scratched. Until I disassembled and took a detail look with a magnifier. This fork could still be used for a while, but the clock to a catastrophic failure was ticking fast.

Likes For Redbullet:

#80

Newbie

I have better things to do than write a failure analysis document and RCA based on a couple of cell phone pics. Having said that I would say, compared to steel and titanium, composite materials "tend to" fail catastrophically, especially if subjected to concentrations of stresses, and / or when the epoxy is penetrated and causes a compromise or damage to the fiber proximate to said concentration of stresses.

On a component where the loads are distributed broadly, like an airplane rudder, this is less of a concern than it is on a component like a bicycle fork where static and cyclic loads are concentrated near the fork crown and steerer tube. Good practice for a critical structure (like a bicycle fork) where failure would result in a crash and possibly injury to the rider would be to replace it at the first sign of damage or compromise.

In aviation, we have non destructive testing tools such as eddy current analyzers to determine the extent of a noted crack or flaw. On Bike Forums, we have a couple cell phone pics and pages of speculation.

Having said that, composite rudders fail too. See American 587. Strictly speaking that is the vertical stabilizer. The rudder came off.

but what do I know ?

/markp

On a component where the loads are distributed broadly, like an airplane rudder, this is less of a concern than it is on a component like a bicycle fork where static and cyclic loads are concentrated near the fork crown and steerer tube. Good practice for a critical structure (like a bicycle fork) where failure would result in a crash and possibly injury to the rider would be to replace it at the first sign of damage or compromise.

In aviation, we have non destructive testing tools such as eddy current analyzers to determine the extent of a noted crack or flaw. On Bike Forums, we have a couple cell phone pics and pages of speculation.

Having said that, composite rudders fail too. See American 587. Strictly speaking that is the vertical stabilizer. The rudder came off.

but what do I know ?

/markp

Likes For LPaul:

#81

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

I've ridden it for a couple of years and besides the spacers being misaligned, it still rides great. But do they make a tube such as I describe?

#82

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,817

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 839 Post(s)

Liked 1,258 Times

in

663 Posts

Good question: what do you know? Did you know that the reason that the vertical stabilizer failed there was because of the violent rudder inputs of the first officer in a misguided attempt to counteract wake turbulence? The fact that the stabilizer was a composite had little to do with its separation from the aircraft.

Reading further from the report:

"damage analysis showed that the bolts and aluminum lugs were intact, but not the composite lugs. This, coupled with two events earlier in the life of the aircraft, namely delamination of part of the vertical stabilizer prior to its delivery from Airbus's Toulouse factory, and an encounter with heavy turbulence in 1994, caused investigators to examine the use of composites. The possibility that the composite materials might not be as strong as previously supposed was a cause of concern, as they are used in other areas of the plane, including the engine mounting and the wings."

As I read it, the composite material used in the vertical stab was a factor in this crash. Not so much ultimate yield strength, but in the way the material fails and how it was attached to the aft fuselage structure. Also note that the incident aircraft had damage history - and as I said above, composite materials are especially unforgiving if they've sustained previous damage.

Which was the point of my earlier post.

There was a subsequent AD (airworthiness directive) on these aircraft to IRAN (inspect and repair as necessary) the stab / aft fuselage join and add a reinforcing plate.

/markp

Last edited by mpetry912; 07-16-23 at 11:41 AM.

#83

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

I've ridden it for a couple of years and besides the spacers being misaligned, it still rides great. But do they make a tube such as I describe, one that could keep the spacers centered?

#84

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,817

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 839 Post(s)

Liked 1,258 Times

in

663 Posts

Carbon does fail on the surface. Below you can see my steerer after a very tough frontal hit. Tacoed front wheel and other damages, but the fork and the frame were still like new on surface, not even scratched. Until I disassembled and took a detail look with a magnifier. This fork could still be used for a while, but the clock to a catastrophic failure was ticking fast.

/markp

#85

Senior Member

Thread Starter

My daughter at the dinner table: "You owe me for the duty that I had to pay on $600 worth of German pitchforks that arrived today". That took some 'splaining.

I'd intended to do the sanding after I'd successfully installed the new fork. Unfortunately, I'm now choking a bit on whether or not to replace the headset first and whether or not I want to do that work myself (first time for fork and headset).

So, alas, I've been dragging heals on the sanding. No more though. I've decided to throw caution to the wind and sand the fork before successfully reinstalling it's replacement, hopefully sometime in the next couple of weeks.

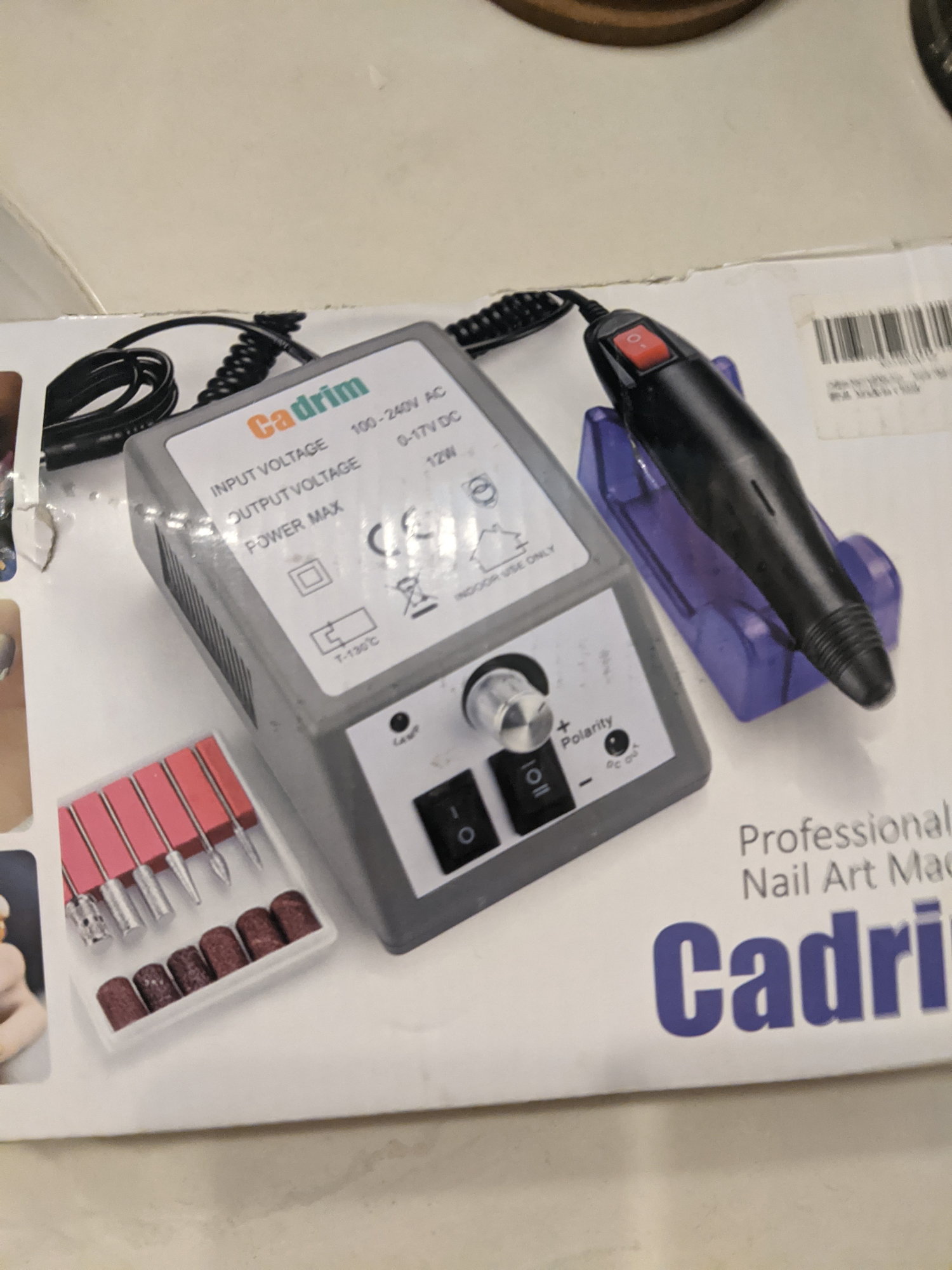

To that end, I'm thinking of doing the sanding with the Dremel like tool shown below. I bought it to trim my dog's nails but feel that it would work well here to expose what needs exposing while limiting the extent of the sanding.

#86

Senior Member

Yeah, if you're good with your dog's claws, I bet you'll be fine with the paint. Some people might come at you and say that's crazy, you'll accidentally burn through the carbon or drill a hole.

If you do ruin the fork with the dremel, though, it will be like that joke about identifying poop, with the punchline, good thing we didn't step in it.

If you do ruin the fork with the dremel, though, it will be like that joke about identifying poop, with the punchline, good thing we didn't step in it.

Likes For ljsense:

#87

Newbie

According to the NTSB report, the yaw damper was off. In case you're not current and qualified on the 300B (full disclosure, I'm not either), the yaw damper is a little switch on the glare shield that functions as a rate limiter to prevent excessive aerodynamic loads on the vertical stab. It's an after takeoff checklist item.

Reading further from the report:

"damage analysis showed that the bolts and aluminum lugs were intact, but not the composite lugs. This, coupled with two events earlier in the life of the aircraft, namely delamination of part of the vertical stabilizer prior to its delivery from Airbus's Toulouse factory, and an encounter with heavy turbulence in 1994, caused investigators to examine the use of composites. The possibility that the composite materials might not be as strong as previously supposed was a cause of concern, as they are used in other areas of the plane, including the engine mounting and the wings."

As I read it, the composite material used in the vertical stab was a factor in this crash. Not so much ultimate yield strength, but in the way the material fails and how it was attached to the aft fuselage structure. Also note that the incident aircraft had damage history - and as I said above, composite materials are especially unforgiving if they've sustained previous damage.

Which was the point of my earlier post.

There was a subsequent AD (airworthiness directive) on these aircraft to IRAN (inspect and repair as necessary) the stab / aft fuselage join and add a reinforcing plate.

/markp

Reading further from the report:

"damage analysis showed that the bolts and aluminum lugs were intact, but not the composite lugs. This, coupled with two events earlier in the life of the aircraft, namely delamination of part of the vertical stabilizer prior to its delivery from Airbus's Toulouse factory, and an encounter with heavy turbulence in 1994, caused investigators to examine the use of composites. The possibility that the composite materials might not be as strong as previously supposed was a cause of concern, as they are used in other areas of the plane, including the engine mounting and the wings."

As I read it, the composite material used in the vertical stab was a factor in this crash. Not so much ultimate yield strength, but in the way the material fails and how it was attached to the aft fuselage structure. Also note that the incident aircraft had damage history - and as I said above, composite materials are especially unforgiving if they've sustained previous damage.

Which was the point of my earlier post.

There was a subsequent AD (airworthiness directive) on these aircraft to IRAN (inspect and repair as necessary) the stab / aft fuselage join and add a reinforcing plate.

/markp

Likes For LPaul: