Rust remover broke my chain?

#51

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,366

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,221 Times

in

2,367 Posts

To understand how outer plates fail at the pin hole, you have to understand how chains are made, which, based on your earlier post, you clearly don't. Outer plate failures at the rivet hole is a very well documented and understood phenomenon. If, instead of assuming, you took the time to research the specific topics at hand, you wouldn't head down false paths and argue endlessly.

Salt, on the other hand, can catalyze the oxidation of the iron and lead to much more iron removal than water exposure would due to the hygroscopic nature of chloride salts and the ability of iron chlorides to release the chloride ions in the presence of water…even a very small amount of water…so that the chloride can go back and oxidize more iron. It’s a catalytic process with little to no passivation occurring on the iron surface.

Now take a rusty chain and drop it into a solution that is designed to remove the rust through chemical reactions but is also capable of reacting with the iron and there is a much higher possibility of the chain cracking that from simple oxidation. Add to that that the observer heard audible sounds when the chain was added to the solutions and I’m on very stable ground in my explanation. My hypothesis is on much more stable ground than blaming this on “hydrogen embrittlement”.

Let me see if I get this straight? You are allowed to disagree with me but I’m not allowed to disagree with you?

I'm starting to believe that you can't read, either. ----- Where did I say that hydrogen embrittlement happens in air?

This is simply more of your strawman tactics to cover your own lack of expertise.

This is simply more of your strawman tactics to cover your own lack of expertise.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#52

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,366

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,221 Times

in

2,367 Posts

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#53

Senior Member

Join Date: Dec 2020

Location: Wake Forest, NC

Posts: 5,795

Bikes: 1989 Cinelli Supercorsa

Mentioned: 11 Post(s)

Tagged: 0 Thread(s)

Quoted: 3514 Post(s)

Liked 2,927 Times

in

1,776 Posts

Your reliance on alternative facts--and failure to rely on your own experience--means I cannot continue this discussion in good faith.

#54

Senior Member

Join Date: Apr 2016

Posts: 1,236

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 501 Post(s)

Liked 436 Times

in

335 Posts

You mean the wear from the inner plate? If there's wear between the pin and outer plate, why doesn't the pin fall out eventually?

C'mon, man. You know better than this. You can't tell me that after working on bikes as long as you have that you actually believe the pins rotate in any way in the outer plates? What, pray tell, would cause such rotation against a press-fit pin? If this is your sincere belief, then we really don't have anything to discuss.

C'mon, man. You know better than this. You can't tell me that after working on bikes as long as you have that you actually believe the pins rotate in any way in the outer plates? What, pray tell, would cause such rotation against a press-fit pin? If this is your sincere belief, then we really don't have anything to discuss.

#55

Senior Member

Join Date: Dec 2020

Location: Wake Forest, NC

Posts: 5,795

Bikes: 1989 Cinelli Supercorsa

Mentioned: 11 Post(s)

Tagged: 0 Thread(s)

Quoted: 3514 Post(s)

Liked 2,927 Times

in

1,776 Posts

He's talking about the pin actually rotating in the outer side plate.

#56

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,366

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,221 Times

in

2,367 Posts

The pin shows little noticeable wear.

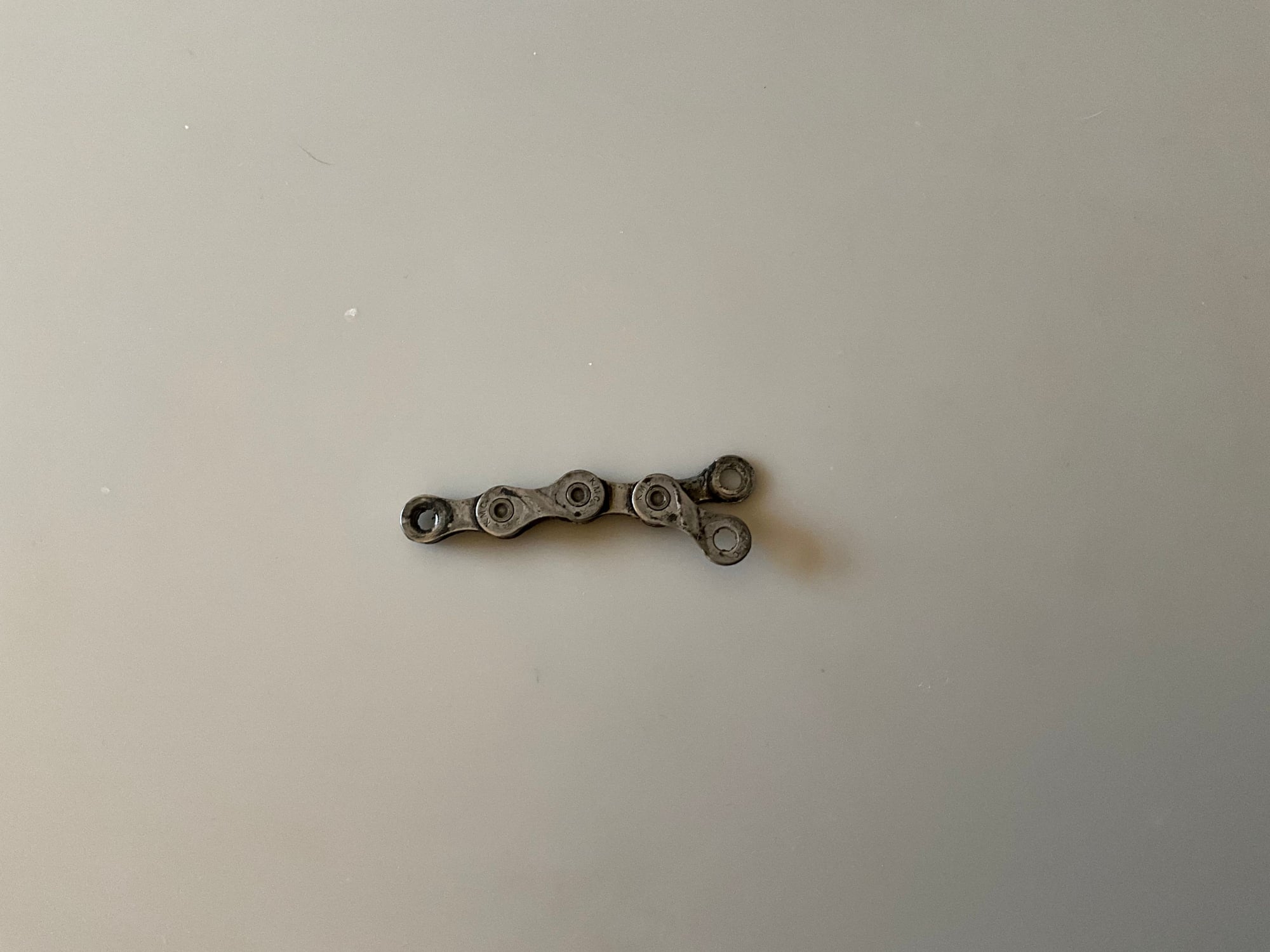

I will admit that I was mostly incorrect about the fit of the outer plates. However, this whole “outer plate force fit” argument is a red herring. The fact that the plates fit tightly on the pin does not mean that that is the cause nor even a contributing factor to the plate fracturing. A chain plate fracture is something of a rare event. I’ll remind you of what was said

I have said over and over and over in this post not to use naval jelly on chains and that I also wouldn’t suggest any kind of cleaner for a very rusty chain. Chains aren’t worth that level of effort.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Likes For cyccommute:

Likes For grumpus:

#58

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,366

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,221 Times

in

2,367 Posts

Grumpus’s point is closer to what I had in mind. There is obvious movement and wear between the outer plate and the pin. It’s not as pronounced as the inner plate wear which have freer movement but there is some wear. But, again, this whole argument has nothing to do with the cracking of the plate.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#59

Senior Member

Join Date: Dec 2020

Location: Wake Forest, NC

Posts: 5,795

Bikes: 1989 Cinelli Supercorsa

Mentioned: 11 Post(s)

Tagged: 0 Thread(s)

Quoted: 3514 Post(s)

Liked 2,927 Times

in

1,776 Posts

The outer plates on a discarded chain can be moved relative to each other but I will admit that it took more force than I expected. This chain was a worn out chain >0.75% elongation but not a highly worn chain. I have handled highly worn chains where the outer plates are easier to move.

The pin shows little noticeable wear.

I will admit that I was mostly incorrect about the fit of the outer plates. However, this whole “outer plate force fit” argument is a red herring. The fact that the plates fit tightly on the pin does not mean that that is the cause nor even a contributing factor to the plate fracturing. A chain plate fracture is something of a rare event. I’ll remind you of what was said

If the force fit put that much stress on the plate at every pin, fracturing of pin plates would be a much more common experience. It happens, yes, but it doesn’t happen all that often nor do people put chains in highly acidic cleaners that have an affinity for iron and then notice that the chain makes a popping noise when they do so.

I have said over and over and over in this post not to use naval jelly on chains and that I also wouldn’t suggest any kind of cleaner for a very rusty chain. Chains aren’t worth that level of effort.

The pin shows little noticeable wear.

I will admit that I was mostly incorrect about the fit of the outer plates. However, this whole “outer plate force fit” argument is a red herring. The fact that the plates fit tightly on the pin does not mean that that is the cause nor even a contributing factor to the plate fracturing. A chain plate fracture is something of a rare event. I’ll remind you of what was said

If the force fit put that much stress on the plate at every pin, fracturing of pin plates would be a much more common experience. It happens, yes, but it doesn’t happen all that often nor do people put chains in highly acidic cleaners that have an affinity for iron and then notice that the chain makes a popping noise when they do so.

I have said over and over and over in this post not to use naval jelly on chains and that I also wouldn’t suggest any kind of cleaner for a very rusty chain. Chains aren’t worth that level of effort.

#60

Senior Member

Join Date: Mar 2011

Posts: 3,095

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 1034 Post(s)

Liked 1,292 Times

in

744 Posts

So, to recap. OP your lack of maintenance is to blame. Buy a new chain, install it correctly, then keep it lubed. Clean it when it's dirty, then lube it. Repeat as necessary. If the chain is clean, you will be able to notice bad spots in the chain easier.

Glad I have one particular person here on ignore, but I made the mistake of clicking to see one of his posts. Wow.

Wow.

Glad I have one particular person here on ignore, but I made the mistake of clicking to see one of his posts.

Wow.

Wow.

Likes For phughes:

#61

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,725

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5793 Post(s)

Liked 2,584 Times

in

1,432 Posts

This thread has reached new levels of rediculousness to the point that I don't remember what we're arguing about. Since Cycocommute and I seem to be the main protagonists, I offer a suggestion. We each post a short summary of our theory relating to the cause of the OP's then simply leave it there for others to consider on their own. Keep in mind thatthe goal is to stop arguing and post positive assertions for folks to consider, rather than attack each other.

I'll start.

---------------------

The proximate cause is hydrogen embrittlement resulting from the OP soaking the chain in an acid bath.

The specific mode of failure is stress cracking of the outer plates at the pin holes. Outer plates are stressed by virtue of the force fit over the pins, which press outward creating a tension stress akin to hoop stress. Normally this is OK and the loads factored into the design. However the embrittlement weakened the plates causing cracks to form at the hole (the point highest localized stress) which then propagated outward to the edge. It's a simple two step process, weaken the plate then let it's own internal stresses take their toll.

In support, crack formation due to hydrogen embrittlement of steel is a well documented phenomenon, with plenty of scholarly articles available on the net. The type of failure at the pins that I describe is also well documented, and a quick search for bicycle chain plate cracks will bring up countless images showing radial cracks running outward from the pin at all angles. The holes are the most common location for plate cracks, and you won't find similar cracks on inner plates which are not stressed the same way. Morevover, the all angle aspect is important because it implies a cause other than the normal tension load imposed by the rider. Note also that you'll see the same radial cracks or relatively new chains showing minimal wear, and no markings near the cracks.

----------------

Now it's Cycocommute's turn to post his theory,

I'll start.

---------------------

The proximate cause is hydrogen embrittlement resulting from the OP soaking the chain in an acid bath.

The specific mode of failure is stress cracking of the outer plates at the pin holes. Outer plates are stressed by virtue of the force fit over the pins, which press outward creating a tension stress akin to hoop stress. Normally this is OK and the loads factored into the design. However the embrittlement weakened the plates causing cracks to form at the hole (the point highest localized stress) which then propagated outward to the edge. It's a simple two step process, weaken the plate then let it's own internal stresses take their toll.

In support, crack formation due to hydrogen embrittlement of steel is a well documented phenomenon, with plenty of scholarly articles available on the net. The type of failure at the pins that I describe is also well documented, and a quick search for bicycle chain plate cracks will bring up countless images showing radial cracks running outward from the pin at all angles. The holes are the most common location for plate cracks, and you won't find similar cracks on inner plates which are not stressed the same way. Morevover, the all angle aspect is important because it implies a cause other than the normal tension load imposed by the rider. Note also that you'll see the same radial cracks or relatively new chains showing minimal wear, and no markings near the cracks.

----------------

Now it's Cycocommute's turn to post his theory,

Last edited by FBinNY; 02-09-24 at 02:05 AM.

#62

Senior Member

You mean the wear from the inner plate? If there's wear between the pin and outer plate, why doesn't the pin fall out eventually?

C'mon, man. You know better than this. You can't tell me that after working on bikes as long as you have that you actually believe the pins rotate in any way in the outer plates? What, pray tell, would cause such rotation against a press-fit pin? If this is your sincere belief, then we really don't have anything to discuss.

Chain wear

C'mon, man. You know better than this. You can't tell me that after working on bikes as long as you have that you actually believe the pins rotate in any way in the outer plates? What, pray tell, would cause such rotation against a press-fit pin? If this is your sincere belief, then we really don't have anything to discuss.

Chain wear

Having said the above, it is possible for the outer links to wear open to a slip fit on the pin, from stress, or more likely, the link fracturing, removing the press fit. And then you will get "fretting wear" like seen in one of the pin pics above. And even before then, any looseness between pin and outer link, and the chain is not long for this world.

Last edited by Duragrouch; 02-09-24 at 12:42 AM.

#63

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,366

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,221 Times

in

2,367 Posts

This thread has reached new levels of rediculousness to the point that I don't remember what we're arguing about. Since Cycocommute and I seem to be the main protagonists, I offer a suggestion. We each post a short summary of our theory relating to the cause of the OP's then simply leave it there for others to consider on their own. Keep in mind thatthe goal is to stop arguing and post positive assertions for folks to consider, rather than attack each other.

I'll start.

---------------------

The proximate cause is hydrogen embrittlement resulting from the OP soaking the chain in an acid bath.

The specific mode of failure is stress cracking of the outer plates at the pin holes. Outer plates are stressed by virtue of the force fit over the pins, which press outward creating a tension stress akin to hoop stress. Normally this is OK and the loads factored into the design. However the embrittlement weakened the plates causing cracks to form at the hole (the point highest localized stress) which then propagated outward to the edge. It's a simple two step process, weaken the plate then let it's own internal stresses take their toll.

In support, crack formation due to hydrogen embrittlement of steel is a well documented phenomenon, with plenty of scholarly articles available on the net. The type of failure at the pins that I describe is also well documented, and a quick search for bicycle chain plate cracks will bring up countless images showing radial cracks running outward from the pin at all angles. The holes are the most common location for plate cracks, and you won't find similar cracks on inner plates which are not stressed the same way. Morevover, the all angle aspect is important because it implies a cause other than the normal tension load imposed by the rider. Note also that you'll see the same radial cracks or relatively new chains showing minimal wear, and no markings near the cracks.

----------------

Now it's Cycocommute's turn to post his theory,

I'll start.

---------------------

The proximate cause is hydrogen embrittlement resulting from the OP soaking the chain in an acid bath.

The specific mode of failure is stress cracking of the outer plates at the pin holes. Outer plates are stressed by virtue of the force fit over the pins, which press outward creating a tension stress akin to hoop stress. Normally this is OK and the loads factored into the design. However the embrittlement weakened the plates causing cracks to form at the hole (the point highest localized stress) which then propagated outward to the edge. It's a simple two step process, weaken the plate then let it's own internal stresses take their toll.

In support, crack formation due to hydrogen embrittlement of steel is a well documented phenomenon, with plenty of scholarly articles available on the net. The type of failure at the pins that I describe is also well documented, and a quick search for bicycle chain plate cracks will bring up countless images showing radial cracks running outward from the pin at all angles. The holes are the most common location for plate cracks, and you won't find similar cracks on inner plates which are not stressed the same way. Morevover, the all angle aspect is important because it implies a cause other than the normal tension load imposed by the rider. Note also that you'll see the same radial cracks or relatively new chains showing minimal wear, and no markings near the cracks.

----------------

Now it's Cycocommute's turn to post his theory,

First, let’s review what elfmachine said in the original post:

Hello. I installed a SunRace CNM84 chain on my bicycle last year and after many months it rusted so much that it got stiff. Pretty strange that it rusted so strongly despite being plated with chrome or nickel. I didn't have time to lubricate it so I rode my bike with an unlubricated chain which became more flexible after a ride. Now removed the chan and placed it into a bath with phosphoric acid with zinc aka rust remover to remove rust before lubricating it with teflon wax. After a while I started hearing popping sounds and after chain inspection I noticed that many links had cracks! Did rust remover somehow cause breakage or cracks developed from riding an unlubricated rusted chain?

The chain may have been compromised before the acid treatment but observations provided point to the acid treatment causing the cracking. Not through hydrogen embrittlement but through acid dissolution of the metal at the stress risers of the stamped logo. If the chain had been treated with a nonacidic or even less acidic rust remover, the chain likely would not have cracked.

To be clear, I am not saying that chains can’t crack. Nor am I saying that inner plates can crack. I am saying that cracking of the outer plates is a rare occurrence. And contrary to what you have stated earlier in the thread, I am also saying that the cracking of the outer plates in this case was caused by placement of the chain in the acid bath and by the acid in that bath.

Finally, I have never attacked you. I have never questioned your expertise nor your abilities nor your knowledge. You, on the other hand, have not offered me the same courtesy.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Last edited by cyccommute; 02-09-24 at 10:14 AM.

Likes For phughes:

#66

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,366

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,221 Times

in

2,367 Posts

In the phosphoric acid solution elfmachine used, the hydrogen ion helps get the ball rolling by providing a low pH but the real dancer in the party is the phosphate ion. It forms complexes with the iron. I suspect that the phosphate in this case worked very quickly (in the presence of the hydrogen ion) to pluck iron out of micro fractures in the chain plate. The audible cracking was likely from the phosphate unzipping the metal along crystalline boundries. The phosphate, unlike chloride, doesn’t release the iron after the work is done so there is no catalytic effect. But it is more efficient at removing metal.

If you were to use weaker acid like acetic or oxalic or other organic acids, the plucking effect would be slower. That may be due to the fact that those acids don’t dissociate completely like phosphoric acid does and the anion doesn’t form as strong a bond either. I suspect that sulfuric acid wouldn’t do the same rapid cracking as the sulfate anion has little affinity for the iron. Over time it would dissolve the iron but it is something of a slower process.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#67

Senior Member

Join Date: Apr 2019

Location: UK

Posts: 1,404

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 682 Post(s)

Liked 453 Times

in

338 Posts

Interesting. Couldn’t it be H- being released fron the phosphoric acid once water escapes from the reaction between the acid and the rust? (I think H2O is a by-product of that)

This is probably not helping the OP any more though.

This is probably not helping the OP any more though.

#68

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,366

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,221 Times

in

2,367 Posts

The reason that I don’t think this is a case of hydrogen embrittlement is because it wouldn’t happen with most any other kind of acidic solution. Hydrogen ions are available with acetic acid, for example, but the chain wouldn’t have cracked audibly if it were placed in a vinegar solution. I doubt if it would have cracked at all. The same would be true if the chain had been treated in a chelating solution.

I also speculated that possible chloride contamination could have some effect.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Likes For cyccommute:

#69

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,095

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4210 Post(s)

Liked 3,875 Times

in

2,315 Posts

I'll add a few observations:

IMO pins are forced into the chain outer plate holes, "force" here to mean they don't enter the plate due to the force of gravity alone. Yes there is a range of "force fit/slip fit/interference fit" but I doubt most here have the experience, education or tooling to measure the forces along this range let alone claim that at some point the term changes from interference fit to force fit. If I'm wrong of readers having the equipment to measure this stuff I am all eyes and ears to learn more. But as we should all know modern derailleur gear systems can (and due to poor rider skills) and do get shifted under tremendous loads as seen by the teeth and links. So even a non deforming pin fit to the outer plate has been shown to not be able to retain the plate on the pin end under there loads. Shimano (Not sure if they are the original designer or they just bought into the design) came up with the idea of peening over the pin ends to create a lip to better capture those outer plates. This peening comes in varying amounts and the amount is usually indirectly refereed to as "strength of chain". This peening can and does create a larger hole in the outer plate if the pin were to be removed, or if a pin was already peened before installation. It is this last bit that drove Shimano to come up with the UG assembly pin. It has a disposable pilot shaft that also has a ramp at it's end by the portion of the pin that will remain in the chain. This assembly pin has a slightly larger diameter then the original pins have and the ramp better allows the install of this pin without further plate hole damage. I do know nothing has been said about the chain's earlier assembly onto the bike.

I have seen the results of what was explained to me as cleaning products caused cracking before too, just not common. That Super Agitene I mentioned would discolor Regina Oro chains if left to soak over night. The brassy colored outer plates would become silver colored. NOT what your customer who paid your price for that chain wants to find out when they pick the service job up...

While outer plate cracking is not a common issue there have been production errors that weren't caught till thousands of chains made their way to the market. The (IIRC) late 1980s saw Sedis (prior to their molding into SRAM) have a number of SedisSport (or the equivalent model for that year) chains suffer from cracking outer plates. I had a chain crack on a tandem we rode and I've seen a few more at work too. It was fairly well known in the LBS world back then. The story I heard was embrittlement from less than right heat treating. I have seen a few other brand and model chains crack at the pin holes over the years but as others have said it is not a common failure mode.

Much more common is a "mechanic" reassembling the chain without aligning the two outer plates so that the pin tries to enter the far hole off center. A small chain pin tool has way more then enough strength to deform that outer plate beyond safe use. This I have seem many times, less so in the last 10ish years as connecting links have become the home assembly method of choice. This thread is not about that though.

Another interesting experience I've had, unrelated to chain cracking but involve heavy rust, was back in the later 70s I had a Raleigh Twenty (not the DL-20) that I had fitted a SA FW . This was to be my ride to work in the winter bike, which I did a couple of times and really didn't like the slushy riding we have here. Away went the bike till summer and low and behold the chain was so rusty I could almost hold it out straight. I solvent cleaned it at work (Super Agitene) which did nearly nothing to the rust or to freeing up the links. Wire brushed off the outsides best possible. I worked the chain link by link till there was enough pivoting freedom to remount the chain. Oiled and tensioned the chain best possible knowing I would be removing it soon to again clean it out. Rode it to and from work for a few days, a flat 1.5 miles one way. When I was to remove the chain for the follow up cleaning I noticed it was drooping as though the wheel had slipped in the slot (those SA nuts do like to strip out their threads on the hardened and flat spotted axle)I flush out the chain and saw the rust was nearly all gone. The wear surfaces were shinny and only very light spec rust remained on the non critical surfaces. Reinstalling the chain showed the wheel was still well secured but now about 4ish mms too far forward for the right chain tension (which we all know that for a SA IGH is no tension . That was how much space the rust had taken up in each link adding up to the "longer" chain after abrading off the rust in that week of riding. Andy

. That was how much space the rust had taken up in each link adding up to the "longer" chain after abrading off the rust in that week of riding. Andy

IMO pins are forced into the chain outer plate holes, "force" here to mean they don't enter the plate due to the force of gravity alone. Yes there is a range of "force fit/slip fit/interference fit" but I doubt most here have the experience, education or tooling to measure the forces along this range let alone claim that at some point the term changes from interference fit to force fit. If I'm wrong of readers having the equipment to measure this stuff I am all eyes and ears to learn more. But as we should all know modern derailleur gear systems can (and due to poor rider skills) and do get shifted under tremendous loads as seen by the teeth and links. So even a non deforming pin fit to the outer plate has been shown to not be able to retain the plate on the pin end under there loads. Shimano (Not sure if they are the original designer or they just bought into the design) came up with the idea of peening over the pin ends to create a lip to better capture those outer plates. This peening comes in varying amounts and the amount is usually indirectly refereed to as "strength of chain". This peening can and does create a larger hole in the outer plate if the pin were to be removed, or if a pin was already peened before installation. It is this last bit that drove Shimano to come up with the UG assembly pin. It has a disposable pilot shaft that also has a ramp at it's end by the portion of the pin that will remain in the chain. This assembly pin has a slightly larger diameter then the original pins have and the ramp better allows the install of this pin without further plate hole damage. I do know nothing has been said about the chain's earlier assembly onto the bike.

I have seen the results of what was explained to me as cleaning products caused cracking before too, just not common. That Super Agitene I mentioned would discolor Regina Oro chains if left to soak over night. The brassy colored outer plates would become silver colored. NOT what your customer who paid your price for that chain wants to find out when they pick the service job up...

While outer plate cracking is not a common issue there have been production errors that weren't caught till thousands of chains made their way to the market. The (IIRC) late 1980s saw Sedis (prior to their molding into SRAM) have a number of SedisSport (or the equivalent model for that year) chains suffer from cracking outer plates. I had a chain crack on a tandem we rode and I've seen a few more at work too. It was fairly well known in the LBS world back then. The story I heard was embrittlement from less than right heat treating. I have seen a few other brand and model chains crack at the pin holes over the years but as others have said it is not a common failure mode.

Much more common is a "mechanic" reassembling the chain without aligning the two outer plates so that the pin tries to enter the far hole off center. A small chain pin tool has way more then enough strength to deform that outer plate beyond safe use. This I have seem many times, less so in the last 10ish years as connecting links have become the home assembly method of choice. This thread is not about that though.

Another interesting experience I've had, unrelated to chain cracking but involve heavy rust, was back in the later 70s I had a Raleigh Twenty (not the DL-20) that I had fitted a SA FW . This was to be my ride to work in the winter bike, which I did a couple of times and really didn't like the slushy riding we have here. Away went the bike till summer and low and behold the chain was so rusty I could almost hold it out straight. I solvent cleaned it at work (Super Agitene) which did nearly nothing to the rust or to freeing up the links. Wire brushed off the outsides best possible. I worked the chain link by link till there was enough pivoting freedom to remount the chain. Oiled and tensioned the chain best possible knowing I would be removing it soon to again clean it out. Rode it to and from work for a few days, a flat 1.5 miles one way. When I was to remove the chain for the follow up cleaning I noticed it was drooping as though the wheel had slipped in the slot (those SA nuts do like to strip out their threads on the hardened and flat spotted axle)I flush out the chain and saw the rust was nearly all gone. The wear surfaces were shinny and only very light spec rust remained on the non critical surfaces. Reinstalling the chain showed the wheel was still well secured but now about 4ish mms too far forward for the right chain tension (which we all know that for a SA IGH is no tension

. That was how much space the rust had taken up in each link adding up to the "longer" chain after abrading off the rust in that week of riding. Andy

. That was how much space the rust had taken up in each link adding up to the "longer" chain after abrading off the rust in that week of riding. Andy

__________________

AndrewRStewart

AndrewRStewart

Likes For Andrew R Stewart:

#70

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,366

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,221 Times

in

2,367 Posts

I'll add a few observations:

IMO pins are forced into the chain outer plate holes, "force" here to mean they don't enter the plate due to the force of gravity alone. Yes there is a range of "force fit/slip fit/interference fit" but I doubt most here have the experience, education or tooling to measure the forces along this range let alone claim that at some point the term changes from interference fit to force fit. If I'm wrong of readers having the equipment to measure this stuff I am all eyes and ears to learn more. But as we should all know modern derailleur gear systems can (and due to poor rider skills) and do get shifted under tremendous loads as seen by the teeth and links. So even a non deforming pin fit to the outer plate has been shown to not be able to retain the plate on the pin end under there loads. Shimano (Not sure if they are the original designer or they just bought into the design) came up with the idea of peening over the pin ends to create a lip to better capture those outer plates. This peening comes in varying amounts and the amount is usually indirectly refereed to as "strength of chain". This peening can and does create a larger hole in the outer plate if the pin were to be removed, or if a pin was already peened before installation. It is this last bit that drove Shimano to come up with the UG assembly pin. It has a disposable pilot shaft that also has a ramp at it's end by the portion of the pin that will remain in the chain. This assembly pin has a slightly larger diameter then the original pins have and the ramp better allows the install of this pin without further plate hole damage. I do know nothing has been said about the chain's earlier assembly onto the bike.

IMO pins are forced into the chain outer plate holes, "force" here to mean they don't enter the plate due to the force of gravity alone. Yes there is a range of "force fit/slip fit/interference fit" but I doubt most here have the experience, education or tooling to measure the forces along this range let alone claim that at some point the term changes from interference fit to force fit. If I'm wrong of readers having the equipment to measure this stuff I am all eyes and ears to learn more. But as we should all know modern derailleur gear systems can (and due to poor rider skills) and do get shifted under tremendous loads as seen by the teeth and links. So even a non deforming pin fit to the outer plate has been shown to not be able to retain the plate on the pin end under there loads. Shimano (Not sure if they are the original designer or they just bought into the design) came up with the idea of peening over the pin ends to create a lip to better capture those outer plates. This peening comes in varying amounts and the amount is usually indirectly refereed to as "strength of chain". This peening can and does create a larger hole in the outer plate if the pin were to be removed, or if a pin was already peened before installation. It is this last bit that drove Shimano to come up with the UG assembly pin. It has a disposable pilot shaft that also has a ramp at it's end by the portion of the pin that will remain in the chain. This assembly pin has a slightly larger diameter then the original pins have and the ramp better allows the install of this pin without further plate hole damage. I do know nothing has been said about the chain's earlier assembly onto the bike.

I have seen the results of what was explained to me as cleaning products caused cracking before too, just not common. That Super Agitene I mentioned would discolor Regina Oro chains if left to soak over night. The brassy colored outer plates would become silver colored. NOT what your customer who paid your price for that chain wants to find out when they pick the service job up...

While outer plate cracking is not a common issue there have been production errors that weren't caught till thousands of chains made their way to the market. The (IIRC) late 1980s saw Sedis (prior to their molding into SRAM) have a number of SedisSport (or the equivalent model for that year) chains suffer from cracking outer plates. I had a chain crack on a tandem we rode and I've seen a few more at work too. It was fairly well known in the LBS world back then. The story I heard was embrittlement from less than right heat treating. I have seen a few other brand and model chains crack at the pin holes over the years but as others have said it is not a common failure mode.

Another interesting experience I've had, unrelated to chain cracking but involve heavy rust, was back in the later 70s I had a Raleigh Twenty (not the DL-20) that I had fitted a SA FW . This was to be my ride to work in the winter bike, which I did a couple of times and really didn't like the slushy riding we have here. Away went the bike till summer and lo and behold the chain was so rusty I could almost hold it out straight. I solvent cleaned it at work (Super Agitene) which did nearly nothing to the rust or to freeing up the links. Wire brushed off the outsides best possible. I worked the chain link by link till there was enough pivoting freedom to remount the chain. Oiled and tensioned the chain best possible knowing I would be removing it soon to again clean it out. Rode it to and from work for a few days, a flat 1.5 miles one way. When I was to remove the chain for the follow up cleaning I noticed it was drooping as though the wheel had slipped in the slot (those SA nuts do like to strip out their threads on the hardened and flat spotted axle)I flush out the chain and saw the rust was nearly all gone. The wear surfaces were shinny and only very light spec rust remained on the non critical surfaces. Reinstalling the chain showed the wheel was still well secured but now about 4ish mms too far forward for the right chain tension (which we all know that for a SA IGH is no tension . That was how much space the rust had taken up in each link adding up to the "longer" chain after abrading off the rust in that week of riding. Andy

. That was how much space the rust had taken up in each link adding up to the "longer" chain after abrading off the rust in that week of riding. Andy

. That was how much space the rust had taken up in each link adding up to the "longer" chain after abrading off the rust in that week of riding. Andy

. That was how much space the rust had taken up in each link adding up to the "longer" chain after abrading off the rust in that week of riding. Andy

This expansion of the oxide is also what is responsible for seized stems and seatposts. Steel posts can because they rust and expand. Aluminum oxide is similarly more voluminous than the metal that forms it. Both expand in an area where there is little room for expansion and, in the case of seat posts, little opportunity to move the part to break up the oxide.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Likes For cyccommute:

#71

Senior Member

Cyccommute,

You mention phosphoric acid. There is a solution called Ospho, a dilute phosphoric acid solution, no issue if it splashes briefly on hands, that is a common treatment for rust, it turns the red rust to black iron phosphate, and then you paint over it (I've had issues with cosmetic white "runs" if painting over too soon, the Ospho needs to dry about a week, and even better if first covered with primer). But anyway...

I treated a shiny carbon steel knife with Ospho, to get the vintage look, like carbon steel Sabatier kitchen knives that have been used for decades, graying from many years of slicing acidic fruits, vegetables, and meats. I didn't soak the knife in Ospho, just actively brush it on for several minutes, then rinse and dry, left a nice flat gray finish. So my question is, did this risk embrittlement of the knife? Thanks in advance.

Many years ago I derusted some files with concentrated hydrochloric acid (outside with full PPE), as I recall, made green solution on surface, but then after rinsing and drying, left them on an electric radiator heater a couple hours in case they absorbed hydrogen, wasn't sure if that would cure. Comments?

You mention phosphoric acid. There is a solution called Ospho, a dilute phosphoric acid solution, no issue if it splashes briefly on hands, that is a common treatment for rust, it turns the red rust to black iron phosphate, and then you paint over it (I've had issues with cosmetic white "runs" if painting over too soon, the Ospho needs to dry about a week, and even better if first covered with primer). But anyway...

I treated a shiny carbon steel knife with Ospho, to get the vintage look, like carbon steel Sabatier kitchen knives that have been used for decades, graying from many years of slicing acidic fruits, vegetables, and meats. I didn't soak the knife in Ospho, just actively brush it on for several minutes, then rinse and dry, left a nice flat gray finish. So my question is, did this risk embrittlement of the knife? Thanks in advance.

Many years ago I derusted some files with concentrated hydrochloric acid (outside with full PPE), as I recall, made green solution on surface, but then after rinsing and drying, left them on an electric radiator heater a couple hours in case they absorbed hydrogen, wasn't sure if that would cure. Comments?

Last edited by Duragrouch; 02-11-24 at 02:34 AM.

Likes For Duragrouch:

#72

Senior Member

Join Date: Nov 2014

Location: Eugene, Oregon, USA

Posts: 27,547

Mentioned: 217 Post(s)

Tagged: 0 Thread(s)

Quoted: 18378 Post(s)

Liked 4,512 Times

in

3,354 Posts

The Wipperman Conex 8sx (8 spd), 9sx (9 spd), 10sx (10 spd), and 11sx (11 spd) chains have stainless link plates, although I believe the pins are not.

It should be more corrosion resistant. However, if you look at the price, you may determine that it is cheaper just to purchase a cheap chain, keep it oiled, and replace as needed.

#73

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,366

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6219 Post(s)

Liked 4,221 Times

in

2,367 Posts

Cyccommute,

You mention phosphoric acid. There is a solution called Ospho, a dilute phosphoric acid solution, no issue if it splashes briefly on hands, that is a common treatment for rust, it turns the red rust to black iron phosphate, and then you paint over it (I've had issues with cosmetic white "runs" if painting over too soon, the Ospho needs to dry about a week, and even better if first covered with primer). But anyway...

I treated a shiny carbon steel knife with Ospho, to get the vintage look, like carbon steel Sabatier kitchen knives that have been used for decades, graying from many years of slicing acidic fruits, vegetables, and meats. I didn't soak the knife in Ospho, just actively brush it on for several minutes, then rinse and dry, left a nice flat gray finish. So my question is, did this risk embrittlement of the knife? Thanks in advance.

You mention phosphoric acid. There is a solution called Ospho, a dilute phosphoric acid solution, no issue if it splashes briefly on hands, that is a common treatment for rust, it turns the red rust to black iron phosphate, and then you paint over it (I've had issues with cosmetic white "runs" if painting over too soon, the Ospho needs to dry about a week, and even better if first covered with primer). But anyway...

I treated a shiny carbon steel knife with Ospho, to get the vintage look, like carbon steel Sabatier kitchen knives that have been used for decades, graying from many years of slicing acidic fruits, vegetables, and meats. I didn't soak the knife in Ospho, just actively brush it on for several minutes, then rinse and dry, left a nice flat gray finish. So my question is, did this risk embrittlement of the knife? Thanks in advance.

Many years ago I derusted some files with concentrated hydrochloric acid (outside with full PPE), as I recall, made green solution on surface, but then after rinsing and drying, left them on an electric radiator heater a couple hours in case they absorbed hydrogen, wasn't sure if that would cure. Comments?

As for rinsing off any parts where you want to avoid rust, I would rinse with denatured alcohol or acetone rather than let it air dry. I treated a bunch of bolts from my co-op with Evapo-Rust, rinsed them, and let the air dry. I had to retreat them and then I used denatured alcohol on the second treatment and avoided the development of the rust the second time.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#74

Happy With My Bikes

Join Date: Sep 2020

Location: Oklahoma

Posts: 2,187

Bikes: Hi-Ten bike boomers, a Trek Domane and some projects

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 884 Post(s)

Liked 2,308 Times

in

1,118 Posts

The OP had a failure due to lack of maintenance. And among these three pages of discussing chain construction and what to use to remove rust, grumpus has the countermeasure for the root cause of the problem.

__________________

"It is the unknown around the corner that turns my wheels." -- Heinz Stücke

"It is the unknown around the corner that turns my wheels." -- Heinz Stücke

#75

Senior Member

Probably not unless the knife has some kind of forging flaw. The issue with elfmachine’s chain and the chain I soaked in salt water has more to do with the stamping of the plate. The stamping is a stress riser and the exposure to oxidizing chemicals opens up the stress riser. Finishing on the outside of the knife probably won’t be an issue. Naval jelly is a good product that doesn’t usually cause problems but it was never meant as something to soak parts in.

Iron chloride solid is usually green but a solution can be yellow.

As for rinsing off any parts where you want to avoid rust, I would rinse with denatured alcohol or acetone rather than let it air dry. I treated a bunch of bolts from my co-op with Evapo-Rust, rinsed them, and let the air dry. I had to retreat them and then I used denatured alcohol on the second treatment and avoided the development of the rust the second time.

Iron chloride solid is usually green but a solution can be yellow.

As for rinsing off any parts where you want to avoid rust, I would rinse with denatured alcohol or acetone rather than let it air dry. I treated a bunch of bolts from my co-op with Evapo-Rust, rinsed them, and let the air dry. I had to retreat them and then I used denatured alcohol on the second treatment and avoided the development of the rust the second time.

Absolutely. Some things rust amazingly fast, like a (low alloy) carbon steel skillet I was initially cleaning before seasoning, the bare metal would rust in seconds after washing. Files, due to alloying elements, while not stainless, will resist rust for the time it takes to blow water off with compressed air, then hit it with a blowdryer or place on a hot radiator.