Thoughts on bolt size to hold 20" wheel flange?

#1

Senior Member

Thread Starter

Join Date: Apr 2013

Posts: 1,173

Bikes: Surly Disk Trucker, 2014 w/Brooks Flyer Special saddle, Tubus racks - Duo front/Logo Evo rear, 2019 Dahon Mariner D8, Both bikes share Ortlieb Packer Plus series panniers, Garmin Edge 1000

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 405 Post(s)

Liked 115 Times

in

99 Posts

Thoughts on bolt size to hold 20" wheel flange?

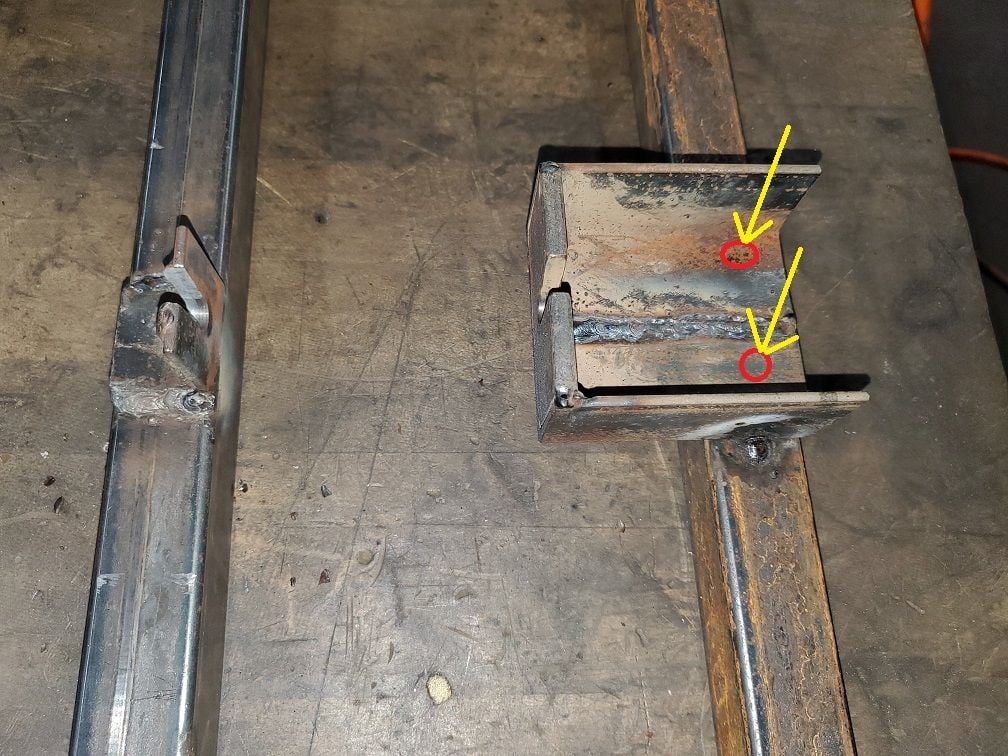

The bolt in the picture is an 8mm. The flange it is resting on is intended to be adjustable to fit various hub widths and will be slotted. The frame it rests on will have a threaded plate welded to it under where you see the flange tack welded (it is upside down in the picture, so the frame would be above the flange when in use).

My concern is to have something sturdy enough to hold the axle from being able to shift the flange bracket if the wheel hits a hard bump so clamping force would be key. I don't think shearing or tensioning the bolts to failure is as much of a concern.

What are your thoughts?

My limitation is up to an 8mm allen wrench. These 8mm bolts use a 6mm allen wrench. So, in theory, I can go bigger if it suits. I think these will work but I want to see what opinions others here have first.

The contraption is a new axle frame section for my bike trailer. See my other thread here:

https://www.bikeforums.net/utility-c...gth-frame.html

My concern is to have something sturdy enough to hold the axle from being able to shift the flange bracket if the wheel hits a hard bump so clamping force would be key. I don't think shearing or tensioning the bolts to failure is as much of a concern.

What are your thoughts?

My limitation is up to an 8mm allen wrench. These 8mm bolts use a 6mm allen wrench. So, in theory, I can go bigger if it suits. I think these will work but I want to see what opinions others here have first.

The contraption is a new axle frame section for my bike trailer. See my other thread here:

https://www.bikeforums.net/utility-c...gth-frame.html

#3

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,100

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4212 Post(s)

Liked 3,883 Times

in

2,318 Posts

For this type of seat of pants engineering I look at what other devices that are sort of the same use. Bicycle axles (rears and some fronts) are around 3/8" (9.5mm) in diameter and have no issues with staying in place if the nuts are properly tightened. For sliding fits like a seat post the clamp's bolts can be as small as M5s.

What I am unsure of is where the bolt is being used. Is it to secure the hub to the flange/dropout? Or to secure the flange/dropout and square tube frame to the trailer's existing frame members? If the latter will the flange/dropout thing have a wrap around clamp (like a seat post usually does) or will the bolts fit into a hole along the length of the frame tube? Big difference IMO as one is under mostly tension and the other will see a shear force. Will just one bolt per trailer side be used?

Since I don't yet have a feel for the bigger picture I can't be more helpful. Andy

What I am unsure of is where the bolt is being used. Is it to secure the hub to the flange/dropout? Or to secure the flange/dropout and square tube frame to the trailer's existing frame members? If the latter will the flange/dropout thing have a wrap around clamp (like a seat post usually does) or will the bolts fit into a hole along the length of the frame tube? Big difference IMO as one is under mostly tension and the other will see a shear force. Will just one bolt per trailer side be used?

Since I don't yet have a feel for the bigger picture I can't be more helpful. Andy

__________________

AndrewRStewart

AndrewRStewart

Likes For Andrew R Stewart:

#4

Senior Member

Thread Starter

Join Date: Apr 2013

Posts: 1,173

Bikes: Surly Disk Trucker, 2014 w/Brooks Flyer Special saddle, Tubus racks - Duo front/Logo Evo rear, 2019 Dahon Mariner D8, Both bikes share Ortlieb Packer Plus series panniers, Garmin Edge 1000

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 405 Post(s)

Liked 115 Times

in

99 Posts

What I am unsure of is where the bolt is being used. Is it to secure the hub to the flange/dropout? Or to secure the flange/dropout and square tube frame to the trailer's existing frame members? If the latter will the flange/dropout thing have a wrap around clamp (like a seat post usually does) or will the bolts fit into a hole along the length of the frame tube? Big difference IMO as one is under mostly tension and the other will see a shear force. Will just one bolt per trailer side be used?

I was hoping the description of the assembly in my 1st paragraph would define the placement of the bolt.

To elaborate - that flange you see the bolt resting on in the picture (where the axle slides in to like a drop out on a bike frame/fork" is welded to a pair of angles set up as a flat U with the flange capping off one end. The flat of the U will mesh flush against the square tube frame. That is the bolted area. However, since the square tube wall is so thin there isn't enough meat to thread in to. So I am going to cut that area out and weld in a 1/4" plate that will be drilled and tapped. The tube wall is only .080". The 1/4" plate is significantly thicker = more thread holding power.

I think the only option I have is a quantity of 2 on each side. The reasons for that are the idea of the slots for adjustment and the welded seam between the flanges. If I tried to go for a 3ord bolt in the middle it would be where the welded seam is and would reduce the holding power of that weld in keeping the parts that make up the U rigid enough to handle some hard bump abuse, as well as the width of the tube frame - at 1-1/4" to work with I don't have much room to stack bolts side by side and go for a 4x bolt pattern in the same 2 slots. So that leaves me with 1 bolt per slot and 2 slots = 2 bolts per side.

Here is a better visual. Red = holes, yellow = bolt direction. Not pictured/doodled = thread plate between the frame and flat U mentioned above of the flange bracket.

Last edited by KC8QVO; 09-09-23 at 09:51 AM.

#5

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,100

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4212 Post(s)

Liked 3,883 Times

in

2,318 Posts

Ok I think I've got it. Have you considered using two bolts that could be somewhat smaller than the M8 you show? I would think two, or more, bolts would both reduce the bracket's shifting about as well as reduce the stress the hub axle will see. With a single bolt the axle will potentially see more bending stresses and a 100mm long axle can bend easily.

Somewhere in this project I thought you were wanting to allow the new design to allow for relocating the wheels along the trailer's length. I then thought this post was about making the wheel axle holder brackets so they could slide along the trailer frame tubes. Perhaps trying to catch up on this project while switching between the two threads was too much for my feeble brain.

I hope to see your final design remade with lighter materials and more attention given to alignment. Andy

Somewhere in this project I thought you were wanting to allow the new design to allow for relocating the wheels along the trailer's length. I then thought this post was about making the wheel axle holder brackets so they could slide along the trailer frame tubes. Perhaps trying to catch up on this project while switching between the two threads was too much for my feeble brain.

I hope to see your final design remade with lighter materials and more attention given to alignment. Andy

__________________

AndrewRStewart

AndrewRStewart