Frames and Framebuilding -- 1970 - 1979 (Part 1)

#1

Senior Member

Thread Starter

Join Date: Aug 2010

Location: Central Florida, USA

Posts: 1,987

Bikes: Litespeed (9); Slingshot (9); Specialized (3); Kestrel (2); Cervelo (1); FELT (1); Trek (2)

Mentioned: 39 Post(s)

Tagged: 0 Thread(s)

Quoted: 433 Post(s)

Liked 3,443 Times

in

994 Posts

Frames and Framebuilding -- 1970 - 1979 (Part 1)

Bicycling magazine has published many articles concerning various aspects of frame building, including design, materials, manufacturing, and custom builders.

I'll post them somewhat chronologically by decade beginning with the first 3 articles in a series written by Fred DeLong.

I'll post them somewhat chronologically by decade beginning with the first 3 articles in a series written by Fred DeLong.

__________________

WTB: Slingshot bicycle promotional documents (catalog, pamphlets, etc).

WTB: American Cycling May - Aug, Oct, Dec 1966.

WTB: Bicycle Guide issues 1984 (any); Jun 1987; Jul, Nov/Dec 1992; Apr 1994; 1996 -1998 (any)

WTB: Bike World issue Jun 1974.

WTB: Slingshot bicycle promotional documents (catalog, pamphlets, etc).

WTB: American Cycling May - Aug, Oct, Dec 1966.

WTB: Bicycle Guide issues 1984 (any); Jun 1987; Jul, Nov/Dec 1992; Apr 1994; 1996 -1998 (any)

WTB: Bike World issue Jun 1974.

Likes For SpeedofLite:

#3

Senior Member

Join Date: Jan 2019

Posts: 528

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

Quoted: 237 Post(s)

Likes: 0

Liked 83 Times

in

64 Posts

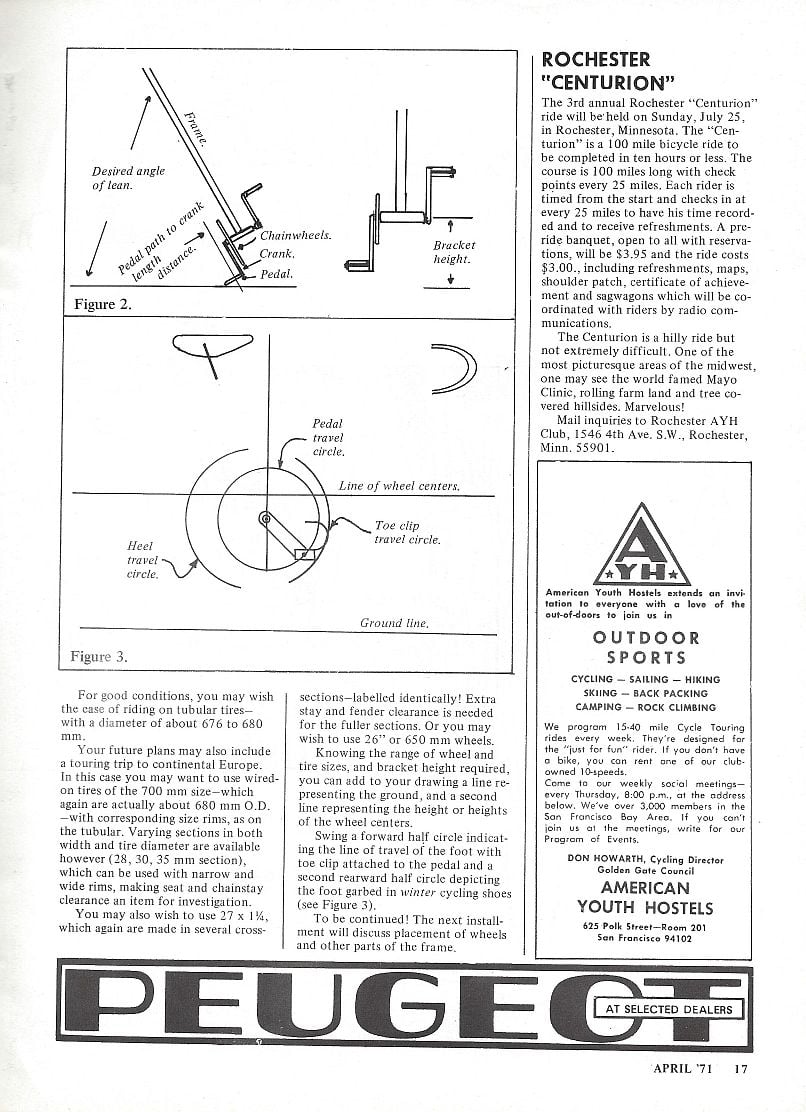

That geometry diagram makes for one ugly bike. I'm not sure how cutouts lead to excessive heating of the tubes, unless we're talking Hetchins extensions. I think someone just doesn't like the look. Low temperature silver will actually generally result in weaker joints than bronze brazing. Bronze brazing will get the steel to a high enough temperature that there is a mild hardening response when air cooled as the unheated portions of the frame act like a heat sink, although the transition area between the hardened area and the unheated area will be weakened. The insulation thing was actually done on some mass production Fujis, although bronze brazed, which would have lowered the hardening response. It's also noteworthy that frames were silver brazed in the jigs, something many modern frame builders think is bad and that frames should only be tacked in jigs because of distortion. However, this seems to have been standard practice, especially for 753 to avoid the need to cold set after brazing. I personally lean to the idea that brazing in jigs is fine as long as distortion is minimized. I suspect the modern thought on brazing in jigs is colored by welding. Ultimately practical experience doesn't seem to show any particular practical advantages of these special treatments being praised here when using normal lugs and tubing that could be joined either way. Silver brazing and insulation offer more advantage to the builder in terms of making alignment and avoiding overheating tubes easier, rather than any advantage to the rider with an otherwise normally bronze brazed and cold set frame.

#4

Senior Member

Join Date: Jun 2006

Posts: 20,305

Mentioned: 130 Post(s)

Tagged: 0 Thread(s)

Quoted: 3464 Post(s)

Liked 2,827 Times

in

1,995 Posts

Even as a kid I knew that the diagrams in the bicycle magazines were lifts from others, terribly done, or done by folk who had no idea on reasonable bicycle reference.

That said, the brazing comments are... interesting. I guess the best lugs are what would come on a Raleigh roadster? Lots of surface area...

In brazing things up, after one does a few things if you are watching reveal themselves.

One understands why pinning is not a bad solution.

That the rear triangle will close up 8mm or so if not compensated for before you braze things up.

brazing sub assemblies when working one at a time is not a bad idea. HT/DT, ST/BB shell first can really reduce the stress stack.

Masi in Carlsbad btw, brazed up the rear dropout to the chainstay first, then the seat stay to that (so the angle was jigged up), the last major connection was ST to Seatlug to a completed rear triangle.

Bridges after. The also brazed up the fork with the legs straight and induced the rake on both blades at once. (some do not like that way, but I can see many virtues)

That said, the brazing comments are... interesting. I guess the best lugs are what would come on a Raleigh roadster? Lots of surface area...

In brazing things up, after one does a few things if you are watching reveal themselves.

One understands why pinning is not a bad solution.

That the rear triangle will close up 8mm or so if not compensated for before you braze things up.

brazing sub assemblies when working one at a time is not a bad idea. HT/DT, ST/BB shell first can really reduce the stress stack.

Masi in Carlsbad btw, brazed up the rear dropout to the chainstay first, then the seat stay to that (so the angle was jigged up), the last major connection was ST to Seatlug to a completed rear triangle.

Bridges after. The also brazed up the fork with the legs straight and induced the rake on both blades at once. (some do not like that way, but I can see many virtues)