Frames and Framebuilding (1970-1979) Optimum Frame Design

#1

Senior Member

Thread Starter

Join Date: Aug 2010

Location: Central Florida, USA

Posts: 1,991

Bikes: Litespeed (9); Slingshot (9); Specialized (3); Kestrel (2); Cervelo (1); FELT (1); Trek (2)

Mentioned: 39 Post(s)

Tagged: 0 Thread(s)

Quoted: 436 Post(s)

Liked 3,471 Times

in

999 Posts

Frames and Framebuilding (1970-1979) Optimum Frame Design

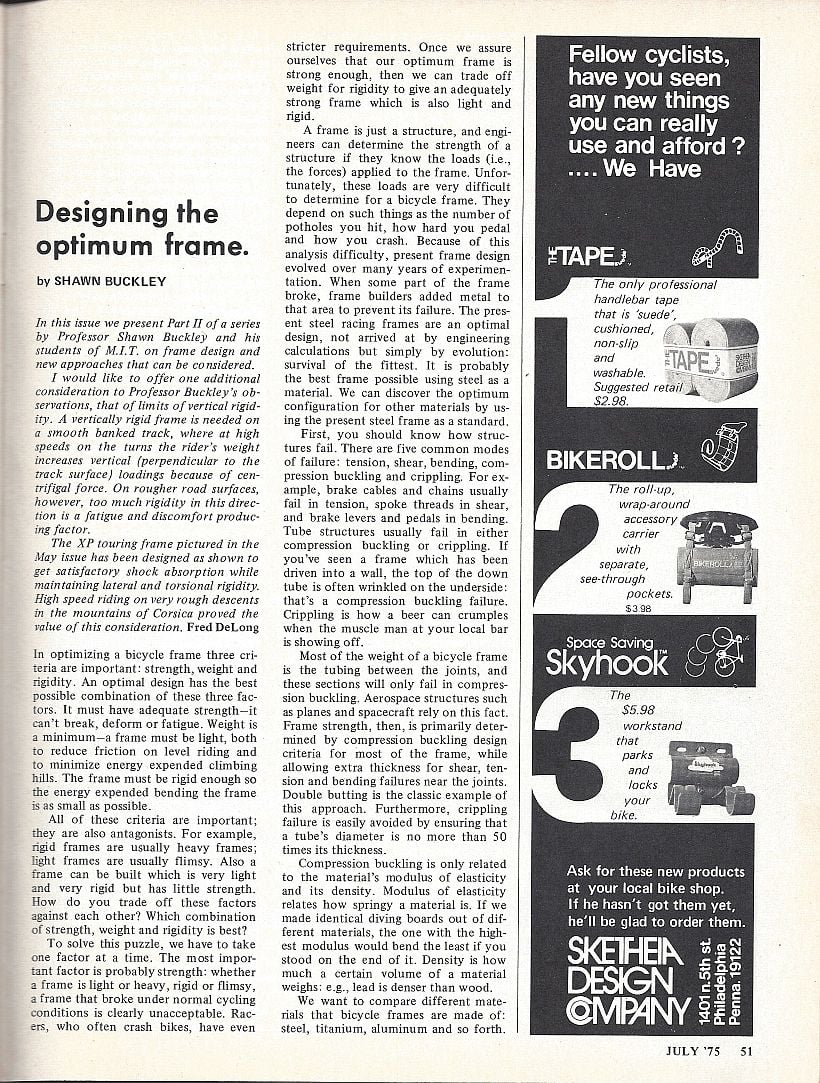

The second of two articles from MIT's Department of Mechanical Engineering.

The first article is found here: https://www.bikeforums.net/classic-v...ke-design.html

The first article is found here: https://www.bikeforums.net/classic-v...ke-design.html

__________________

WTB: Slingshot bicycle promotional documents (catalog, pamphlets, etc).

WTB: American Cycling May - Aug, Oct, Dec 1966.

WTB: Bicycle Guide issues 1984 (any); Jun 1987; Jul, Nov/Dec 1992; Apr 1994; 1996 -1998 (any)

WTB: Bike World issue Jun 1974.

WTB: Slingshot bicycle promotional documents (catalog, pamphlets, etc).

WTB: American Cycling May - Aug, Oct, Dec 1966.

WTB: Bicycle Guide issues 1984 (any); Jun 1987; Jul, Nov/Dec 1992; Apr 1994; 1996 -1998 (any)

WTB: Bike World issue Jun 1974.

Likes For SpeedofLite:

#2

Senior Member

Join Date: Jan 2019

Posts: 528

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

Quoted: 237 Post(s)

Likes: 0

Liked 83 Times

in

64 Posts

This made me think some about buckling failures in bicycle frames. This guy has a doctorate in this, so I really wish he explained his methodology more. I'm sure he's a smart guy, maybe he's right, but I can't really follow along with his thinking with his summary of findings, but as far as I can tell, several premises of this article are wrong.

-Somehow fatigue resistance is ignored as a primary consideration

-Most bicycles aren't designed for headers and I basically only see buckling failures from headers

-These calculations don't apply to tubes with dents that result in later buckling

-Bicycles aren't real space frames and tubes experience some mix of bending, torsion and axial loads, and only drive side chain stays and seat stays experience significant compression loads

-The 50:1 rule is a rule of thumb that works out to some high number in compression depending on what formula is used, it's just a rule of thumb of safe wall thickness where you don't need to bother calculating around buckling

-Headers with walls impart significant bending loads, which I guess is related, but deviating even further from how the 50:1 rule is normally applied

-Wall header buckling mentioned in the article usually happens on lugged frames near the lug at the thick part of the tube which is closer to 30:1

-Bicycle frames probably fail in yield before elastic buckling occurs, making elastic buckling moot, apparent buckling is probably either yield buckling or from the lug point pushing the wall of the tube in, as we've all see bent frames that haven't buckled

-It maybe has some application when really pushing the limits of wall thickness, but then the 50:1 rule of thumb probably shouldn't be used there

I welcome anyone who actually gets what the good doctor is saying to correct me though. I feel like he zeroed in on something that's not really worth designing around while basing the entire analysis around a rule of thumb that has little application even in his own examples of buckle failures.

-Somehow fatigue resistance is ignored as a primary consideration

-Most bicycles aren't designed for headers and I basically only see buckling failures from headers

-These calculations don't apply to tubes with dents that result in later buckling

-Bicycles aren't real space frames and tubes experience some mix of bending, torsion and axial loads, and only drive side chain stays and seat stays experience significant compression loads

-The 50:1 rule is a rule of thumb that works out to some high number in compression depending on what formula is used, it's just a rule of thumb of safe wall thickness where you don't need to bother calculating around buckling

-Headers with walls impart significant bending loads, which I guess is related, but deviating even further from how the 50:1 rule is normally applied

-Wall header buckling mentioned in the article usually happens on lugged frames near the lug at the thick part of the tube which is closer to 30:1

-Bicycle frames probably fail in yield before elastic buckling occurs, making elastic buckling moot, apparent buckling is probably either yield buckling or from the lug point pushing the wall of the tube in, as we've all see bent frames that haven't buckled

-It maybe has some application when really pushing the limits of wall thickness, but then the 50:1 rule of thumb probably shouldn't be used there

I welcome anyone who actually gets what the good doctor is saying to correct me though. I feel like he zeroed in on something that's not really worth designing around while basing the entire analysis around a rule of thumb that has little application even in his own examples of buckle failures.

Last edited by Kuromori; 03-15-20 at 01:16 AM.

#3

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,990

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1176 Post(s)

Liked 2,572 Times

in

1,074 Posts

This made me think some about buckling failures in bicycle frames. This guy has a doctorate in this, so I really wish he explained his methodology more. I'm sure he's a smart guy, maybe he's right, but I can't really follow along with his thinking with his summary of findings, but as far as I can tell, several premises of this article are wrong.

-Somehow fatigue resistance is ignored as a primary consideration

-Most bicycles aren't designed for headers and I basically only see buckling failures from headers

-These calculations don't apply to tubes with dents that result in later buckling

-Bicycles aren't real space frames and tubes experience some mix of bending, torsion and axial loads, and only drive side chain stays and seat stays experience significant compression loads

-The 50:1 rule is a rule of thumb that works out to some high number in compression depending on what formula is used, it's just a rule of thumb of safe wall thickness where you don't need to bother calculating around buckling

-Headers with walls impart significant bending loads, which I guess is related, but deviating even further from how the 50:1 rule is normally applied

-Wall header buckling mentioned in the article usually happens on lugged frames near the lug at the thick part of the tube which is closer to 30:1

-Bicycle frames probably fail in yield before elastic buckling occurs, making elastic buckling moot, apparent buckling is probably either yield buckling or from the lug point pushing the wall of the tube in, as we've all see bent frames that haven't buckled

-It maybe has some application when really pushing the limits of wall thickness, but then the 50:1 rule of thumb probably shouldn't be used there

I welcome anyone who actually gets what the good doctor is saying to correct me though. I feel like he zeroed in on something that's not really worth designing around while basing the entire analysis around a rule of thumb that has little application even in his own examples of buckle failures.

-Somehow fatigue resistance is ignored as a primary consideration

-Most bicycles aren't designed for headers and I basically only see buckling failures from headers

-These calculations don't apply to tubes with dents that result in later buckling

-Bicycles aren't real space frames and tubes experience some mix of bending, torsion and axial loads, and only drive side chain stays and seat stays experience significant compression loads

-The 50:1 rule is a rule of thumb that works out to some high number in compression depending on what formula is used, it's just a rule of thumb of safe wall thickness where you don't need to bother calculating around buckling

-Headers with walls impart significant bending loads, which I guess is related, but deviating even further from how the 50:1 rule is normally applied

-Wall header buckling mentioned in the article usually happens on lugged frames near the lug at the thick part of the tube which is closer to 30:1

-Bicycle frames probably fail in yield before elastic buckling occurs, making elastic buckling moot, apparent buckling is probably either yield buckling or from the lug point pushing the wall of the tube in, as we've all see bent frames that haven't buckled

-It maybe has some application when really pushing the limits of wall thickness, but then the 50:1 rule of thumb probably shouldn't be used there

I welcome anyone who actually gets what the good doctor is saying to correct me though. I feel like he zeroed in on something that's not really worth designing around while basing the entire analysis around a rule of thumb that has little application even in his own examples of buckle failures.

I can't prove it, but my feeling is most race frames are too stiff and would be actually faster if they could be designed for more give, without suffering in fatigue endurance. Not counting a few extreme cases like Match Sprint. Let's say limited to road race, and not a few edge cases like André Greipel or even Caleb Ewan.

When people like Greg Lemond and Sean Kelly (yes I'm old, so my references are old) gravitate to the most flexible frames they can find, what normal mortal should think he needs a stiffer frame than that? In at least one way those guys are still relevant, because they rode at a time when the stars could actually have some influence over the frames they rode. Now, monocoque frames are pretty much all cookie-cutter clones, little to no customization possible. You not only have to ride whatever they give you, you have to wax poetic about how excellent they are, how incredibly stiff they are. 20% stiffer than last year's model! (But more vertically compliant -- as if that matters)

If we start with different assumptions, and include the possibility that some non-zero amount of flex is actually optimal -- and not just this mythical vertical compliance, but out of plane (lateral/tosional) flex too -- then it completely changes the calculations about what materials and diameters are best. What if almost everyone is riding a frame that's too stiff for them?

As I said, I can't prove it, but the "stiffer is better" crowd definitely haven't proven their side. They just state it as if it's obvious. That's $$ talking -- follow the money! It's easy and cheap to make stiff frames that last. If some significant amount of flex is a requirement instead of a bogeyman, then adequate fatigue life becomes much trickier. That's why the bike industry will always fight this idea.

Mark B in Seattle

#4

Senior Member

Join Date: Jan 2019

Posts: 528

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

Quoted: 237 Post(s)

Likes: 0

Liked 83 Times

in

64 Posts

As I said, I can't prove it, but the "stiffer is better" crowd definitely haven't proven their side. They just state it as if it's obvious. That's $$ talking -- follow the money! It's easy and cheap to make stiff frames that last. If some significant amount of flex is a requirement instead of a bogeyman, then adequate fatigue life becomes much trickier. That's why the bike industry will always fight this idea.

However, it seems to me the solution here for flexible frames on the cheap is pretty simple. Undersize tubing, the opposite of oversize tubing. If you can make an equivalent stiffness tube at a lighter weight with a stronger steel, it follows that you can make an equivalent stiffness tube at a heavier weight with a weaker steel. It would be an interesting experiment to braze up something like a Caminargent and swap tubes that way, or flange fittings with lugscrews because who has the money for a dozen real couplers. You can get 19mm (3/4") tubes from 0.7mm to 4.8mm off the shelf. 1.1mm wall is approximately equivalent to a 25.4mm dia 0.4mm wall tube. 4.8mm wall is equivalent to a 28.6mm dia 0.7mm tube. So you can get every stiffness tube you would reasonably want to test quite easily, and flexier tubes than anything on the market. Lathe or centerless grind a tube down if you need something in between. But no one pays me money to do bike R&D so there's that.

Last edited by Kuromori; 03-15-20 at 04:28 AM.

#5

Old fart

Join Date: Nov 2004

Location: Appleton WI

Posts: 24,786

Bikes: Several, mostly not name brands.

Mentioned: 153 Post(s)

Tagged: 0 Thread(s)

Quoted: 3588 Post(s)

Liked 3,400 Times

in

1,934 Posts

As I said, I can't prove it, but the "stiffer is better" crowd definitely haven't proven their side. They just state it as if it's obvious. That's $$ talking -- follow the money! It's easy and cheap to make stiff frames that last. If some significant amount of flex is a requirement instead of a bogeyman, then adequate fatigue life becomes much trickier. That's why the bike industry will always fight this idea.

So, like so many other things, "stiffness" needs to be judged in the context of individual requirements.

#7

Senior Member

Join Date: Apr 2005

Location: Ann Arbor, MI

Posts: 16,878

Bikes: 1980 Masi, 1984 Mondonico, 1984 Trek 610, 1980 Woodrup Giro, 2005 Mondonico Futura Leggera ELOS, 1967 PX10E, 1971 Peugeot UO-8

Mentioned: 49 Post(s)

Tagged: 0 Thread(s)

Quoted: 1858 Post(s)

Liked 664 Times

in

506 Posts

He also has a bias that goes unexamined I think (I haven't studied every bit of it), namely that stiffer is always better and stiffest is best.

I can't prove it, but my feeling is most race frames are too stiff and would be actually faster if they could be designed for more give, without suffering in fatigue endurance. Not counting a few extreme cases like Match Sprint. Let's say limited to road race, and not a few edge cases like André Greipel or even Caleb Ewan.

When people like Greg Lemond and Sean Kelly (yes I'm old, so my references are old) gravitate to the most flexible frames they can find, what normal mortal should think he needs a stiffer frame than that? In at least one way those guys are still relevant, because they rode at a time when the stars could actually have some influence over the frames they rode. Now, monocoque frames are pretty much all cookie-cutter clones, little to no customization possible. You not only have to ride whatever they give you, you have to wax poetic about how excellent they are, how incredibly stiff they are. 20% stiffer than last year's model! (But more vertically compliant -- as if that matters)

If we start with different assumptions, and include the possibility that some non-zero amount of flex is actually optimal -- and not just this mythical vertical compliance, but out of plane (lateral/tosional) flex too -- then it completely changes the calculations about what materials and diameters are best. What if almost everyone is riding a frame that's too stiff for them?

As I said, I can't prove it, but the "stiffer is better" crowd definitely haven't proven their side. They just state it as if it's obvious. That's $$ talking -- follow the money! It's easy and cheap to make stiff frames that last. If some significant amount of flex is a requirement instead of a bogeyman, then adequate fatigue life becomes much trickier. That's why the bike industry will always fight this idea.

Mark B in Seattle

I can't prove it, but my feeling is most race frames are too stiff and would be actually faster if they could be designed for more give, without suffering in fatigue endurance. Not counting a few extreme cases like Match Sprint. Let's say limited to road race, and not a few edge cases like André Greipel or even Caleb Ewan.

When people like Greg Lemond and Sean Kelly (yes I'm old, so my references are old) gravitate to the most flexible frames they can find, what normal mortal should think he needs a stiffer frame than that? In at least one way those guys are still relevant, because they rode at a time when the stars could actually have some influence over the frames they rode. Now, monocoque frames are pretty much all cookie-cutter clones, little to no customization possible. You not only have to ride whatever they give you, you have to wax poetic about how excellent they are, how incredibly stiff they are. 20% stiffer than last year's model! (But more vertically compliant -- as if that matters)

If we start with different assumptions, and include the possibility that some non-zero amount of flex is actually optimal -- and not just this mythical vertical compliance, but out of plane (lateral/tosional) flex too -- then it completely changes the calculations about what materials and diameters are best. What if almost everyone is riding a frame that's too stiff for them?

As I said, I can't prove it, but the "stiffer is better" crowd definitely haven't proven their side. They just state it as if it's obvious. That's $$ talking -- follow the money! It's easy and cheap to make stiff frames that last. If some significant amount of flex is a requirement instead of a bogeyman, then adequate fatigue life becomes much trickier. That's why the bike industry will always fight this idea.

Mark B in Seattle

I'm going to assume the Raleigh Team bikes in 753 were rather flexy, considering the narrow walls of their tubing. I know the upper end bike shops in Chicago all talked about how stiff they were. But many more people now know that the modulus of 753 is the same as that of 531, so for the same diameter a thin-wall 753 tube will be a softer spring than a similar thicker wall 531 tube. If flexibility serves to return strain energy to the propulsion in the form of chain tension, then "stiff" is not "faster" except in terms of pedaling transient response - when you quickly increase pedal force, the stiff bike should jump somewhat harder than the less flexy one.

I'm not worried about the "omission" of fatigue resistance in steel frames. It's well-established in metallurgy that if you stress a piece of steel (unless aluminum, for one example) repeatedly within its elastic limits, it shows no detectable signs of fatigue. Same should be true for a hardened steel like 753, Nivachrome, or OX-Plat just to name a few alloys. Clearly if a piece of steel of any grade, from basic iron up to exotica like 953 or "higher" is bent into its INelastic range (from which it will not spring back into its original form), it has fatigued and it might fracture. This is sometimes called "exceeding Young's Modulus," but I'm not sure it's a correct term. But one of the tasks of the tubing designer and frame designer is to select tube that will resist the degree of elastic flexing so that the frame cannot be forced to exceed Young's modulus. So stiffness is a factor in frame durability in the expected usage. A frame for a career of track sprinting might have more than a horsepower, 746 watts, applied to the frame. This has a much different "stress life" than a frame used for a career of 1200 km randonneuring events, say 0.25 horsepower average for 90 hours. I think management of fatigue resistance was done in this case on the design side just as it has been for the >10 decades of frame design that went before.

Mark, I think some of the most modern steel tubesets from Cinelli, with a complex of "exotic" butting profiles, are designed as a system to consider exactly what you raised in your fourth paragraph. I agree, chances are that most of us, even those with say a frame made with Columbus ELOS, have frames that are not optimal, and most likely somewhat overbuilt. But I have to say my ELOS frame is very nice to ride, even compared to my SL or 531 db frames.

#8

Senior Member

Join Date: Apr 2005

Location: Ann Arbor, MI

Posts: 16,878

Bikes: 1980 Masi, 1984 Mondonico, 1984 Trek 610, 1980 Woodrup Giro, 2005 Mondonico Futura Leggera ELOS, 1967 PX10E, 1971 Peugeot UO-8

Mentioned: 49 Post(s)

Tagged: 0 Thread(s)

Quoted: 1858 Post(s)

Liked 664 Times

in

506 Posts

I've never really been satisfied by the argument of either "side." There's clearly a point where additional stiffness doesn't matter, and there's clearly a point where lack of stiffness feels unsafe. There's been 0.38mm tubing since the 30's, yet it's only really in the modern day people are praising the ride quality. And off the shelf or speccing one tubeset for a range of sizes, stiffer is a safer bet.

However, it seems to me the solution here for flexible frames on the cheap is pretty simple. Undersize tubing, the opposite of oversize tubing. If you can make an equivalent stiffness tube at a lighter weight with a stronger steel, it follows that you can make an equivalent stiffness tube at a heavier weight with a weaker steel. It would be an interesting experiment to braze up something like a Caminargent and swap tubes that way, or flange fittings with lugscrews because who has the money for a dozen real couplers. You can get 19mm (3/4") tubes from 0.7mm to 4.8mm off the shelf. 1.1mm wall is approximately equivalent to a 25.4mm dia 0.4mm wall tube. 4.8mm wall is equivalent to a 28.6mm dia 0.7mm tube. So you can get every stiffness tube you would reasonably want to test quite easily, and flexier tubes than anything on the market. Lathe or centerless grind a tube down if you need something in between. But no one pays me money to do bike R&D so there's that.

However, it seems to me the solution here for flexible frames on the cheap is pretty simple. Undersize tubing, the opposite of oversize tubing. If you can make an equivalent stiffness tube at a lighter weight with a stronger steel, it follows that you can make an equivalent stiffness tube at a heavier weight with a weaker steel. It would be an interesting experiment to braze up something like a Caminargent and swap tubes that way, or flange fittings with lugscrews because who has the money for a dozen real couplers. You can get 19mm (3/4") tubes from 0.7mm to 4.8mm off the shelf. 1.1mm wall is approximately equivalent to a 25.4mm dia 0.4mm wall tube. 4.8mm wall is equivalent to a 28.6mm dia 0.7mm tube. So you can get every stiffness tube you would reasonably want to test quite easily, and flexier tubes than anything on the market. Lathe or centerless grind a tube down if you need something in between. But no one pays me money to do bike R&D so there's that.

#9

Senior Member

I love looking through the window into the past. Inert gas welding was new/rare, graphite fibers were "too brittle",...

This article is a prime example of the "stiffer is better" wave that swept over bike design in that era. Bikes went from 2" of fork rake to 1"; frame angles got steeper; over-sized tubing became popular...

On the other hand, soft frames suck the life out of your legs when you are trying to climb that hill.

99.999999999% of lugged steel bikes will never suffer from fatigue life or strength issues, as they are purchased, ridden a little and shuttered away.

I do, however, wonder if my 1975 Bob Jackson will ever have fatigue life issues. A quick estimate showed multiple tens-of-millions of stress cycles on the frame from pedaling over its 45 year lifetime. That does not include the vibration cycles on components like the fork crown-fork blades joint (where a fatigue failure would likely have serious consequences, especially if going downhill at the time).

This article is a prime example of the "stiffer is better" wave that swept over bike design in that era. Bikes went from 2" of fork rake to 1"; frame angles got steeper; over-sized tubing became popular...

On the other hand, soft frames suck the life out of your legs when you are trying to climb that hill.

99.999999999% of lugged steel bikes will never suffer from fatigue life or strength issues, as they are purchased, ridden a little and shuttered away.

I do, however, wonder if my 1975 Bob Jackson will ever have fatigue life issues. A quick estimate showed multiple tens-of-millions of stress cycles on the frame from pedaling over its 45 year lifetime. That does not include the vibration cycles on components like the fork crown-fork blades joint (where a fatigue failure would likely have serious consequences, especially if going downhill at the time).

#10

Senior Member

Join Date: Jan 2019

Posts: 528

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

Quoted: 237 Post(s)

Likes: 0

Liked 83 Times

in

64 Posts

Sorry but this has to be corrected on multiple counts.

Reynolds soon released 753R which was made in 531SL gauges, with centers of 0.56mm, which later just became 753 as the original metric tubes were phased out. A good deal of 753 frames were just on the thin side of normal for crmo.

This paperclip thing is a pet peeve. Unfortunately, this is completely wrong, and steel frames do fail from fatigue. The generally accepted approximation of the fatigue limit for steel is approximately one half of UTS. The fatigue limit also doesn't apply in corrosive environments, which has been shown to include just very humid air for some steels studied. Fatigue failure starts as crack propagation and cracks propagate when steel fails under tension. It is nowhere near yield strength. Young's modulus is stress:strain in the elastic region. Once the elastic limit is reached, stress:strain actually decreases. The entire point of the article is trying to come up with equivalent figures solely for compression buckling when departing from decades of experimental frame design. For fatigue when steel is subjected to strains exceeding yield, weaker more ductile steels will actually last longer, but then we're talking about fatigue life in the span of 1,000-10,000 cycles when 90 rpm for an hour is 5,400 cycles.

There is no optimum unless you have a specific parameter to optimize for. If you're trying to maximize only stiffness and strength, then weight suffers, and it's just making an infinitely large solid steel rod.

I'm going to assume the Raleigh Team bikes in 753 were rather flexy, considering the narrow walls of their tubing. I know the upper end bike shops in Chicago all talked about how stiff they were. But many more people now know that the modulus of 753 is the same as that of 531, so for the same diameter a thin-wall 753 tube will be a softer spring than a similar thicker wall 531 tube.

I'm not worried about the "omission" of fatigue resistance in steel frames. It's well-established in metallurgy that if you stress a piece of steel (unless aluminum, for one example) repeatedly within its elastic limits, it shows no detectable signs of fatigue. Same should be true for a hardened steel like 753, Nivachrome, or OX-Plat just to name a few alloys. Clearly if a piece of steel of any grade, from basic iron up to exotica like 953 or "higher" is bent into its INelastic range (from which it will not spring back into its original form), it has fatigued and it might fracture. This is sometimes called "exceeding Young's Modulus," but I'm not sure it's a correct term. But one of the tasks of the tubing designer and frame designer is to select tube that will resist the degree of elastic flexing so that the frame cannot be forced to exceed Young's modulus. So stiffness is a factor in frame durability in the expected usage. A frame for a career of track sprinting might have more than a horsepower, 746 watts, applied to the frame. This has a much different "stress life" than a frame used for a career of 1200 km randonneuring events, say 0.25 horsepower average for 90 hours. I think management of fatigue resistance was done in this case on the design side just as it has been for the >10 decades of frame design that went before.

You could solve numerically for tube stiffness and strength to see for what diameter plus wall dimension an optimum may exist. Most likely you could see it with a set of plots of the equations.

Last edited by Kuromori; 03-15-20 at 11:34 AM.

#11

Senior Member

Join Date: Jan 2019

Posts: 528

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

Quoted: 237 Post(s)

Likes: 0

Liked 83 Times

in

64 Posts

99.999999999% of lugged steel bikes will never suffer from fatigue life or strength issues, as they are purchased, ridden a little and shuttered away.

I do, however, wonder if my 1975 Bob Jackson will ever have fatigue life issues. A quick estimate showed multiple tens-of-millions of stress cycles on the frame from pedaling over its 45 year lifetime. That does not include the vibration cycles on components like the fork crown-fork blades joint (where a fatigue failure would likely have serious consequences, especially if going downhill at the time).

I do, however, wonder if my 1975 Bob Jackson will ever have fatigue life issues. A quick estimate showed multiple tens-of-millions of stress cycles on the frame from pedaling over its 45 year lifetime. That does not include the vibration cycles on components like the fork crown-fork blades joint (where a fatigue failure would likely have serious consequences, especially if going downhill at the time).

#12

Old fart

Join Date: Nov 2004

Location: Appleton WI

Posts: 24,786

Bikes: Several, mostly not name brands.

Mentioned: 153 Post(s)

Tagged: 0 Thread(s)

Quoted: 3588 Post(s)

Liked 3,400 Times

in

1,934 Posts

#13

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,906

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4806 Post(s)

Liked 3,929 Times

in

2,554 Posts

I did a quick ride on a Klein in 1977. At the time I was racing a conventional steel frame. It became very apparent almost immediately that the Klein was way too stiff for this 150 pound hill climber. (And even on near perfect pavement, it was obvious this bike would beat me up on rough roads.) At the time, I was putting in 10,000 mile years, half of which was on my steel race bike. The bike felt to me to be perfect. I never felt more stiffness would change anything (other than perhaps fatigue on rougher roads). I loved climbing on that bike. And I suspect more than one opponent wished the bike didn't suit me so well. No, it was not stiff. Healthy flex with a push of the foot to the BB. (I did have, I believe, the stiffer tubing of that frame, a Fuji Professional. 59cm which I believe was their step up form the lighter tubing of the smaller frames.) It was and still is my opinion that the flex of a steel or titanium frame in the hands of a smooth and disciplined rider can help the overall efficiency of bike and rider.

Ben

Ben

#14

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,990

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1176 Post(s)

Liked 2,572 Times

in

1,074 Posts

Back then I think most people thought I was kidding or maybe just a wack-case (the jury's out on that). But then more recently I started noticing the idea getting a foot-hold, notably after Jan Heine started developing his idea of "planing". A terrible word for it, bad analogy IMHO, but I don't have a better one-word catch phrase for it so I have grown to accept it as short-hand.

Planing or just wanting a frame with some noticeable flex is now a fad, and as with any fad, there's a backlash, some of it from people who already didn't like Heine for some other reason. Advocating fat road tires, low steering trail or other old French rando designs, or whatever he said that someone didn't like (or the way he said it), it all gets lumped together.

So the winds of fashion blow this way and that, and we never get any closer to converging on a theory, it's all just unsubstantiated hypotheses. I guess I'm OK with that. I sure don't have any ideas on how to put the questions to rest.

Mark B