Lubrication for Shimano 3cc 3-speed hub

#1

Junior Member

Thread Starter

Lubrication for Shimano 3cc 3-speed hub

I have a 1991 Schwinn Suburban with a Shimano 3cc 3-speed hub. I do no see a port for lubrication. (some hubs have a port on the outer cylinder of the hub itself) The axle is hollow and has a removable shaft. When removed, the hole that the shaft fit into looks like lubricating fluids can be injected into it. I've injected oil into this hole but not sure if this was a good idea. It may have helped shifting but it's hard to tell. Should oil or grease be injected into this hole? If so, what type and how much?

#2

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,113

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4222 Post(s)

Liked 3,908 Times

in

2,331 Posts

I have dripped medium viscosity oil into many IGH axles/hubs via the indicator rod hole. Any factory grease isn't a life time never needing attention product and grease will dry out over time. having said that adding a thinner and fluid lube can cause more weeping/seeping out of the lube from the hub (and this is why an oil only hub like the older SA AWs show such grimy spokes over time, the weeping out oil get's pulled to the most outer part of the rotating wheel). If one bothers to wipe off any flung out lube the wheel stays vastly cleaner.

I suspect a reason why IGH manufactures have more and more gone to no oil hole design (and that indicator hole in the axle doesn't count here) is because they don't have faith in the general public to routinely oil their oil only hubs every so often. By closing up the hub better and using a grease (and sometimes a "special" grade of grease) they extend the life of the factory lubing. Still on my IGHs, and those others I have serviced, I do add oil through the axle's hole. Just not too much. SA use to suggest a few drops of oil annually as one example of volume and frequency for their non grease hubs. Andy

I suspect a reason why IGH manufactures have more and more gone to no oil hole design (and that indicator hole in the axle doesn't count here) is because they don't have faith in the general public to routinely oil their oil only hubs every so often. By closing up the hub better and using a grease (and sometimes a "special" grade of grease) they extend the life of the factory lubing. Still on my IGHs, and those others I have serviced, I do add oil through the axle's hole. Just not too much. SA use to suggest a few drops of oil annually as one example of volume and frequency for their non grease hubs. Andy

__________________

AndrewRStewart

AndrewRStewart

#3

Junior Member

Thread Starter

Interesting. So would a relatively low viscosity grease (if it exists) be a bad idea? I suppose regular grease could be mixed with some motor oil to make a lower viscosity grease, but again I'm not sure if that's a good idea. IGHs are a mystery to me.

#4

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,113

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4222 Post(s)

Liked 3,908 Times

in

2,331 Posts

There's really a shade of grey WRT when a lube is considered an oil VS a grease as greases and oils vary in their thickness. A thinner grease might be more injectable but it generally will then be more easily washed out over time with use.

The viscosity of grease, or oil, is but one characteristic that matters. The chemistry and/or additives are also quite important, especially with an enclosed part that is costly to take apart and service. An example of this is that some people have used automatic transmission fluid for IGH lubing. I've read (likely here in BF) of removing the guts and soaking them in ATF for both a "cleaning" and the after service lubing. ATF is pretty thick and has all kinds of additives compared to oils.

I'm no IGH expert (even though I rebuilt my first SA AW back when most here were not yet born) and others here might offer more opinion and experience than I have. There is a lot of posts and vids on line in various forums and video service sites that cover this stuff if you wish to dive deep. Andy

The viscosity of grease, or oil, is but one characteristic that matters. The chemistry and/or additives are also quite important, especially with an enclosed part that is costly to take apart and service. An example of this is that some people have used automatic transmission fluid for IGH lubing. I've read (likely here in BF) of removing the guts and soaking them in ATF for both a "cleaning" and the after service lubing. ATF is pretty thick and has all kinds of additives compared to oils.

I'm no IGH expert (even though I rebuilt my first SA AW back when most here were not yet born) and others here might offer more opinion and experience than I have. There is a lot of posts and vids on line in various forums and video service sites that cover this stuff if you wish to dive deep. Andy

__________________

AndrewRStewart

AndrewRStewart

Likes For Andrew R Stewart:

#5

Senior Member

Like Andy above, I last rebuilt an internal gear hub 50 years ago.

Aaron's Bike repair in greater Seattle has a great web page on internal gear hubs, they do a lot of servicing on them. Scroll way down for info:

https://www.rideyourbike.com/internalgears.shtml

If you had the hub apart like them, I would use a top-quality grease on the gears and outer wheel bearings (they use green marine wheel bearing grease, it helps seal out water), and a light oil on all the other parts (they use Phil Tenacious Oil).

If you don't have the hub apart, I would drip into the shifter hole in the axle, 75/90 gear lube, which is what they use in heavy duty manual transmissions, it flows great but provides a bit more lube for hard metal-on-metal things than a light oil. If ridden in cold weather, I might use a thinner oil like motor oil or automatic transmission fluid like Dexron, as the ratchet pawls and light springs may do better with that, not get stuck in if the lube gets thick. Some criticize the additives in those, and yes, you don't need a detergent additive to remove carbon deposits like engine oil, however, all of the above have "anti-wear" additives, also known as "high-pressure" additives, and tests of bike chain lubes show a lot less wear with lubes that have that additive (as opposed to 3-In-One oil which does not, for example). That's good stuff.

Aaron's Bike repair in greater Seattle has a great web page on internal gear hubs, they do a lot of servicing on them. Scroll way down for info:

https://www.rideyourbike.com/internalgears.shtml

If you had the hub apart like them, I would use a top-quality grease on the gears and outer wheel bearings (they use green marine wheel bearing grease, it helps seal out water), and a light oil on all the other parts (they use Phil Tenacious Oil).

If you don't have the hub apart, I would drip into the shifter hole in the axle, 75/90 gear lube, which is what they use in heavy duty manual transmissions, it flows great but provides a bit more lube for hard metal-on-metal things than a light oil. If ridden in cold weather, I might use a thinner oil like motor oil or automatic transmission fluid like Dexron, as the ratchet pawls and light springs may do better with that, not get stuck in if the lube gets thick. Some criticize the additives in those, and yes, you don't need a detergent additive to remove carbon deposits like engine oil, however, all of the above have "anti-wear" additives, also known as "high-pressure" additives, and tests of bike chain lubes show a lot less wear with lubes that have that additive (as opposed to 3-In-One oil which does not, for example). That's good stuff.

Last edited by Duragrouch; 04-24-24 at 02:51 AM.

Likes For Duragrouch:

#6

Palmer

Join Date: Mar 2007

Location: Parts Unknown

Posts: 8,636

Bikes: Mike Melton custom, Alex Moulton AM, Dahon Curl

Mentioned: 37 Post(s)

Tagged: 0 Thread(s)

Quoted: 1676 Post(s)

Liked 1,837 Times

in

1,067 Posts

It's sort of a given that here on Bike Forums Bicycle Mechanics posters will suggest and claim they use anything but the factory lubrication. Shrug. Anyway: Shimano Internal Hub Grease Y-041 20600

Google is finding some YouTube videos on the disassembly/reassembly of the 3CC.

Google is finding some YouTube videos on the disassembly/reassembly of the 3CC.

Last edited by tcs; 04-24-24 at 06:42 AM.

Likes For tcs:

#7

Senior Member

It's sort of a given that here on Bike Forums Bicycle Mechanics posters will suggest and claim they use anything but the factory lubrication. Shrug. Anyway: Shimano Internal Hub Grease Y-041 20600

Google is finding some YouTube videos on the disassembly/reassembly of the 3CC.

Google is finding some YouTube videos on the disassembly/reassembly of the 3CC.

#8

Palmer

Join Date: Mar 2007

Location: Parts Unknown

Posts: 8,636

Bikes: Mike Melton custom, Alex Moulton AM, Dahon Curl

Mentioned: 37 Post(s)

Tagged: 0 Thread(s)

Quoted: 1676 Post(s)

Liked 1,837 Times

in

1,067 Posts

So long as we're talking about 3-speeds, I encourage folks not to be intimidated and do the job per factory rather than sling seeping oil all over their rear wheel. Maybe that's just me. Anyway, SRAM (Fichtel&Sachs) and Shimano 3-speeds come apart with a cone wrench and std. open-end wrenches. Sturmey & Sturmey copy 3-speeds can be tapped apart with a drift punch. There are lots of manuals, guides and videos on this.

#9

Senior Member

So long as we're talking about 3-speeds, I encourage folks not to be intimidated and do the job per factory rather than sling seeping oil all over their rear wheel. Maybe that's just me. Anyway, SRAM (Fichtel&Sachs) and Shimano 3-speeds come apart with a cone wrench and std. open-end wrenches. Sturmey & Sturmey copy 3-speeds can be tapped apart with a drift punch. There are lots of manuals, guides and videos on this.

#10

Senior Member

Join Date: Sep 2004

Location: Chicago area

Posts: 2,562

Bikes: Airborne "Carpe Diem", Motobecane "Mirage", Trek 6000, Strida 2, Dahon "Helios XL", Dahon "Mu XL", Tern "Verge S11i"

Mentioned: 23 Post(s)

Tagged: 0 Thread(s)

Quoted: 982 Post(s)

Liked 587 Times

in

403 Posts

I was having an occasional "crunching" sensation in this hub, which has over 12,000 miles on it. After the rinse in mineral spirits, I found several small bits of metal in the sludge at the bottom of the jar. These were able to be picked up with a magnet. After reassembling the hub, it was dipped in gear oil (75w-140), drained then reinstalled. The bearings were lubricated with Nexus grease. The hub now performs perfectly.

The gear cluster after cleaning and reassembly. Use caution removing and replacing the circlip that holds the cluster on the axle... it likes to escape.

The reassembled cluster immersed in the gear oil.

For some reason, the black plastic cap that covers the drive-side bearing keeps coming loose. An easy fix is a few zip-ties. No leaks here! (Sprocket is due for replacement.)

Another view of the zip ties holding the cover in place.

Likes For sweeks:

#12

Senior Member

Join Date: Sep 2004

Location: Chicago area

Posts: 2,562

Bikes: Airborne "Carpe Diem", Motobecane "Mirage", Trek 6000, Strida 2, Dahon "Helios XL", Dahon "Mu XL", Tern "Verge S11i"

Mentioned: 23 Post(s)

Tagged: 0 Thread(s)

Quoted: 982 Post(s)

Liked 587 Times

in

403 Posts

Thanks! :-)

#13

Senior Member

Sweeks, superb post, thank you. While you had it apart, you didn't think there was merit to also putting grease on the gears and roller bearings? Also, after draining entire assembly, no extra gear lube into what I've heard called the "oil void" in the casing before reassembly? (I can see the oil staying there when the bike is vertical, but might leak out when layed down and when reassembling the hub with the axle vertical.) Gear lube is... well... gear lube, I just wonder if flung off over time and not in an oil bath (and not greased), if there needs to be a small amount to drip back on the gears. However, I have 75W-90 gear lube and you use a higher viscosity 75W-140, so perhaps it clings to the gears better. Thanks.

#14

Senior Member

Join Date: Sep 2004

Location: Chicago area

Posts: 2,562

Bikes: Airborne "Carpe Diem", Motobecane "Mirage", Trek 6000, Strida 2, Dahon "Helios XL", Dahon "Mu XL", Tern "Verge S11i"

Mentioned: 23 Post(s)

Tagged: 0 Thread(s)

Quoted: 982 Post(s)

Liked 587 Times

in

403 Posts

While you had it apart, you didn't think there was merit to also putting grease on the gears and roller bearings? Also, after draining entire assembly, no extra gear lube into what I've heard called the "oil void" in the casing before reassembly? (I can see the oil staying there when the bike is vertical, but might leak out when layed down and when reassembling the hub with the axle vertical.) Gear lube is... well... gear lube, I just wonder if flung off over time and not in an oil bath (and not greased), if there needs to be a small amount to drip back on the gears. However, I have 75W-90 gear lube and you use a higher viscosity 75W-140, so perhaps it clings to the gears better. Thanks.

I think I originally learned about the "oil dip" on THIS SITE. But there is a Shimano protocol for the dip. See THIS. (Looks like they've decreased the price on the oil... it used to be $80-100 for a liter!)

The oil may pool at the lowest point in the hub when the bike is stationary for a while, but the gears and rolling parts of the hub are close to the hub shell, so when the wheel starts rolling, the oil is redistributed. Whenever I open a hub, there's oil all over the gears.

Too much oil in the hub would leak out, because the plastic cap that seals the drive side doesn't actually seal very well. The cap fits into a groove in the hub shell; I fill this groove with waterproof bearing grease, and this does a pretty good job of containing the oil. This is also why I put the zip-ties on the hub to keep the end cap in place.

About that oil... the first number (75w) pertains to the viscosity of the oil at room temperature; the second (90, 140, etc.) relates to its viscosity at "operating" temperature. Unless something is **very, very** wrong, bicycle hubs don't reach these temperatures. So your oil and my oil are basically the same.

Hope this helps!

EDIT: Here's my home-brew set-up for oil-dipping the hub. It's a Talenti frozen yogurt jar with a hole drilled in the bottom, and a syringe body epoxied to the jar to accommodate the axle. This requires *much* less oil to perform the service.

This shows the syringe on the bottom, which allows the hub assembly to be submerged with much less oil.

Close-up of the attached syringe. Actually, this is dental acrylic... but epoxy would work as well.

The jar is a convenient fit on top of this can. Reminds me... I need more of those peas!

Last edited by sweeks; 04-27-24 at 04:39 PM.

Likes For sweeks:

#15

Senior Member

(above) I had forgotten about viscosity improvers, been too many decades. Yep.

I also save those Talenti jars! Dental acrylic, that's hilarious.

Gosh I would think that a long enough soak in solvent would dissolve the grease, but maybe it would need ultrasonic. Of late, I use tiki torch fuel as solvent as it's 98% mineral oil and mostly filled bottles are dirt cheap at goodwill at the end of summer. Works great as chain cleaner in Park Tool on-bike chain whirlygig.

Gears being timed/clocked, interesting! Must be something non-symmetrical on the same body (like a cam?), otherwise doesn't make sense to me. I'll have to think about that, perhaps look at an exploded view.

I also save those Talenti jars! Dental acrylic, that's hilarious.

Gosh I would think that a long enough soak in solvent would dissolve the grease, but maybe it would need ultrasonic. Of late, I use tiki torch fuel as solvent as it's 98% mineral oil and mostly filled bottles are dirt cheap at goodwill at the end of summer. Works great as chain cleaner in Park Tool on-bike chain whirlygig.

Gears being timed/clocked, interesting! Must be something non-symmetrical on the same body (like a cam?), otherwise doesn't make sense to me. I'll have to think about that, perhaps look at an exploded view.

#16

Senior Member

Join Date: Sep 2004

Location: Chicago area

Posts: 2,562

Bikes: Airborne "Carpe Diem", Motobecane "Mirage", Trek 6000, Strida 2, Dahon "Helios XL", Dahon "Mu XL", Tern "Verge S11i"

Mentioned: 23 Post(s)

Tagged: 0 Thread(s)

Quoted: 982 Post(s)

Liked 587 Times

in

403 Posts

I'll bet Dan Burkhart could explain it!

#17

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,113

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4222 Post(s)

Liked 3,908 Times

in

2,331 Posts

"Gears being timed/clocked, interesting! Must be something non-symmetrical on the same body (like a cam?), otherwise doesn't make sense to me. I'll have to think about that, perhaps look at an exploded view." Duragrouch

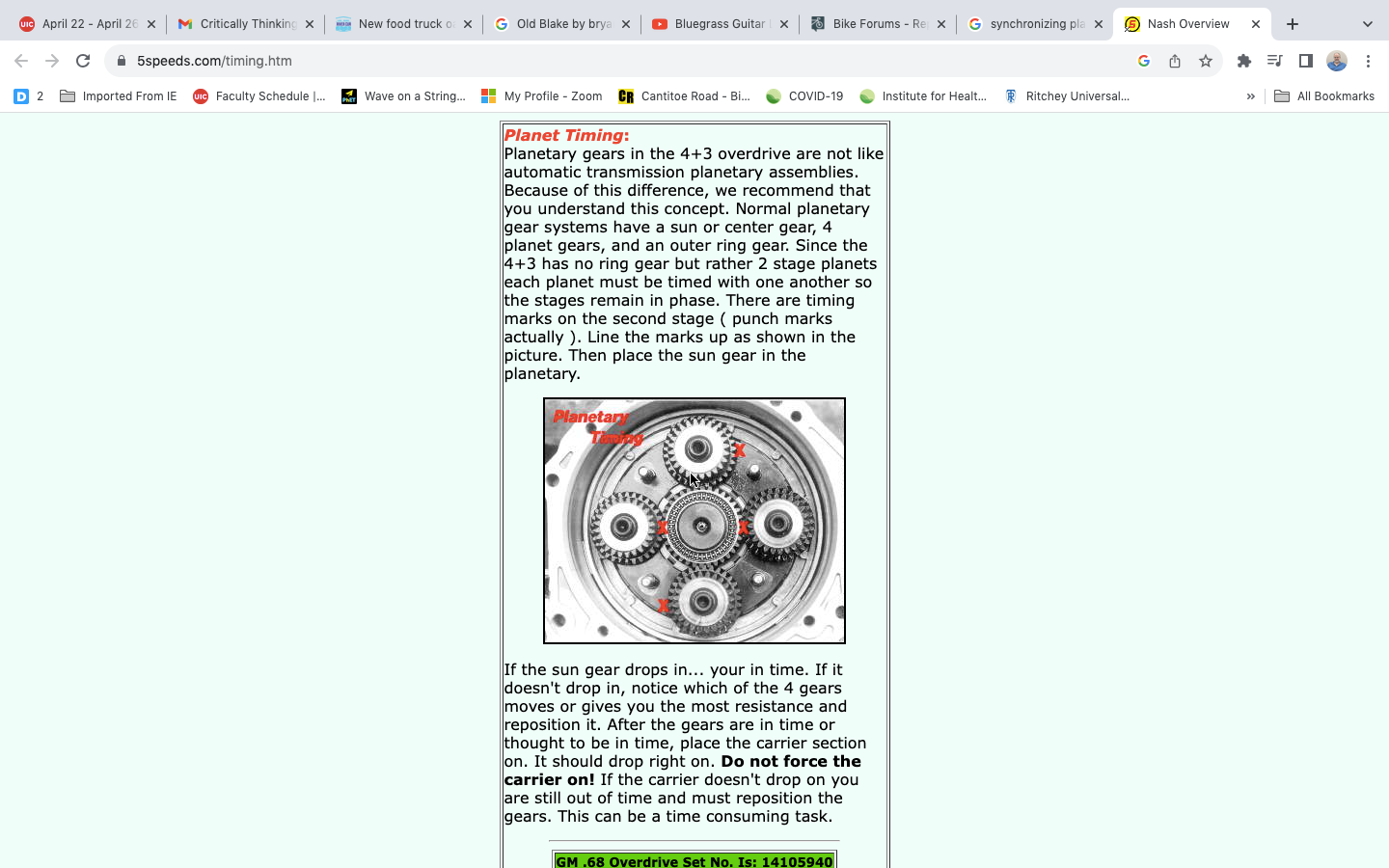

This is something I was taught way back when. IIRC some planet gears of some IGHs had timing pock marks on them for this reason. But the same boss would track which screw came out of which fitting as he restored old bikes too. I never went to this much effort with the SA AWs I have serviced and with the slight slop these hubs liked never had an issue with tolerances adding up too much and bind. Andy

This is something I was taught way back when. IIRC some planet gears of some IGHs had timing pock marks on them for this reason. But the same boss would track which screw came out of which fitting as he restored old bikes too. I never went to this much effort with the SA AWs I have serviced and with the slight slop these hubs liked never had an issue with tolerances adding up too much and bind. Andy

__________________

AndrewRStewart

AndrewRStewart

#18

Senior Member

Clocking gears: I took a look at the Nexus-8 service manual. So it appears, that there are two sets of planet gears there, side-by-side, of different diameters and number of teeth. When the gears are clocked, the clocked tooth of both gears line up perfectly. I do not know if those gears are two separate parts, or as a unit. But either way, my guess is clocking them that way may prevent some gears from fighting each other in zero backlash or some other way. If they point out in the service manual to clock the gears, there's probably a really good reason for it.

#19

Senior Member

Join Date: May 2010

Location: Bastrop Texas

Posts: 4,513

Bikes: Univega, Peu P6, Peu PR-10, Ted Williams, Peu UO-8, Peu UO-18 Mixte, Peu Dolomites

Mentioned: 13 Post(s)

Tagged: 0 Thread(s)

Quoted: 982 Post(s)

Liked 1,647 Times

in

1,058 Posts

Oh No... I am talking about a lube on the bikeforums... Look Out Ya All...

__________________

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)Last edited by zandoval; 04-28-24 at 12:02 AM.

Likes For zandoval:

#20

Senior Member

Join Date: Sep 2004

Location: Chicago area

Posts: 2,562

Bikes: Airborne "Carpe Diem", Motobecane "Mirage", Trek 6000, Strida 2, Dahon "Helios XL", Dahon "Mu XL", Tern "Verge S11i"

Mentioned: 23 Post(s)

Tagged: 0 Thread(s)

Quoted: 982 Post(s)

Liked 587 Times

in

403 Posts

Clocking gears: I took a look at the Nexus-8 service manual. So it appears, that there are two sets of planet gears there, side-by-side, of different diameters and number of teeth. When the gears are clocked, the clocked tooth of both gears line up perfectly. I do not know if those gears are two separate parts, or as a unit. But either way, my guess is clocking them that way may prevent some gears from fighting each other in zero backlash or some other way. If they point out in the service manual to clock the gears, there's probably a really good reason for it.

This topic gets pretty technical: In The Weeds.

Also, I found this:

This helps a bit!

For some reason, I can't do selective (cropped) screenshots on my Mac... sorry.

Last edited by sweeks; 04-28-24 at 07:54 AM.

#21

Senior member

Join Date: Oct 2004

Location: Oakville Ontario

Posts: 8,122

Mentioned: 25 Post(s)

Tagged: 0 Thread(s)

Quoted: 945 Post(s)

Liked 660 Times

in

373 Posts

Clocking gears: I took a look at the Nexus-8 service manual. So it appears, that there are two sets of planet gears there, side-by-side, of different diameters and number of teeth. When the gears are clocked, the clocked tooth of both gears line up perfectly. I do not know if those gears are two separate parts, or as a unit. But either way, my guess is clocking them that way may prevent some gears from fighting each other in zero backlash or some other way. If they point out in the service manual to clock the gears, there's probably a really good reason for it.

All of the fixed stepped gears on the multiple shafts must have a common alignment point on each rotation or the gears would climb out of equilibrium after about one rotation, causing the entire assembly to bind.

Obviously not an issue with a single countershaft or in the case of a 3 speed hub with a single sun and planetary set.

Last edited by Dan Burkhart; 04-28-24 at 08:59 AM.

Likes For Dan Burkhart:

#22

Senior Member

This is exactly right. Imagine a system with three "compound" planets (gears of different diameters and numbers of teeth). The teeth on the two diameters may not have a one-to-one correspondence. If the three planets are haphazardly placed, the teeth of one or more may not line up with the relevant sun gear. I'm not explaining this very well.