Maximum spoke tension?

#1

Full Member

Thread Starter

Join Date: Feb 2015

Location: Pittsburgh, PA

Posts: 400

Bikes: Schwinn, Nishiki, Santana, Trek, Rodriguez

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 189 Post(s)

Likes: 0

Liked 106 Times

in

69 Posts

Maximum spoke tension?

Is 1200 N too much tension on weinmann zac19 rims, will nipples eventually pull through rim? I cannot find a specification and no response from company. Listed specs...it says single eyelet, but I do not see eyelet collars in the rims.

SIZE:559(26")

SPOKE HOLES:36H

WEIGHT:452G

JOINT:PINNED

EYELET:SINGLE EYELET

SIZE:559(26")

SPOKE HOLES:36H

WEIGHT:452G

JOINT:PINNED

EYELET:SINGLE EYELET

#2

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,056

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4195 Post(s)

Liked 3,837 Times

in

2,295 Posts

I suspect that the ZAC 19 is like many rims that are OEM products in that they have a lower cost version intended for the OEM market and a nicer version for the aftermarket. Without and with spoke hole eyelets is a common difference. No surprise that there's no tension specs published. To do so opens the company to more claims of manufacturing defects.

Side story- I had a need to return a built wheel to the US hub manufacturer for bearing issues. On it's return (after a special oversized bearing was installed at a cost) I was told that the spoke count and tension was too much for their hub shell to handle and had "opened up" the bearing's bore. Sad in that the company offers the hub in the spoke count I have and no rim exclusions or tension limits were ever made known to me. Needless to say I have not sourced the same brand of hub again (for customers and my 8 following bikes). Andy

Side story- I had a need to return a built wheel to the US hub manufacturer for bearing issues. On it's return (after a special oversized bearing was installed at a cost) I was told that the spoke count and tension was too much for their hub shell to handle and had "opened up" the bearing's bore. Sad in that the company offers the hub in the spoke count I have and no rim exclusions or tension limits were ever made known to me. Needless to say I have not sourced the same brand of hub again (for customers and my 8 following bikes). Andy

__________________

AndrewRStewart

AndrewRStewart

#3

Senior member

Join Date: Oct 2004

Location: Oakville Ontario

Posts: 8,115

Mentioned: 25 Post(s)

Tagged: 0 Thread(s)

Quoted: 942 Post(s)

Liked 656 Times

in

370 Posts

That's a bit higher than I would go with a rim like that. I work in KGF rather than Newtons, but the conversion is pretty simple. 1200N is about 120 KGF. I would settle for about 100 KGF.

#5

Senior Member

1200Nm will be fine. Any rim can take that. Two caveats. First is that if the rim lacks eyelets you simply must use spoke washers. For OEM builds this step is omitted. OEM builds are seldom very good. OEM rims also often have extra thick spoke beds. Which works, but not so well as using washers. Second caveat is that any rim can crack when spoke tension is uneven. With uneven tension the load at spoke hole is completely random and variable. Of course they crack. If OP is mentioning tension presumably a tension meter is available. Use that meter on every spoke.

100kgpf is sufficient for any wheel. Problem is if a hard limit is put on drive side tension the resulting non-drive side is too loose to maintain a stable wheel. Even with 135mm hubs or prehistoric 5speed freewheels non drive side is frequently plain loose when 100kgpf is reached on other side.

Take your tension meter to the shop and check the tension on pre-built wheels from same manufacturers who say no more than 120. Their own wheels have 150 and 170 and more and that applies to many mfrs. Not recommended practice, but do not lose sleep over 120 or 130.

100kgpf is sufficient for any wheel. Problem is if a hard limit is put on drive side tension the resulting non-drive side is too loose to maintain a stable wheel. Even with 135mm hubs or prehistoric 5speed freewheels non drive side is frequently plain loose when 100kgpf is reached on other side.

Take your tension meter to the shop and check the tension on pre-built wheels from same manufacturers who say no more than 120. Their own wheels have 150 and 170 and more and that applies to many mfrs. Not recommended practice, but do not lose sleep over 120 or 130.

#6

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,801

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 829 Post(s)

Liked 1,241 Times

in

655 Posts

It's a bit of a long discussion but just because it says on the internet that 100 KgF is a good spoke tension, that's what you should aim for on your tension guage - don't.

A spoked wheel is a complex structure and many books have been written to describe the fine art of building bike wheels.

Ideally you want the optimum spoke tension for the spokes and rim you select, considering the lacing pattern, spoke guage, and other factors.

To confuse things further, remember that on clincher wheels, spoke tension is reduced when you inflate the tire. By how much? Hard to say, but it's in the region of 5-10%.

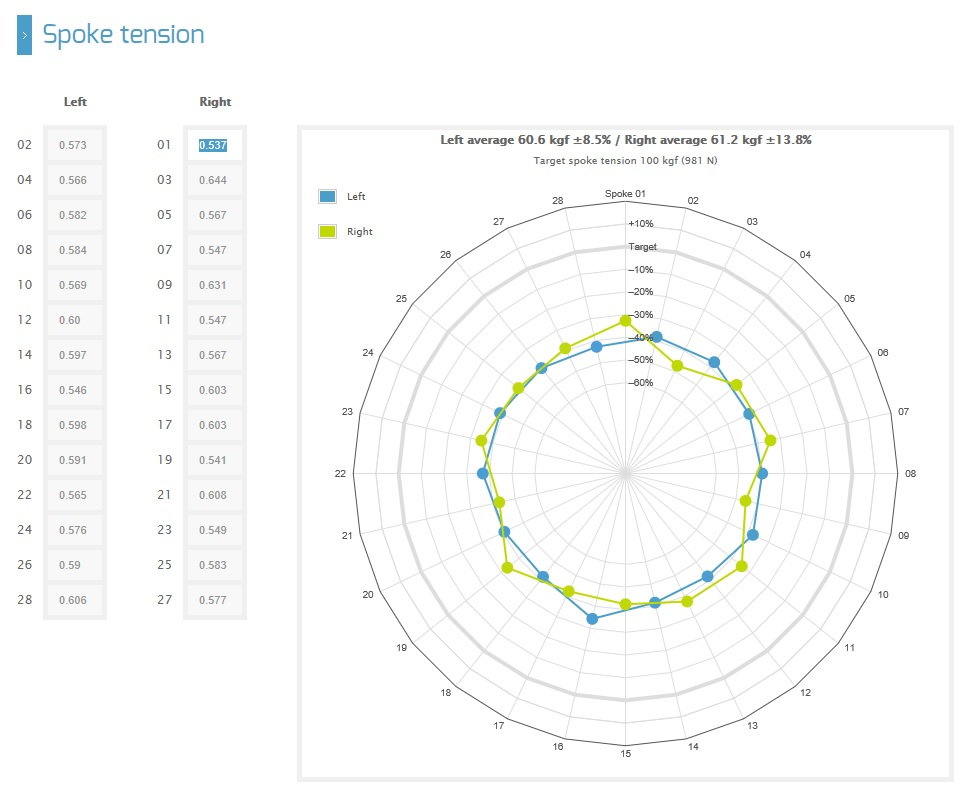

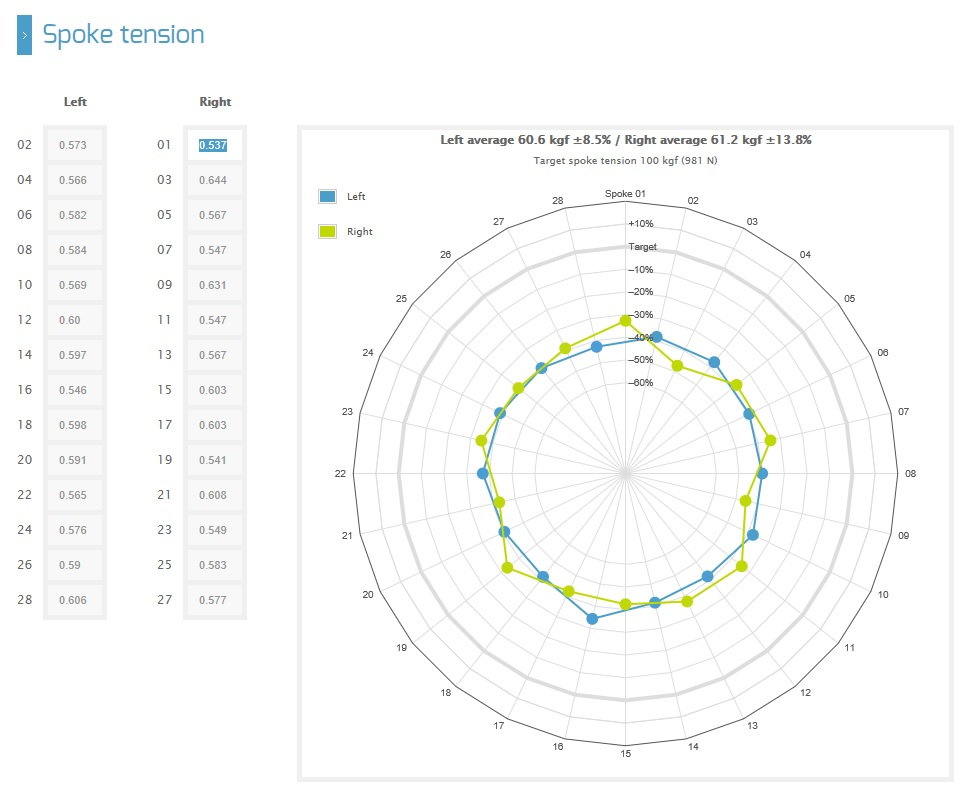

Remember that very few wheels have absolutely even spoke tension. I have the Wheel Fanatyk instrumentation that lets you "visualize" the spoke tension around the wheel. What I find is that if you can get spoke tension within about a 10% range you are doing pretty good. There will always be 2-3 spokes usually at the rim joint that will be hard to get in that range. Those spokes are the ones that will tend to pop or pull thru the rim, since they are under the highest tension.

I'd suggest to you that for bikes wheels appropriate to this group (not talking about 18 spoke Enve or Reynolds Carbon here) 75-85 KgF is a much more reasonable tension for tangentially spoked, 32 or 36 spoke wheels with aluminum clincher rims that will run true and be reliable for years.

A couple suggestions for developing your wheelbuilding skills : Yes, tension relieve your wheels 2-3 times during the build process. Listen to the "ping" to find spokes that are too loose or too tight and adjust your truing technique accordingly. Use a 3 sided spoke wrench like the DT. Use a spoke prep (Wheel Fanatyk "Fix", or something else). Keep notes of your wheel builds. Watch the Gerd Schraner video a couple times. And don't over-focus on the tensiometer - use it as a guideline, not a go/no go guage.

Mark Petry

Bainbridge Island, WA USA

A spoked wheel is a complex structure and many books have been written to describe the fine art of building bike wheels.

Ideally you want the optimum spoke tension for the spokes and rim you select, considering the lacing pattern, spoke guage, and other factors.

To confuse things further, remember that on clincher wheels, spoke tension is reduced when you inflate the tire. By how much? Hard to say, but it's in the region of 5-10%.

Remember that very few wheels have absolutely even spoke tension. I have the Wheel Fanatyk instrumentation that lets you "visualize" the spoke tension around the wheel. What I find is that if you can get spoke tension within about a 10% range you are doing pretty good. There will always be 2-3 spokes usually at the rim joint that will be hard to get in that range. Those spokes are the ones that will tend to pop or pull thru the rim, since they are under the highest tension.

I'd suggest to you that for bikes wheels appropriate to this group (not talking about 18 spoke Enve or Reynolds Carbon here) 75-85 KgF is a much more reasonable tension for tangentially spoked, 32 or 36 spoke wheels with aluminum clincher rims that will run true and be reliable for years.

A couple suggestions for developing your wheelbuilding skills : Yes, tension relieve your wheels 2-3 times during the build process. Listen to the "ping" to find spokes that are too loose or too tight and adjust your truing technique accordingly. Use a 3 sided spoke wrench like the DT. Use a spoke prep (Wheel Fanatyk "Fix", or something else). Keep notes of your wheel builds. Watch the Gerd Schraner video a couple times. And don't over-focus on the tensiometer - use it as a guideline, not a go/no go guage.

Mark Petry

Bainbridge Island, WA USA

Last edited by mpetry912; 09-29-19 at 09:28 AM.

Likes For mpetry912:

#8

Really Old Senior Member

And nobody has mentioned front or rear???

#9

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,801

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 829 Post(s)

Liked 1,241 Times

in

655 Posts

You made my point ! With what rim ? What guage spoke ? What lacing pattern.

Lets take the ridiculous extreme - Mavic OR10 with 14g spokes, radial laced to large flange hub, and 100 KgF - won't even make it to the end of the driveway ! spokes will pull thru the rim.

Again, there's a lot more to this discussion than internet "wisdom" or the reading on your tensiometer.

Mark Petry

Bainbridge Island, WA USA

Lets take the ridiculous extreme - Mavic OR10 with 14g spokes, radial laced to large flange hub, and 100 KgF - won't even make it to the end of the driveway ! spokes will pull thru the rim.

Again, there's a lot more to this discussion than internet "wisdom" or the reading on your tensiometer.

Mark Petry

Bainbridge Island, WA USA

#10

Senior Member

Unfortunate that any discussion of wheelbuilding is always shrouded in arcana. With modern tools and current rims the task is accessible to all.

Just for the record I've not seen an OR10 in a very long time. About 5 years back built a GEL280 to a high flange onecross and tensioned it to 100kgpf. That wheel is still in use and the owner pushes it quite hard. Any time spoke pullthrough has been observed there was something very wrong and odd going on. No reason to frighten novices with stories of pullthrough.

75 or 85kgpf is enough in most cases. Problem is that a rear wheel built to 75 drive side is still so loose the nondrive side won't even give a reading. Pull the non drive to 60, get it dished, don't worry about being a bit high on drive tension. If drive side tension ends up very high, like 140 or 150, then you have to make a decision. If NDS will go to 55 that is probably enough. Or you get to start over with a better spaced hub. Or you can decide to go with 140. Which will work more often than not.

Spoke nipples work exactly the same as any other threaded fastener. Get them tight enough and they will stay put. Not tight enough and red loctite will not make them stay put. Oil is good spoke prep. Makes building easier and does not cause anything to come loose. In my time I have watched Oscar Wastyn, Ron Boi, Mark Muller, George Noyes build with oil. Other darn good builders no one has heard of. If you prefer solid lubricant beeswax rubbed on the threads is good.

The common green Park spoke wrench is fine for DT nipples and most other nipples at least up to 100kgpf. Fast to work with. The black Park wrench will take you to 120. Tight wheels need the three corner wrenches. The three corner wrench is very slow to work with and makes the builder slow down and think. Which is a good thing.

Tight spokes at the rim join is a characteristic of older (much older) and lower quality rims. It has always been possible to juggle tension until they get somewhat more even and good builders have always done that. Generally don't worry about it.

There are really simple methods for stress relieving and simple methods for most everything involved in wheelbuilding and we never get there because someone wants it all to be hard.

Just for the record I've not seen an OR10 in a very long time. About 5 years back built a GEL280 to a high flange onecross and tensioned it to 100kgpf. That wheel is still in use and the owner pushes it quite hard. Any time spoke pullthrough has been observed there was something very wrong and odd going on. No reason to frighten novices with stories of pullthrough.

75 or 85kgpf is enough in most cases. Problem is that a rear wheel built to 75 drive side is still so loose the nondrive side won't even give a reading. Pull the non drive to 60, get it dished, don't worry about being a bit high on drive tension. If drive side tension ends up very high, like 140 or 150, then you have to make a decision. If NDS will go to 55 that is probably enough. Or you get to start over with a better spaced hub. Or you can decide to go with 140. Which will work more often than not.

Spoke nipples work exactly the same as any other threaded fastener. Get them tight enough and they will stay put. Not tight enough and red loctite will not make them stay put. Oil is good spoke prep. Makes building easier and does not cause anything to come loose. In my time I have watched Oscar Wastyn, Ron Boi, Mark Muller, George Noyes build with oil. Other darn good builders no one has heard of. If you prefer solid lubricant beeswax rubbed on the threads is good.

The common green Park spoke wrench is fine for DT nipples and most other nipples at least up to 100kgpf. Fast to work with. The black Park wrench will take you to 120. Tight wheels need the three corner wrenches. The three corner wrench is very slow to work with and makes the builder slow down and think. Which is a good thing.

Tight spokes at the rim join is a characteristic of older (much older) and lower quality rims. It has always been possible to juggle tension until they get somewhat more even and good builders have always done that. Generally don't worry about it.

There are really simple methods for stress relieving and simple methods for most everything involved in wheelbuilding and we never get there because someone wants it all to be hard.

#11

Senior Member

Join Date: Sep 2004

Location: Chicago area

Posts: 2,546

Bikes: Airborne "Carpe Diem", Motobecane "Mirage", Trek 6000, Strida 2, Dahon "Helios XL", Dahon "Mu XL", Tern "Verge S11i"

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 980 Post(s)

Liked 580 Times

in

398 Posts

That sounds "made-up" to me. Most hubs I've seen have aluminum shells with pressed-in steel cups. High spoke tension might cause the cup to fall out, but it would be unlikely to change the dimensions of the cup itself significantly.

#12

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,801

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 829 Post(s)

Liked 1,241 Times

in

655 Posts

here's an OR10 from the "positive net worth" Cinelli that I sold a few years ago. These are very light rims, and quite difficult to build because they are so soft. I doubt you could get 65KgF of spoke tension on these. The point being, you can't just say "100KgF" is the right spoke tension because you read it on the internet (even here). Generally I start with a target tension based on rim, spoke, and lacing pattern, and try to converge on trueness and dish at a tension level as close to that as I can get, confirmed by the tensiometer, which I use mainly to identify outliers.

Mark Petry

Bainbridge Island, WA USA

Mark Petry

Bainbridge Island, WA USA

Last edited by mpetry912; 09-29-19 at 01:15 PM.

#13

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,056

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4195 Post(s)

Liked 3,837 Times

in

2,295 Posts

I agree with that best spoke tension varies with the components. But also the spoke gages and numbers come into play. I've build and ridden a number of sub 300gn sew up rims for thousands of miles with no pull throughs but I always balanced the spoke gage to the rim, and most of these were 36 spoke rims. Not mentioned with these classic (I dare use that term for these rims) wheels are that the flange to center off sets tend to be less different side to side, so tensions are also less different.

sweeks- I believe the company's reasons re: hub shell opening up about the bearing. The hub uses angular contact cartridge bearings with an adjustment collar on it's left side. The "bearing adjustment" would be loose so I would snug up the adjustment collar and ultimately ran out of adjustment range. The company's explanation is that the RH shell bearing was rocking ever so slightly in the shell, due the shell's expansion from the spoke tension (don't remember the exact number but about 100/110 KgF on that side, my usual goal for middle weight rims when new). With the OS bearing (as listed on the invoice with their part number) the adjustment collar is back to the first third of it's range and there's been no further issues for the last half dozen years. This company is known for their light weight and "superior engineering and design". The many Phil hubs I have in use (and all the Campy NR ones I use to run from the 1970s) never had this issue. Only a couple (maybe three) times I have seen a cup loose in a hub shell were with cup and cone unit, with rather low cost ones at that and one was in the front hub. Was my fancy USA hub slightly out of dimension from the "factory"? Maybe. But The company would challenge that as their reputation is pretty stellar in that aspect. Andy

sweeks- I believe the company's reasons re: hub shell opening up about the bearing. The hub uses angular contact cartridge bearings with an adjustment collar on it's left side. The "bearing adjustment" would be loose so I would snug up the adjustment collar and ultimately ran out of adjustment range. The company's explanation is that the RH shell bearing was rocking ever so slightly in the shell, due the shell's expansion from the spoke tension (don't remember the exact number but about 100/110 KgF on that side, my usual goal for middle weight rims when new). With the OS bearing (as listed on the invoice with their part number) the adjustment collar is back to the first third of it's range and there's been no further issues for the last half dozen years. This company is known for their light weight and "superior engineering and design". The many Phil hubs I have in use (and all the Campy NR ones I use to run from the 1970s) never had this issue. Only a couple (maybe three) times I have seen a cup loose in a hub shell were with cup and cone unit, with rather low cost ones at that and one was in the front hub. Was my fancy USA hub slightly out of dimension from the "factory"? Maybe. But The company would challenge that as their reputation is pretty stellar in that aspect. Andy

__________________

AndrewRStewart

AndrewRStewart

Last edited by Andrew R Stewart; 09-29-19 at 01:19 PM. Reason: miss spelling

#14

Full Member

Thread Starter

Join Date: Feb 2015

Location: Pittsburgh, PA

Posts: 400

Bikes: Schwinn, Nishiki, Santana, Trek, Rodriguez

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 189 Post(s)

Likes: 0

Liked 106 Times

in

69 Posts

I would like to very much thank everyone for the interesting responses. I apologize for not giving more details. We ride a tandem and tour with camping gear often, so 470lbs/214kg for riders+gear+bike. Weinmann zac19 rims/36hole/559. A rear rohloff hub, so no dish. I built something to calibrate my park gauge, after which I found that both wheels were higher than expected, at average of 120 kgf (variance of +/-20%). I like higher tension, but concerned that the rim (no eyelets, no nipple washers) will not support the nipples. Furthermore, the high spoke angle at the rim causes the nipple to angle significantly (good for spoke), but the asymmetry of nipple in hole (I suspect) will make it easier for the nipple to pull through rim.

So, back all off 1/4 turn to about 100kgf, or is that too low for a loaded tandem?

Thanks again.

So, back all off 1/4 turn to about 100kgf, or is that too low for a loaded tandem?

Thanks again.

#15

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,801

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 829 Post(s)

Liked 1,241 Times

in

655 Posts

I would not back 'em off. If they seem ok, just keep a close eye on the rim and spoke eyelets, watching for cracks.

also if you have the spoke angle problem at the rim, don't be afraid to put a little bend in the spoke about an inch above where the spoke enters the rim to normalize that angle. maybe do that for the "pulling" spokes only on the rear wheel.

Mark Petry

Bainbridge Island, WA USA

also if you have the spoke angle problem at the rim, don't be afraid to put a little bend in the spoke about an inch above where the spoke enters the rim to normalize that angle. maybe do that for the "pulling" spokes only on the rear wheel.

Mark Petry

Bainbridge Island, WA USA

#16

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,801

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 829 Post(s)

Liked 1,241 Times

in

655 Posts

Here is just about the coolest thing in wheelbuilding - splined nipples. These are 7000 series aluminum and definitely strong enough for any wheel build.

They are super fast to build with because there's a tool engagement every 60 degrees. Very positive and will NOT round off.

Ric Hjertberg (WheelFanatyk.com) has these in a number of colors - they are AWESOME ! https://www.wheelfanatyk.com/store/splined-nipples/

Mark Petry

Bainbridge Island, WA USA

They are super fast to build with because there's a tool engagement every 60 degrees. Very positive and will NOT round off.

Ric Hjertberg (WheelFanatyk.com) has these in a number of colors - they are AWESOME ! https://www.wheelfanatyk.com/store/splined-nipples/

Mark Petry

Bainbridge Island, WA USA

Last edited by mpetry912; 10-06-19 at 08:07 AM.

#17

Full Member

Thread Starter

Join Date: Feb 2015

Location: Pittsburgh, PA

Posts: 400

Bikes: Schwinn, Nishiki, Santana, Trek, Rodriguez

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 189 Post(s)

Likes: 0

Liked 106 Times

in

69 Posts

I would not back 'em off. If they seem ok, just keep a close eye on the rim and spoke eyelets, watching for cracks.

also if you have the spoke angle problem at the rim, don't be afraid to put a little bend in the spoke about an inch above where the spoke enters the rim to normalize that angle. maybe do that for the "pulling" spokes only on the rear wheel.

Mark Petry

Bainbridge Island, WA USA

also if you have the spoke angle problem at the rim, don't be afraid to put a little bend in the spoke about an inch above where the spoke enters the rim to normalize that angle. maybe do that for the "pulling" spokes only on the rear wheel.

Mark Petry

Bainbridge Island, WA USA

They are ok so far. My concern is that if I do in fact see cracks develop, it is too late to remedy.

They are ok so far. My concern is that if I do in fact see cracks develop, it is too late to remedy.regarding...

"put a little bend in the spoke about an inch above where the spoke enters the rim"

This seems to be in contrast to Brandt where he says to remove such bends (p.98) ..."In this case the desired spoke alignment is an abrupt bend where the spoke enters the nipple."

#18

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,801

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 829 Post(s)

Liked 1,241 Times

in

655 Posts

I knew Jobst slightly and Ric (for whom I have great respect) worked closely with him for years.

I just looked at my (signed) copy of "the bicycle wheel", thank you for the reference. I think what is being suggested is not at variance with Jobst's book at all.

Here's what Ric says about adjusting spoke angle. https://www.wheelfanatyk.com/blog/spoke-angle/

Up to you

Mark Petry

Bainbridge Island, WA USA

I just looked at my (signed) copy of "the bicycle wheel", thank you for the reference. I think what is being suggested is not at variance with Jobst's book at all.

Here's what Ric says about adjusting spoke angle. https://www.wheelfanatyk.com/blog/spoke-angle/

Up to you

Mark Petry

Bainbridge Island, WA USA

#19

Senior Member

Join Date: Sep 2004

Location: Chicago area

Posts: 2,546

Bikes: Airborne "Carpe Diem", Motobecane "Mirage", Trek 6000, Strida 2, Dahon "Helios XL", Dahon "Mu XL", Tern "Verge S11i"

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 980 Post(s)

Liked 580 Times

in

398 Posts

You could load the bike up, have both riders seated and get someone to mention the spoke tension on the spoke(s) closest to the ground. They should not be slack (or probably anywhere close to slack). Probably too much work.

#20

Full Member

Thread Starter

Join Date: Feb 2015

Location: Pittsburgh, PA

Posts: 400

Bikes: Schwinn, Nishiki, Santana, Trek, Rodriguez

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 189 Post(s)

Likes: 0

Liked 106 Times

in

69 Posts

Thanks for your input. I have read every ones comments, all interesting. It comes down to 100 versus 120 kgf, which seems subtle, until your in the middle of nowhere and your wheel fails.

@mpetry912, thanks for the link. One of Ric's statement I came to independently. Rim makers need to respond to hub changes and maybe this will happen because of the electric motorbike crowd push. Well, at least something good about "e-bikes"

.

.

#21

Full Member

Thread Starter

Join Date: Feb 2015

Location: Pittsburgh, PA

Posts: 400

Bikes: Schwinn, Nishiki, Santana, Trek, Rodriguez

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 189 Post(s)

Likes: 0

Liked 106 Times

in

69 Posts

I would have loved to meet Brandt (and my particular wish, S. Brown), your are fortunate. I feel simply fortunate in having gained much knowledge over the years from their writings.

#22

Senior Member

I would like to very much thank everyone for the interesting responses. I apologize for not giving more details. We ride a tandem and tour with camping gear often, so 470lbs/214kg for riders+gear+bike. Weinmann zac19 rims/36hole/559. A rear rohloff hub, so no dish. I built something to calibrate my park gauge, after which I found that both wheels were higher than expected, at average of 120 kgf (variance of +/-20%). I like higher tension, but concerned that the rim (no eyelets, no nipple washers) will not support the nipples. Furthermore, the high spoke angle at the rim causes the nipple to angle significantly (good for spoke), but the asymmetry of nipple in hole (I suspect) will make it easier for the nipple to pull through rim.

So, back all off 1/4 turn to about 100kgf, or is that too low for a loaded tandem?

Thanks again.

So, back all off 1/4 turn to about 100kgf, or is that too low for a loaded tandem?

Thanks again.

#23

Senior Member

Link to manufacturer's site: https://www.ryde.nl/zac-19

Max tension is given as 1300Nm. Also please note they consider this as a lighter duty rim. I would agree with that. Upgrade to Andra. Even then the mfr says your tandem is too heavy but a stronger rim probably means steel. The Andra is rated for 1400Nm and I'd suggest using all of that. 10% over on one or two spokes is acceptable.

Plus or minus 20% is not that good. Would mean a poorly made rim or a wheelbuilder who gave up too soon. Either way not good on a tandem.

All the Ryde rims have a substantial bed for spokes whether or not they are eyeletted. Use a washer if no eyelets. Getting a washer in on V shaped rims can be tricky, for a Zac or Andra it's simple.

Max tension is given as 1300Nm. Also please note they consider this as a lighter duty rim. I would agree with that. Upgrade to Andra. Even then the mfr says your tandem is too heavy but a stronger rim probably means steel. The Andra is rated for 1400Nm and I'd suggest using all of that. 10% over on one or two spokes is acceptable.

Plus or minus 20% is not that good. Would mean a poorly made rim or a wheelbuilder who gave up too soon. Either way not good on a tandem.

All the Ryde rims have a substantial bed for spokes whether or not they are eyeletted. Use a washer if no eyelets. Getting a washer in on V shaped rims can be tricky, for a Zac or Andra it's simple.

#24

Senior Member

A further note. Often, not always but often, a washer helps the spoke nipple find alignment. Hardware store washers do this, specific nipple washers do it better. I've a small stock of Raleigh washers from 1940s that are really good. But am running low. Sapim has washers, have never tried them.

#25

Junior Member

Join Date: Sep 2019

Location: West Midlands, England

Posts: 10

Bikes: Cinelli Nemo TIG w/ Campy S.R., Cotic BFE, Brompton, Pashley Unicycle, Sunday BMX, plenty of old and vintage bits and bobs.

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 3 Post(s)

Liked 0 Times

in

0 Posts

Most DT Swiss rims specify and supply washers, but that's because of no eyelet. You'll only be able to fit washers on certain rims, as the profiles won't match. Lube the nipples, use brass if you can, and remember that a tandem wheel has a lot more stress and load than a conventional wheel. Spoke tension usually decreases with an inflated tyre on, but this shouldn't influence the initial spoke tension.