Spoke tension meter recommedations

#26

Senior Member

Join Date: Jan 2010

Location: se MIch.

Posts: 2,303

Bikes: 1938 claud butler,1983 Basso,teledyne titan,teocali super,nrs,1993 stumpjumper fsr,Paramountain,Paramount Buell(sold),4 banger,Zaskar LE,Colnago Master Ibex MTB,1987ish,.etc....

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 800 Post(s)

Liked 2,964 Times

in

1,494 Posts

wheelsmith chart.

google will find it.

#28

working on my sandal tan

Join Date: Aug 2011

Location: CID

Posts: 22,627

Bikes: 1991 Bianchi Eros, 1964 Armstrong, 1988 Diamondback Ascent, 1988 Bianchi Premio, 1987 Bianchi Sport SX, 1980s Raleigh mixte (hers), All-City Space Horse (hers)

Mentioned: 98 Post(s)

Tagged: 0 Thread(s)

Quoted: 3870 Post(s)

Liked 2,563 Times

in

1,577 Posts

#29

Senior Member

I have read the book. You may use that word differently than I do but he said to tension it hard so that that it is overtensioned (it won't remain true) and then back off. So maybe taco isn't the right word but I know what he said as I have read it and used the book to build more than a few wheels.

I'm curious, do you specialize in being a jerk? You're doing a fine job so far. There are a lot of ways you could have made your point without stating that I looked at the pictures rather than read the book . . . .

I'm curious, do you specialize in being a jerk? You're doing a fine job so far. There are a lot of ways you could have made your point without stating that I looked at the pictures rather than read the book . . . .

#30

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,801

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 829 Post(s)

Liked 1,241 Times

in

655 Posts

I have the WheelFanatyk digital tensiometer that lets you generate a "radar plot" of spoke tension. It is a great tool. It gives merciless feedback !

Mark Petry

Bainbridge Island, WA

Mark Petry

Bainbridge Island, WA

#31

Senior Member

Join Date: Apr 2012

Location: Middle Earth (aka IA)

Posts: 20,433

Bikes: A bunch of old bikes and a few new ones

Mentioned: 178 Post(s)

Tagged: 0 Thread(s)

Quoted: 5888 Post(s)

Liked 3,471 Times

in

2,079 Posts

FINDING THE RIGHT TENSION The following method works well in determining proper spoke tension for conventional road rims of up to 43 0 grams with 3 6 spokes. Tighten all the spokes a quarter turn at a time, starting at the valve stem hole. Once a distinct tone can be made by plucking, and spokes are not easily squeezed together by grasping them in pairs, it is time to check tension. After each round of tightening, test the tension by stress relieving. If the wheel becomes untrue in two large waves during stress relieving, the maximum, safe tension has been exceeded. Approach this tension carefully to avoid major rim distortions. When the wheel loses alignment from stress relieving, loosen all spokes a half turn before retruing the wheel.

I also appreciate the quote from the book.

But this thread has me thinking that maybe it's time to buy the right tool as well.

#32

Senior Member

Join Date: Jun 2015

Location: Down Under

Posts: 1,936

Bikes: A steel framed 26" off road tourer from a manufacturer who thinks they are cool. Giant Anthem. Trek 720 Multiroad pub bike. 10 kids bikes all under 20". Assorted waifs and unfinished projects.

Mentioned: 11 Post(s)

Tagged: 0 Thread(s)

Quoted: 1188 Post(s)

Liked 1,154 Times

in

640 Posts

I'm talking good second hand wheels or rims that are unmarked, Trev.

I got given a Novotec front wheel - that's marked on the hub! (double walled, 36 round stainless spokes)

trued it up and now with the meter tool it reads anywhere from 20-25, thinking i may have tightened it a bit much, dunno

I got given a Novotec front wheel - that's marked on the hub! (double walled, 36 round stainless spokes)

trued it up and now with the meter tool it reads anywhere from 20-25, thinking i may have tightened it a bit much, dunno

Likes For Trevtassie:

#33

Senior Member

if you are not putting the data into a spreadsheet to correlate radial runout for each spoke with tension variance then you miss the main purpose/use of a precise tension meter. it's not as much as to provide circle graphs. but to be able to better adjust radial runout to tension variance and therefore being able to straighten the rim if you want to. or just let the wheel straighten itself over time. but i'd choose the first variant.

i'd only invest in a tension meter if it is at least as accurate as the acoustics method which has the disadvantage of being a slow one when using a tone generator (the computer doing the math after you feed in the value in Hz) with the advantage of being zero expense.

and then i'd not have too much use of a proper tension meter if not for figuring out the delta elongation from the average for each spoke. i'd have my estimation as to the final tension without needing anything else but acoustics and a quick calculation given the length between the cross and the nipple etc.

but that's just me who am a perfectionist and only build my own wheels.

if i were servicing/building more than 30 wheels per year i'd buy a precise tension meter to have productivity as well and not only accuracy.

then again... if you don't measure with dial gauges radial runout (supposing the lateral runout is low enough as to have insignificant errors) you also are unable to balance radial runout with tension variance unless you true down to zero which can be very tedious. many people don't get it. you can true the wheel but not have it fixed once and for good (best durability). it will be either luck once in a while or just sloppier work. and even more slow work.

need i mention that you can very well bring the lateral true to such a low value after you balance the other two figures which are more important for wheel durability?

if you don't believe me... just try it once.

and circle graphs are of use only to impress customers who don't have a clue regarding radial true needing to be balanced to tension variance. when it comes to working with imperfect from the factory or just bent rims (pulling the rim and twisting it etc.) you are better off with linear graphs from the spreadsheet software you'd have available.

just make the adjustments by calculating the angle for nipple turn - each spoke - and all will be easy as cake afterwards. and put some labels as to monitor spoke twist.

or you might as well just go on doing a bit less sloppy work than what machines do. machines don't monitor spoke twist as to calculate nipple turn angle by backing off from spoke twist. nor do they correlate spoke tension variance with runout for all the spokes as to calculate all 16 or 18 angles of adjustments afterwards. do they?...

if you aren't getting my my point... i give up. even if my english is not as from a native... you can give a careful reading if you want to.

then again... you might understand how easy it would be to achieve +/-0.05mm lateral and also radial runout (which is more important) with +/-5% spoke tension variance. that after you do the stress relieving and straightening the rim whenever it is not perfectly round. it is not hard to do when you adjust the DS nipples positions and from then on you work only with the NDS. it may take two operations if the first one has the bedding in of nipples/spokes/flanges not equal for all spokes.

~179GPa the elastic modulus of stainless steel - when not in very low tension that is; very low tension has 206GPa; the slight difference throughout the strain-stress curve is not to worry about (later edit).

i'd only invest in a tension meter if it is at least as accurate as the acoustics method which has the disadvantage of being a slow one when using a tone generator (the computer doing the math after you feed in the value in Hz) with the advantage of being zero expense.

and then i'd not have too much use of a proper tension meter if not for figuring out the delta elongation from the average for each spoke. i'd have my estimation as to the final tension without needing anything else but acoustics and a quick calculation given the length between the cross and the nipple etc.

but that's just me who am a perfectionist and only build my own wheels.

if i were servicing/building more than 30 wheels per year i'd buy a precise tension meter to have productivity as well and not only accuracy.

then again... if you don't measure with dial gauges radial runout (supposing the lateral runout is low enough as to have insignificant errors) you also are unable to balance radial runout with tension variance unless you true down to zero which can be very tedious. many people don't get it. you can true the wheel but not have it fixed once and for good (best durability). it will be either luck once in a while or just sloppier work. and even more slow work.

need i mention that you can very well bring the lateral true to such a low value after you balance the other two figures which are more important for wheel durability?

if you don't believe me... just try it once.

and circle graphs are of use only to impress customers who don't have a clue regarding radial true needing to be balanced to tension variance. when it comes to working with imperfect from the factory or just bent rims (pulling the rim and twisting it etc.) you are better off with linear graphs from the spreadsheet software you'd have available.

just make the adjustments by calculating the angle for nipple turn - each spoke - and all will be easy as cake afterwards. and put some labels as to monitor spoke twist.

or you might as well just go on doing a bit less sloppy work than what machines do. machines don't monitor spoke twist as to calculate nipple turn angle by backing off from spoke twist. nor do they correlate spoke tension variance with runout for all the spokes as to calculate all 16 or 18 angles of adjustments afterwards. do they?...

if you aren't getting my my point... i give up. even if my english is not as from a native... you can give a careful reading if you want to.

then again... you might understand how easy it would be to achieve +/-0.05mm lateral and also radial runout (which is more important) with +/-5% spoke tension variance. that after you do the stress relieving and straightening the rim whenever it is not perfectly round. it is not hard to do when you adjust the DS nipples positions and from then on you work only with the NDS. it may take two operations if the first one has the bedding in of nipples/spokes/flanges not equal for all spokes.

~179GPa the elastic modulus of stainless steel - when not in very low tension that is; very low tension has 206GPa; the slight difference throughout the strain-stress curve is not to worry about (later edit).

Last edited by adipe; 09-09-19 at 05:37 PM.

#34

Senior Member

I bought the book over 25 years ago. I also bought my Wheelsmith meter around that time so I did not use his method. I do stress relieve my wheels after tensioning and they hold up well.

#35

Senior Member

Join Date: Dec 2007

Location: San Jose, California

Posts: 3,504

Bikes: 2001 Tommasini Sintesi w/ Campagnolo Daytona 10 Speed

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 145 Post(s)

Likes: 0

Liked 35 Times

in

30 Posts

What's really important here is that you have an assembly by which to keep the meter calibrated.

As general rule of thumb for modern day alloy rims:

Single wall = 90 to 95 kgf

Double wall = 95 to 110 kgf

...assuming they're the 32 to 36 hole variety and the inner wall thickness to the eye is around the 2mm to 2.5mm ballpark.

Helps though to have the manufacturer give you a number...DT, Stan's, Rolf Prima (Astral) and many others do.

Where you really really have to be careful are today's super light weight alloy rims . . .

. . . AND the super lights such as Martano's from the 70s. Certain Martano's could only handle 50 kgf.

And yes, there are some alloy super lights out there today that are only rated for 95 kgf.

When in doubt, call 'em, email 'em.

=8-)

As general rule of thumb for modern day alloy rims:

Single wall = 90 to 95 kgf

Double wall = 95 to 110 kgf

...assuming they're the 32 to 36 hole variety and the inner wall thickness to the eye is around the 2mm to 2.5mm ballpark.

Helps though to have the manufacturer give you a number...DT, Stan's, Rolf Prima (Astral) and many others do.

Where you really really have to be careful are today's super light weight alloy rims . . .

. . . AND the super lights such as Martano's from the 70s. Certain Martano's could only handle 50 kgf.

And yes, there are some alloy super lights out there today that are only rated for 95 kgf.

When in doubt, call 'em, email 'em.

=8-)

__________________

5000+ wheels built since 1984...

Disclaimer:

1. I do not claim to be an expert in bicycle mechanics despite my experience.

2. I like anyone will comment in other areas.

3. I do not own the preexisting concepts of DISH and ERD.

4. I will provide information as I always have to others that I believe will help them protect themselves from unscrupulous mechanics.

5. My all time favorite book is:

Kahane, Howard. Logic and Contemporary Rhetoric: The Use of Reason in Everyday Life

5000+ wheels built since 1984...

Disclaimer:

1. I do not claim to be an expert in bicycle mechanics despite my experience.

2. I like anyone will comment in other areas.

3. I do not own the preexisting concepts of DISH and ERD.

4. I will provide information as I always have to others that I believe will help them protect themselves from unscrupulous mechanics.

5. My all time favorite book is:

Kahane, Howard. Logic and Contemporary Rhetoric: The Use of Reason in Everyday Life

Likes For mrrabbit:

#37

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,801

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 829 Post(s)

Liked 1,241 Times

in

655 Posts

I still think you are asking the wrong question here and following an unknown / uncalibrated "tension guage" will lead you further down the wrong path.

The right tension for a given wheel is determined by the expert builder (that would be YOU) based on your assessment of the rim, spokes, rider weight, and intended use. If the wheel "starts to taco" you have already deformed the rim and compromised the strength.

For most of the wheels we build and ride, you want to arrive at a true, round, properly dished wheel with an average spoke tension of about 70-80 KGF. Compare with other well built wheels and use your educated ear to listen for the right "ping".

The tension guage can help you find the outliers - spokes that are too tight or too loose - and then you can try to address those. But based on my own limited experience I suggest you not blindly follow the guage. I remember Spence Wolf showing me a Hozan guage (this would have been 1971 - 2) and saying "now Mark, this is the instrument of the devil".

Mark Petry

Bainbridge Island, WA USA

The right tension for a given wheel is determined by the expert builder (that would be YOU) based on your assessment of the rim, spokes, rider weight, and intended use. If the wheel "starts to taco" you have already deformed the rim and compromised the strength.

For most of the wheels we build and ride, you want to arrive at a true, round, properly dished wheel with an average spoke tension of about 70-80 KGF. Compare with other well built wheels and use your educated ear to listen for the right "ping".

The tension guage can help you find the outliers - spokes that are too tight or too loose - and then you can try to address those. But based on my own limited experience I suggest you not blindly follow the guage. I remember Spence Wolf showing me a Hozan guage (this would have been 1971 - 2) and saying "now Mark, this is the instrument of the devil".

Mark Petry

Bainbridge Island, WA USA

#38

Senior Member

Join Date: Feb 2004

Location: St Peters, Missouri

Posts: 30,225

Bikes: Catrike 559 I own some others but they don't get ridden very much.

Mentioned: 16 Post(s)

Tagged: 0 Thread(s)

Quoted: 1572 Post(s)

Liked 643 Times

in

364 Posts

Yep, an el cheapo that i'm guessing is the same tension as the park tool. I like to think i got it down pat or off by heart - reasonably had that wheel pretty much there i believe..but i adjusted the tension to 86kgf which would be a 22 reading on the tool to each spoke, now it's out of true Lol

First of all, it's possible to have a wheel that is entirely acceptable in both lateral and radial true that has spoke tensions all over the place. If you take the digital approach and try to adjust all of the spokes to the same tension, the result will usually be a wonky trued wheel.

My system is to start with one thread showing on each spoke. Then I build tension into the wheel by counting turns as I tighten each spoke. When I think the wheel is close to the right tension, I check each spoke with my tension meter and make them all equal. I once built a 40 spoke tandem wheel that required no truing at all after this point in the process. Any required truing I do by tightening and loosening the same number of fractional turns from opposing pairs of spokes. I think that method results in the least deviation possible from the average spoke tension.

__________________

My greatest fear is all of my kids standing around my coffin and talking about "how sensible" dad was.

My greatest fear is all of my kids standing around my coffin and talking about "how sensible" dad was.

#39

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,801

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 829 Post(s)

Liked 1,241 Times

in

655 Posts

My system is to start with one thread showing on each spoke. Then I build tension into the wheel by counting turns as I tighten each spoke. When I think the wheel is close to the right tension, I check each spoke with my tension meter and make them all equal.

Then any deviation in tension should be attributed to making the wheel run laterally true.

Mark Petry

Bainbridge Island, WA USA

#40

Full Member

Just a warning: I bought a brand new Park TM-1 and tensioned spokes to the manufacturer’s specs based on it. Later I noticed cracks forming around the spoke holes in the rim. I finally got around to building a jig to calibrate the TM-1 and found out it was reading low...by 30 Kgf! I sent it back to Park and they replaced the spring for $5, but it still read low by 10-15 Kgf. However that was at least close enough to correct using the adjustment screw on the meter.

#41

working on my sandal tan

Join Date: Aug 2011

Location: CID

Posts: 22,627

Bikes: 1991 Bianchi Eros, 1964 Armstrong, 1988 Diamondback Ascent, 1988 Bianchi Premio, 1987 Bianchi Sport SX, 1980s Raleigh mixte (hers), All-City Space Horse (hers)

Mentioned: 98 Post(s)

Tagged: 0 Thread(s)

Quoted: 3870 Post(s)

Liked 2,563 Times

in

1,577 Posts

Just a warning: I bought a brand new Park TM-1 and tensioned spokes to the manufacturer’s specs based on it. Later I noticed cracks forming around the spoke holes in the rim. I finally got around to building a jig to calibrate the TM-1 and found out it was reading low...by 30 Kgf! I sent it back to Park and they replaced the spring for $5, but it still read low by 10-15 Kgf. However that was at least close enough to correct using the adjustment screw on the meter.

__________________

RUSA #7498

Originally Posted by noglider

People in this forum are not typical.

Last edited by ThermionicScott; 12-17-19 at 01:35 PM.

#42

Senior Member

Join Date: Apr 2010

Location: Mountain View, CA USA and Golden, CO USA

Posts: 6,341

Bikes: 97 Litespeed, 50-39-30x13-26 10 cogs, Campagnolo Ultrashift, retroreflective rims on SON28/PowerTap hubs

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 550 Post(s)

Liked 325 Times

in

226 Posts

Unfortunately, that only works for classic box section rims. With beam stiffness proportional to the cube of depth modern rims are too stiff for that to work and the limit comes from the tension which will cause eventual fatigue failures in the spoke bed. You need an app, tension meter, or similar wheel built with same gauge spokes to calibrate today's deeper profiles.

I should point out that some rim mfrs recommend pretty low high limits on spoke tension (these ZTR rims state a 95kgf maximum). If your Deckas chart is like my Park chart, that 25 reading is more like 120kgf for 2mm spokes, right?

#43

Senior Member

Join Date: Apr 2010

Location: Mountain View, CA USA and Golden, CO USA

Posts: 6,341

Bikes: 97 Litespeed, 50-39-30x13-26 10 cogs, Campagnolo Ultrashift, retroreflective rims on SON28/PowerTap hubs

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 550 Post(s)

Liked 325 Times

in

226 Posts

if you are not putting the data into a spreadsheet to correlate radial runout for each spoke with tension variance then you miss the main purpose/use of a precise tension meter. it's not as much as to provide circle graphs. but to be able to better adjust radial runout to tension variance and therefore being able to straighten the rim if you want to. or just let the wheel straighten itself over time. but i'd choose the first variant.

True is adjusted purely based on clearance. Relative tension will be close enough based on tone.

#44

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,801

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 829 Post(s)

Liked 1,241 Times

in

655 Posts

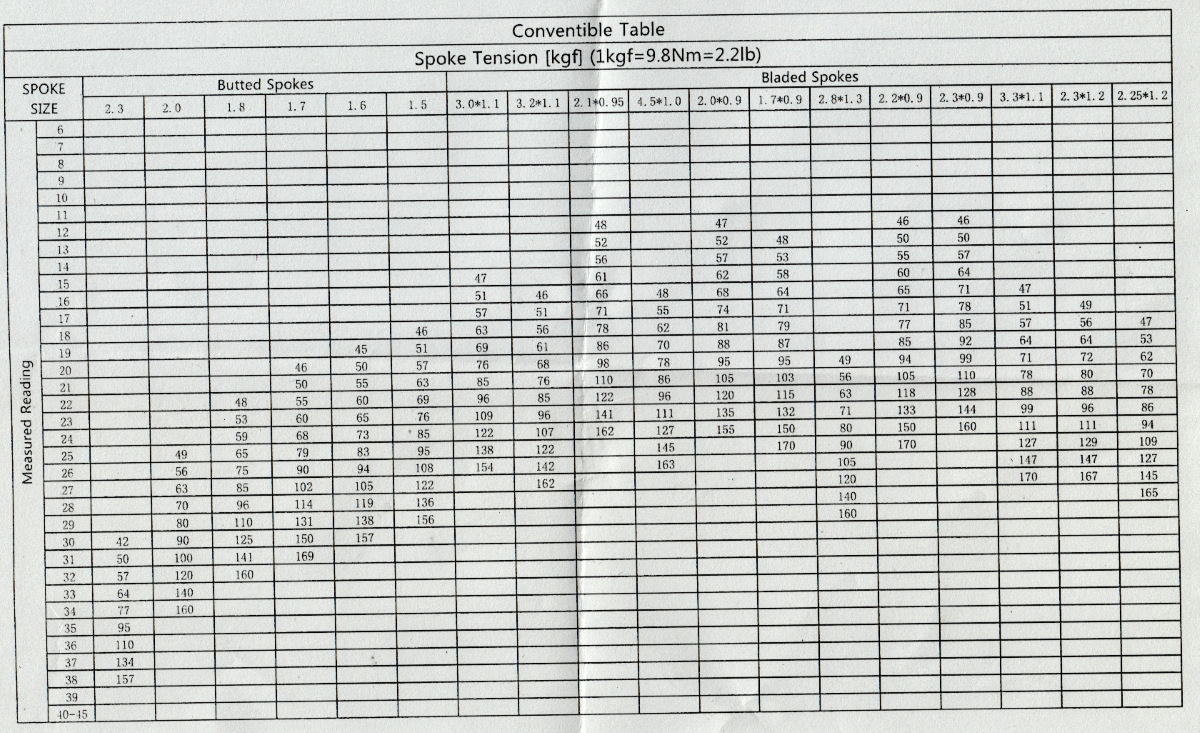

These tools measure spoke tension indirectly from the spokes deflection over a known distance when the spring force is applied.

The spoke guage can have a large impact on your readings. The same reading on the guage can vary by 5-10 KgF depending on the spoke guage (1.8-.2.0 for example).

So be sure you're looking at the right column on the conversion chart.

Mark Petry

Bainbridge Island, WA USA

The spoke guage can have a large impact on your readings. The same reading on the guage can vary by 5-10 KgF depending on the spoke guage (1.8-.2.0 for example).

So be sure you're looking at the right column on the conversion chart.

Mark Petry

Bainbridge Island, WA USA

#46

Senior Member

Join Date: Feb 2015

Location: Mission Viejo

Posts: 5,801

Bikes: 1986 Cannondale SR400 (Flat bar commuter), 1988 Cannondale Criterium XTR, 1992 Serotta T-Max, 1995 Trek 970

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1943 Post(s)

Liked 2,164 Times

in

1,323 Posts

Being the dunce in this group, I built wheels by feel, squeezing spokes, years ago. But I now have a Park tension meter that I use. I’ll follow the charts to be in the range. I don’t calibrate, but I do a comparison of readings from existing wheels that have survived many years. Seems to work well.

Because I’m running 32hole wheels, it is not critical.

John

Because I’m running 32hole wheels, it is not critical.

John

#47

Senior Member

Join Date: Dec 2010

Location: northern Deep South

Posts: 8,895

Bikes: Fuji Touring, Novara Randonee

Mentioned: 36 Post(s)

Tagged: 0 Thread(s)

Quoted: 2599 Post(s)

Liked 1,924 Times

in

1,208 Posts

Obviously the top one, and #2 & 4 on the bottom, are the most accurate. They're digital!

OK, getting my tongue out of my cheek, it would depend on the precision and accuracy of the readouts, and the calibration of the individual units. For most users, I'd think it's overkill. The point of using a tensiometer, in my book, is that it substitutes an independent measuring device's reading for user judgment. There is doubtless a number of skilled and experienced wheelbuilders who don't need one. There are also many more less experienced people who can build a wheel just as good as the experts by using the tensiometer. (And the latter is cheaper for a shop to hire.)

OK, getting my tongue out of my cheek, it would depend on the precision and accuracy of the readouts, and the calibration of the individual units. For most users, I'd think it's overkill. The point of using a tensiometer, in my book, is that it substitutes an independent measuring device's reading for user judgment. There is doubtless a number of skilled and experienced wheelbuilders who don't need one. There are also many more less experienced people who can build a wheel just as good as the experts by using the tensiometer. (And the latter is cheaper for a shop to hire.)