Wheel Builders.... Spoke length calculations with 2d CAD software?

#1

Senior Member

Thread Starter

Join Date: Jun 2006

Posts: 1,407

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 23 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Wheel Builders.... Spoke length calculations with 2d CAD software?

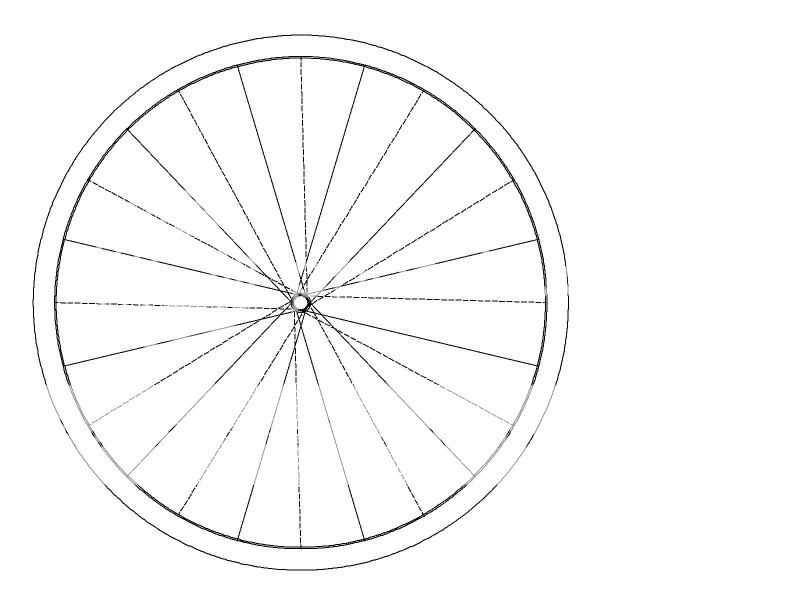

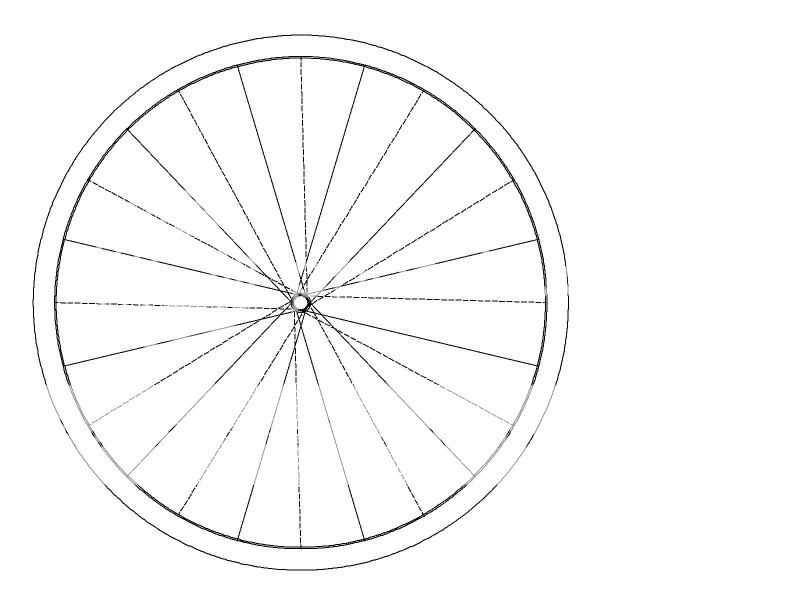

I've recently been learning the basics of Autocad LT/DraftSight at work and at home respectively, and was curious to know if there is a reasonably simple way of setting up a 2D drawing with customizable flange heights/rim depths etc...and use it for drawing custom lacing patterns, allowing me to calculate the spoke lengths directly off of the drawing. It's easy to drag and place spokes on a drawing to different flange holes etc..and measure with specificity the lengths of those lines once the desired lacing pattern is set up. The problem of course is how best to compensate for the flange offset from hub-center.

My thought was possibly to do a simple hypotenuse calculation and then increase the ERD in the drawing by the difference before taking my measurement. Will this work?

I like the idea of having different files set up with differing spoke counts that I can play with to get accurate wheel build information without having to work purely with numbers. I do have SpokeCalc, and realize that it works very well with standard lacing. But that is not what this thread is about.

I have the tools to accurately measure the rim's ERD, which I can then input into the drawing, as well as the hub's spoke hole diameters etc.

Have any of you guys done this before with success?

This is probably as much drawing as I do unless I get confirmation that this will work reliably enough. I'll increase the detail and accuracy of the drawing if it'll be worth the effort.

-Jeremy

My thought was possibly to do a simple hypotenuse calculation and then increase the ERD in the drawing by the difference before taking my measurement. Will this work?

I like the idea of having different files set up with differing spoke counts that I can play with to get accurate wheel build information without having to work purely with numbers. I do have SpokeCalc, and realize that it works very well with standard lacing. But that is not what this thread is about.

I have the tools to accurately measure the rim's ERD, which I can then input into the drawing, as well as the hub's spoke hole diameters etc.

Have any of you guys done this before with success?

This is probably as much drawing as I do unless I get confirmation that this will work reliably enough. I'll increase the detail and accuracy of the drawing if it'll be worth the effort.

-Jeremy

#2

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 39,073

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 141 Post(s)

Tagged: 1 Thread(s)

Quoted: 5983 Post(s)

Liked 2,909 Times

in

1,615 Posts

It sounds lie a nice practical exercise for developing skill in usig the autocad tool. Lay out the basic parameters, and work up a program.

I don't know what you'd call simple or difficult or why you'd bother, since it's fairly straightforward geometry and there are enough calculators available already.

I don't see any need to reinvent the wheel (so to speak) but it could be a nice learning project for an autocad newbie.

I don't know what you'd call simple or difficult or why you'd bother, since it's fairly straightforward geometry and there are enough calculators available already.

I don't see any need to reinvent the wheel (so to speak) but it could be a nice learning project for an autocad newbie.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

#4

Type 1 Racer

Join Date: Apr 2006

Location: Davis, CA

Posts: 2,579

Bikes: A dozen or so.

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I did this once when trying to figure out the spoke lengths for some "dog-bone" drilled hub flanges. Just draw up your rim in 2D, determine the spoke length (in 2D), and divide that by sin x, where x is the bracing angle (use average bracing angle for alternating heads in/out).

In my case, the lengths came out good. Just be sure to get the drawing right.

EDIT: Not sure what the convention is, but my bracing angle is the angle the spoke makes at the hub flange toward the rim.

In my case, the lengths came out good. Just be sure to get the drawing right.

EDIT: Not sure what the convention is, but my bracing angle is the angle the spoke makes at the hub flange toward the rim.

Last edited by rydaddy; 12-12-10 at 08:58 PM.

#5

Senior Member

Thread Starter

Join Date: Jun 2006

Posts: 1,407

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 23 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

^^ This is sort of what I was thinking of using it for. In the case that I have access to a non standard rim/hub and want to built it to a standard rim/hub. I imagine that something like this would be easier than figuring it out on paper (at least for a non math guy).

I started thinking about the possibility of this when myself and 3 friends had problems with some paired spoke wheels...and realized that replacing the rims just wasn't going to be straight forward. However, if I could input the details of the replacement rim into the drawing with the "paired flange offset" hubset, I'd have a shot at getting the hubset back into use.

Plus I enjoy tinkering both on my bike and in software, so a little time spent doesn't bother me.

-Jeremy

I started thinking about the possibility of this when myself and 3 friends had problems with some paired spoke wheels...and realized that replacing the rims just wasn't going to be straight forward. However, if I could input the details of the replacement rim into the drawing with the "paired flange offset" hubset, I'd have a shot at getting the hubset back into use.

Plus I enjoy tinkering both on my bike and in software, so a little time spent doesn't bother me.

-Jeremy

#6

Senior Member

It can be done the whole way through just with measuring your parts and drawing the wheel up. Just be sure to take into accout the inner diameter of the rim, allowance for the nipple seat thickness or eyelet depth, nipple head thickness, and the flange holes diameter, spacing and thickness. The side view of the final spoke will give you the long side of the right angle triangle that determines the spoke length. Off that spoke center line draw a right angle line off one end vertex out by half the distance of the flange spacing. The spoke length would be the dimension for the hypoteneuse of that resulting triangle. This assumes symetrical flange angles such as on a road front wheel. If not then you need to do two triangles. One for each side of center of the rim to allow for dishing needs of drive wheels or disc brakes. But either way the whole thing can be done without the need to use a sin funtion or indeed to type out any numbers in a calculator.

#7

Roadkill

Join Date: Sep 2004

Location: East Tennessee

Posts: 858

Bikes: 2002 Lightspeed Classic; 2010 Pedalforce RS

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Several good replies here. The way I would approach this is: spoke length = sqrt (x ^2 + y^2 + z^2). Where x,y,z, are the offsets in each dimension. The length indicated in your 2D drawing will be sqrt ( x^2 + y^2). All you need to do is square the drawing length, add z squared (where z is the offset of the hub flange from the hub centerline), and take the square root. No need to calculate any angles that way.

#8

Senior Member

Thread Starter

Join Date: Jun 2006

Posts: 1,407

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 23 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Excellent, Thanks for the advice. I don't currently have any wheel builds going right now, but will probably spend a bit more time setting up drawings for the different options and measurements. DraftSight seems to be a VERY capable free 2d CAD option, for those who don't want to spend $ on autodesk products. It's worth a look if you're interested and is uses the .DWG format AND of course all the same autocad commands.

-Jeremy

-Jeremy

Thread

Thread Starter

Forum

Replies

Last Post

bowlofsalad

Bicycle Mechanics

4

08-18-14 01:35 PM

BugsInMyTeeth

Bicycle Mechanics

14

03-01-11 10:22 PM