Steel bike failure. Is this manufacturing or something else?

#26

Senior Member

Join Date: Nov 2014

Location: Eugene, Oregon, USA

Posts: 27,547

Mentioned: 217 Post(s)

Tagged: 0 Thread(s)

Quoted: 18350 Post(s)

Liked 4,502 Times

in

3,346 Posts

The government will likely be on the hook for a substantial portion of his medical and living expenses if he doesn't collect it from a private party.

It is quite possible that if Ronnie Woodall hit as hard as he appears to have hit, then he would have no first-hand recollection of the event.

Thus, the missing video and witness statements will be key.

With some luck, there might even be photos or video somewhere indicating the condition of the bicycle prior to the collision with the fence.

There is no way to attribute blame or damages without corroboration of what actually happened.

If the cracks happened without warning, JRA, then All City Bicycles could have substantial liability.

On the other hand, if he crashed first, then the bike crumbled on impact, then All City Bicycles could have zero liability, and depending on state policies, might even be able to recover legal expenses.

Was Ronnie Woodall doing jumps and riding consistent with the advertising of the bike? Warning notes on the bike?

#27

Senior Member

Join Date: Nov 2014

Location: Eugene, Oregon, USA

Posts: 27,547

Mentioned: 217 Post(s)

Tagged: 0 Thread(s)

Quoted: 18350 Post(s)

Liked 4,502 Times

in

3,346 Posts

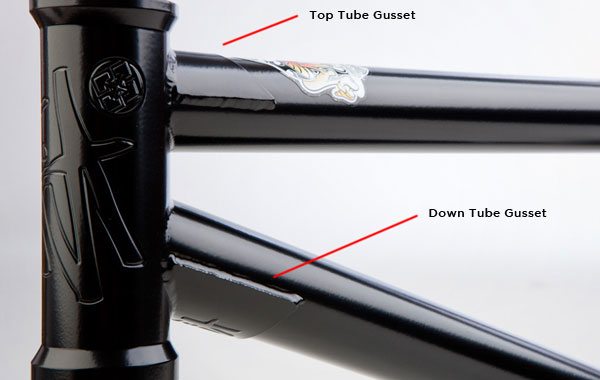

I have noticed that several cheaper off-road frames have gussets that the All City Bikes seem to lack.

#28

Tragically Ignorant

Join Date: Jun 2018

Location: New England

Posts: 15,613

Bikes: Serotta Atlanta; 1994 Specialized Allez Pro; Giant OCR A1; SOMA Double Cross Disc; 2022 Allez Elite mit der SRAM

Mentioned: 62 Post(s)

Tagged: 0 Thread(s)

Quoted: 8186 Post(s)

Liked 9,095 Times

in

5,053 Posts

All City Bicycles Macho Man Flat Bar

https://allcitycycles.com/bikes/macho_man_flat_bar

It is supposed to be:

https://allcitycycles.com/blog/what_is

https://allcitycycles.com/bikes/macho_man_flat_bar

It is supposed to be:

Frame: 612 Select double-butted CroMoly tubeset, double bottle cage mount, 135 mm rear spacing, 1-1/8" headset, English BB

Fork: 612 Select double-butted CroMoly, tapered fork blades, lugged crown & matching dropouts w/IS disc tabs

With their notes on 612 Select:Fork: 612 Select double-butted CroMoly, tapered fork blades, lugged crown & matching dropouts w/IS disc tabs

https://allcitycycles.com/blog/what_is

#29

Senior Member

Join Date: Jan 2010

Posts: 39,214

Mentioned: 211 Post(s)

Tagged: 1 Thread(s)

Quoted: 18397 Post(s)

Liked 15,492 Times

in

7,316 Posts

My money is on deliberate or previous damage ignored.

Likes For mr_bill:

#31

Tragically Ignorant

Join Date: Jun 2018

Location: New England

Posts: 15,613

Bikes: Serotta Atlanta; 1994 Specialized Allez Pro; Giant OCR A1; SOMA Double Cross Disc; 2022 Allez Elite mit der SRAM

Mentioned: 62 Post(s)

Tagged: 0 Thread(s)

Quoted: 8186 Post(s)

Liked 9,095 Times

in

5,053 Posts

So the story is from October. For all we know, this might have been quietly settled by now. Anyone have info to the contrary?

#32

Senior Member

Join Date: Sep 2007

Location: Far beyond the pale horizon.

Posts: 14,258

Mentioned: 31 Post(s)

Tagged: 0 Thread(s)

Quoted: 4244 Post(s)

Liked 1,348 Times

in

935 Posts

Since that's really rare, people might not be considering it as a possible cause.

Last edited by njkayaker; 12-06-19 at 06:54 PM.

Likes For njkayaker:

#33

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,801

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 829 Post(s)

Liked 1,241 Times

in

655 Posts

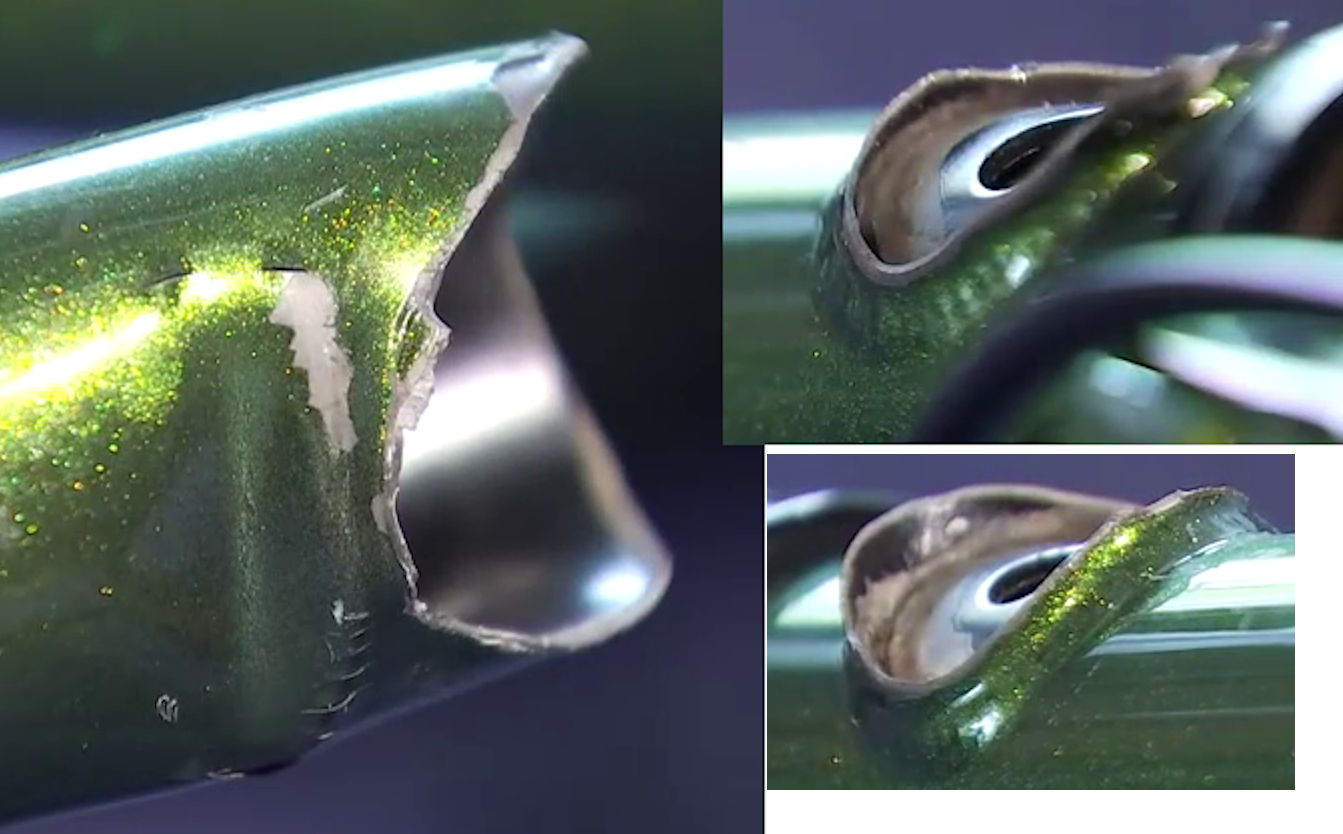

if he did run directly into something, the crease in the downtube that you mention is to be expected. However, the tube(s) should bend, not just pop apart cleanly like that. What I can see from the pictures sure looks like inadequate penetration at the head tube welds (which would be TIG). I've seen many bikes crashed, running into cars and other seriously immovable objects. The tubes buckle and bend. The fork may bend. But the mitered joints do not pop apart. Look how "clean" the separation is ! I'd suspect that the TIG welder was not set to the right voltage, sufficient to get full penetration and a large enough bead for an adequately strong joint..

REI house brand bikes (Novarra) had a spate of these about 10 years ago - "just riding along" and the head tube separated. Like they got past QA, got painted and shipped, and then failed while riding.

I sure would like to look at one that came from the same batch as the indcident bike. I wonder if visual inspection would show the lack of a weld bead.

Mark Petry

Bainbridge Island, WA USA

REI house brand bikes (Novarra) had a spate of these about 10 years ago - "just riding along" and the head tube separated. Like they got past QA, got painted and shipped, and then failed while riding.

I sure would like to look at one that came from the same batch as the indcident bike. I wonder if visual inspection would show the lack of a weld bead.

Mark Petry

Bainbridge Island, WA USA

Last edited by mpetry912; 12-05-19 at 11:10 AM.

#34

Senior Member

Join Date: Nov 2014

Location: Eugene, Oregon, USA

Posts: 27,547

Mentioned: 217 Post(s)

Tagged: 0 Thread(s)

Quoted: 18350 Post(s)

Liked 4,502 Times

in

3,346 Posts

if he did run directly into something, the crease in the downtube that you mention is to be expected. However, the tube(s) should bend, not just pop apart cleanly like that. What I can see from the pictures sure looks like inadequate penetration at the head tube welds (which would be TIG). I've seen many bikes crashed, running into cars and other seriously immovable objects. The tubes buckle and bend. The fork may bend. But the mitered joints do not pop apart. Look how "clean" the separation is ! I'd suspect that the TIG welder was not set to the right voltage, sufficient to get full penetration and a large enough bead for an adequately strong bead.

I sure would like to look at one that came from the same batch as the indcident bike. I wonder if visual inspection would show the lack of a weld bead.

I sure would like to look at one that came from the same batch as the indcident bike. I wonder if visual inspection would show the lack of a weld bead.

A very clean tear all the way around the tubes.

However, it is the toptube and the downtube that have torn. The weld itself is intact. And, the weld has not separated from the headtube in any place that is visible.

If it was a penetration problem, then the weld would have torn off of the headtube. Or, potentially we would have seen a socket of weld around the top/down tubes with the tube sliding out. Neither of this is the case.

The miters appear good, and I don't see any signs of excessive gaps.

I'm not seeing signs of rust, discoloration, or rubbing indicative of a slowly progressing crack, although better photos would help. The view from inside the lower dowtube/headtube joint (top right) seems to show good penetration through the tube. But, again, we need better shots to verify that follows all the way around on both affected joints. Still, in no place have the two tubes separated below the weld that I can see.

- I can not discern tube thickness at the weld. Butting? All the way around?

- One would have to carefully inspect for erosion, or lack of filler. I don't see signs of that, but it is possible, even localized in critical areas could be problematic. One would need good photos and careful measurements. Of course, there could also be an element of stretching as the tube fails, confounding potential analysis. Does weld erosion often have a sharp edge which one could look for?

- Heat affected zone & grain structure. The tear seems to be a tear of the tube within about 1/16" from the weld. I don't have comparative data on grain structure, but that does look like fairly course grain.

I assume the frames aren't post-heat treated. But, perhaps that is something that the TIG industry should consider. - The prominent ripple in the downtube is seen in the left photo. I am having troubles envisioning how that ripple could have occurred other than hard frontal impact of the wheel. If it had happened as say the tubes were separating (JRA), then one would expect a simple bend at the weld, rather than a compression ripple. Say the top tube separated, leaving the downtube attached to the headtube. I'm not sure one could replicate that kind of compression ripple. But, it would be easy enough for the company to test with a partly welded frame, and certainly worth a couple $million to build the test jigs.

- There are no gussets on the toptube and downtube. This is common on MTBs, especially aluminum, and should be considered with cross bikes, and steel bikes. Probably best if brazed (like a lug).

We don't have data to verify whether the crash that damaged the tubes was the crash that broke the guy's neck. However, say there were 2 crashes, one that damaged the tubes, and a later one from riding on a damaged bike. I'm not sure one could hold the company liable for a person riding a CLEARLY damaged bike if that was the case.

Steel has the advantage that crash damage is frequently visible from residual bends, or even paint cracking. Unfortunately, that is one of the big debates about carbon fiber that may hide unseen damage.

Likes For CliffordK:

Likes For nomadmax:

#37

Banned

Join Date: Apr 2010

Location: Lincoln Ne

Posts: 9,924

Bikes: RANS Stratus TerraTrike Tour II

Mentioned: 46 Post(s)

Tagged: 0 Thread(s)

Quoted: 3352 Post(s)

Liked 1,056 Times

in

635 Posts

It is just an example of the cheap way bikes are built these days. Butt welded frames can quickly be welded up by robots. It is a cheap and weak way to make frames. Back in the 80s and before we had brazed lug frames.

They were much stronger and almost never failed.

They were much stronger and almost never failed.

Last edited by rydabent; 12-26-19 at 04:12 PM.

#38

Tragically Ignorant

Join Date: Jun 2018

Location: New England

Posts: 15,613

Bikes: Serotta Atlanta; 1994 Specialized Allez Pro; Giant OCR A1; SOMA Double Cross Disc; 2022 Allez Elite mit der SRAM

Mentioned: 62 Post(s)

Tagged: 0 Thread(s)

Quoted: 8186 Post(s)

Liked 9,095 Times

in

5,053 Posts

#39

Senior Member

Join Date: Feb 2014

Location: Pasadena, CA

Posts: 4,848

Bikes: Schwinn Varsity

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 1931 Post(s)

Liked 742 Times

in

422 Posts

Apparently I sped read the post and didn't see the other reference to 612 tubing being All City's area code....... long time joke, because their frames seem heavy and WTH is 612 tubing?

Photos look like he crashed and the frame came apart..... not the frame came apart and he crashed.

Photos look like he crashed and the frame came apart..... not the frame came apart and he crashed.

#40

Tragically Ignorant

Join Date: Jun 2018

Location: New England

Posts: 15,613

Bikes: Serotta Atlanta; 1994 Specialized Allez Pro; Giant OCR A1; SOMA Double Cross Disc; 2022 Allez Elite mit der SRAM

Mentioned: 62 Post(s)

Tagged: 0 Thread(s)

Quoted: 8186 Post(s)

Liked 9,095 Times

in

5,053 Posts

Assuming it goes to trial, it will be up to a jury and/or judge to decide the facts of the case based upon the evidence provided by both sides. Since we aren't privy to any of that evidence, I think the only reasonable thing to do is sit and wait, and hope each side receives a fair hearing. (I have a considerable degree of sympathy for both sides.)

It is also worth keeping in mind that even if the plaintiff himself has no desire to go to court, his health insurance company would file a suit on his behalf, to recover the expenses.

It is also worth keeping in mind that even if the plaintiff himself has no desire to go to court, his health insurance company would file a suit on his behalf, to recover the expenses.

If I had to bet at this point, my money would be on we'll never know what happened because it will be quietly settled or dropped.

#41

Senior Member

Join Date: Nov 2014

Location: Eugene, Oregon, USA

Posts: 27,547

Mentioned: 217 Post(s)

Tagged: 0 Thread(s)

Quoted: 18350 Post(s)

Liked 4,502 Times

in

3,346 Posts

But, I was wondering a bit about brazing.

I had mentioned gussets.

I think these are welded on, but brazing the gussets would be an excellent way of attaching them and in many senses, lugs are a natural form of gussets.

The other thing that is happening is a movement towards thinner/lighter tubes, but two very different technologies of attaching them. One with lower heat/heat affected zones, and natural gussets. The other with high focal heat and bare tube to tube connections.

Nonetheless, that bike took a hard frontal impact which would have damaged many "road" frames. But should the All City Macho Man have been made stronger?

Limit liability to a new replacement frame (for someone who is confined in a wheelchair)?

#42

Senior Member

The article says this was a brand new frame. Subject to interpretation of course.

The tube edge is improbably clean. There is one point facing the camera about the size of a tack weld where the metal seems to have torn. To the extent the rest of the tube edge is ragged at all it could just as well be what high speed production mitering looks like. It does look like we are seeing a complete tube and there was no effective joining of metal at all. Others here know more about welding than I do and would be happy to hear their input.

Seems like a massive QC failure. I would like to think that this could have been avoided. Would like to think that a sharp mechanic would have spotted the weak joint, that an alert rider would have noticed the ride was bad, that All-City would have inspected what arrived from their vendor and caught this. I would like to think that but do not know. Further I would think that any metallurgist could examine the physical evidence and provide a complete explanation. Again I would like to think that but do not know. If there is a clear explanation then the next accident can be prevented. And the victim deserves to know what happened.

Lugged frames did have cognate failures and they were common. Very common. Most frequent was a lug with no brass inside at all. The joint might have been pinned and that would hold it for a while. And then the tube would have to move fairly far before popping out of lug. The other common failure was approximate mitering or tubes that migrated during brazing. Tube ends did not meet and all load was taken by the lug. Heavy production lugs as Raleigh or Peugeot would survive that for a very long time but would always crack in the end.

Frames are built by people. Steps in process may be robotized, process control is always by human. People mess up.

The tube edge is improbably clean. There is one point facing the camera about the size of a tack weld where the metal seems to have torn. To the extent the rest of the tube edge is ragged at all it could just as well be what high speed production mitering looks like. It does look like we are seeing a complete tube and there was no effective joining of metal at all. Others here know more about welding than I do and would be happy to hear their input.

Seems like a massive QC failure. I would like to think that this could have been avoided. Would like to think that a sharp mechanic would have spotted the weak joint, that an alert rider would have noticed the ride was bad, that All-City would have inspected what arrived from their vendor and caught this. I would like to think that but do not know. Further I would think that any metallurgist could examine the physical evidence and provide a complete explanation. Again I would like to think that but do not know. If there is a clear explanation then the next accident can be prevented. And the victim deserves to know what happened.

Lugged frames did have cognate failures and they were common. Very common. Most frequent was a lug with no brass inside at all. The joint might have been pinned and that would hold it for a while. And then the tube would have to move fairly far before popping out of lug. The other common failure was approximate mitering or tubes that migrated during brazing. Tube ends did not meet and all load was taken by the lug. Heavy production lugs as Raleigh or Peugeot would survive that for a very long time but would always crack in the end.

Frames are built by people. Steps in process may be robotized, process control is always by human. People mess up.

#43

Senior Member

Join Date: Aug 2013

Posts: 2,321

Mentioned: 35 Post(s)

Tagged: 0 Thread(s)

Quoted: 767 Post(s)

Liked 1,898 Times

in

889 Posts

That image doesn't seem to show a weld failure, but a tube failure just behind the weld. Maybe embrittlement? Cooling too quickly?

From millerwelds.com:

"Note that if the tubing is below 60 degrees F, use a small propone torch to heat the base metal to up to 300 degrees F. Otherwise, the metal could cool too quickly and become brittle. Welding cold metal may also promote hydrogen cracking, so thatís another reason to preheat 4130 if itís cold."

From millerwelds.com:

"Note that if the tubing is below 60 degrees F, use a small propone torch to heat the base metal to up to 300 degrees F. Otherwise, the metal could cool too quickly and become brittle. Welding cold metal may also promote hydrogen cracking, so thatís another reason to preheat 4130 if itís cold."

Last edited by BFisher; 12-06-19 at 02:46 PM.

#45

Senior Member

Join Date: Aug 2013

Posts: 2,321

Mentioned: 35 Post(s)

Tagged: 0 Thread(s)

Quoted: 767 Post(s)

Liked 1,898 Times

in

889 Posts

"Refrigerator" is a bit of a jump.

No one here knows how the process that went into making this bicycle unfolded. Manufacturing defects can and do occur, even to the best of companies. That may or may not be the case here.

Still, the failure looks like brittle steel. Whether that is the case is pure speculation.

No one here knows how the process that went into making this bicycle unfolded. Manufacturing defects can and do occur, even to the best of companies. That may or may not be the case here.

Still, the failure looks like brittle steel. Whether that is the case is pure speculation.

#46

Senior Member

Join Date: Sep 2013

Location: Massachusetts

Posts: 4,530

Mentioned: 34 Post(s)

Tagged: 0 Thread(s)

Quoted: 2112 Post(s)

Liked 663 Times

in

443 Posts

"Refrigerator" is a bit of a jump.

No one here knows how the process that went into making this bicycle unfolded. Manufacturing defects can and do occur, even to the best of companies. That may or may not be the case here.

Still, the failure looks like brittle steel. Whether that is the case is pure speculation.

No one here knows how the process that went into making this bicycle unfolded. Manufacturing defects can and do occur, even to the best of companies. That may or may not be the case here.

Still, the failure looks like brittle steel. Whether that is the case is pure speculation.

But do speculate.

-mr. bill

Last edited by mr_bill; 12-06-19 at 06:15 PM. Reason: speeling

#47

Senior Member

Join Date: Aug 2013

Posts: 2,321

Mentioned: 35 Post(s)

Tagged: 0 Thread(s)

Quoted: 767 Post(s)

Liked 1,898 Times

in

889 Posts

Ha ha.

Look, I've no dog in any of this. Maybe the bike was abused. Maybe the heat went out in the factory that day.

It does seem to be an odd failure, and all of us are just speculating as to the cause. The discussion is interesting.

Thanks for sharing. Happy riding.

Look, I've no dog in any of this. Maybe the bike was abused. Maybe the heat went out in the factory that day.

It does seem to be an odd failure, and all of us are just speculating as to the cause. The discussion is interesting.

Thanks for sharing. Happy riding.

#49

Tragically Ignorant

Join Date: Jun 2018

Location: New England

Posts: 15,613

Bikes: Serotta Atlanta; 1994 Specialized Allez Pro; Giant OCR A1; SOMA Double Cross Disc; 2022 Allez Elite mit der SRAM

Mentioned: 62 Post(s)

Tagged: 0 Thread(s)

Quoted: 8186 Post(s)

Liked 9,095 Times

in

5,053 Posts

I agree with you completely. There's a lot of "that dent looks like one that was caused by x, therefore x must have happened" reasoning going on here, ignoring the fact that probably none of us have seen a dent caused by y, and therefore have no idea what it would look like.

#50

I'm the anecdote.

Join Date: Apr 2019

Location: S.E. Texas

Posts: 1,822

Bikes: '12 Schwinn, '13 Norco

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 1110 Post(s)

Liked 1,176 Times

in

795 Posts

Bah humbug.

Give me a news story to share with my friends and let the speculation begin. Good times, good times.

Give me a news story to share with my friends and let the speculation begin. Good times, good times.