Building 24 spoke wheel with 36H hub?

#1

Junior Member

Thread Starter

Building 24 spoke wheel with 36H hub?

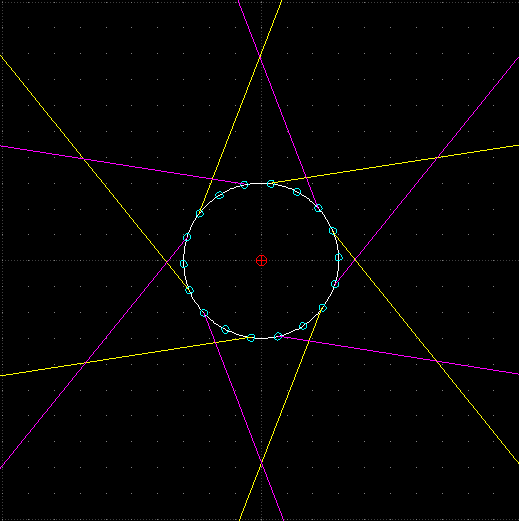

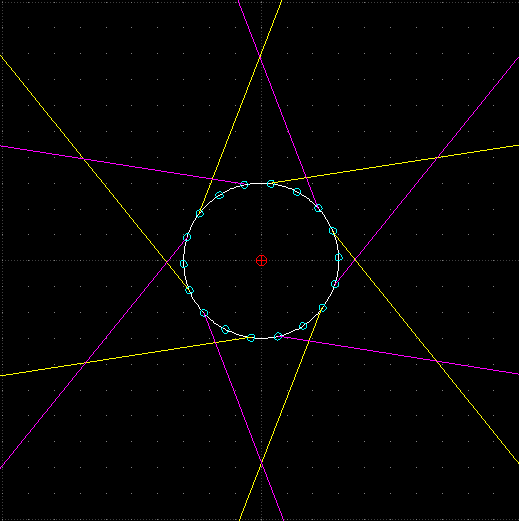

Long story short -- I need to build aero wheels around a 36H hub and want them to have 24 spokes, regular 2 cross symmetric pattern same on both sides, no dish required on this hub. In theory easy, just skip every third hole and indeed then I can line up one side so it becomes identical to 24H lacing with equal length spokes. However as the difference to the opposite side is 10 degrees (360/36) rather than 15 (360/24) that will then be 5 degrees off and require different spoke lengths. My suggested "solution" is to turn the hub 2.5 degrees so the offset is 2.5 degrees both sides, then the whole wheel can be built with 2 spoke lengths. To the eye it will look symmetric and even as it's only 2.5 degrees off, but in reality the crosses are no longer exactly along the spoke center lines.

As far as I can understand this will still not be a problem as the distribution of the two different spoke sizes are symmetric, ie each spoke is paired with a corresponding spoke of the exact dimension and angle that pulls in the opposite direction.

I've attached an image that shows the layout. My question is, will this work, or will there be some balance issues? As said I'm quite sure it will work but I'm no wheel builder expert, so I'd thought I'd ask here.

24 spoke wheel with 36H hub

As far as I can understand this will still not be a problem as the distribution of the two different spoke sizes are symmetric, ie each spoke is paired with a corresponding spoke of the exact dimension and angle that pulls in the opposite direction.

I've attached an image that shows the layout. My question is, will this work, or will there be some balance issues? As said I'm quite sure it will work but I'm no wheel builder expert, so I'd thought I'd ask here.

24 spoke wheel with 36H hub

#2

Junior Member

Thread Starter

Thought I should add this reference to an old thread which discusses 36->24 lacing: https://www.bikeforums.net/bicycle-m...g-again-3.html

I had already figured out that the 5 degree offset between flanges lead to that you will need two spoke lengths. That's not an issue. I wonder though if there will be some torque-issue or similar thing I haven't figured out...

There's also a solution when using a standard 2-cross (equal spoke length) on one side, and radial on the other, here: https://www.sheldonbrown.com/rinard/36-24.htm actually the radial side needs two different lengths, but as they differ only about 0.5mm it's generally negligible. I would prefer 2-cross on both sides though in this build.

I had already figured out that the 5 degree offset between flanges lead to that you will need two spoke lengths. That's not an issue. I wonder though if there will be some torque-issue or similar thing I haven't figured out...

There's also a solution when using a standard 2-cross (equal spoke length) on one side, and radial on the other, here: https://www.sheldonbrown.com/rinard/36-24.htm actually the radial side needs two different lengths, but as they differ only about 0.5mm it's generally negligible. I would prefer 2-cross on both sides though in this build.

#3

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

But you're obviously committed to this, so perhaps my objections are immaterial. Let me think it through by writing. The reasoning seems sound: the 18 holes on each side of the hub, separated by 20°. The set of holes on one side are offset 10° from each other. If you use only 24 spokes, 12 per side, then you'll have to have 6 pairs of spokes pulling in opposite directions, which means each pair of pulling spokes is separated by an unused spoke hole. Thought experiment: imagine one side of the hub setup with equal-sized spokes and symmetrical relationship with the rim. The holes in the other side the hub are offset by 10°, but the rim holes for the other side of the wheel are offset by 15. This would require two different size spokes to allow for the 5° difference in spoke angles on that opposing side. To make the wheel a little more symmetrical and to minimize spoke size difference, you propose to use different sized spokes on both sides of the wheel to "move" the rim so that instead of 0 offset on one side, and 5° offset on the other, you have 2.5° offset on both sides. Am I properly catching up to your thinking?

The question is: can different sized spokes and different spoke angles be used successfully. My first thought is that all the forces have to balance out a) tangentially, b) radially, and c) laterally. I suppose you could figure out some wildly complex way to true a wheel in unbalanced fashion so that the spokes on one side had net tangential force and twisted the rim one way (e.g. forward) while the other side twisted it backward, with torque balanced out by torsion through the hub. This seems a bad idea. Too complex, and most hubs aren't designed for that kind of torque. The hub would deflect and all your spoke sizing and such would go South. So you'd want a tangentially balanced design. In a tangentially balanced design, the spokes at different angles must have different tensions. To keep this simple, each pair of adjacent spokes would have a different tension, and all "innie" (inward pointing spokes, where the spoke head is on the outside of the hub) spokes would have one tension and one angle, and the outies have a different angle and tension. From a big-picture standpoint that would give you tangential and lateral symmetry (that is, the total forces acting on the rim aren't trying to push the rim "forward" or "backward" relative to the hub, nor to the left or right of the hub center). From the local (spoke to spoke) point of view, you'll of necessity have spoke tensions with a Low Low High High pattern. Tangentially and even laterally, these can balance out. Radially this could give you a periodic variation in rim diameter.

With modern, stiff rims this might not be an issue. They seem to be strong enough to maintain their rim shape. After all, look at the wheel offerings from many makers that use "triplet" patterns. But if you are using a more flexible lightweight rim it might give you a little periodic variation in rim diameter. This is the point of my reply - I tried to separate out the different directions of force differences. Would period variation in spoke tension matter? Don't know. I suspect it could work depending upon your rim and hub. Certainly, in the other thread cited above, you see that others have actually done this successfully.

This is an interesting engineering problem. If you try it, please let us know how you made out.

Last edited by WizardOfBoz; 11-29-19 at 10:20 AM.

Likes For WizardOfBoz:

#4

Junior Member

Thread Starter

Thank you very much for your long detailed reply, very appreciated. I need to think about it for a while and see if I truly understand everything.

Yes you have understood my drawing correctly, shift 2.5 degrees to "only" end up with two spoke lengths and as small error as possible when compared to a normal 24->24 build.

The reason for using a 36H hub and 24H rim is that the hub is a DT Swiss 540 145mm tandem hub, they only make them in 36H and 40H (it's more of a heavy-duty touring hub rather than racing hub), the rim will be a custom-reinforced 55mm deep section carbon rim intended for aerodynamics. I aim to use Pillar Wing 23 aero spokes to gain enough stiffness for for tandem wheels with that low spoke count. If I judge this project unfeasible plan B is to try to get hold of a 28H tandem hub from white industries or chris king, but this is supposed to be a budget project and here in Sweden the DT Swiss hubs are much cheaper, and another advantage of using the 540 is that the same hubs will be on the gravel wheelset so I can switch the tandem between gravel/touring and tarmac racing mode without having to realign disc brakes etc.

I also find this problem quite interesting from an engineering standpoint, so if I come to the conclusion that it can be done I'll probably do it, even if it's wiser to pay up for a 28H hub and get make a normal 28H build. I'm not doing 36->28 as that becomes even messier, but only 24 spokes on tandem wheels is not something that I would generally recommend, but the reinforced rim plus the heavy-duty aero spokes should do it (Rolf Prima is doing it in their commercial tandem wheels). If I get a new hub, it will be 28 spokes though, which is the smallest I have found 145mm tandem hubs do, and then only Chris King and White Industries premium hubs, and probably made to order. Normally racing tandems use standard hubs so you can easily get any size you want, but our Cannondale is more of a do-it-all racy tourer so it uses the tandem-specific 145mm width. So why not just run with 36 spokes and call it a day? An obvious question so I thought I better answer that too: no commercial aero wheel design use 36 spokes, and I managed to find some data: While the loss of going from 24 to 28 (aero) spokes is not that bad (most would call it negligible), 36 is past a point when there is quite significant detrimental effects to aerodynamics, and why go through the effort to make fast aero wheels with when wasting a big part of the advantage by using too many spokes.

Anyway, it will surely be a tough build, not only because of the different spoke lengths, but I also plan to exclude the center channel holes to insert nipples for even more rim robustness, so there will be magnet/wire. I can live with that though. This is a winter project so it doesn't hurt if it takes some time :-)

What I am worried about that it would be almost impossible to get this wheel trued and tensioned properly due to the 2.5 degree shift thing... it seems like the information for figuring that out is in your answer, I need to think more about it though, I'm not wheel building expert so I don't have that deep knowledge about exactly what happens when tensioning a wheel.

Yes you have understood my drawing correctly, shift 2.5 degrees to "only" end up with two spoke lengths and as small error as possible when compared to a normal 24->24 build.

The reason for using a 36H hub and 24H rim is that the hub is a DT Swiss 540 145mm tandem hub, they only make them in 36H and 40H (it's more of a heavy-duty touring hub rather than racing hub), the rim will be a custom-reinforced 55mm deep section carbon rim intended for aerodynamics. I aim to use Pillar Wing 23 aero spokes to gain enough stiffness for for tandem wheels with that low spoke count. If I judge this project unfeasible plan B is to try to get hold of a 28H tandem hub from white industries or chris king, but this is supposed to be a budget project and here in Sweden the DT Swiss hubs are much cheaper, and another advantage of using the 540 is that the same hubs will be on the gravel wheelset so I can switch the tandem between gravel/touring and tarmac racing mode without having to realign disc brakes etc.

I also find this problem quite interesting from an engineering standpoint, so if I come to the conclusion that it can be done I'll probably do it, even if it's wiser to pay up for a 28H hub and get make a normal 28H build. I'm not doing 36->28 as that becomes even messier, but only 24 spokes on tandem wheels is not something that I would generally recommend, but the reinforced rim plus the heavy-duty aero spokes should do it (Rolf Prima is doing it in their commercial tandem wheels). If I get a new hub, it will be 28 spokes though, which is the smallest I have found 145mm tandem hubs do, and then only Chris King and White Industries premium hubs, and probably made to order. Normally racing tandems use standard hubs so you can easily get any size you want, but our Cannondale is more of a do-it-all racy tourer so it uses the tandem-specific 145mm width. So why not just run with 36 spokes and call it a day? An obvious question so I thought I better answer that too: no commercial aero wheel design use 36 spokes, and I managed to find some data: While the loss of going from 24 to 28 (aero) spokes is not that bad (most would call it negligible), 36 is past a point when there is quite significant detrimental effects to aerodynamics, and why go through the effort to make fast aero wheels with when wasting a big part of the advantage by using too many spokes.

Anyway, it will surely be a tough build, not only because of the different spoke lengths, but I also plan to exclude the center channel holes to insert nipples for even more rim robustness, so there will be magnet/wire. I can live with that though. This is a winter project so it doesn't hurt if it takes some time :-)

What I am worried about that it would be almost impossible to get this wheel trued and tensioned properly due to the 2.5 degree shift thing... it seems like the information for figuring that out is in your answer, I need to think more about it though, I'm not wheel building expert so I don't have that deep knowledge about exactly what happens when tensioning a wheel.

#5

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

Thanks for the nice note, torger. I think others have done this (the thread you quoted) so you should be able to true the thing after some fashion, especially with a reinforced deep section CF rim.

Normally tandems get MORE spokes though, not less! Older tandems have 40 spokes. But I'm a big (>110kg) guy - you may be 50kg, or this may be a tandem for junior racers or something. Orthodox thinking would be a 40 hole rear and 36 hole front would be appropriate. Or a 36 hole rear and a 32 spoke front in a 40 hole hub:. But you clearly have reasons (aero rim, spoke drag) for going with fewer spokes.

But you clearly have reasons (aero rim, spoke drag) for going with fewer spokes.

Anyway, for your amusement:

Normally tandems get MORE spokes though, not less! Older tandems have 40 spokes. But I'm a big (>110kg) guy - you may be 50kg, or this may be a tandem for junior racers or something. Orthodox thinking would be a 40 hole rear and 36 hole front would be appropriate. Or a 36 hole rear and a 32 spoke front in a 40 hole hub:.

But you clearly have reasons (aero rim, spoke drag) for going with fewer spokes.

But you clearly have reasons (aero rim, spoke drag) for going with fewer spokes.Anyway, for your amusement:

Likes For WizardOfBoz:

#6

Junior Member

Thread Starter

Interesting example, your picture shows 40H->32H with cross. This leads to the same situation as mine, but to a lesser degree. 360/40=9 degrees between hub holes (and thus offset between flanges), and 360/32=11.25 degrees between rim holes. So if we align one side the other get 11.25 - 9 = 2.25 degrees off. To get equal distribution of the error both sides should be 2.25/2 = 1.125 degrees off (the angle that is 2.5 degree in my 36->24 case).

Was the pictured build made with some special tricks regarding spoke lengths and tensioning? Or maybe 1.125 degrees off is small enough to be negligible?

Was the pictured build made with some special tricks regarding spoke lengths and tensioning? Or maybe 1.125 degrees off is small enough to be negligible?

#7

Junior Member

Thread Starter

I think I just realized (hopefully) the main issue you were describing. I think one can look at one side isolated, and in the attached image I have colored the shorter spokes magenta, the longer yellow. One can see that all yellow spokes when tensioned will strive to turn the hub clockwise, which then need to be balanced by the shorter spokes which turns in the opposite direction. However the shorter spokes is less tangential, and thus to counteract they will need more tension.

However due to my limited experience I don't really have any idea how large this effect will be. The shorter spoke is 111.45 degrees and the longer 106.26 degrees (where 90 = perfect tangent), a difference of 5.19 degrees, which to my intuition does seem as it could be significant. Even if it is, it should be possible to balance out, but how hard is it?

One side (12 spokes, 18 holes) with 2.5 degree offset. Yellow = Longer spokes, Magenta shorter spokes.

However due to my limited experience I don't really have any idea how large this effect will be. The shorter spoke is 111.45 degrees and the longer 106.26 degrees (where 90 = perfect tangent), a difference of 5.19 degrees, which to my intuition does seem as it could be significant. Even if it is, it should be possible to balance out, but how hard is it?

One side (12 spokes, 18 holes) with 2.5 degree offset. Yellow = Longer spokes, Magenta shorter spokes.

#8

Senior Member

Join Date: May 2019

Location: Bloomington, IN

Posts: 2,949

Bikes: Paramount, Faggin, Ochsner, Ciocc, Basso

Mentioned: 117 Post(s)

Tagged: 0 Thread(s)

Quoted: 1303 Post(s)

Liked 1,911 Times

in

1,141 Posts

Wiz,

I have seen wheels with spokes tied, spokes twisted into each other, and straight cross patterns of all configurations that work well. But there are always constants about the wheels. Even tensions across both sides of the wheel. Regardless of the pattern chosen the tension to the hub to rim needs to be pretty close to have a wheel that works. When the tension between both sides of the rim is different , it will result n a wheel that does not track correctly. HTH, MH

I have seen wheels with spokes tied, spokes twisted into each other, and straight cross patterns of all configurations that work well. But there are always constants about the wheels. Even tensions across both sides of the wheel. Regardless of the pattern chosen the tension to the hub to rim needs to be pretty close to have a wheel that works. When the tension between both sides of the rim is different , it will result n a wheel that does not track correctly. HTH, MH

#9

Junior Member

Thread Starter

Looking in 2D space, splitting up the tension force in pure tangent the long spoke is 96.00% tangential (96% of the spoke tension pulls in pure tangent), the short spoke has 93.07%. That would mean that the short spoke needs to be tensioned 1.031 (96.00/93.07) times more, or 3.1%, so if the long spoke is 120 kgf the short would be 123.8 kgf. Is that a small enough difference to not be a problem?

A wheel which is dished to the side (front wheel with disc brake, or rear wheel due to cassette space) can have huge difference in tension between left and right side, for example 120kg on one side and only 70 on the other, and modern rims seem to be handling that, which makes me think that this small tension variation would not be a problem in terms of causing radial hop or similar.

Note that I changed spoke placement from my first post, the hole skipping was not made such that the spokes got maximally tangential, which I've fixed now, and is fixed in the second drawing (that one with yellow/magenta spokes).

A wheel which is dished to the side (front wheel with disc brake, or rear wheel due to cassette space) can have huge difference in tension between left and right side, for example 120kg on one side and only 70 on the other, and modern rims seem to be handling that, which makes me think that this small tension variation would not be a problem in terms of causing radial hop or similar.

Note that I changed spoke placement from my first post, the hole skipping was not made such that the spokes got maximally tangential, which I've fixed now, and is fixed in the second drawing (that one with yellow/magenta spokes).

Last edited by torger; 11-30-19 at 09:38 AM. Reason: added further information

#10

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

Wiz,

I have seen wheels with spokes tied, spokes twisted into each other, and straight cross patterns of all configurations that work well. But there are always constants about the wheels. Even tensions across both sides of the wheel. Regardless of the pattern chosen the tension to the hub to rim needs to be pretty close to have a wheel that works. When the tension between both sides of the rim is different , it will result n a wheel that does not track correctly. HTH, MH

I have seen wheels with spokes tied, spokes twisted into each other, and straight cross patterns of all configurations that work well. But there are always constants about the wheels. Even tensions across both sides of the wheel. Regardless of the pattern chosen the tension to the hub to rim needs to be pretty close to have a wheel that works. When the tension between both sides of the rim is different , it will result n a wheel that does not track correctly. HTH, MH

Since others have done this, and also have done some pretty wild and silly things that you mention, and I assume that they have worked, I suspect that torger will be ok. Though keeping those spoke lengths straight would probably confuse me. But pretty soon I'll be consigned to the Wisconsin Home for the Bewildered, so I suspect torger has an advantage. I will say, though, that the weirdnesses (twists, different spoke lengths, skipping holes in the hub) are probably suboptimal in some sense. torger has made a case that other criteria override this aspect of non-optimality. As I say, I think he'll be ok.

From https://www.instructables.com/id/Twi...ng---flowers!/

Last edited by WizardOfBoz; 11-30-19 at 10:21 AM.

#11

Junior Member

Thread Starter

Thanks for all replies, they have been very helpful for me to get more understanding on what happens in a build like this.

I think I will proceed. I'll post an update how it goes if I remember, but the delivery time of the parts will be long so it can be into next year before I actually start building.

To summarize:

My current understanding of this design is as follows: lacing 36->24 2-cross 2.5 degree offset will not be as optimal in terms of spoke tensions compared to a standard 24->24 2-cross lacing, but I think the issue is small enough that it can be handled by the rim.

The root of the problem is that due to 10 degree flange offset (360/36) rather than 15 (360/24) the pattern will require two different length of spokes, differing about 2mm, and the short being slightly less tangential than the long (less tangential = more force/spoke tension required to put the same amount of torque to the hub than a more tangential spoke). They will be arranged such that seen on one side isolated, all the short spokes apply torque in one direction and all the long in the opposite, meaning that the short spokes will need more tension, about 3% more to completely balance out.

On the other side of the wheel the pattern is mirrored, which in theory means that if you tension all spokes equally net torque would transfer over the hub and cancel out, but in practice that would probably not work, so the 3% extra tensioning of the short spokes is probably required, to keep each side balanced in itself.

This will leave a pattern around the rim of high high low low spoke tension, which is not ideal (high low high low would have been better). However as the tension difference is only 3% and the rim is a reinforced high profile carbon rim I think it will work without any significant radial compression issues.

I think I will proceed. I'll post an update how it goes if I remember, but the delivery time of the parts will be long so it can be into next year before I actually start building.

To summarize:

My current understanding of this design is as follows: lacing 36->24 2-cross 2.5 degree offset will not be as optimal in terms of spoke tensions compared to a standard 24->24 2-cross lacing, but I think the issue is small enough that it can be handled by the rim.

The root of the problem is that due to 10 degree flange offset (360/36) rather than 15 (360/24) the pattern will require two different length of spokes, differing about 2mm, and the short being slightly less tangential than the long (less tangential = more force/spoke tension required to put the same amount of torque to the hub than a more tangential spoke). They will be arranged such that seen on one side isolated, all the short spokes apply torque in one direction and all the long in the opposite, meaning that the short spokes will need more tension, about 3% more to completely balance out.

On the other side of the wheel the pattern is mirrored, which in theory means that if you tension all spokes equally net torque would transfer over the hub and cancel out, but in practice that would probably not work, so the 3% extra tensioning of the short spokes is probably required, to keep each side balanced in itself.

This will leave a pattern around the rim of high high low low spoke tension, which is not ideal (high low high low would have been better). However as the tension difference is only 3% and the rim is a reinforced high profile carbon rim I think it will work without any significant radial compression issues.

Last edited by torger; 11-30-19 at 12:22 PM.

#12

Newbie

Join Date: Jan 2021

Posts: 1

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Thanks, torger and others, this thread has been super helpful.

Can someone confirm that entering 2.083 cross (short spokes) and 2.25 (long spokes) into a spoke calculator would give me the exact spoke lengths for this pattern?

At least this is what I get when I follow the Sheldon Brown article and replace the 5° from the formula with 2.5° (short spokes) and 7.5° (long spokes).

I am relatively sure about it, but it would be great to have a second opinion before I buy anything. Thanks!

Can someone confirm that entering 2.083 cross (short spokes) and 2.25 (long spokes) into a spoke calculator would give me the exact spoke lengths for this pattern?

At least this is what I get when I follow the Sheldon Brown article and replace the 5° from the formula with 2.5° (short spokes) and 7.5° (long spokes).

I am relatively sure about it, but it would be great to have a second opinion before I buy anything. Thanks!

#13

Junior Member

Thread Starter

Thanks, torger and others, this thread has been super helpful.

Can someone confirm that entering 2.083 cross (short spokes) and 2.25 (long spokes) into a spoke calculator would give me the exact spoke lengths for this pattern?

At least this is what I get when I follow the Sheldon Brown article and replace the 5° from the formula with 2.5° (short spokes) and 7.5° (long spokes).I am relatively sure about it, but it would be great to have a second opinion before I buy anything. Thanks!

Can someone confirm that entering 2.083 cross (short spokes) and 2.25 (long spokes) into a spoke calculator would give me the exact spoke lengths for this pattern?

At least this is what I get when I follow the Sheldon Brown article and replace the 5° from the formula with 2.5° (short spokes) and 7.5° (long spokes).I am relatively sure about it, but it would be great to have a second opinion before I buy anything. Thanks!

They seem to perform well and I didn't have any issues tensioning the wheel. I didn't get that much time to ride them though (only made 150 km or so on them), and now it's winter here.

I used a CAD software to make the drawings, not a spoke calculator, so I can unfortunately not answer the question. Mixing spoke lengths etc make them quite tricky to build and easy to mess up, so actually taking some time and make a CAD drawing to get a deeper understanding what's going on can be a good idea.

#14

Senior Member

Next time contact DT directly. They might ignore you entirely. They might respond to a customer who has clearly done his homework. My experience has been that custom drillings are not that hard to get. Or they can supply undrilled which leaves them clear of liability. All depends on who takes the call.

My main concern would be the hub flanges are not up to tandem duty with only 24 spokes. DT could tell you more about that.

In the collection here I have 24 hole no-Record Campy, 24 hole Maillard 700, 24 hole Normandy from 1950s. None of that would be useful to you. Pretty sure none of it was ever in a catalog.

My main concern would be the hub flanges are not up to tandem duty with only 24 spokes. DT could tell you more about that.

In the collection here I have 24 hole no-Record Campy, 24 hole Maillard 700, 24 hole Normandy from 1950s. None of that would be useful to you. Pretty sure none of it was ever in a catalog.

#15

**thusi*st

I am looking at a similar situation. I have some nice 24 hole (305 iso) wheels that I want to make bike trailer wheels from. Basically wheelchair hubs are all I can find that would provide a quick release from the side like I would like (perhaps there are other approaches). All wheelchair hubs I am finding are 36 hole.

I did also find the following link on Sheldon Brown site.. https://www.sheldonbrown.com/rinard/36-24.htm

Seems an interesting, generally understandable approach there...

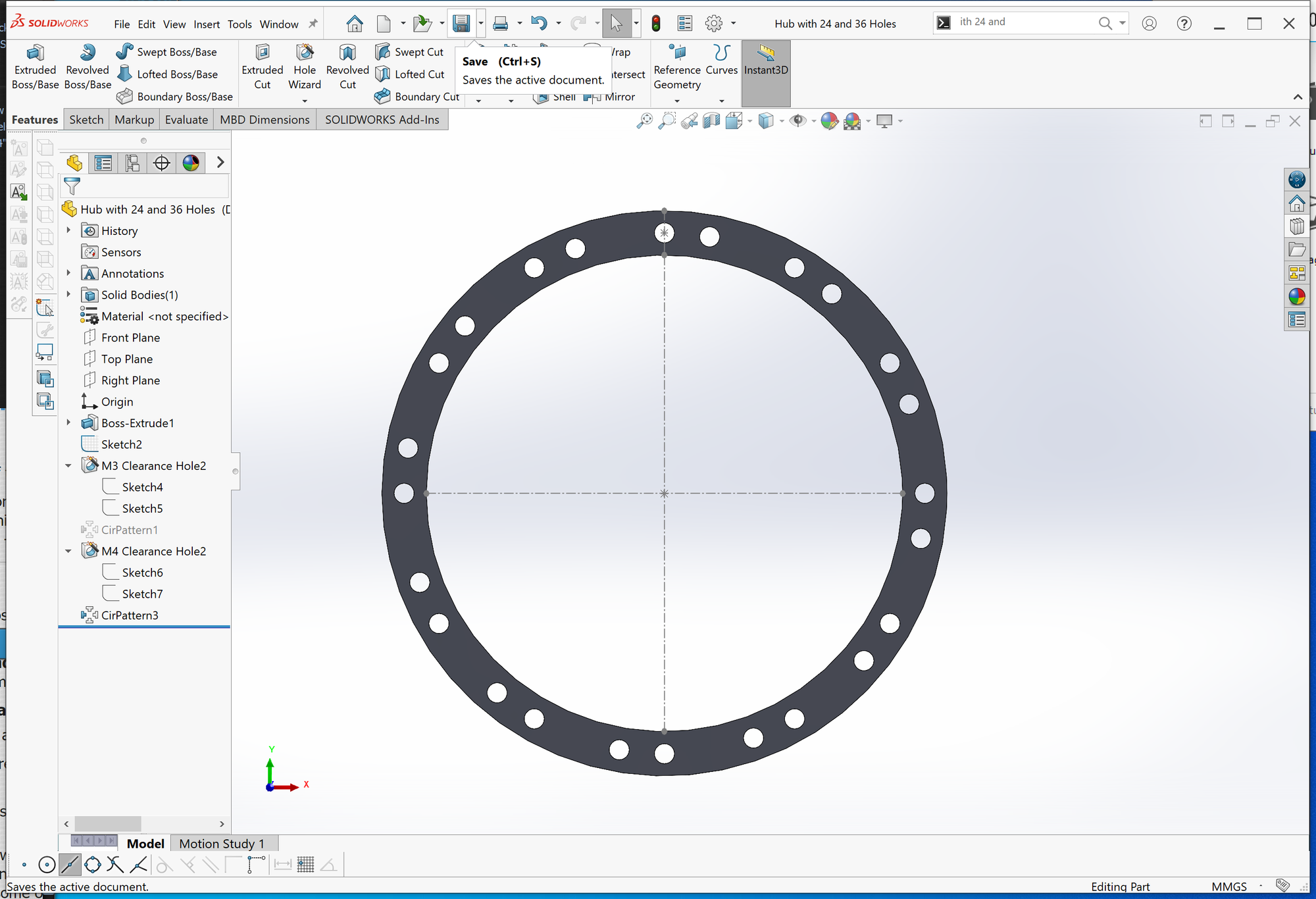

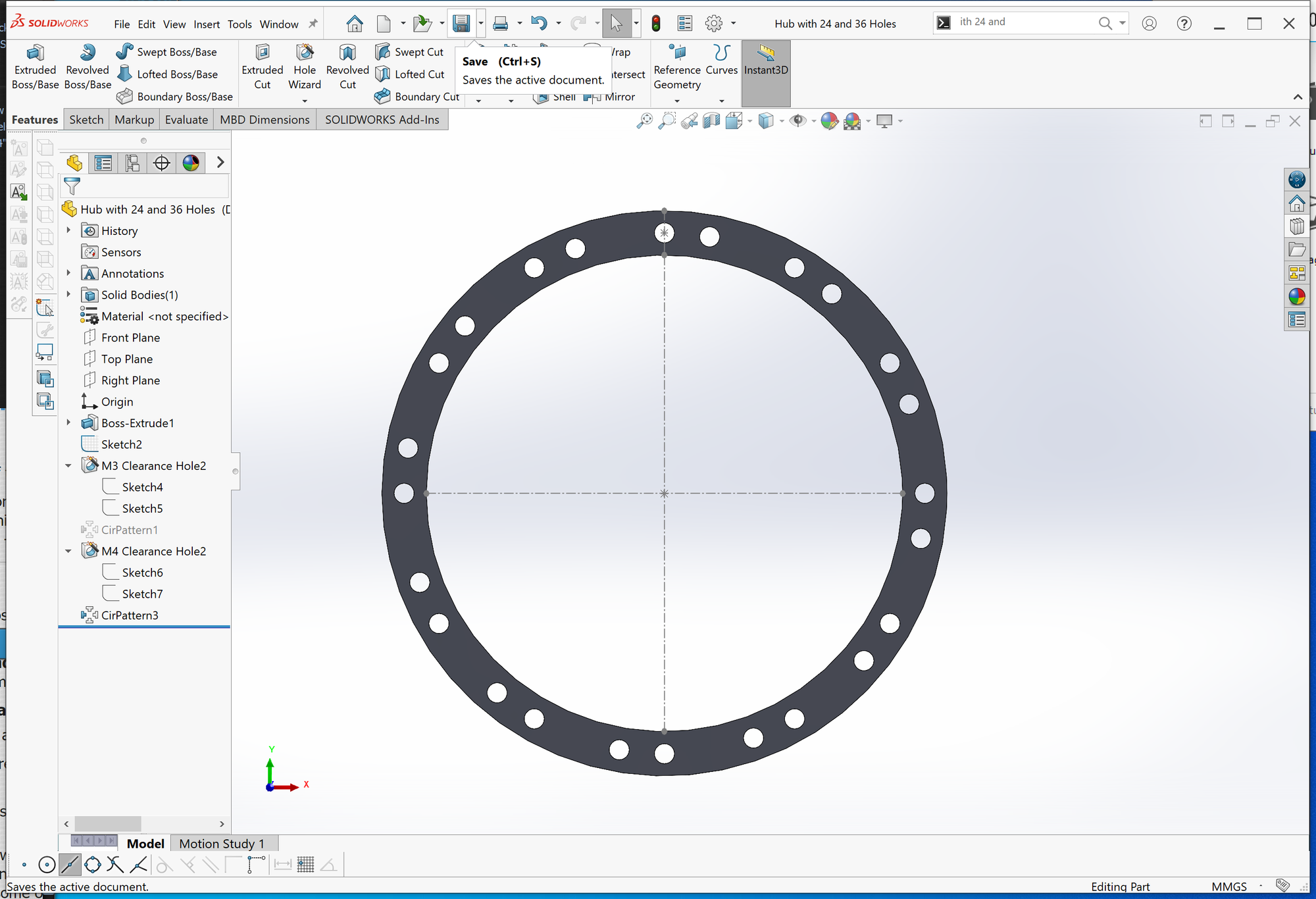

For my part I am just thinking about the Hub Holes I would use (spoke length subject to follow) to match 24 to 36.

Straight intervals do not work, but skipped intervals might be a solution (skip every4th 3rd hole?) (in a Circular pattern CAD I find you should start by skipping the 3rd hole as you can't really skip your starting root hole that creates the pattern)

UPDATED to every 3rd hole from 4th

The picture below shows the holes with3 out of 4 2 out of 3 in use around a 36 hole pattern. (Likely well described above)

(but also, since this is a HUB subject (corrected below). mainly showing a pattern of 24 of 36 here in the new image)

I did also find the following link on Sheldon Brown site.. https://www.sheldonbrown.com/rinard/36-24.htm

Seems an interesting, generally understandable approach there...

For my part I am just thinking about the Hub Holes I would use (spoke length subject to follow) to match 24 to 36.

Straight intervals do not work, but skipped intervals might be a solution (skip every

UPDATED to every 3rd hole from 4th

The picture below shows the holes with

(but also, since this is a HUB subject (corrected below). mainly showing a pattern of 24 of 36 here in the new image)

Last edited by L Arnold; 12-06-23 at 12:29 PM. Reason: wrong math 24/36 not 27/36

#16

**thusi*st

But of course the hub only has 18 holes per side.. The Rim has 24 holes.

Assumably then, the "skipping" holes on the hub needs to use 12 of the 18 that would be each side... so.. lets see...

Assumably then, the "skipping" holes on the hub needs to use 12 of the 18 that would be each side... so.. lets see...

#17

**thusi*st

So this is a pattern with 2 holes, and 1 skipped, then 2 holes. The Ratio of 18 dropping to 12.

#18

**thusi*st

Nice part there is that each pair of holes is across the globe from another pair of holes so tension should be balanced.