Is there a way to see the gap between truing stand and wheel better?

#51

Junior Member

Join Date: Jun 2017

Posts: 15

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 2 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I am almost embarrassed how I lucked into mine. I'm not sure how useful the hollow ends are for qr or through axles. Some people apparently have found/made conical inserts to hold hollow axles. Mine needs a good cleanup and they are crude but somehow really nice to use such a solid tool.

#52

Friendship is Magic

Join Date: Nov 2010

Location: Sacramento, CA

Posts: 22,984

Bikes: old ones

Mentioned: 304 Post(s)

Tagged: 0 Thread(s)

Quoted: 26415 Post(s)

Liked 10,380 Times

in

7,208 Posts

First comment is about what's good enough. How perfectly molder are tires (and that's not mentioning sew ups)? I've worked to about 1mm of trueness. I balance this with the spoke tension evenness. Both are factors to a good wheel. The trueness is what's judged right away. The spoke evenness is what is noticed later, many mile later.

He made me feel healthy.

He made me feel healthy.

#53

Senior Member

Join Date: Nov 2008

Location: South Jersey

Posts: 1,959

Bikes: Too many Bicycles to list

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 90 Post(s)

Liked 137 Times

in

45 Posts

I was really lucky to find an HTK truing stand - very similar to the hozan. 30+pounds of cast iron. The original build tolerances weren't great but the indicators are threaded bolts with knurled ends. I replaced these with bolts holding brackets attached to dial gauges. It needs a sturdy bench to work on but there is 0 movement of the guages do to vibration or anything other than the rim.

#54

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,396

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,696 Times

in

2,517 Posts

I think most of you get closer than a millimeter, even if you don't measure. I just finished up my first fatbike wheel build, and I had to make myself stop tweaking. Disc brakes and big, low pressure tires make tension the most important thing about a fatbike wheel build. I don't think I have anything to be embarrassed about, but it isn't true to my usual standards. It's probably out about a millimeter in both directions.

I used to try to get radial hop out even if it was from a weld. Nowadays, I stop with even tension, maybe tweak a little. Even high quality rims can have funky joins.

I used to try to get radial hop out even if it was from a weld. Nowadays, I stop with even tension, maybe tweak a little. Even high quality rims can have funky joins.

#55

Newbie

Join Date: Jun 2018

Posts: 1

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

So there is no one way to measure a wheels trueness. Yes, you can measure down to the thousandth of an inch with a multitude of instruments, but over the years the dial indicator has been put away and I use my senses, hearing, sight and feel to get a wheel that stays true for years if you watch where you ride and maintain your bike. I do use a light colored background and directed backlighting to watch the gap, and that seems to be my way that works.

I do hope "bikerbobbbb" has figured it out for himself by now and would love to hear from him on what he has decided upon with all this great advice over time!

I do hope "bikerbobbbb" has figured it out for himself by now and would love to hear from him on what he has decided upon with all this great advice over time!

#57

Senior Member

Join Date: Dec 2009

Location: Melbourne, Oz

Posts: 9,545

Bikes: https://weightweenies.starbike.com/forum/viewtopic.php?f=10&t=152015&p=1404231

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 1528 Post(s)

Liked 718 Times

in

510 Posts

One of those, plus a magnifier app.

#58

Senior Member

Join Date: Mar 2012

Location: santa barbara CA

Posts: 1,087

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 96 Post(s)

Liked 30 Times

in

21 Posts

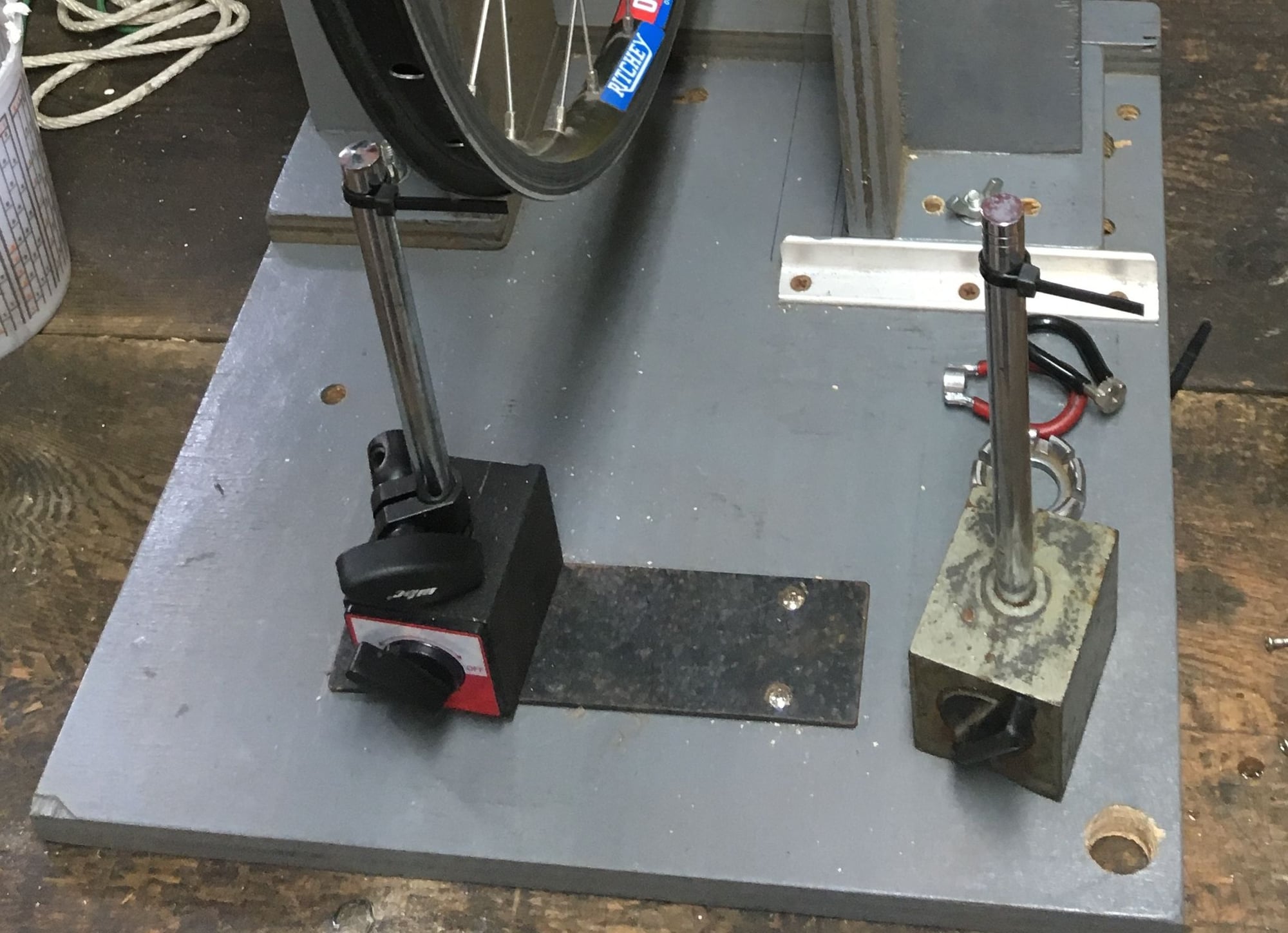

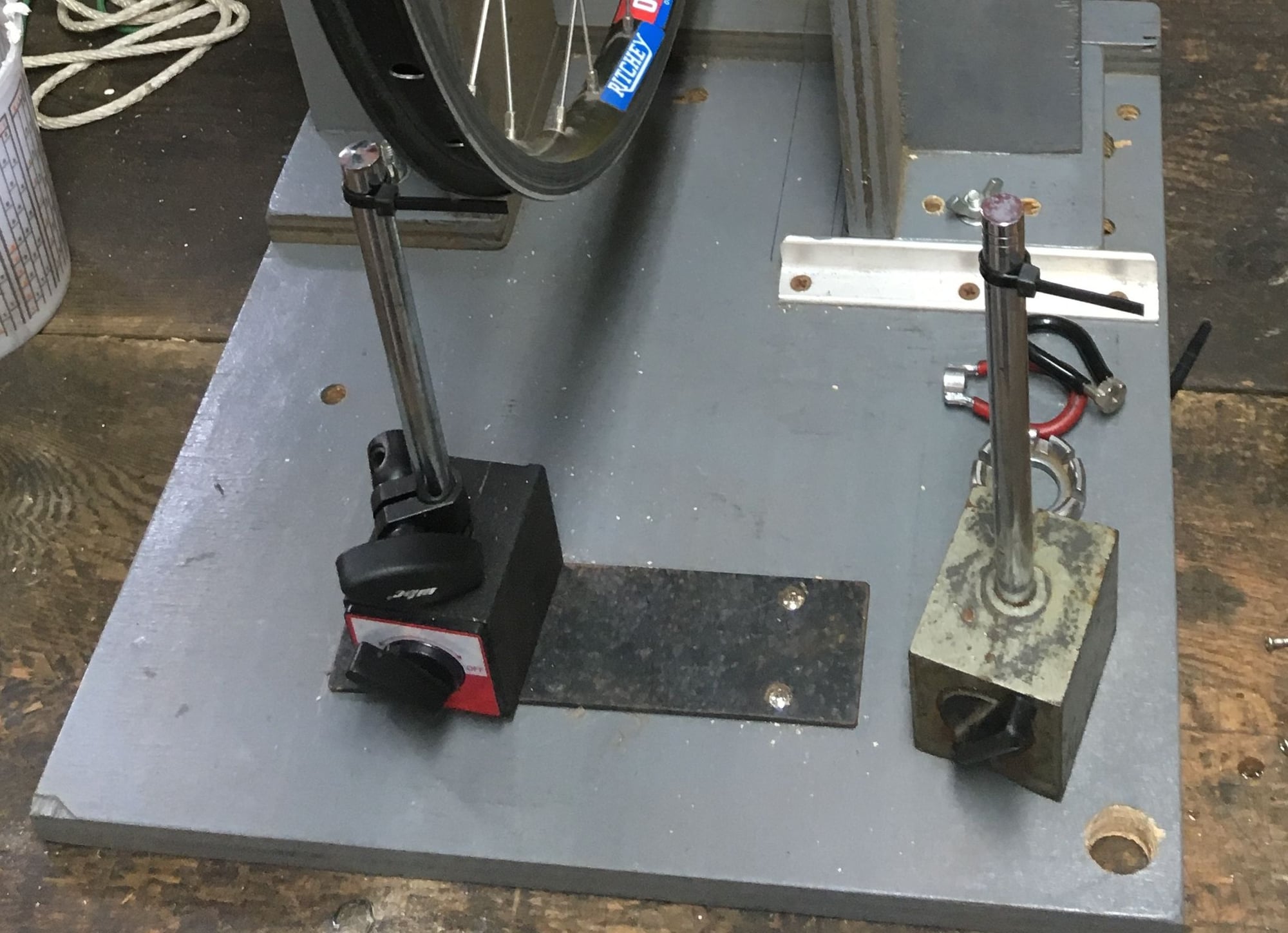

nfmisso shows his mag base(post 56) on a metal plate to secure it, I used the same idea on the Musson designed stand I built as seen in the pics , handy to have the option of magnets whether or not you use indicators.

regards, Brian

regards, Brian

__________________

Brian

Brian

Last edited by calstar; 12-05-18 at 05:11 PM.

#59

Senior Member

Join Date: Jun 2006

Posts: 1,407

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 23 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Those of us who build wheels on the Roger Musson truing stand operate purely from referencing the visual gap. The suggestions above for squaring up the indicators on the park tool with a squared off piece of electrical tape or a rubber cap would nicely mimmick Roger's design. I can't stand the sound of metal scratching on the braking surface, so doing it purely visually works well for me. If the indicator is squared off and properly aligned, and you've put a high contrast color behind, you can easily get as true as is necessary without resorting to using your ears.

p.s. Tension is far more importal than perfect true. Most factory built wheels are visually perfect despite varying tensions throughout. That wheel won't last nearly as long as one with evenly tensioned spokes that is even ~1mm out of true. 1mm out of true is extremely obvious on a visual gauge.

-Jeremy

p.s. Tension is far more importal than perfect true. Most factory built wheels are visually perfect despite varying tensions throughout. That wheel won't last nearly as long as one with evenly tensioned spokes that is even ~1mm out of true. 1mm out of true is extremely obvious on a visual gauge.

-Jeremy

#60

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,905

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4806 Post(s)

Liked 3,928 Times

in

2,553 Posts

I'm about to throw a hand grenade in the outhouse, but IMHO there is no reason to worry about less than a mm or so of lateral or vertical true. One of the reasons is that it does nothing to improve wheel strength or stability. Another big reason is that there isn't a tire made within a 1 mm tolerance across the sidewalls and tred so all those nano-adjustments are lost between the rim and the ground. Finally, unless you are riding on a glass smooth surface, you will never feel the difference 1 mm (4/100 inch) of truing makes. I've watched guys obsess for hours to get a wheel down to a few 1/1000ths true with the spokes within a micro-narrow range of tension variation. All they have accomplished is to waste perfectly good riding time. I'm not saying do a sloppy job, just don't obsess about minutia that are irrelevant in the real world. Craftsmanship = YES, OCD = NO.

As far as making it easier to see. I painted my caliper tips bright green so they stand out against either black or silver rim surfaces. The other suggestions of good lighting (goose neck lamp with a soft white LED bulb is great), proper positioning of the stand relative to the craftsman's eye, and the use of reading or prescription glasses for those with less that 20/20 eyesight are all good ideas.

As far as making it easier to see. I painted my caliper tips bright green so they stand out against either black or silver rim surfaces. The other suggestions of good lighting (goose neck lamp with a soft white LED bulb is great), proper positioning of the stand relative to the craftsman's eye, and the use of reading or prescription glasses for those with less that 20/20 eyesight are all good ideas.

I use sound as my primary indicator for spoke tension. Use the Park tensioner to get the basic tension right but all the rest is by ear, And with all pretty quite for that pinging, listening to the rub for the truing is easy.

Wheelbuilding really requires very little. The sturdy, accurate stands are nice that they save removing the wheel to check dish but if you make a dishing tool plunger that fits under the nut or quick release so you don't have to pull them and replace every time, doing that check is also pretty easy.

Ben

#61

Junior Member

Join Date: Nov 2018

Location: Chicago, IL

Posts: 12

Bikes: Velo-Orange Campeur, Dahon Helios P8

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

If your brake tracks are relatively shiny and clean, look for the reflection (really more like a diffuse shadow) of the truing stand caliper. The distance between the reflection and the actual caliper is twice the distance between the caliper and the rim. You can easily pick up x2 precision without any additional equipment.