Seatstay angle and Chainstay length

#1

Newbie

Thread Starter

Seatstay angle and Chainstay length

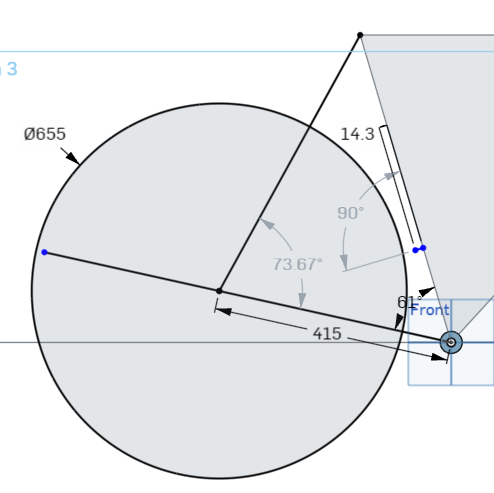

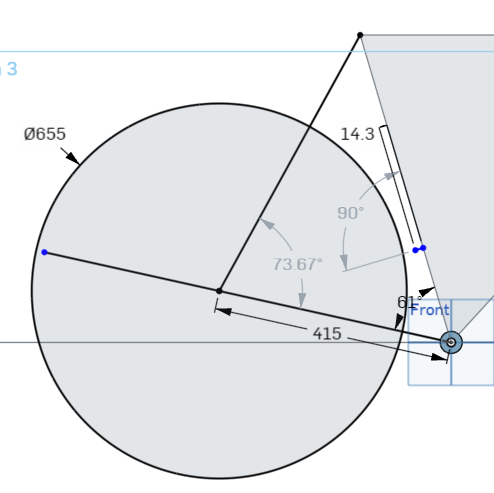

I am attempting to build my first frame. It will be a lugged fixed gear. The steepest angle I can find for rear dropouts is 70 degrees which gives me 449mm chainstays which is longer than I would like. I really like my Lemond that has 415mm stays, but that would require 73.7 degrees. One solution I can think of is to used a hooded dropout and braze the joint, but that's not the appearance I'm after nor do I want to buy all the additional equipment. Are there any other solutions?

Also how many degrees of wiggle room do the other lugs have? The bottom headtube lug I plan to use is 59.5 degrees but the drawing is at 59 degrees.

Also how many degrees of wiggle room do the other lugs have? The bottom headtube lug I plan to use is 59.5 degrees but the drawing is at 59 degrees.

#2

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,095

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4210 Post(s)

Liked 3,875 Times

in

2,315 Posts

1- There have been many rear dropouts with far less a chain/seat stay angle of 70*. I have some in my stash. But these are usually vertical designs.

2- One of the marks of a good builder is how they work around these issues...

3- der hangerless dropouts are fairly simple, if time consuming, to make at whatever stay angle you call out.

4- Traditional track dropouts are often more agreeable with fringes of the bell curve stay angles.

5- Don't let the frame components limit your design. Andy

2- One of the marks of a good builder is how they work around these issues...

3- der hangerless dropouts are fairly simple, if time consuming, to make at whatever stay angle you call out.

4- Traditional track dropouts are often more agreeable with fringes of the bell curve stay angles.

5- Don't let the frame components limit your design. Andy

__________________

AndrewRStewart

AndrewRStewart

#3

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,906

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4806 Post(s)

Liked 3,932 Times

in

2,557 Posts

You can cut 1/4" plate to any design you like. My custom fix gear has a modified horizontal road dropout designed to a slot 11 degrees from horizontal to just keep the brake pad on the rim throughout the travel of the roughly 2" slot. (I can run any cog from 12 to 24 teeth without messing with chain length. Since the big cog put the tire very close tot he seattube, I have the slot do a right angle turn down so the wheel comes out like from a vertical dropout.)

Sorry,this photo is more about the bike than the dropout but you can see it.

+

This dropout also has a chain peg, an M5 pan head screw, threaded into it. Makes for a really easy wheel flip keeping my hands completely clean. 2 minutes. I pick the chain up with the Pedros Trixie tool you can see hanging from my tool bags. (That spanner is also much better than the plate steel spanners like the Park for 12 tooth bell-shaped lockrings.) This bike has 20k miles and hundreds of wheel flips. Absolutely love it. I'd copy that rear end exactly dong this bike over.

Sorry,this photo is more about the bike than the dropout but you can see it.

+

This dropout also has a chain peg, an M5 pan head screw, threaded into it. Makes for a really easy wheel flip keeping my hands completely clean. 2 minutes. I pick the chain up with the Pedros Trixie tool you can see hanging from my tool bags. (That spanner is also much better than the plate steel spanners like the Park for 12 tooth bell-shaped lockrings.) This bike has 20k miles and hundreds of wheel flips. Absolutely love it. I'd copy that rear end exactly dong this bike over.

#4

Newbie

Thread Starter

Is it possible to attach a tab style without fillet brazing or welding? Alternatively, would it compromise the dropout to heat it and bend it to my desired angle or to take a pie cut and find someone to weld it?

#5

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,399

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,699 Times

in

2,519 Posts

I doubt that small of an angular mismatch for the dropout is going to be a problem. Pick the chainstay length that you like and go with that, and the dropout should be fine. The difference in lug angle might not even be noticeable.

I'm not sure I would modify a dropout like that, but cutting and welding would be the best approach if you were going to do that.

I have seen some frames with a jarring mismatch of seat stay angle and dropout angle. I try not to judge. I'm not sure why the people that designed some of the available dropouts didn't use a smaller angle, it seems like some of them only work well on large bikes.

I'm not sure I would modify a dropout like that, but cutting and welding would be the best approach if you were going to do that.

I have seen some frames with a jarring mismatch of seat stay angle and dropout angle. I try not to judge. I'm not sure why the people that designed some of the available dropouts didn't use a smaller angle, it seems like some of them only work well on large bikes.

Last edited by unterhausen; 07-21-23 at 07:08 AM.

#6

Senior Member

Join Date: Jul 2006

Location: San Jose (Willow Glen) Ca

Posts: 9,847

Bikes: Kirk Custom JK Special, '84 Team Miyata,(dura ace old school) 80?? SR Semi-Pro 600 Arabesque

Mentioned: 106 Post(s)

Tagged: 0 Thread(s)

Quoted: 2338 Post(s)

Liked 2,827 Times

in

1,543 Posts

You can cut 1/4" plate to any design you like. My custom fix gear has a modified horizontal road dropout designed to a slot 11 degrees from horizontal to just keep the brake pad on the rim throughout the travel of the roughly 2" slot. (I can run any cog from 12 to 24 teeth without messing with chain length. Since the big cog put the tire very close tot he seattube, I have the slot do a right angle turn down so the wheel comes out like from a vertical dropout.)

Sorry,this photo is more about the bike than the dropout but you can see it.

+

This dropout also has a chain peg, an M5 pan head screw, threaded into it. Makes for a really easy wheel flip keeping my hands completely clean. 2 minutes. I pick the chain up with the Pedros Trixie tool you can see hanging from my tool bags. (That spanner is also much better than the plate steel spanners like the Park for 12 tooth bell-shaped lockrings.) This bike has 20k miles and hundreds of wheel flips. Absolutely love it. I'd copy that rear end exactly dong this bike over.

Sorry,this photo is more about the bike than the dropout but you can see it.

+

This dropout also has a chain peg, an M5 pan head screw, threaded into it. Makes for a really easy wheel flip keeping my hands completely clean. 2 minutes. I pick the chain up with the Pedros Trixie tool you can see hanging from my tool bags. (That spanner is also much better than the plate steel spanners like the Park for 12 tooth bell-shaped lockrings.) This bike has 20k miles and hundreds of wheel flips. Absolutely love it. I'd copy that rear end exactly dong this bike over.

super nice overall.... not that my knees do fixie

__________________

Life is too short not to ride the best bike you have, as much as you can

(looking for Torpado Super light frame/fork or for Raleigh International frame fork 58cm)

Life is too short not to ride the best bike you have, as much as you can

(looking for Torpado Super light frame/fork or for Raleigh International frame fork 58cm)

#7

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,095

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4210 Post(s)

Liked 3,875 Times

in

2,315 Posts

How one deals with the angular difference between the dropout tabs and the stays is all part of being a good builder. As the stay angle closes up[ (as with small frames) matching the seat stay's lines with the dropout's is often done by having the stay overlap with the tab a bit lower down on the tab. The top of the tab will be proud of stay the and be filed down pretty easily. But the underside of the tab will have an awkward angle and be on the dropout's curved web, below the tab. Most will just build up enough brass and file away, leaving that awkward web curve not flowing nicely into the stay. Paul Brodie showed a neat trick for this detail. When making the stay's slot (that overlaps the dropout) the usual is to hack saw two slits about dropout tab thickness apart, bend down the stay's tab that you just created, break it off and file the slot all nice and even on both sides of the stay end. What Paul does instead is to leave the stay's cut tab on the stay's underside and curl it so it butts against the dropout's web. Then braze it up and file the curled stay tab down. This trick adds material to the web and lets one better form/file the joint. Such a little trick but makes a big detail difference.

I haven't yet needed to use this as I use vertical drops on most of my bikes and they are available in relatively low tab angles (and most of the frames I build are on the small side). Andy

__________________

AndrewRStewart

AndrewRStewart

#8

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,906

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4806 Post(s)

Liked 3,932 Times

in

2,557 Posts

I did create a mountain geared fix gear out of my Mooney that does not require a chainwhip but does have three mountain gears but I did that with a custom made "dingle"(two cogs on one set of threads and mounted just like a single fix gear cog using the same lockring) and a triple chainring, Not a straight velodrome drivetrain but it does work very well. Much harder to fine tune though. The dingles are $100+ each and require skilled labor, brazing and machine tools to make.

#9

Senior Member

Join Date: Dec 2019

Posts: 957

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Liked 263 Times

in

212 Posts

I attach them with TIG brazing. But this probably isn't helpful to you as it sounds like you're set up for brazing things that slot into each other. The other variable you can change is the BB drop to make it work with the CS length and angle you have-- but don't have the BB too low on a fixie in case of pedal strike.

#10

Newbie

Thread Starter

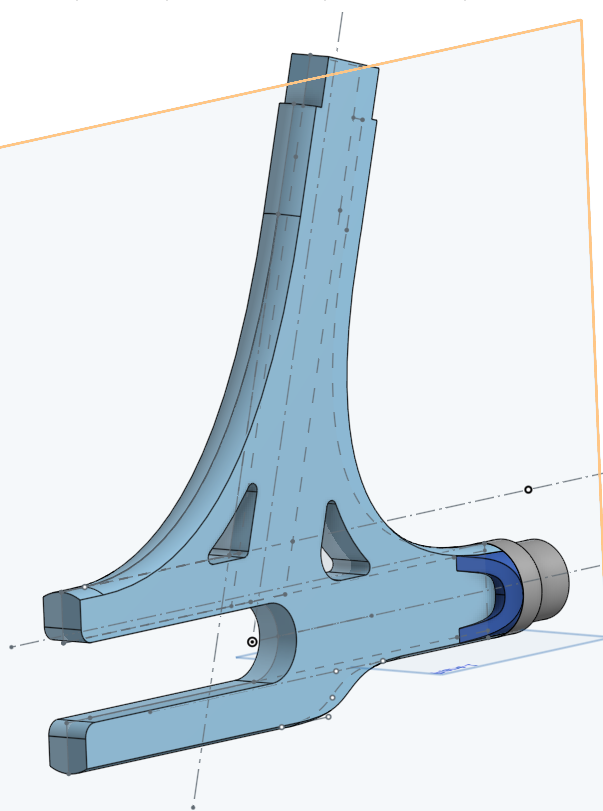

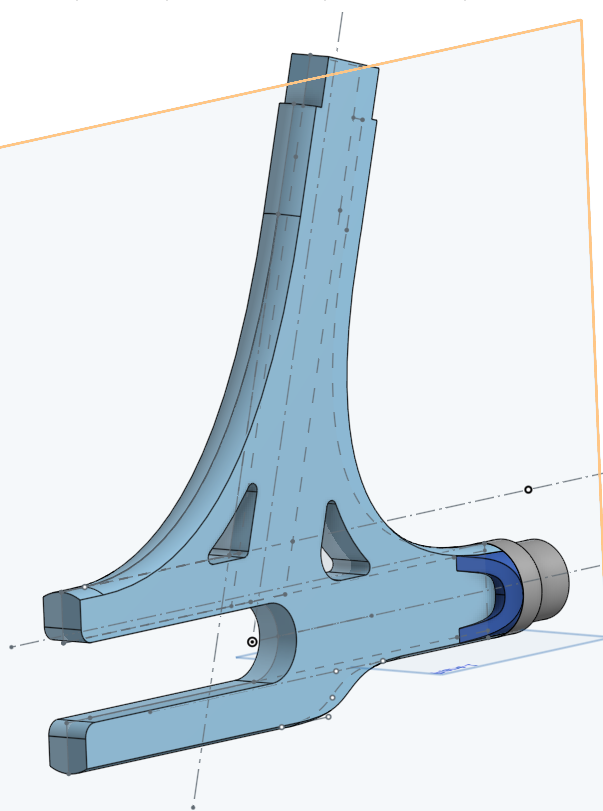

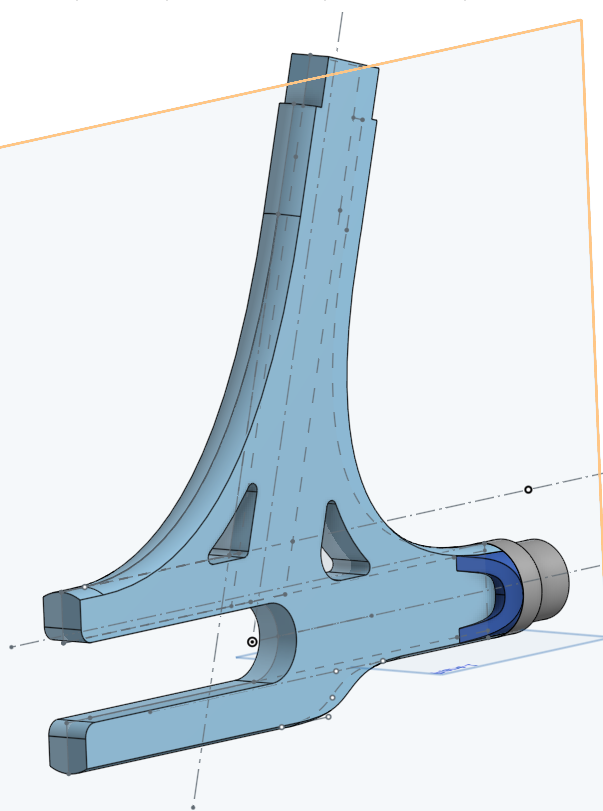

I also drew this mockup that hopefully I can get cast for free or cheaply through a connect so I could extend the slot length for more surface area. It looks chunky, but I will adjust after recieveing the tubing to get more exact measurements and also match the plug side to the profile of the dome tip. Reason I am doing the chainstay plug type is that I can't seem to find any dome tipped chainstays.

#11

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,906

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4806 Post(s)

Liked 3,932 Times

in

2,557 Posts

Is this a road or velodrome fix gear? I was under the impression you wanted this for the road. If so, why do a custom casting to make a track end instead of a horizontal road dropout tailored for fix gear riding? Same effort to make and so much nicer to own. Now the road dropout will probably require you to angle the chainstay up a tad so the wheel and axle pull out under it. (Not an issue with my "L" shaped slot - again, you are starting from scratch so why not?) If you do a road styule dropout, leave a little extra material above the slot so you can drill and tap a fender eye and for chainpeg later.

#12

Newbie

Thread Starter

Yes this is for road, but I don't see the benefit do doing a road style horizontal dropout. I assume you mean this type?

I can see how its easier to remove the wheel when needed, but I've never had issue with that with track ends.

I can see how its easier to remove the wheel when needed, but I've never had issue with that with track ends.

#13

The Wheezing Geezer

Join Date: Oct 2021

Location: Espaņola, NM

Posts: 1,056

Bikes: 1976 Fredo Speciale, Jamis Citizen 1, Ellis-Briggs FAVORI, Rivendell Clem Smith Jr.

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 414 Post(s)

Liked 920 Times

in

447 Posts

Small differences in angles between the dropouts and the stays themselves seem par for the course to me. The visual misalignment is exaggerated by longer dropout arms, though.

#14

Senior Member

Join Date: Dec 2019

Posts: 957

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Liked 263 Times

in

212 Posts

I was thinking of silver brazing. Sorry If my vocab is mixed up, I was under the impression that fillet brazing refered only to bronze brazing. I like how the tip for closer angle would work for a more open angle too, but I am trying to avoid bronze brazing so I don't need to get all the related equipment. Would silver brazing a tab into a dome tipped seatstay like this have enough surface area?https://www.torchandfile.com/reynold...nish-pair.html

I also drew this mockup that hopefully I can get cast for free or cheaply through a connect so I could extend the slot length for more surface area. It looks chunky, but I will adjust after recieveing the tubing to get more exact measurements and also match the plug side to the profile of the dome tip. Reason I am doing the chainstay plug type is that I can't seem to find any dome tipped chainstays.

I also drew this mockup that hopefully I can get cast for free or cheaply through a connect so I could extend the slot length for more surface area. It looks chunky, but I will adjust after recieveing the tubing to get more exact measurements and also match the plug side to the profile of the dome tip. Reason I am doing the chainstay plug type is that I can't seem to find any dome tipped chainstays.

But I think the way older bikes were made is you cut two slots in the end of the stay and then pushed the dropout into them. If you shove them in about half an inch or so then although it's really only the edge of the tube wall touching the dropout it's all along that length on both slots and you have a reasonable amount of area. I guess if the wall thickness is 0.7mm then you have around 70 square mm altogether for the braze to flow around.

This is a dropout on an old 531 Raleigh frame from probably the 1960s. In those days Reynolds made dropouts with those domed ends which I suppose gives you a little bit more contact. But it's still only the edges of the cut tube that are touching the dropout. I don't think they had any technology that could build up fillets in the Raleigh factory back then, and the dropout itself is just stamped out of a bit of sheet metal.

#15

Newbie

Thread Starter

I think we are on the same page now. This is the type of joint I would trying for with the seat stay.

Likes For trashbiker:

#16

Senior Member

Join Date: Dec 2019

Posts: 957

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Liked 263 Times

in

212 Posts

I think actually looking at that Raleigh that the inner wall of the tube is touching the dropout across its thickness. That should be achievable with careful shaping of the dropout.

#17

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,994

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1181 Post(s)

Liked 2,576 Times

in

1,076 Posts

Maybe not a beginner-level skill though.

I can't describe it well in words, would need to make a video, and I don't have a video camera or a tripod or know how to edit video... Not a youtuber!

But here's the basics: Hacksaw a long Vee into the end of the tube, the length you want the slot to be, longer looks better. Where the plane of the cut intersects the cylinder you get something like a parabola. Hammer those parabola curves down with many hammer blows, while rotating the stay this way and that, gradually shaping the dome as the V notch closes up. You don't have to take the two hacksaw cuts all the way down until they touch, just to the point where the original notch is now narrower than the slot for the dropout. When the domes look how you like, slot the stay precisely for the dropout.

Instead of a hemispheric or "ball-end" dome like Reynolds, you get a longer tapered dome with that sort of parabola shape, much more elegant IMHO. Bianchi used to use that shape prior to maybe 1960? Plenty of other brands/builders too.

Likes For bulgie:

#18

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,906

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4806 Post(s)

Liked 3,932 Times

in

2,557 Posts

Yes, for flat ground riding, track ends work but they have no great advantage. Pulling the wheel out takes an extra step usually. You have to pull the chain off the cog, pull the wheel out then do something with the chain or let it hang. Road dropouts skip one step. Now if you are casting from scratch, skip the derailleur hanger. Make the slot closer to true horizontal vs the classic right angles to the seatstay to allow for complete movement withing the dropout slot without changing brake pad location on the rim.

Designing for a fix gear - make that slot long! Like most of two inches. Then you can run any cog you want without messing with chain length. I can bring any cog between 12 and 24 teeth and do on the road swaps and never mess with chain length. And I do. Mountain days on Cycle Oregon I go with 17 and 24 on the hub and carry a 12. A chainwhip to unscrew cogs but no tools for the chain. Putting the wheel in and pulling it out with the 24 on is easy.

Yes I know I sound full of myself. And I confess I've never owned a track-ended bike. I do have a lifetime of road fix gear experience and know what works there. Didn't start the flip-flop hubs and on-the-road gear changes until 12 years ago when I had my custom built to do it. But 20k miles later, I would do it again; no changes. Or use a bike with the road dropouts you pictured like my other two fix gears. As long as I have a choice, I will never own a track ended bike (and if it were decreed I could only have one bike, it would be a fix gear).

#19

Newbie

Thread Starter

Claremont, CA. If you ever want to take your fix gear into the local hills and really have fun, you'll want a big cog (23 or 24) on there. If you do it with a flip-flop hub and have a normal of small one to come down; well your wheel is going to be far forward when the chain is on the big cog and might be a challenge to lift off with no slot left to slide the wheel forward. A dropout like the one shown here makes that easy (unless hitting the seatstay becomes an issue. There my "L" shaped dropout rules

Yes, for flat ground riding, track ends work but they have no great advantage. Pulling the wheel out takes an extra step usually. You have to pull the chain off the cog, pull the wheel out then do something with the chain or let it hang. Road dropouts skip one step.

Yes, for flat ground riding, track ends work but they have no great advantage. Pulling the wheel out takes an extra step usually. You have to pull the chain off the cog, pull the wheel out then do something with the chain or let it hang. Road dropouts skip one step.

#20

Newbie

Thread Starter

But here's the basics: Hacksaw a long Vee into the end of the tube, the length you want the slot to be, longer looks better. Where the plane of the cut intersects the cylinder you get something like a parabola. Hammer those parabola curves down with many hammer blows, while rotating the stay this way and that, gradually shaping the dome as the V notch closes up. You don't have to take the two hacksaw cuts all the way down until they touch, just to the point where the original notch is now narrower than the slot for the dropout. When the domes look how you like, slot the stay precisely for the dropout.

#21

Newbie

Thread Starter

Thank you all for so much free knowledge. I missed a comment from guy153 about bb drop. I checked the drawing and I had almost 90mm of drop which is way too much so I found a different bb shell and raised the bb to 68mm of drop. Now this makes my chainstay/seatstay angle 71.4. I feel silly not checking bb drop on a fixed gear to begin with, but glad it was caught before I went out and bought everything. Do I have enough wiggle room within tolerance to use a 70 degree plug style dropout? Each plug would experience .7 degrees of difference wich is tiny, but as someone else said, silver brazing relies on tight tolerances for the capillary action. I will also have .5degrees difference on my bottom headtube lug. If I made the chainstays 425mm, that would bring to angle to 70.4 which will be my fallback. Might cast the dropouts anyways for fun.

Last edited by trashbiker; 07-24-23 at 08:05 PM.

Likes For trashbiker:

#22

Senior Member

Join Date: Dec 2019

Posts: 957

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Liked 263 Times

in

212 Posts

Thank you all for so much free knowledge. I missed a comment from guy153 about bb drop. I checked the drawing and I had almost 90mm of drop which is way too much so I found a different bb shell and raised the bb to 68mm of drop. Now this makes my chainstay/seatstay angle 71.4. I feel silly not checking bb drop on a fixed gear to begin with, but glad it was caught before I went out and bought everything. Do I have enough wiggle room within tolerance to use a 70 degree plug style dropout? Each plug would experience .7 degrees of difference wich is tiny, but as someone else said, silver brazing relies on tight tolerances for the capillary action. I will also have .5degrees difference on my bottom headtube lug. If I made the chainstays 425mm, that would bring to angle to 70.4 which will be my fallback. Might cast the dropouts anyways for fun.