Common misconceptions about wheels and bike engineering

#1

Bicycling Gnome

Thread Starter

Join Date: Apr 2006

Location: 55.0N 1.59W

Posts: 1,877

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Common misconceptions about wheels and bike engineering

Is your weight carried by dangling from the upper spokes, or is it supported on the lower ones?

How are the forces on your spokes distributed around the wheel?

Do small wheeled bikes steer fast because they have less gyroscopic effect than bigger ones or because you have a higher centre of gravity on a small wheeled bike?

All of us know the answers to these old chestnuts, don't we?

Load distribution in a bicycle wheel:

https://www.astounding.org.uk/ian/wheel/

Gyroscopic forces:

https://www.sheldonbrown.com/brandt/gyro.html

https://www.sheldonbrown.com/brandt/gyro.html

https://www.google.co.uk/search?hl=en...&start=30&sa=N

How are the forces on your spokes distributed around the wheel?

Do small wheeled bikes steer fast because they have less gyroscopic effect than bigger ones or because you have a higher centre of gravity on a small wheeled bike?

All of us know the answers to these old chestnuts, don't we?

Load distribution in a bicycle wheel:

https://www.astounding.org.uk/ian/wheel/

Gyroscopic forces:

https://www.sheldonbrown.com/brandt/gyro.html

https://www.sheldonbrown.com/brandt/gyro.html

https://www.google.co.uk/search?hl=en...&start=30&sa=N

#2

Senior Member

Join Date: Jun 2006

Location: Boston Area

Posts: 1,998

Bikes: Univega Gran Turismo, Guerciotti, Bridgestone MB2, Bike Friday New World Tourist, Serotta Ti

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Stop confusing us with facts!

Speedo

Speedo

#7

Senior Member

Join Date: Dec 2008

Location: Under the Downunder

Posts: 1,014

Bikes: MTBs, BMX, Pocket MTB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

OK, I'll bite...

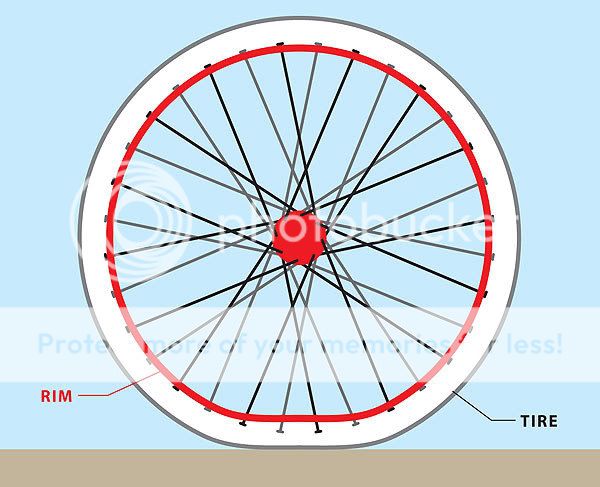

I tried to take in as much as I could from the articles, and somewhat pickup the gist as to why their conclusion was that the hub stands on the spokes directly beneath it.

However, this conclusion has really surprised me. Yes, I would have to agree with their conclusion IF the spokes were permanently fixed at their ends or welded to the rim (like the struts on a ferris-wheel), as in their theoretical illustration:

... but this is not the case in a bicycle rim. Spoke nipples do not have flanges on both sides of the rim wall, but only at the inside... and so a bicycle "spoke" in reality is not capable of holding a compression load because the spoke would simply push through it's rim hole. The equivalent illustration in real life would be more like this:

Surely a hub can only but hang from the tension of it's spokes? Any spokes that "push" are OUT of the equation.

Similarly on wheels with disc brakes... when braking forces are applied, only the pulling spokes stop the bike... inversely, only the opposite group of spokes would bear the acceleration loads.

.

#8

Banned

Join Date: Oct 2006

Posts: 2,294

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

... but this is not the case in a bicycle rim. Spoke nipples do not have flanges on both sides of the rim wall, but only at the inside... and so a bicycle "spoke" in reality is not capable of holding a compression load because the spoke would simple push through it's rim hole.

So your line of reasoning gets cut short and since the bottom part of the rim is also getting squashed by the ground, the bottom spokes have to reduce tension before the top spokes increase tension and, thus, the load is primarily "supported" by the bottom spokes (though not by compression, but, rather, reduced tension).

The pretension is like the opposite of a paper weight (which offsets lift forces with extra compression). It just adds a constant to all the forces so that we never get negative tension, but it doesn't change anything else. What's on top has nothing to do with it; The paper is not hanging from the weight.

Last edited by makeinu; 02-12-09 at 12:10 AM.

#9

Uber Goober

If you'll notice in his analysis, the tension/compression in the spokes is the change from the original uniform-tension condition. So in reality, all spokes are in tension before the load is applied and afterwards. Which to me, completely invalidates his conclusion that the load somehow stands on the spokes. He is taking a reduction in tension to mean an uplift, which it is not.

__________________

"be careful this rando stuff is addictive and dan's the 'pusher'."

"be careful this rando stuff is addictive and dan's the 'pusher'."

#10

Senior Member

Join Date: May 2005

Location: Albany, WA

Posts: 7,393

Mentioned: 16 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Likes: 0

Liked 7 Times

in

6 Posts

In a old-fashioned wooden-spoked wagon wheel, it is rather obvious the axle stands on the bottom spokes. When you look at such a wheel, you don't "care" whether the spokes are under compression or not - it does not confuse.

Introduce tension in the spokes, and suddenly people throw up their hands and say, "ah, so now we are hanging, no longer standing!" The wheel doesn't care what the spoke pre-tension is, whether it is positive or negative. The basic function of the spokes remain the same. Forget about hanging or standing semantics - the bottom spokes are still doing the work. If you loaded and unloaded a stationary wheel thousands of times such that the bottom spokes each time lost almost all of their tension, those bottom spokes would eventually break, since they are doing all the work. The rest of the spokes would be just fine.

#11

Senior Member

Join Date: May 2005

Location: Albany, WA

Posts: 7,393

Mentioned: 16 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Likes: 0

Liked 7 Times

in

6 Posts

Now ignore the direction that gravity gives that scenario, and you have the wheel's situation.

#12

Senior Member

Join Date: Dec 2008

Location: Under the Downunder

Posts: 1,014

Bikes: MTBs, BMX, Pocket MTB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Not meaning to upset anyone, just friendly forum conversation here.

I actually flat-spotted my 24 inch BMX cruiser rear wheel from a bad jump landing, so that it looked exactly like my illustration. I've also seen this on MTB downhill wheels as I meched for a couple of pros that like to ride with low tire pressure even over rock gardens. About 4 nipples at the flat spots are sunken and can be easily turned by hand (thank goodness they're double-walled rims so they didn't quite reach the tubes) and the spokes are loose and wobbly. I can move them side to side by about an inch so they might as well not be there. They didn't break. Also out of necessity, the guys had to continue to use their wheels in this condition until we got back to the workshop, and in my case until I saw the flat-spot while loading up the bikes. Every time the hub was directly over the loose spokes, I didn't notice any hub "drop," in fact the wheels worked just fine, no sounds, no creaking... still true side to side.

Obviously the wheels had to be rebuilt because the "load" was then being shared by a lesser number of spokes and some would be over-taxed (like a rugby team with several players in the sin bin).

I don't understand the principle of "negative pre-tension" that produces lift. This would mean the lesser the pre-tension the greater the lift? But isn't the tension up top increasing as the hub pushes harder down the wheel?

We also raced in Australia up at the Mount Buller Ski Resort during summer some years ago where the national downhill track was literally head sized rocks all the way down. After several practice runs the vibration was so bad that ALL the spokes on the front and rear wheels had loosened to a point where they resembled a wheel that had just been hand laced prior to tensioning (like you can move the hubs from side to side). Needless to say, those wheels were rolling with the hubs literally hanging from the top of the rims. We tightened spokes after every run after we caught that.

Now I've been working on bikes long enough to know that there are a few weird things that ARE the opposite of what they seem, so I'm open and willing to learn. So I have a feeling that, the fact that I haven't grasped the other theorem would mean that none of what I said really matters?

So what am I missing? I'd really like to get my head around it if I can.

Cheers - Pocko

.

I actually flat-spotted my 24 inch BMX cruiser rear wheel from a bad jump landing, so that it looked exactly like my illustration. I've also seen this on MTB downhill wheels as I meched for a couple of pros that like to ride with low tire pressure even over rock gardens. About 4 nipples at the flat spots are sunken and can be easily turned by hand (thank goodness they're double-walled rims so they didn't quite reach the tubes) and the spokes are loose and wobbly. I can move them side to side by about an inch so they might as well not be there. They didn't break. Also out of necessity, the guys had to continue to use their wheels in this condition until we got back to the workshop, and in my case until I saw the flat-spot while loading up the bikes. Every time the hub was directly over the loose spokes, I didn't notice any hub "drop," in fact the wheels worked just fine, no sounds, no creaking... still true side to side.

Obviously the wheels had to be rebuilt because the "load" was then being shared by a lesser number of spokes and some would be over-taxed (like a rugby team with several players in the sin bin).

I don't understand the principle of "negative pre-tension" that produces lift. This would mean the lesser the pre-tension the greater the lift? But isn't the tension up top increasing as the hub pushes harder down the wheel?

We also raced in Australia up at the Mount Buller Ski Resort during summer some years ago where the national downhill track was literally head sized rocks all the way down. After several practice runs the vibration was so bad that ALL the spokes on the front and rear wheels had loosened to a point where they resembled a wheel that had just been hand laced prior to tensioning (like you can move the hubs from side to side). Needless to say, those wheels were rolling with the hubs literally hanging from the top of the rims. We tightened spokes after every run after we caught that.

Now I've been working on bikes long enough to know that there are a few weird things that ARE the opposite of what they seem, so I'm open and willing to learn. So I have a feeling that, the fact that I haven't grasped the other theorem would mean that none of what I said really matters?

So what am I missing? I'd really like to get my head around it if I can.

Cheers - Pocko

.

Last edited by Pocko; 02-12-09 at 07:23 AM.

#13

You gonna eat that?

Spoke nipples are designed only to put the spoke in tension, not compression. The analysis in the OP neglects this; you can't "push on a rope".

#14

Banned

Join Date: Oct 2006

Posts: 2,294

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Not meaning to upset anyone, just friendly forum conversation here.

I actually flat-spotted my 24 inch BMX cruiser rear wheel from a bad jump landing, so that it looked exactly like my illustration. I've also seen this on MTB downhill wheels as I meched for a couple of pros that like to ride with low tire pressure even over rock gardens. About 4 nipples at the flat spots are sunken and can be easily turned by hand (thank goodness they're double-walled rims so they didn't quite reach the tubes) and the spokes are loose and wobbly. I can move them side to side by about an inch so they might as well not be there. They didn't break. Also out of necessity, the guys had to continue to use their wheels in this condition until we got back to the workshop, and in my case until I saw the flat-spot while loading up the bikes. Every time the hub was directly over the loose spokes, I didn't notice any hub "drop," in fact the wheels worked just fine, no sounds, no creaking... still true side to side.

Obviously the wheels had to be repaired because the "load" was then being shared by a lesser number of spokes and some would be over-taxed (like a rugby team with several players in the sin bin).

I actually flat-spotted my 24 inch BMX cruiser rear wheel from a bad jump landing, so that it looked exactly like my illustration. I've also seen this on MTB downhill wheels as I meched for a couple of pros that like to ride with low tire pressure even over rock gardens. About 4 nipples at the flat spots are sunken and can be easily turned by hand (thank goodness they're double-walled rims so they didn't quite reach the tubes) and the spokes are loose and wobbly. I can move them side to side by about an inch so they might as well not be there. They didn't break. Also out of necessity, the guys had to continue to use their wheels in this condition until we got back to the workshop, and in my case until I saw the flat-spot while loading up the bikes. Every time the hub was directly over the loose spokes, I didn't notice any hub "drop," in fact the wheels worked just fine, no sounds, no creaking... still true side to side.

Obviously the wheels had to be repaired because the "load" was then being shared by a lesser number of spokes and some would be over-taxed (like a rugby team with several players in the sin bin).

However, under normal circumstances the whole purpose of the tension is to keep you in the mode of operation where the wheel can behave like a wagon wheel without putting a compressive load on the spokes.

pretension-load=net force

If load were increasing the overall tension up top, then it would be better to have less pretension to balance it out, but that's not the case. The tensioned wheel is stronger because the tension opposes, rather than contributes, to the load.

I think what you're missing is the notion of storing up force for later. If you need 100 pounds of force to support a load and you can preset -100 pounds of force ahead of time then your components only need to be able to withstand from -100 to 0 pounds of force as opposed to 0 to 100 pounds of force. It's just like adding an extra 100 dollars into your checking account; Although the start and end balances are different all other transactions are the same.

Last edited by makeinu; 02-12-09 at 08:23 AM.

#15

multimodal commuter

Join Date: Nov 2006

Location: NJ, NYC, LI

Posts: 19,808

Bikes: 1940s Fothergill, 1959 Allegro Special, 1963? Claud Butler Olympic Sprint, Lambert 'Clubman', 1974 Fuji "the Ace", 1976 Holdsworth 650b conversion rando bike, 1983 Trek 720 tourer, 1984 Counterpoint Opus II, 1993 Basso Gap, 2010 Downtube 8h, and...

Mentioned: 584 Post(s)

Tagged: 0 Thread(s)

Quoted: 1908 Post(s)

Liked 574 Times

in

339 Posts

Okay, I'll bite. I agree with that; but not with this:

Even if, as you say:

I'm not at all sure the reason for it is If it is true, as you say, that it does not necessarily follow that they haven't been doing any work. The bottom spokes would be the ones to suffer, not because they're doing all the work, but because they're doing nothing or worse: getting in the way. Let's say you tried your experiment many different ways, always with wheel intended for the same number of spokes (16 or 32 would be good), but in each rendition you have different spokes missing. Remove four spokes from the bottom of one wheel, four from the top of another, four from the leading or trailing edge from another; four from each leading and trailing edge of one; all but the bottom four spokes from one, all but the top four spokes from another, and so on. I think we agree that removing the four bottom spokes will wreak the least havoc of all; but I'd argue the reason for this is that they are the most dispensable ones rather than the most essential.

#16

Banned

Join Date: Oct 2006

Posts: 2,294

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Even if, as you say:I'm not at all sure the reason for it is If it is true, as you say, that it does not necessarily follow that they haven't been doing any work. The bottom spokes would be the ones to suffer, not because they're doing all the work, but because they're doing nothing or worse: getting in the way. Let's say you tried your experiment many different ways, always with wheel intended for the same number of spokes (16 or 32 would be good), but in each rendition you have different spokes missing. Remove four spokes from the bottom of one wheel, four from the top of another, four from the leading or trailing edge from another; four from each leading and trailing edge of one; all but the bottom four spokes from one, all but the top four spokes from another, and so on. I think we agree that removing the four bottom spokes will wreak the least havoc of all; but I'd argue the reason for this is that they are the most dispensable ones rather than the most essential.

Last edited by makeinu; 02-12-09 at 08:27 AM.

#17

Bicycling Gnome

Thread Starter

Join Date: Apr 2006

Location: 55.0N 1.59W

Posts: 1,877

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

The writer of the article at https://www.astounding.org.uk/ian/wheel/ claims that compressed spokes carry loads. This is clearly mad as the drawing made by Poko points out. It is obvious that the loads are carried in tension by the majority of the spokes pretty much after the manner of the wire ropes in a suspension bridge carry load or the shrouds holding up a mast on a sailing boat transmit loads into the hull.

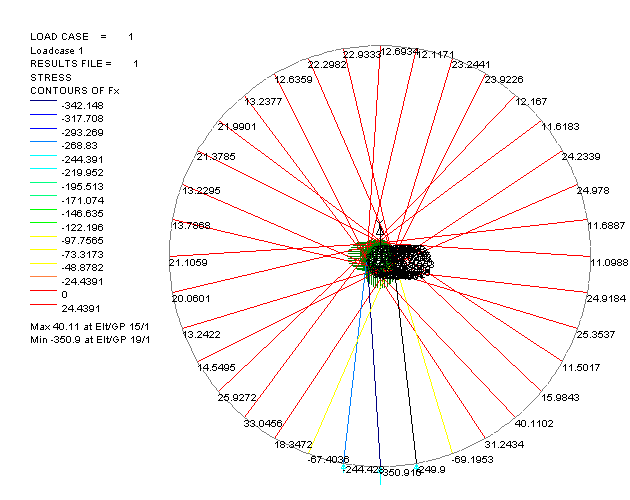

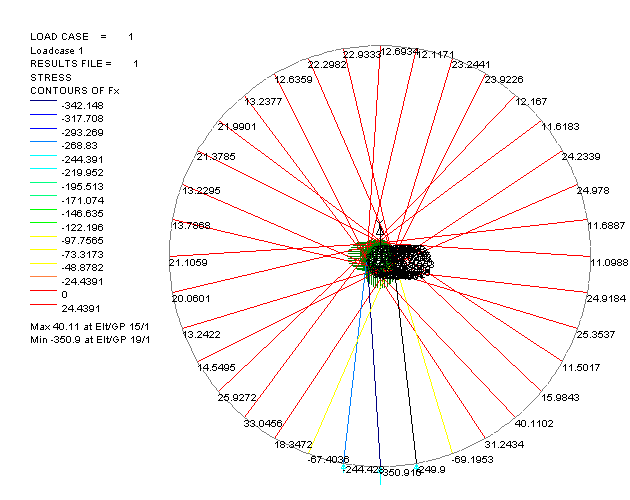

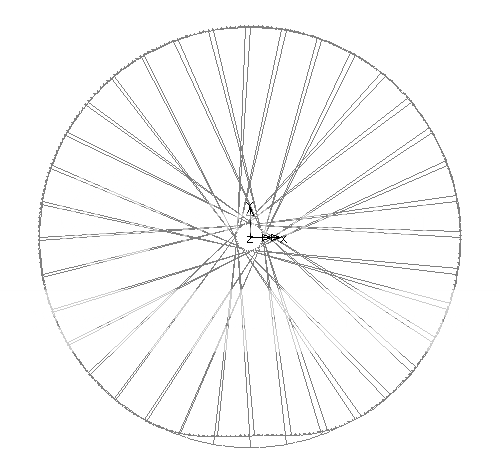

What I found interesting is that his model shows that the loads on individual spokes vary greatly as the wheel rotates and the rim distorts minutely at the contact patch. This unloads the lower spokes momentarily, while other become tighter in response to the small change in shape of the rim.

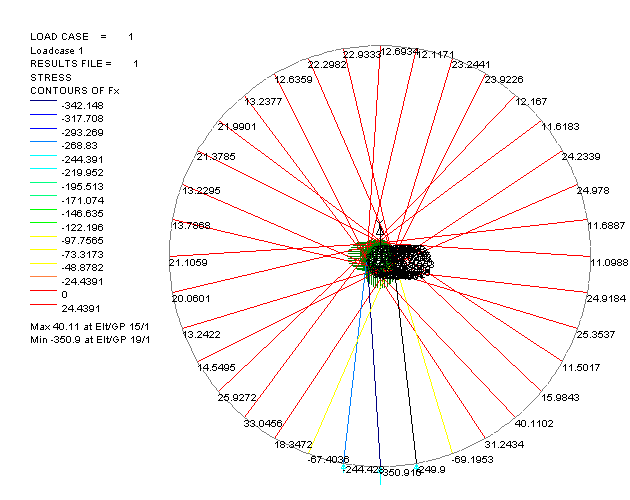

No spokes are taking any load in compression, even though their tension in the positions between five o clock and seven oclock goes temporarily negative. That doesn't mean that the nipples poke through to the tube. In some of those links I read yesterday the lengths of the spokes were pulled and relaxed by only tiny parts of a mm - less than 0.2mm which he gives as the maximum distortion of the rim at the contact point. Where the yellow coloured spokes relax, their neighbours slightly further up (about four spokes up from six o clock on either side) tighten up in response to the rim moving out of true. Look at the values on the diagram. The tension at five and seven o clock rises to 40N and 33N to absorb the load. The spokes at the top of the wheel are lighter loaded.

The links I posted at the top of the thread are pretty interesting and worth looking at I think.

This stuff makes my head hurt.

Last edited by EvilV; 02-12-09 at 01:48 PM.

#18

Bicycling Gnome

Thread Starter

Join Date: Apr 2006

Location: 55.0N 1.59W

Posts: 1,877

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I doubt it. You seem a fairly polite fellow yourself. Perhaps you are suggesting I have nothing to teach you about engineering. This may be true. I simply put up the thread because I thought it interesting and know that I have sometimes misunderstood how these issues like loading in bicycle wheels and the contribution of gyroscopic effects to stability in bicycles, really work.

#19

Junior Member

Join Date: Dec 2007

Posts: 11

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Think of the spokes as long, stiff springs because that is how they act within the normal range of forces they encounter. A spoke will not carry much compression load before it buckles anyways even if it was attached to the rim.

#20

Senior Member

Join Date: Sep 2005

Location: Michigan

Posts: 3,706

Bikes: Trek 730 (quad), 720 & 830, Bike Friday NWT, Brompton M36R & M6R, Dahon HAT060 & HT060, ...

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 840 Post(s)

Liked 336 Times

in

251 Posts

I think that this is also true to a degree for the wooden spokes mentioned by jur above.

#21

Senior Member

__________________

novis rebus studentem

novis rebus studentem

#22

Senior Member

Join Date: May 2005

Location: Albany, WA

Posts: 7,393

Mentioned: 16 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Likes: 0

Liked 7 Times

in

6 Posts

Perhaps the simplest way to go about understanding this, is to ignore individual spokes for the moment.

Where the wheel touches the ground, there is a force on the rim inwards. As you might expect, in that spot there is a small amount of inwards deformation of the rim (think very small). This deformation is local only, since the force is local. So, at this local area of inwards deformation, between the rim and axle, the wheel structure is experiencing a small compression - the distance between axle and rim becomes less.

Now think for a moment how wheels are made. Initially, wheels were solid discs and that presented no problem to understand. If you overloaded your wooden disc wheel, the axle would crush through the bottom bit of the wheel and you would curse and go and cut a new disc.

Some bright spark thought that wheels might work equally well if the were made from wooden spokes instead of a disc. It was just a problem how to keep those wooden spokes in place, so they came up with the idea of a steel tyre which is slightly too small, so that it puts the wheel structure under radial compression, keeping everything together.

Still later the idea surfaced of making a metal spoked wheel. The new problem was, if you make the spokes thin enough so the weight is acceptable, they would simply buckle under load. So the next bright spark thought, well what if we put those thin metal spokes under pre-tension, enough to cancel out the load force that would buckle those spokes? Well as we all know, this was a great idea; a bicycle wheel is an enormously strong structure while being very light indeed, all because of thin wire spokes under tension.

The problem has not changed since the old days: If you overload a wheel it will crush through the bottom part of the wheel. The wheel pieces are not strong enough by themselves.

So what typically happens to a wire spoked wheel, is because the bottom spokes some lose tension under load due to the local inwards deformation, there is a maximum load where they lose all tension and they will immediately buckle if the load exceeds the maximum. When this happens, the wheel has lost all capability to resist further load and the rim at the bottom will deform inwards, in effect dropping the axle downwards (same as crushing your wooden disc wheel). Deform far enough and the rim suffers permanent deformation or under very severe conditions, it will completely collapse inwards at the bottom.

Spokes break due to metal fatigue at the elbow. With each wheel revolution, each spoke undergoes a small loss of tension as it passes through BDC; and each time the elbow bends to and fro a tiny bit. Do that enough times, and the tiny cracks from metal fatigue will break off at the elbow. So it makes sense to design spokes with no elbows. This also a very old idea - check out this window made form an old wheel - no elbows and nipples at the hub, all seemingly modern ideas:

So while wheel theory has not changed, the clever idea of pre-tensioning spokes has caused enormous confusion of what actually happens in a metal wire spoked wheel.

Where the wheel touches the ground, there is a force on the rim inwards. As you might expect, in that spot there is a small amount of inwards deformation of the rim (think very small). This deformation is local only, since the force is local. So, at this local area of inwards deformation, between the rim and axle, the wheel structure is experiencing a small compression - the distance between axle and rim becomes less.

Now think for a moment how wheels are made. Initially, wheels were solid discs and that presented no problem to understand. If you overloaded your wooden disc wheel, the axle would crush through the bottom bit of the wheel and you would curse and go and cut a new disc.

Some bright spark thought that wheels might work equally well if the were made from wooden spokes instead of a disc. It was just a problem how to keep those wooden spokes in place, so they came up with the idea of a steel tyre which is slightly too small, so that it puts the wheel structure under radial compression, keeping everything together.

Still later the idea surfaced of making a metal spoked wheel. The new problem was, if you make the spokes thin enough so the weight is acceptable, they would simply buckle under load. So the next bright spark thought, well what if we put those thin metal spokes under pre-tension, enough to cancel out the load force that would buckle those spokes? Well as we all know, this was a great idea; a bicycle wheel is an enormously strong structure while being very light indeed, all because of thin wire spokes under tension.

The problem has not changed since the old days: If you overload a wheel it will crush through the bottom part of the wheel. The wheel pieces are not strong enough by themselves.

So what typically happens to a wire spoked wheel, is because the bottom spokes some lose tension under load due to the local inwards deformation, there is a maximum load where they lose all tension and they will immediately buckle if the load exceeds the maximum. When this happens, the wheel has lost all capability to resist further load and the rim at the bottom will deform inwards, in effect dropping the axle downwards (same as crushing your wooden disc wheel). Deform far enough and the rim suffers permanent deformation or under very severe conditions, it will completely collapse inwards at the bottom.

Spokes break due to metal fatigue at the elbow. With each wheel revolution, each spoke undergoes a small loss of tension as it passes through BDC; and each time the elbow bends to and fro a tiny bit. Do that enough times, and the tiny cracks from metal fatigue will break off at the elbow. So it makes sense to design spokes with no elbows. This also a very old idea - check out this window made form an old wheel - no elbows and nipples at the hub, all seemingly modern ideas:

So while wheel theory has not changed, the clever idea of pre-tensioning spokes has caused enormous confusion of what actually happens in a metal wire spoked wheel.

#23

Banned

Join Date: Oct 2006

Posts: 2,294

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

So what typically happens to a wire spoked wheel, is because the bottom spokes some lose tension under load due to the local inwards deformation, there is a maximum load where they lose all tension and they will immediately buckle if the load exceeds the maximum. When this happens, the wheel has lost all capability to resist further load and the rim at the bottom will deform inwards, in effect dropping the axle downwards (same as crushing your wooden disc wheel). Deform far enough and the rim suffers permanent deformation or under very severe conditions, it will completely collapse inwards at the bottom.

#24

Senior Member

Join Date: May 2005

Location: Albany, WA

Posts: 7,393

Mentioned: 16 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Likes: 0

Liked 7 Times

in

6 Posts

Agreed... all the confusion arises when the words hanging and standing are introduced. The chap from the OP explains it well but still managed to perpetuate confusion (and so did I!) by using those 2 words.

The the original question posed by EvilV, does a hub hang or stand, is therefore an incorrect question - it is neither. The hub is supported by the entire structure, ie all the spokes, whether they be infinite in number (solid disc) or few in number.

The the original question posed by EvilV, does a hub hang or stand, is therefore an incorrect question - it is neither. The hub is supported by the entire structure, ie all the spokes, whether they be infinite in number (solid disc) or few in number.

Last edited by jur; 02-12-09 at 06:10 PM.

#25

Senior Member

Join Date: May 2005

Location: Albany, WA

Posts: 7,393

Mentioned: 16 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Likes: 0

Liked 7 Times

in

6 Posts

The argument that the bottom spokes are stressed, stems form the observation that they are the ones to suffer metal fatigue in the static wheel thought experiment. Analysis and experiment have shown that the rest of the spokes do not experience a corresponding increase in tension - maybe a marginal amount - but not a cumulative amount equalling the reduction of tension of the bottom ones. The only spokes that go through a tension change are the bottom ones, simply because the inwards deformation is local.