Rehabilitation of a Dahon speed D7, big play in the hinge

#1

Senior Member

Thread Starter

Join Date: Apr 2015

Location: High Normandy, France

Posts: 58

Bikes: Raleigh Maverick '15, Dahon Speed D7 ~2007, and a lot :)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Rehabilitation of a Dahon speed D7, big play in the hinge

Hi

I bought for cheap a used Dahon D7, sell for parts cause of big problems with it hinge.

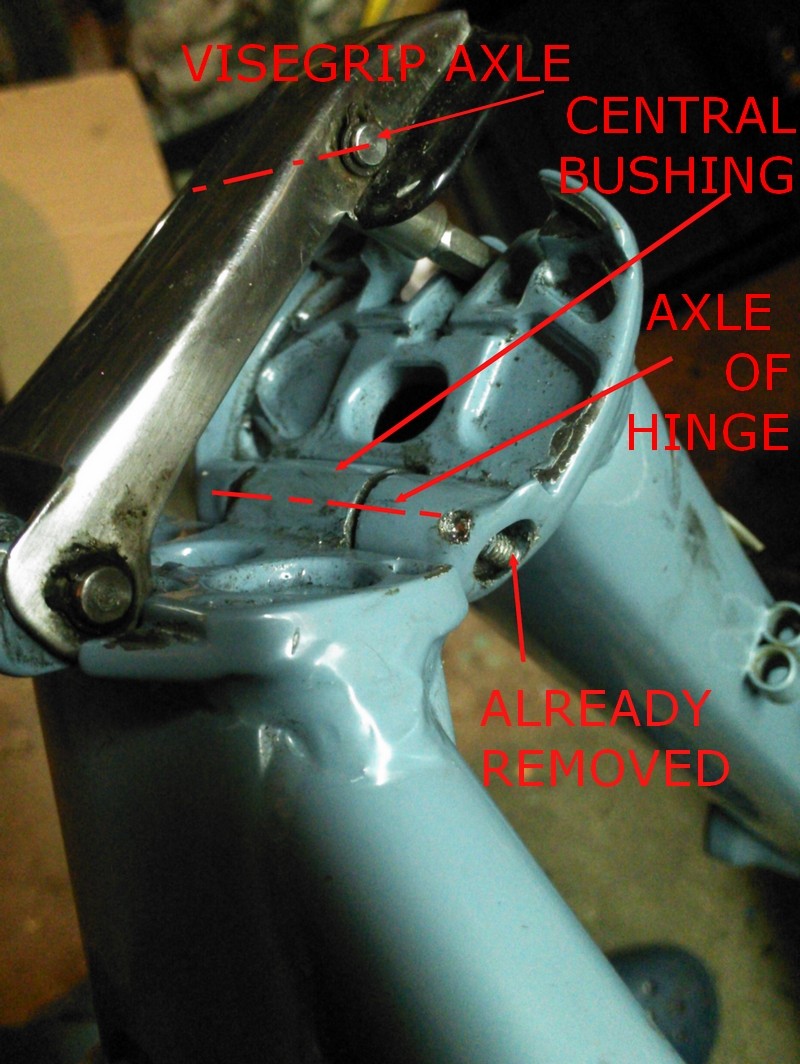

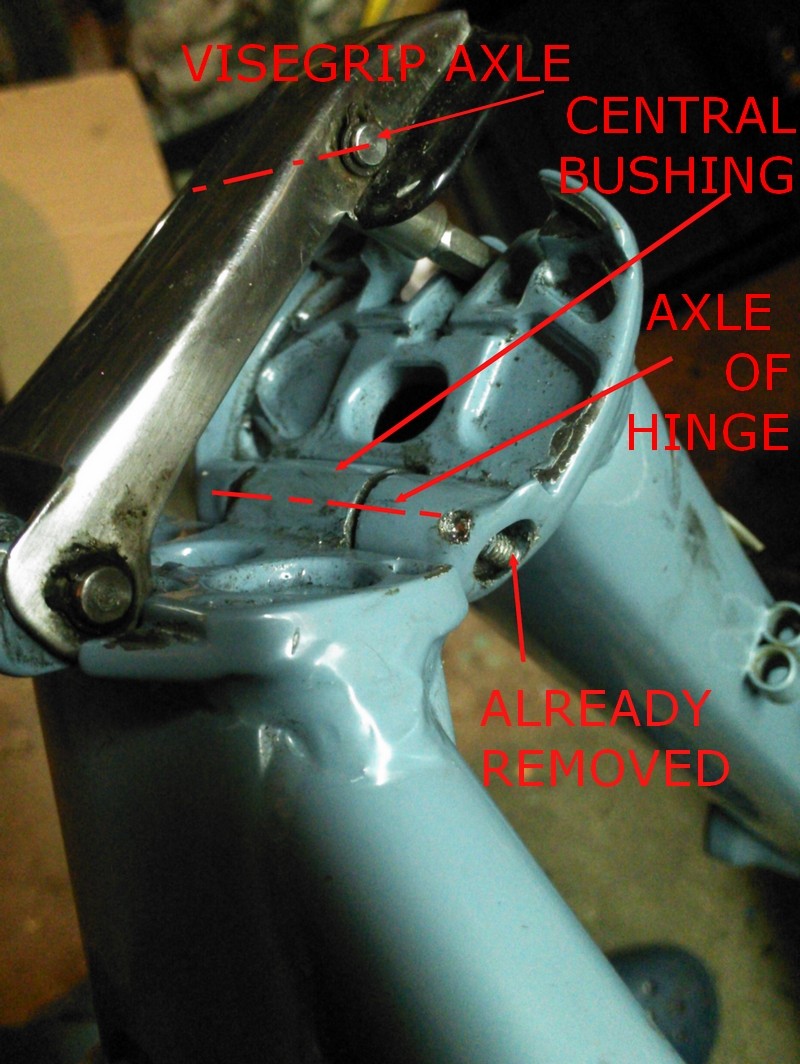

The axle of the Visegrip is bent, but the bigger problem is an enormous play between the 2 parts of frame. The central bushing is bend too cause of a lack of maintenance, and it cause this play. Like in this video, but harder on mine ...

...

This frame is made of cromo 4130 steel , so welding is possible if necessary.

, so welding is possible if necessary.

My idea is to remove the axle, look how the bushings are going, made a ring for the central bushing to make it rounder and a new axle.

But 1st problem: the axle move a little, but i have no access to pull or push it easily. I have try to glue it to a screw head and pull, but epoxy glue is too weak... Have you an idea before weld it to a stick of steel and pull ? A little explicative picture:

And none of you have had this problem? I found almost nothing on the web... I see that:

DEBCAR Story

Very interesting, it prove that this problem could be repaired but unfortunately the Jetstream's hinge is different.

And i use to contact Dahon support and forum but no answer.

Any idea, help or constructive opinion is welcome .

.

If I can repair it, I guess i will upgrade a little the bike and convert it to a mini road or touring bike, to have fun during vacations or travels.

Thanks

I bought for cheap a used Dahon D7, sell for parts cause of big problems with it hinge.

The axle of the Visegrip is bent, but the bigger problem is an enormous play between the 2 parts of frame. The central bushing is bend too cause of a lack of maintenance, and it cause this play. Like in this video, but harder on mine

...

...This frame is made of cromo 4130 steel

, so welding is possible if necessary.

, so welding is possible if necessary.My idea is to remove the axle, look how the bushings are going, made a ring for the central bushing to make it rounder and a new axle.

But 1st problem: the axle move a little, but i have no access to pull or push it easily. I have try to glue it to a screw head and pull, but epoxy glue is too weak... Have you an idea before weld it to a stick of steel and pull ? A little explicative picture:

And none of you have had this problem? I found almost nothing on the web... I see that:

DEBCAR Story

Very interesting, it prove that this problem could be repaired but unfortunately the Jetstream's hinge is different.

And i use to contact Dahon support and forum but no answer.

Any idea, help or constructive opinion is welcome

.

.If I can repair it, I guess i will upgrade a little the bike and convert it to a mini road or touring bike, to have fun during vacations or travels.

Thanks

#2

Full Member

Join Date: Apr 2012

Location: Nottingham

Posts: 440

Bikes: Mezzo I4, Trek 1200, Rudge (Montague) BiFrame, Bickerton

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 6 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

If its anything like the axle on the Dahon Jack then the end of the axle is drilled and tapped, probably an M5 screw thread. With the grub screw removed (as you have already done) screw a bolt into the end of the axle and pull. Expect it to be corroded and difficult to move so try soaking it in penetrating oil/spray first.

Good luck.

Good luck.

#3

Senior Member

Thread Starter

Join Date: Apr 2015

Location: High Normandy, France

Posts: 58

Bikes: Raleigh Maverick '15, Dahon Speed D7 ~2007, and a lot :)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Unfortunately the end of the axle is slick, i tried to drill it but my cheap bits have only scratch it (I love so much to drill hardened stainless steel  , like the cogs) ! Plus, if he's free in the hinge it would be very hard to drill... And the frame is hard to keep in place while drilling, I think about some machining assembly to maintain it into the vice under the drill.

, like the cogs) ! Plus, if he's free in the hinge it would be very hard to drill... And the frame is hard to keep in place while drilling, I think about some machining assembly to maintain it into the vice under the drill.

The hinge have already drink a lot of WD40, the axle can move on ~5mm but it block just before the end of the hole. I used the dremel to enlarge a little the end of the hole but it's not enough...

Seems the best thing to do now is to weld something on it and pull.

, like the cogs) ! Plus, if he's free in the hinge it would be very hard to drill... And the frame is hard to keep in place while drilling, I think about some machining assembly to maintain it into the vice under the drill.

, like the cogs) ! Plus, if he's free in the hinge it would be very hard to drill... And the frame is hard to keep in place while drilling, I think about some machining assembly to maintain it into the vice under the drill.The hinge have already drink a lot of WD40, the axle can move on ~5mm but it block just before the end of the hole. I used the dremel to enlarge a little the end of the hole but it's not enough...

Seems the best thing to do now is to weld something on it and pull.

#4

Banned

Join Date: Dec 2013

Location: Olney Illinois USA

Posts: 1,021

Bikes: to many

Mentioned: 18 Post(s)

Tagged: 0 Thread(s)

Quoted: 213 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

first .. the vid is cute ... but when the bike is folded you really don't want to ride it... meaning does it matter if there is play ?

Of course there should be no play when the frame is not folded and the latch adjusted correctly....

Latches kits are available, not super cheap but available

Of course there should be no play when the frame is not folded and the latch adjusted correctly....

Latches kits are available, not super cheap but available

#5

Senior Member

Thread Starter

Join Date: Apr 2015

Location: High Normandy, France

Posts: 58

Bikes: Raleigh Maverick '15, Dahon Speed D7 ~2007, and a lot :)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Folded or not, so much of play isn't normal, it mean that the hinge have a big problem...

I have found some spare parts but it's rather rare, and for my bike I think it could'nt resolve the problem because the central part of the hinge seems to be a little flare at one end. So I think that replace the axle would not be enough.

But if you know some replacement kits for the hinge, do you know how to replace the axle "in theory" ? Or are you talking about these kits ?

Anyway the axle of this part of the hinge in bent too on mine, but a good screw should replace it.

Thanks

I have found some spare parts but it's rather rare, and for my bike I think it could'nt resolve the problem because the central part of the hinge seems to be a little flare at one end. So I think that replace the axle would not be enough.

But if you know some replacement kits for the hinge, do you know how to replace the axle "in theory" ? Or are you talking about these kits ?

Anyway the axle of this part of the hinge in bent too on mine, but a good screw should replace it.

Thanks

#7

Full Member

Join Date: Apr 2012

Location: Nottingham

Posts: 440

Bikes: Mezzo I4, Trek 1200, Rudge (Montague) BiFrame, Bickerton

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 6 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

If the main hinge pin is free enough to move by 5mm and can rotate freely then it seems unlikley what welding something onto it to pull it out will work. Is there even enough space around the recess to get a welding tip or rod to contact the end of the hinge pin? I suspect that either there is a burr on the inside of the recess which is stopping the pin from dropping out or the hinge pin is bent. The latter is more likley as you have already opened the recess out with a dremel. I think you might need to take it to an engineering shop that has a good pillar drill with a large machine vice and high quality drill bits. It might be possible to stop the pin spinning when drilling by poring Loctite retaining compound into the hole. You might need to wash the wd40 out first with alcohol to get the retaining compound to bond to the metal.

#8

Senior Member

Thread Starter

Join Date: Apr 2015

Location: High Normandy, France

Posts: 58

Bikes: Raleigh Maverick '15, Dahon Speed D7 ~2007, and a lot :)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

@Bruce that was one of my 1st idea, with a thread on the hole to make an extractor, but the top of the hinge is cambered (not easy to drill on that...) and the cromo is hard to drill. And I fear that could weakens the frame.

@cpg: the pin is not totaly free, it need some help to move or rotate (press on it, tap on or shake the frame). I don't think it could remain a blur into the hole, but your idea that the pin could be bent and block is good. It's a ~8mm pin, light enough for the main axle of the frame... It could be not easy to access to weld something on it too, I plan to but a metal rod on the "-" of the welding machine, cause the pin is not accessible, and make some points of welding between the rod and the pin, it should be enough strong to pull it in a vise.

By using a drill press you mean destroy the pin or try to made a thread into it ?

An other possibility is to cut the pin in 3 parts, using a very thin saw blade between the bushings, but do that without damage these last seems to be rather impossible...

@cpg: the pin is not totaly free, it need some help to move or rotate (press on it, tap on or shake the frame). I don't think it could remain a blur into the hole, but your idea that the pin could be bent and block is good. It's a ~8mm pin, light enough for the main axle of the frame... It could be not easy to access to weld something on it too, I plan to but a metal rod on the "-" of the welding machine, cause the pin is not accessible, and make some points of welding between the rod and the pin, it should be enough strong to pull it in a vise.

By using a drill press you mean destroy the pin or try to made a thread into it ?

An other possibility is to cut the pin in 3 parts, using a very thin saw blade between the bushings, but do that without damage these last seems to be rather impossible...

#9

Full Member

Join Date: Apr 2012

Location: Nottingham

Posts: 440

Bikes: Mezzo I4, Trek 1200, Rudge (Montague) BiFrame, Bickerton

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 6 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

Yes, my idea was drill the pin and effectively destroy it and replace it with a new one. You might find that when the pin is finally removed from the frame that the holes are so big due to wear that you need a bigger pin or you will need to drill the holes to a larger size and install a bushing to allow an 8mm pin to fit. Phosphor bronze bushes perhaps?

As you say, you could cut the pin in two places, ie, between the two points where the two half's of the frame/hinge come together. A hacksaw probably wont cut the pin if it has been hardened. You could use a thin cutting disk in the dremel or a 1mm cutting disk in an angle grinder. This method will almost certainly mean removing a small amount of material from the two joints so washers or spacers placed between the two joints will be needed to remove the slack when the hinge is reassembled. Try cutting the lower one first and removing that piece of the pin. This may be enough for the upper part to come out without having to make the second cut.

As you say, you could cut the pin in two places, ie, between the two points where the two half's of the frame/hinge come together. A hacksaw probably wont cut the pin if it has been hardened. You could use a thin cutting disk in the dremel or a 1mm cutting disk in an angle grinder. This method will almost certainly mean removing a small amount of material from the two joints so washers or spacers placed between the two joints will be needed to remove the slack when the hinge is reassembled. Try cutting the lower one first and removing that piece of the pin. This may be enough for the upper part to come out without having to make the second cut.

#10

Senior Member

Join Date: May 2005

Location: Albany, WA

Posts: 7,393

Mentioned: 16 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Likes: 0

Liked 7 Times

in

6 Posts

When hinge is suitably tightly shut, is there movement as well? I would think if the hinge is firm while shut then movement while open is not really important. My approach would be to use a hard rubber sheet between the hinge faces to get it really tight.

#11

Senior Member

Join Date: May 2005

Location: Albany, WA

Posts: 7,393

Mentioned: 16 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Likes: 0

Liked 7 Times

in

6 Posts

Also, in some cases there is a grub screw in the central part of the hinge, to hold it in place even if the blocking screw in the end of tge hole is out. Look for a grub screw in the central part.

#12

Senior Member

Thread Starter

Join Date: Apr 2015

Location: High Normandy, France

Posts: 58

Bikes: Raleigh Maverick '15, Dahon Speed D7 ~2007, and a lot :)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

@cpg: I'll see when the pin will be pull out of the hinge, but I also thought to enlarge the hole and put a bigger pin, as the material is rather oversize. It seems that a good 8mm screw can support 300kg in shearing, it's rather large. A 10mm must be better of course, but it's large for the hinge...

Good idea to try first to cut 1 time and pull the pin, if welding don't work I guess i'll try this with dremel.

@jur: for the moment i can't close tightly the hinge, I don't know if it's cause of the play around the axle or the vise which have problems too... The adjustment screw is totally screwed.

Put something as a wedge is an idea too, but I will not trust rubber to do that, too soft. Eventually a little sheet of aluminium or steel, screwed, but it's not totally trustfull for me ...

...

I haven't see any screw in the central part, but I'll look again. However it's the role of the little screw down of the axle (see picture in 1st post, the smashed screw...).

Thanks a lot for your valuable help !

!

Good idea to try first to cut 1 time and pull the pin, if welding don't work I guess i'll try this with dremel.

@jur: for the moment i can't close tightly the hinge, I don't know if it's cause of the play around the axle or the vise which have problems too... The adjustment screw is totally screwed.

Put something as a wedge is an idea too, but I will not trust rubber to do that, too soft. Eventually a little sheet of aluminium or steel, screwed, but it's not totally trustfull for me

...

... I haven't see any screw in the central part, but I'll look again. However it's the role of the little screw down of the axle (see picture in 1st post, the smashed screw...).

Thanks a lot for your valuable help

!

!

#13

Banned

Join Date: Dec 2013

Location: Olney Illinois USA

Posts: 1,021

Bikes: to many

Mentioned: 18 Post(s)

Tagged: 0 Thread(s)

Quoted: 213 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

if you cannot close the frame you will need to address this problem first ... get a new clamp and than after all of that is adjusted correctly than you can take more steps.

but it seems to me that you are desperate to do some cutting/welding/ of that nature to fix something which MIGHT or might not be broken .

thor

but it seems to me that you are desperate to do some cutting/welding/ of that nature to fix something which MIGHT or might not be broken .

thor

#14

Senior Member

Thread Starter

Join Date: Apr 2015

Location: High Normandy, France

Posts: 58

Bikes: Raleigh Maverick '15, Dahon Speed D7 ~2007, and a lot :)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

If the frame don't close cause of the play in the axle, a new clamp will not resolve it, but I'll make a new axle for the clamp too.

Sorry I don't really understand the last part of your message, you mean it's a bad idea to touch the axle ? If only I could don't move it I'll not do, but the play of the frame is really too big to be ignored, frame tightly closed or not.

Sorry I don't really understand the last part of your message, you mean it's a bad idea to touch the axle ? If only I could don't move it I'll not do, but the play of the frame is really too big to be ignored, frame tightly closed or not.

#15

Banned

Join Date: Dec 2013

Location: Olney Illinois USA

Posts: 1,021

Bikes: to many

Mentioned: 18 Post(s)

Tagged: 0 Thread(s)

Quoted: 213 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

it bothers me

you say u have play when the frame is closed. but also that the clamp is bend or broken or ? and you cannot close it ?

how do u know u have play if u cannot close it ?

let a dealer look at it ...

you say u have play when the frame is closed. but also that the clamp is bend or broken or ? and you cannot close it ?

how do u know u have play if u cannot close it ?

let a dealer look at it ...

#16

Senior Member

Thread Starter

Join Date: Apr 2015

Location: High Normandy, France

Posts: 58

Bikes: Raleigh Maverick '15, Dahon Speed D7 ~2007, and a lot :)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Sorry, I believe i misspoke. I just mean that even IF the frame could close tighly, I couldn't be in trust to the frame with such a play on the hinge.

The axle which go through the hole of the nut at the bottom of the picture is bent on my bike (the "visegrip axle" on picture in 1st post)

I just plan to cut it out and replace it with a good (M8 ?) screw. The rest of the clamp seems to be OK.

I'll try to make some pictures and a video this weekend, it will be more clear.

I haven't a dealer near to my location, anyway it seems that the answer of the brand is "get a new frame"...

Repair kit for old Mu frame hinge (type A)? - Dahon Forum

In fact they don't bother to treat these kind of issues... Which is somewhere understandable...

The axle which go through the hole of the nut at the bottom of the picture is bent on my bike (the "visegrip axle" on picture in 1st post)

I just plan to cut it out and replace it with a good (M8 ?) screw. The rest of the clamp seems to be OK.

I'll try to make some pictures and a video this weekend, it will be more clear.

I haven't a dealer near to my location, anyway it seems that the answer of the brand is "get a new frame"...

Repair kit for old Mu frame hinge (type A)? - Dahon Forum

In fact they don't bother to treat these kind of issues... Which is somewhere understandable...

#17

Full Member

Join Date: Apr 2012

Location: Nottingham

Posts: 440

Bikes: Mezzo I4, Trek 1200, Rudge (Montague) BiFrame, Bickerton

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 6 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

I wouldn't replace the hinge pin with an M8 screw or bolt, it really needs to be a piece of plain bar, no screw threads as they will fail too quickly and be a source of further slack.

Without seeing your frame in person to judge just how bad the slack in the hinge pin is, it is difficult for the rest of us to give the best advice but I agree with Thor's comments that it is better to get the hinge clamp working first and to then see if there is any movement with the hinge closed and clamped shut. I made a replacement hinge for my Bickerton which has a small amount of play in the hinge pin (not as bad as in the video) but with clamp done up tight the frame is solid. You really dont want to have to cut the pin out unless it is really necessary.

Without seeing your frame in person to judge just how bad the slack in the hinge pin is, it is difficult for the rest of us to give the best advice but I agree with Thor's comments that it is better to get the hinge clamp working first and to then see if there is any movement with the hinge closed and clamped shut. I made a replacement hinge for my Bickerton which has a small amount of play in the hinge pin (not as bad as in the video) but with clamp done up tight the frame is solid. You really dont want to have to cut the pin out unless it is really necessary.

Last edited by cpg; 04-30-15 at 01:54 AM.

#18

Senior Member

Thread Starter

Join Date: Apr 2015

Location: High Normandy, France

Posts: 58

Bikes: Raleigh Maverick '15, Dahon Speed D7 ~2007, and a lot :)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Hi

Firstly, I've make a big mistake during the setting of the hinge: I had screwed a maximum the screw whereas it needed to be unscrew to tight the hinge ... So I have unscrew it, and now the frame is relatively rigid, even if the play feels always and it seems the screw or the nut which tight the frame is half dead.

... So I have unscrew it, and now the frame is relatively rigid, even if the play feels always and it seems the screw or the nut which tight the frame is half dead.

A little picture of the axis (red line) I wanted to change, quite clear it had a little problem..:

strangely the clamp made in sheet metal seems to haven't suffer so much.

I though well to take a screw with a major part of plain, like that:

I don't see why it would be less strong than the original, even in shearing.

Firstly, I've make a big mistake during the setting of the hinge: I had screwed a maximum the screw whereas it needed to be unscrew to tight the hinge

... So I have unscrew it, and now the frame is relatively rigid, even if the play feels always and it seems the screw or the nut which tight the frame is half dead.

... So I have unscrew it, and now the frame is relatively rigid, even if the play feels always and it seems the screw or the nut which tight the frame is half dead. A little picture of the axis (red line) I wanted to change, quite clear it had a little problem..:

strangely the clamp made in sheet metal seems to haven't suffer so much.

I though well to take a screw with a major part of plain, like that:

I don't see why it would be less strong than the original, even in shearing.

#19

Senior Member

Thread Starter

Join Date: Apr 2015

Location: High Normandy, France

Posts: 58

Bikes: Raleigh Maverick '15, Dahon Speed D7 ~2007, and a lot :)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Hello all !

I've made a new clamp system, based on the original, but... bigger ! An so cheaper than a (rare) spare part.

But it's a DIY part, so be carefull if you try to do the same... It's the only thing that keep your frame tightly closed when you drive your bike...

The original system (M6) has been replaced by a M8, and the axle of the bolt (which was bent) increased from M5 to M6. Not as clean than the original, but stronger I hope.

I haven't reassemble the bike yet, but it seems to close the frame tight enough.

Now, the big question: do you think it is enough to use the bike ? I've read on the net that if the frame is close tightly there is no reason to worry, but I find that the main axle play is always bothering...

Thanks for your opinion and advices.

I've made a new clamp system, based on the original, but... bigger ! An so cheaper than a (rare) spare part.

But it's a DIY part, so be carefull if you try to do the same... It's the only thing that keep your frame tightly closed when you drive your bike...

The original system (M6) has been replaced by a M8, and the axle of the bolt (which was bent) increased from M5 to M6. Not as clean than the original, but stronger I hope.

I haven't reassemble the bike yet, but it seems to close the frame tight enough.

Now, the big question: do you think it is enough to use the bike ? I've read on the net that if the frame is close tightly there is no reason to worry, but I find that the main axle play is always bothering...

Thanks for your opinion and advices.

#20

Senior Member

Thread Starter

Join Date: Apr 2015

Location: High Normandy, France

Posts: 58

Bikes: Raleigh Maverick '15, Dahon Speed D7 ~2007, and a lot :)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Hello,

nobody ?... I know it's hard to give an objective opinion without seeing the bike for real, but don't some peoples here had a play in the hinge of them bike ? Do you continue to use it ?

I'm rather in trust about the solidity of the part I've made, it's the hinge which effraid me...

Thanks for your help

nobody ?... I know it's hard to give an objective opinion without seeing the bike for real, but don't some peoples here had a play in the hinge of them bike ? Do you continue to use it ?

I'm rather in trust about the solidity of the part I've made, it's the hinge which effraid me...

Thanks for your help

#21

Senior Member

Join Date: May 2005

Location: Albany, WA

Posts: 7,393

Mentioned: 16 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Likes: 0

Liked 7 Times

in

6 Posts

Hello,

nobody ?... I know it's hard to give an objective opinion without seeing the bike for real, but don't some peoples here had a play in the hinge of them bike ? Do you continue to use it ?

I'm rather in trust about the solidity of the part I've made, it's the hinge which effraid me...

Thanks for your help

nobody ?... I know it's hard to give an objective opinion without seeing the bike for real, but don't some peoples here had a play in the hinge of them bike ? Do you continue to use it ?

I'm rather in trust about the solidity of the part I've made, it's the hinge which effraid me...

Thanks for your help

It is hard to make a call that the repair is going to be good or not. The best you can do is start riding (suspect you have already done so) and form a view on how sturdy the frame is holding up especially over bumps and so on. If the frame is holding firm, I would not worry about it. The other thing is to monitor the clamp carefully to see if it will require periodic adjustment because it is coming loose. If so, maybe some Loctite to make the screw thread hold more secure would be a good thing.

In short, build confidence.

#22

Senior Member

Thread Starter

Join Date: Apr 2015

Location: High Normandy, France

Posts: 58

Bikes: Raleigh Maverick '15, Dahon Speed D7 ~2007, and a lot :)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Hello

Thanks for the reply. I have not begin already to reassemble the bike, I waited for some advices about the play staying in the hinge, to don't have to disassemble it again if I had to weld the hinge pin. But I'll try it soon.

I thinked about put some Loctite on the screw, yes. For the test it will be some nail polish, rather equal as a soft loctite but cheaper.

Thanks for the reply. I have not begin already to reassemble the bike, I waited for some advices about the play staying in the hinge, to don't have to disassemble it again if I had to weld the hinge pin. But I'll try it soon.

I thinked about put some Loctite on the screw, yes. For the test it will be some nail polish, rather equal as a soft loctite but cheaper.

#23

Member

Join Date: May 2015

Location: Lethbridge, Alberta

Posts: 34

Bikes: Breezer Zag8

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 5 Times

in

1 Post

I have a Breezer 20" folding bike (supposedly a licensed Dahon P8 frame?) that also has fairly significant play in the hinge pin. My solution was to shim the gap between the clamped frame.

full album for those interested...

The material is 1mm LEXAN. One custom-cut piece on either side of the hinge. It seems to have solved my hinge play issue for the time being. The clamp adjustment screw/pin does seem to loosen itself over time, but a little adjustment every now and then ensure the clamping force is what it should be.

full album for those interested...

The material is 1mm LEXAN. One custom-cut piece on either side of the hinge. It seems to have solved my hinge play issue for the time being. The clamp adjustment screw/pin does seem to loosen itself over time, but a little adjustment every now and then ensure the clamping force is what it should be.

#24

Senior Member

Thread Starter

Join Date: Apr 2015

Location: High Normandy, France

Posts: 58

Bikes: Raleigh Maverick '15, Dahon Speed D7 ~2007, and a lot :)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Thanks for the idea. It seems that you replaced your hinge pin by a screw ? How did you remove the original axle ?

#25

Member

Join Date: May 2015

Location: Lethbridge, Alberta

Posts: 34

Bikes: Breezer Zag8

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 5 Times

in

1 Post

The original pin is still in the hinge. The bolt you see was threaded into the pin when I tried to remove the pin. I wasn't able to remove the pin without resorting to a lot of force. Couldn't remove the bolt as the pin now rotates freely in the hinge, so, the bolt stays where it is.