Velo Orange 60mm fenders installation question

#1

Senior Member

Thread Starter

Join Date: Oct 2015

Posts: 201

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 72 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Velo Orange 60mm fenders installation question

I finally got around to installing my Velo Orange Smooth aluminum 60mm fenders on my 1986 Bridgestone MB-2. I'm running 55-559 Big Apple tires. I'm having clearance issues with the bolt that secures the L bracket to the front fork. Any suggestions for an extremely low profile bolt / nut combo that won't rub on my tire?

#2

Senior Member

Join Date: Mar 2013

Location: Maryland

Posts: 3,800

Bikes: Lots of English 3-speeds, a couple of old road bikes, 3 mountain bikes, 1 hybrid, and a couple of mash-ups

Mentioned: 53 Post(s)

Tagged: 0 Thread(s)

Quoted: 887 Post(s)

Liked 335 Times

in

225 Posts

Would this work? It is cheap.

#3

Senior Member

Thread Starter

Join Date: Oct 2015

Posts: 201

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 72 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I was thinking maybe something like this?

SETS - Hexalobular Socket Head Cap Screw (Extra Low Head/Stainless Steel) On The Precision Alliance (TPA)

Seems a bit expensive to order one bolt online since I'd be paying mostly for the shipping, but basically I need something low-profile.

SETS - Hexalobular Socket Head Cap Screw (Extra Low Head/Stainless Steel) On The Precision Alliance (TPA)

Seems a bit expensive to order one bolt online since I'd be paying mostly for the shipping, but basically I need something low-profile.

#4

Senior Member

Do you mean the bolt that attaches the bracket to the fender?

Any chance you could use a daruma? There was a thread a couple years ago with all sorts of fender installation tips and work-arounds, many supplied by Southpawboston. One of his suggested using the cylindrical nut from a recessed brake to attach the fender to a daruma when clearances are tight.

[edit] here's the thread: https://www.bikeforums.net/classic-vi...se-things.html

Any chance you could use a daruma? There was a thread a couple years ago with all sorts of fender installation tips and work-arounds, many supplied by Southpawboston. One of his suggested using the cylindrical nut from a recessed brake to attach the fender to a daruma when clearances are tight.

[edit] here's the thread: https://www.bikeforums.net/classic-vi...se-things.html

Last edited by due ruote; 11-15-16 at 05:49 PM.

#5

Bike Butcher of Portland

Join Date: Jul 2014

Location: Portland, OR

Posts: 11,638

Bikes: It's complicated.

Mentioned: 1299 Post(s)

Tagged: 0 Thread(s)

Quoted: 4680 Post(s)

Liked 5,798 Times

in

2,283 Posts

I finally got around to installing my Velo Orange Smooth aluminum 60mm fenders on my 1986 Bridgestone MB-2. I'm running 55-559 Big Apple tires. I'm having clearance issues with the bolt that secures the L bracket to the front fork. Any suggestions for an extremely low profile bolt / nut combo that won't rub on my tire?

__________________

If someone tells you that you have enough bicycles and you don't need any more, stop talking to them. You don't need that kind of negativity in your life.

If someone tells you that you have enough bicycles and you don't need any more, stop talking to them. You don't need that kind of negativity in your life.

#6

Old fart

Join Date: Nov 2004

Location: Appleton WI

Posts: 24,784

Bikes: Several, mostly not name brands.

Mentioned: 153 Post(s)

Tagged: 0 Thread(s)

Quoted: 3587 Post(s)

Liked 3,400 Times

in

1,934 Posts

I have used the thin nuts from Presta valve stems to secure mudguards to their mounting hardware. Unfortunately, many modern inner tubes use a knurled nut instead of a proper hex nut for this.

#8

Banned.

Join Date: Jul 2016

Location: downtown Bulverde, Texas

Posts: 2,717

Bikes: '74 Raleigh International utility; '98 Moser Forma road; '92 Viner Pro CX upright

Mentioned: 44 Post(s)

Tagged: 0 Thread(s)

Quoted: 939 Post(s)

Likes: 0

Liked 5 Times

in

5 Posts

I'm assuming you're talking about your daruma bolt. You should have a small flat washer and nut under the fender.

Sounds like you need more washer over the fender to take up more bolt thread.

Boulder Cycles makes and sells these:

Back in stock! Fender Wedge for underside of forkcrown - thin

they also sell a thick - I bet if the thin is not enough, you can measure what length of thread is protruding and they'll machine you just what you need - Fender Wedge for underside of forkcrown - thick

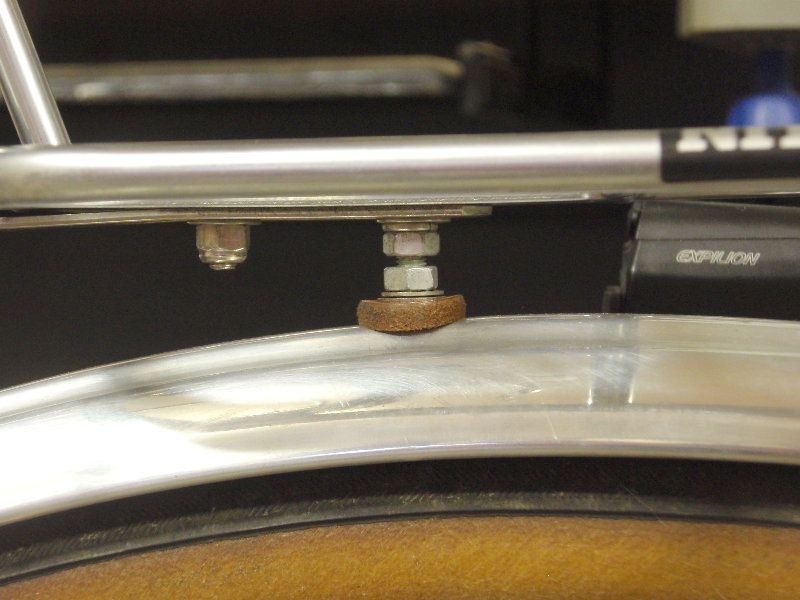

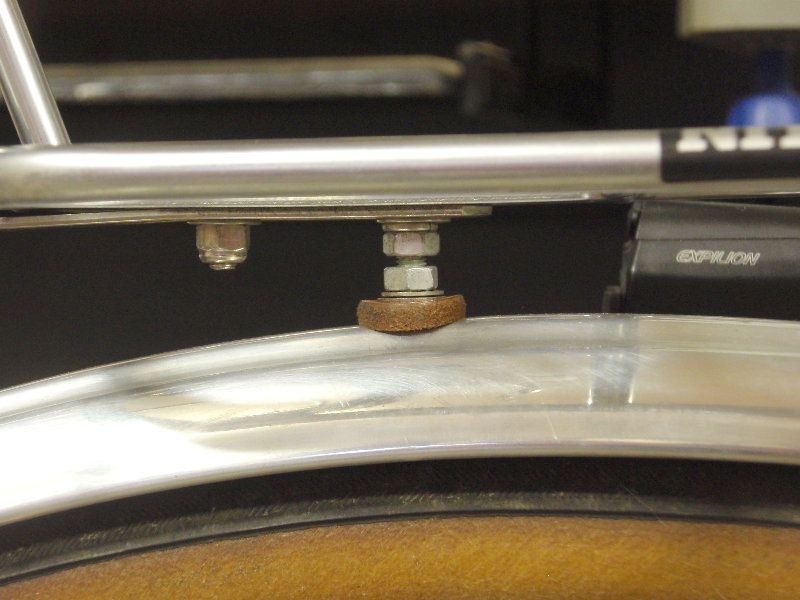

they work really well - you can actually see mine in this photo - there's a rubber washer between the wedge and fender

The wedge is also slightly wedged - a couple mm thicker in the rear than front, which is everything a fender needs at the fork crown.

and if all else fails, take a dremel cut-off wheel to the bolt end, and chase it with a fine file.

Throwing up another good idea here - the long cantilevered front end of a fender will buffet in the wind without additional support.

This required a precise height measurement, drilling a hole, the correct-length M5, and a stack of washers and half nuts.

There is only a star washer and half nut on the inside of the fender.

Sounds like you need more washer over the fender to take up more bolt thread.

Boulder Cycles makes and sells these:

Back in stock! Fender Wedge for underside of forkcrown - thin

they also sell a thick - I bet if the thin is not enough, you can measure what length of thread is protruding and they'll machine you just what you need - Fender Wedge for underside of forkcrown - thick

they work really well - you can actually see mine in this photo - there's a rubber washer between the wedge and fender

The wedge is also slightly wedged - a couple mm thicker in the rear than front, which is everything a fender needs at the fork crown.

and if all else fails, take a dremel cut-off wheel to the bolt end, and chase it with a fine file.

Throwing up another good idea here - the long cantilevered front end of a fender will buffet in the wind without additional support.

This required a precise height measurement, drilling a hole, the correct-length M5, and a stack of washers and half nuts.

There is only a star washer and half nut on the inside of the fender.

Last edited by bulldog1935; 11-16-16 at 10:31 AM.

#9

FLIR Kitten to 0.05C

Join Date: Sep 2014

Location: Lincoln, Nebraska

Posts: 5,331

Bikes: Roadie: Seven Axiom Race Ti w/Chorus 11s. CX/Adventure: Carver Gravel Grinder w/ Di2

Mentioned: 30 Post(s)

Tagged: 0 Thread(s)

Quoted: 2349 Post(s)

Liked 406 Times

in

254 Posts

I used a spare countersunk machine screw I had lying around that matched the VO pitch. Gets the screw head even further from the tire and even less of a problem.

#10

multimodal commuter

Join Date: Nov 2006

Location: NJ, NYC, LI

Posts: 19,808

Bikes: 1940s Fothergill, 1959 Allegro Special, 1963? Claud Butler Olympic Sprint, Lambert 'Clubman', 1974 Fuji "the Ace", 1976 Holdsworth 650b conversion rando bike, 1983 Trek 720 tourer, 1984 Counterpoint Opus II, 1993 Basso Gap, 2010 Downtube 8h, and...

Mentioned: 584 Post(s)

Tagged: 0 Thread(s)

Quoted: 1908 Post(s)

Liked 574 Times

in

339 Posts

I realize this will probably not help @kalash74, but for those considering these fenders with tires over 50 mm, you might want to do what I did.

These (the ones this thread is about) are the widest fenders Velo Orange offers for 26" wheels.

But they offer a fluted fender that is wider, intended for use with 29'er tires:

VO Fluted 63mm Fenders, 700c - 700c - Fenders, Accessories, Hardware - Accessories

It is not difficult to re-radius them to fit 26" wheels. In the process they get a bit wider, and consequently fit very nicely over Compass Rat Trap Pass tires:

These (the ones this thread is about) are the widest fenders Velo Orange offers for 26" wheels.

But they offer a fluted fender that is wider, intended for use with 29'er tires:

VO Fluted 63mm Fenders, 700c - 700c - Fenders, Accessories, Hardware - Accessories

It is not difficult to re-radius them to fit 26" wheels. In the process they get a bit wider, and consequently fit very nicely over Compass Rat Trap Pass tires:

__________________

www.rhmsaddles.com.

www.rhmsaddles.com.

#11

Senior Member

Thread Starter

Join Date: Oct 2015

Posts: 201

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 72 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Do you mean the bolt that attaches the bracket to the fender?

Any chance you could use a daruma? There was a thread a couple years ago with all sorts of fender installation tips and work-arounds, many supplied by Southpawboston. One of his suggested using the cylindrical nut from a recessed brake to attach the fender to a daruma when clearances are tight.

[edit] here's the thread: https://www.bikeforums.net/classic-vi...se-things.html

Any chance you could use a daruma? There was a thread a couple years ago with all sorts of fender installation tips and work-arounds, many supplied by Southpawboston. One of his suggested using the cylindrical nut from a recessed brake to attach the fender to a daruma when clearances are tight.

[edit] here's the thread: https://www.bikeforums.net/classic-vi...se-things.html

Would I likely benefit from a wider fender? Perhaps try spreading the fender with some sort of tool?

#12

Senior Member

Thread Starter

Join Date: Oct 2015

Posts: 201

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 72 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I realize this will probably not help @kalash74, but for those considering these fenders with tires over 50 mm, you might want to do what I did.

These (the ones this thread is about) are the widest fenders Velo Orange offers for 26" wheels.

But they offer a fluted fender that is wider, intended for use with 29'er tires:

VO Fluted 63mm Fenders, 700c - 700c - Fenders, Accessories, Hardware - Accessories

It is not difficult to re-radius them to fit 26" wheels. In the process they get a bit wider, and consequently fit very nicely over Compass Rat Trap Pass tires:

These (the ones this thread is about) are the widest fenders Velo Orange offers for 26" wheels.

But they offer a fluted fender that is wider, intended for use with 29'er tires:

VO Fluted 63mm Fenders, 700c - 700c - Fenders, Accessories, Hardware - Accessories

It is not difficult to re-radius them to fit 26" wheels. In the process they get a bit wider, and consequently fit very nicely over Compass Rat Trap Pass tires:

#13

Banned.

Join Date: Jul 2016

Location: downtown Bulverde, Texas

Posts: 2,717

Bikes: '74 Raleigh International utility; '98 Moser Forma road; '92 Viner Pro CX upright

Mentioned: 44 Post(s)

Tagged: 0 Thread(s)

Quoted: 939 Post(s)

Likes: 0

Liked 5 Times

in

5 Posts

So if you used an L-bracket at the brake bolt, even the VO instructions show the bolt pan-head on the inside of the fender. If the bolt is sticking way above the nut on top of the fender, you could still cut off the excess with a dremel and dress it with a file.

#14

multimodal commuter

Join Date: Nov 2006

Location: NJ, NYC, LI

Posts: 19,808

Bikes: 1940s Fothergill, 1959 Allegro Special, 1963? Claud Butler Olympic Sprint, Lambert 'Clubman', 1974 Fuji "the Ace", 1976 Holdsworth 650b conversion rando bike, 1983 Trek 720 tourer, 1984 Counterpoint Opus II, 1993 Basso Gap, 2010 Downtube 8h, and...

Mentioned: 584 Post(s)

Tagged: 0 Thread(s)

Quoted: 1908 Post(s)

Liked 574 Times

in

339 Posts

I have the aluminum 60mm VO fenders. I'm wondering if perhaps the steel version has a different profile? I think it would help if the profile was less round and more flat with a squared off lip, similar to the 700C ones you have shown in your pictures. BTW, how did you re-radius the 700C fenders?

To re-radius the fluted fenders, well, that was pretty easy. Initially I measured them 64 mm outside, 56 mm inside. I cut three pieces of half inch dowel, about 62 mm, 64 mm and 66 mm respectively. I placed the smallest one obliquely between the curled edges of the fender -the 56 mm dimension-- and straightened it, then slid it from one end to the other several times. Then I did the same with the 64 mm dowel, and finally the 66 mm one. The final result is fenders about 72 mm wide and a very nice fit over Rat Trap Pass tires.

So let's see how I'm doing with flickr...

That's one of the pieces of dowel, jammed between the edges. Note how the fender bulges out there. Slide that up and down from one end of the fender to the other, and the whole thing ends up the same width. Then do it with a wider one.

Here's a before and after. One end of the fender was placed at the start of the yard stick; here's where the other end came to rest, before (on the right) and after (on the left).

Here's a before and after of the width. Before is on the left this time. You can see how much wider the thing got.

__________________

www.rhmsaddles.com.

www.rhmsaddles.com.

#15

Senior Member

Thread Starter

Join Date: Oct 2015

Posts: 201

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 72 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Whether the aluminum and steel are different in any way (other than the material) I don't know, but Velo Orange uses the same photo for both, so I really doubt the profile is different.

To re-radius the fluted fenders, well, that was pretty easy. Initially I measured them 64 mm outside, 56 mm inside. I cut three pieces of half inch dowel, about 62 mm, 64 mm and 66 mm respectively. I placed the smallest one obliquely between the curled edges of the fender -the 56 mm dimension-- and straightened it, then slid it from one end to the other several times. Then I did the same with the 64 mm dowel, and finally the 66 mm one. The final result is fenders about 72 mm wide and a very nice fit over Rat Trap Pass tires.

So let's see how I'm doing with flickr...

That's one of the pieces of dowel, jammed between the edges. Note how the fender bulges out there. Slide that up and down from one end of the fender to the other, and the whole thing ends up the same width. Then do it with a wider one.

Here's a before and after. One end of the fender was placed at the start of the yard stick; here's where the other end came to rest, before (on the right) and after (on the left).

Here's a before and after of the width. Before is on the left this time. You can see how much wider the thing got.

To re-radius the fluted fenders, well, that was pretty easy. Initially I measured them 64 mm outside, 56 mm inside. I cut three pieces of half inch dowel, about 62 mm, 64 mm and 66 mm respectively. I placed the smallest one obliquely between the curled edges of the fender -the 56 mm dimension-- and straightened it, then slid it from one end to the other several times. Then I did the same with the 64 mm dowel, and finally the 66 mm one. The final result is fenders about 72 mm wide and a very nice fit over Rat Trap Pass tires.

So let's see how I'm doing with flickr...

That's one of the pieces of dowel, jammed between the edges. Note how the fender bulges out there. Slide that up and down from one end of the fender to the other, and the whole thing ends up the same width. Then do it with a wider one.

Here's a before and after. One end of the fender was placed at the start of the yard stick; here's where the other end came to rest, before (on the right) and after (on the left).

Here's a before and after of the width. Before is on the left this time. You can see how much wider the thing got.

I'm confused on one point, though. You mentioned that you adapted 700C fenders for use with your 26" Rat Trap tires. How did you change the overall diameter so that it matched the curve for the 26" tires?

#16

multimodal commuter

Join Date: Nov 2006

Location: NJ, NYC, LI

Posts: 19,808

Bikes: 1940s Fothergill, 1959 Allegro Special, 1963? Claud Butler Olympic Sprint, Lambert 'Clubman', 1974 Fuji "the Ace", 1976 Holdsworth 650b conversion rando bike, 1983 Trek 720 tourer, 1984 Counterpoint Opus II, 1993 Basso Gap, 2010 Downtube 8h, and...

Mentioned: 584 Post(s)

Tagged: 0 Thread(s)

Quoted: 1908 Post(s)

Liked 574 Times

in

339 Posts

The fender is basically an incomplete torus:

So in this diagram you see there's two diameters; applied to the 63 mm 700c fenders, the 700c diameter is drawn in blue, the 63 mm diameter is drawn in red. If you stretch out the former, the latter gets narrower; if you stretch out the latter, the former gets smaller. Look at the two before and after photos again, and you'll see the differences.

__________________

www.rhmsaddles.com.

www.rhmsaddles.com.

#17

Senior Member

Join Date: Apr 2014

Location: Minneapols, Minnesota

Posts: 538

Bikes: 89 Raleigh Technium PRE, 92 SP 1000 ti, '09 Team Pro, 72 International, 63 Hercules 3-spd, '81 Vitus 979, 2 Kabuki Submariners, 2 C. Itoh Submariners, Gary Fisher Big Sur, Skyway 3-spd, Robin Hood w/ S-A IGH 5 speed.

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 6 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I would use a

panhead screw with the head inside the fender. Use an acorn nut on top to make it look purdy.

I have spread a narrow aluminum fender with a small glass jar (model paint from hobby shop). It worked nicely I just pressed it in at one end and just worked my way along.

panhead screw with the head inside the fender. Use an acorn nut on top to make it look purdy.

I have spread a narrow aluminum fender with a small glass jar (model paint from hobby shop). It worked nicely I just pressed it in at one end and just worked my way along.

#18

Senior Member

Thread Starter

Join Date: Oct 2015

Posts: 201

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 72 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I don't have the math to explain this with the correct terminology, but trust me, it happens automatically.

The fender is basically an incomplete torus:

So in this diagram you see there's two diameters; applied to the 63 mm 700c fenders, the 700c diameter is drawn in blue, the 63 mm diameter is drawn in red. If you stretch out the former, the latter gets narrower; if you stretch out the latter, the former gets smaller. Look at the two before and after photos again, and you'll see the differences.

The fender is basically an incomplete torus:

So in this diagram you see there's two diameters; applied to the 63 mm 700c fenders, the 700c diameter is drawn in blue, the 63 mm diameter is drawn in red. If you stretch out the former, the latter gets narrower; if you stretch out the latter, the former gets smaller. Look at the two before and after photos again, and you'll see the differences.

#19

multimodal commuter

Join Date: Nov 2006

Location: NJ, NYC, LI

Posts: 19,808

Bikes: 1940s Fothergill, 1959 Allegro Special, 1963? Claud Butler Olympic Sprint, Lambert 'Clubman', 1974 Fuji "the Ace", 1976 Holdsworth 650b conversion rando bike, 1983 Trek 720 tourer, 1984 Counterpoint Opus II, 1993 Basso Gap, 2010 Downtube 8h, and...

Mentioned: 584 Post(s)

Tagged: 0 Thread(s)

Quoted: 1908 Post(s)

Liked 574 Times

in

339 Posts

But if you only widen them a tiny bit, the effect might be negligible. Any bending of this kind is going to do a little stretching here and a little compressing there, and I doubt you'll do any harm. In my experience it's better to widen the whole thing evenly, because that way everything stays predictable. If you widen one area, you'll put a gentle kink into the overall curve, which may cause problems you hadn't anticipated.

That said, I wouldn't worry about it too much. If you need to bend it to make it fit, go for it.

Another thing you might consider is to dent the part of the mudguard where it interferes with the fork crown. Bluemels fenders used to come like this; perhaps you can see it in this photo:

__________________

www.rhmsaddles.com.

www.rhmsaddles.com.