4 Piston Calipers?

#1

- Soli Deo Gloria -

Thread Starter

Join Date: Aug 2015

Location: Northwest Georgia

Posts: 14,779

Bikes: 2018 Rodriguez Custom Fixed Gear, 2017 Niner RLT 9 RDO, 2015 Bianchi Pista, 2002 Fuji Robaix

Mentioned: 235 Post(s)

Tagged: 0 Thread(s)

Quoted: 6844 Post(s)

Liked 736 Times

in

469 Posts

4 Piston Calipers?

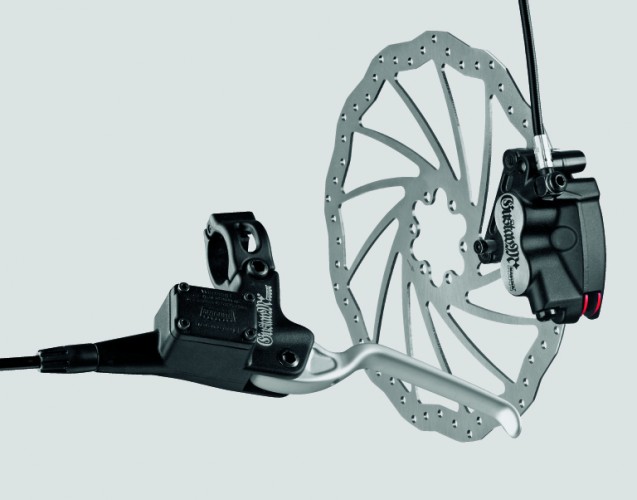

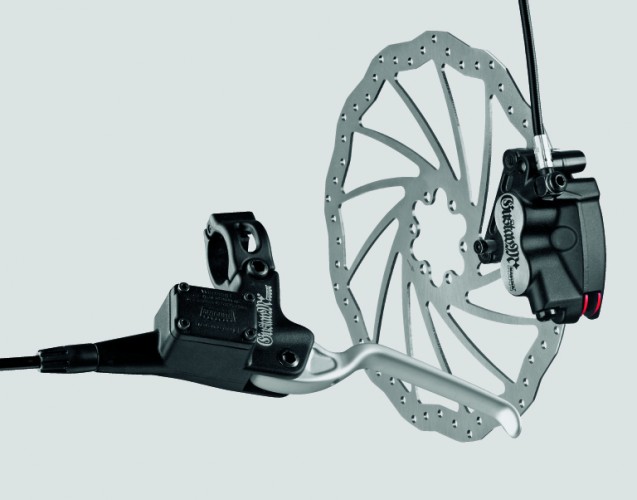

Anyone using 4 piston calipers for gravel such as the Hope RX4?

I realize that it might not be needed apart from racing but what are the benefits from a purely academic perspective?

Other brands besides Hope?

-Tim-

I realize that it might not be needed apart from racing but what are the benefits from a purely academic perspective?

Other brands besides Hope?

-Tim-

#2

Non omnino gravis

#3

Senior Member

Join Date: Jun 2008

Location: Vancouver, BC

Posts: 9,201

Mentioned: 11 Post(s)

Tagged: 0 Thread(s)

Quoted: 1186 Post(s)

Liked 289 Times

in

177 Posts

More piston area equals greater force. The pressure applied by the master cylinder in the brake handle doesn't change but if you make the pistons in the calipers bigger, or increase the area by adding another piston, the force applied to the pads will be higher.

Basically, it increases the leverage and gives you more powerful brakes.

Basically, it increases the leverage and gives you more powerful brakes.

#4

Senior Member

Join Date: Sep 2011

Posts: 4,764

Mentioned: 28 Post(s)

Tagged: 0 Thread(s)

Quoted: 1975 Post(s)

Liked 232 Times

in

173 Posts

More piston area equals greater force. The pressure applied by the master cylinder in the brake handle doesn't change but if you make the pistons in the calipers bigger, or increase the area by adding another piston, the force applied to the pads will be higher.

Basically, it increases the leverage and gives you more powerful brakes.

Basically, it increases the leverage and gives you more powerful brakes.

#5

- Soli Deo Gloria -

Thread Starter

Join Date: Aug 2015

Location: Northwest Georgia

Posts: 14,779

Bikes: 2018 Rodriguez Custom Fixed Gear, 2017 Niner RLT 9 RDO, 2015 Bianchi Pista, 2002 Fuji Robaix

Mentioned: 235 Post(s)

Tagged: 0 Thread(s)

Quoted: 6844 Post(s)

Liked 736 Times

in

469 Posts

These appear to be only post mount, no?

Anything for flat mount besides Hope?

-Tim-

#6

Non omnino gravis

...probably not. Flat mount is pretty much road specific, I think only Cannondale is putting flat-mount on a MTB frame-- in MTB, there are still frames that are IS-- weight and aero are really considerations when bombing down the side of a mountain on a full-suspension bike. Give it a couple years, and we'll probably have dual caliper flat mount setups. If only so they can sell us 4x as many brake pads.

#7

Senior Member

Posted by a user on ww about the Hope's:

"I've fitted up a few of these brakes to replace the usual leaking Shimano ones…..

I had high hopes for them based on their excellent MTB brakes.

The Hope calipers fit directly onto the Shimano hoses, using the supplied Hope fittings. I've found them to be pretty awkward to bleed. If you follow their instructions exactly, then you get there in the end, but it's definitely not a case of popping the bleed pot on the lever reservoir and pumping one lot of oil through. Once bled they're super powerful, and don't squeal or rub. I would say feeling almost too powerful for a road bike…

I also had some problems with side to side clearances, the caliper body is wider than a Shimano one, and I've had to do some annoying hub respacing as the callipers wouldn't move sideways enough to centre up over the rotor…."

"I've fitted up a few of these brakes to replace the usual leaking Shimano ones…..

I had high hopes for them based on their excellent MTB brakes.

The Hope calipers fit directly onto the Shimano hoses, using the supplied Hope fittings. I've found them to be pretty awkward to bleed. If you follow their instructions exactly, then you get there in the end, but it's definitely not a case of popping the bleed pot on the lever reservoir and pumping one lot of oil through. Once bled they're super powerful, and don't squeal or rub. I would say feeling almost too powerful for a road bike…

I also had some problems with side to side clearances, the caliper body is wider than a Shimano one, and I've had to do some annoying hub respacing as the callipers wouldn't move sideways enough to centre up over the rotor…."

#9

Senior Member

Join Date: Jun 2008

Location: Vancouver, BC

Posts: 9,201

Mentioned: 11 Post(s)

Tagged: 0 Thread(s)

Quoted: 1186 Post(s)

Liked 289 Times

in

177 Posts

A side effect of a larger slave piston is the master piston will have to travel proportionately farther.

This is the principle of how hydraulic jacks work. The mechanical advantage of a hydraulic jack is the ratio of the slave piston area over the master piston area. Make the slave bigger and you can lift a heavier load. Same principle for brakes, i.e. more braking force.

#10

Senior Member

Join Date: Sep 2011

Posts: 4,764

Mentioned: 28 Post(s)

Tagged: 0 Thread(s)

Quoted: 1975 Post(s)

Liked 232 Times

in

173 Posts

If I push with 1lb of force on a 1 inch master cylinder I create 1psi of pressure in the hydraulic lines. If I have a slave cylinder with 10 square inches I can apply 10 lbs. Increase the slave to 100 sq in and you'll get 100 lbs.

A side effect of a larger slave piston is the master piston will have to travel proportionately farther.

This is the principle of how hydraulic jacks work. The mechanical advantage of a hydraulic jack is the ratio of the slave piston area over the master piston area. Make the slave bigger and you can lift a heavier load. Same principle for brakes, i.e. more braking force.

A side effect of a larger slave piston is the master piston will have to travel proportionately farther.

This is the principle of how hydraulic jacks work. The mechanical advantage of a hydraulic jack is the ratio of the slave piston area over the master piston area. Make the slave bigger and you can lift a heavier load. Same principle for brakes, i.e. more braking force.

#11

Senior Member

Join Date: Jun 2008

Location: Vancouver, BC

Posts: 9,201

Mentioned: 11 Post(s)

Tagged: 0 Thread(s)

Quoted: 1186 Post(s)

Liked 289 Times

in

177 Posts

As I said before, increasing the size of the slave, or doubling the number of pistons at the caliper, results in greater braking force for an equivalent force on the brake lever. In a properly adjusted braking system there shouldn't be much movement of the lever. Ideally the pads are sitting right next to the rotor. On bikes they allow a little space between the pads and rotor that needs to be taken up initially but it's a small amount.

#12

Senior Member

Join Date: Sep 2011

Posts: 4,764

Mentioned: 28 Post(s)

Tagged: 0 Thread(s)

Quoted: 1975 Post(s)

Liked 232 Times

in

173 Posts

The force applied has nothing to do with the lever travel distance. The force your fingers apply is constant as is the master cylinder size in the shifter handle.

As I said before, increasing the size of the slave, or doubling the number of pistons at the caliper, results in greater braking force for an equivalent force on the brake lever. In a properly adjusted braking system there shouldn't be much movement of the lever. Ideally the pads are sitting right next to the rotor. On bikes they allow a little space between the pads and rotor that needs to be taken up initially but it's a small amount.

As I said before, increasing the size of the slave, or doubling the number of pistons at the caliper, results in greater braking force for an equivalent force on the brake lever. In a properly adjusted braking system there shouldn't be much movement of the lever. Ideally the pads are sitting right next to the rotor. On bikes they allow a little space between the pads and rotor that needs to be taken up initially but it's a small amount.

#13

Senior Member

Join Date: Jun 2008

Location: Vancouver, BC

Posts: 9,201

Mentioned: 11 Post(s)

Tagged: 0 Thread(s)

Quoted: 1186 Post(s)

Liked 289 Times

in

177 Posts

Its clearly not that simple, lever travel is the limiting variable on road discs, not force. Doubling the number of same sized pistons, while keeping the force the same means doubling the lever travel then, which would be unacceptable on either shimano or sram hydraulic road levers. If you doubled the pistons while decreasing size so the area is the same, then you would have the same force exerted on the pads.

#14

Banned

4 pistons got them able to use a longer disc pad , for more surface to make the friction..

IDK if the fluid goes to 1 cylinder-pair , before the other , so modulated application, not as sudden..

IDK if the fluid goes to 1 cylinder-pair , before the other , so modulated application, not as sudden..

#15

Senior Member

Join Date: Sep 2011

Posts: 4,764

Mentioned: 28 Post(s)

Tagged: 0 Thread(s)

Quoted: 1975 Post(s)

Liked 232 Times

in

173 Posts

Why don't you explain how a hydraulic system is anything more than a two ended fluid displacement that changes work done moving one piston(the MC) and to the other end of the system(2+ pistons in caliper)?It's been awhile, but I'll try to follow along with my PhD in Chemical Engineering.

Or maybe you can explain why Hope, the only 4 piston road caliper manufacturer would bother decreasing piston sizes for their 4 piston and 6 piston calipers compared to their 2 piston calipers if they could magically have more clamping force if they simply increased the number of pistons? https://www.hopetech.com/wp-content/u...eals-chart.pdf

Or maybe you can explain why Hope, the only 4 piston road caliper manufacturer would bother decreasing piston sizes for their 4 piston and 6 piston calipers compared to their 2 piston calipers if they could magically have more clamping force if they simply increased the number of pistons? https://www.hopetech.com/wp-content/u...eals-chart.pdf

#16

Senior Member

Join Date: Jun 2008

Location: Vancouver, BC

Posts: 9,201

Mentioned: 11 Post(s)

Tagged: 0 Thread(s)

Quoted: 1186 Post(s)

Liked 289 Times

in

177 Posts

Why don't you explain how a hydraulic system is anything more than a two ended fluid displacement that changes work done moving one piston(the MC) and to the other end of the system(2+ pistons in caliper)?It's been awhile, but I'll try to follow along with my PhD in Chemical Engineering.

Or maybe you can explain why Hope, the only 4 piston road caliper manufacturer would bother decreasing piston sizes for their 4 piston and 6 piston calipers compared to their 2 piston calipers if they could magically have more clamping force if they simply increased the number of pistons? https://www.hopetech.com/wp-content/u...eals-chart.pdf

Or maybe you can explain why Hope, the only 4 piston road caliper manufacturer would bother decreasing piston sizes for their 4 piston and 6 piston calipers compared to their 2 piston calipers if they could magically have more clamping force if they simply increased the number of pistons? https://www.hopetech.com/wp-content/u...eals-chart.pdf

That said, Hope's 4 piston caliper with 16/18 mm pistons provides about 20% more braking force than the typical calipers used by Shimano (22mm). I believe Shimano also offers a 4 piston caliper with 16/18mm pistons for MTB.

I think you're getting confused with fluid displacement, lever travel etc. Those items are relevant only when the pads are moving. In an ideal system the pads would be right next to the rotors and not have to move at all. In the real world rotors warp and calipers are not perfectly aligned so the calipers are designed to pull the pads back a little, say .5mm.

When you initially pull on the brake levers very little force is required and there is some fluid displacement and piston movement while the pads are pushed up against the rotors. Once they are touching there is no more fluid movement and the force applied to the pads is simply a multiple of the force applied to the brake levers. The pressure in the lines is the force applied to the master piston divided by the area of the master piston. The force applied to the pads is the pressure multiplied by the total area of the slave pistons within the calipers.

In a well adjusted and aligned system the pads will be very close to the rotors and lever travel to move the pads will be minimal. In a poorly adjusted system or one that contained some air it is possible for the lever to bottom out. If you increase the size of the slave pistons, the risk of this happening is higher but shouldn't be an issue in a properly adjusted and bled system.

P.S. - If you're serious about understanding how a hydraulic braking system works it is typically covered in 1st year physics. Here is an open textbook https://d3bxy9euw4e147.cloudfront.ne...Physics-OP.pdf which discusses hydraulic brakes on page 400.

Last edited by gregf83; 04-08-18 at 08:18 PM.

#17

Senior Member

Join Date: Sep 2011

Posts: 4,764

Mentioned: 28 Post(s)

Tagged: 0 Thread(s)

Quoted: 1975 Post(s)

Liked 232 Times

in

173 Posts

I don't know the specifics about the examples you provided but I do understand how hydraulic brakes work and have explained it in my earlier posts. I presume they reduced the size of the pistons because they didn't need double the braking power and that there were other design factors at play. Some of the two piston version they offered had 25mm pistons which require very large pads and rotors.

That said, Hope's 4 piston caliper with 16/18 mm pistons provides about 20% more braking force than the typical calipers used by Shimano (22mm). I believe Shimano also offers a 4 piston caliper with 16/18mm pistons for MTB.

I think you're getting confused with fluid displacement, lever travel etc. Those items are relevant only when the pads are moving. In an ideal system the pads would be right next to the rotors and not have to move at all. In the real world rotors warp and calipers are not perfectly aligned so the calipers are designed to pull the pads back a little, say .5mm.

When you initially pull on the brake levers very little force is required and there is some fluid displacement and piston movement while the pads are pushed up against the rotors. Once they are touching there is no more fluid movement and the force applied to the pads is simply a multiple of the force applied to the brake levers. The pressure in the lines is the force applied to the master piston divided by the area of the master piston. The force applied to the pads is the pressure multiplied by the total area of the slave pistons within the calipers.

In a well adjusted and aligned system the pads will be very close to the rotors and lever travel to move the pads will be minimal. In a poorly adjusted system or one that contained some air it is possible for the lever to bottom out. If you increase the size of the slave pistons, the risk of this happening is higher but shouldn't be an issue in a properly adjusted and bled system.

P.S. - If you're serious about understanding how a hydraulic braking system works it is typically covered in 1st year physics. Here is an open textbook https://d3bxy9euw4e147.cloudfront.ne...Physics-OP.pdf which discusses hydraulic brakes on page 400.

That said, Hope's 4 piston caliper with 16/18 mm pistons provides about 20% more braking force than the typical calipers used by Shimano (22mm). I believe Shimano also offers a 4 piston caliper with 16/18mm pistons for MTB.

I think you're getting confused with fluid displacement, lever travel etc. Those items are relevant only when the pads are moving. In an ideal system the pads would be right next to the rotors and not have to move at all. In the real world rotors warp and calipers are not perfectly aligned so the calipers are designed to pull the pads back a little, say .5mm.

When you initially pull on the brake levers very little force is required and there is some fluid displacement and piston movement while the pads are pushed up against the rotors. Once they are touching there is no more fluid movement and the force applied to the pads is simply a multiple of the force applied to the brake levers. The pressure in the lines is the force applied to the master piston divided by the area of the master piston. The force applied to the pads is the pressure multiplied by the total area of the slave pistons within the calipers.

In a well adjusted and aligned system the pads will be very close to the rotors and lever travel to move the pads will be minimal. In a poorly adjusted system or one that contained some air it is possible for the lever to bottom out. If you increase the size of the slave pistons, the risk of this happening is higher but shouldn't be an issue in a properly adjusted and bled system.

P.S. - If you're serious about understanding how a hydraulic braking system works it is typically covered in 1st year physics. Here is an open textbook https://d3bxy9euw4e147.cloudfront.ne...Physics-OP.pdf which discusses hydraulic brakes on page 400.

Draw a free body diagram around the piston in the caliper, while the pad side of the piston doesn't move any more relative to the rotor once it makes contact, the whole caliper body flexes an equal amount to counter the pressure exerted on the piston. There is additional fluid displacement as the pressure/force increases on the lever and subsequently at the pad/piston interface. What you need to do to determine lever travel is to integrate the change in force and volume displacement to determine the total amount of work done and subsequent lever travel. Your physics books exerpt even implies this at the bottom of the page in the box discussing conservation of energy, but it is beyond the scope of a 1st year physics student to perform the calculation. There is no free lunch, the same amount of work needs to be done.

Take your example to the extreme, and hook up a road brake lever to an automobile caliper, which has essentially no gap between the pad and rotor and according to you should be able to just multiply the force by 10+x based on the change in piston area size, but I would put money on it that you couldn't slow even a free moving rotor with the road lever, you would simply run out of lever stroke before any meaningful pad pressure would occur.

Still don't believe me? How about we go straight to the source, racing brake manufacturer Stoptech's white paper on the subject

1) Line pressure can only be increased by either increasing the mechanical pedal ratio or by decreasing the master cylinder diameter. In either case the pedal travel will be increased.

2) Clamping force can only be increased either by increasing the line pressure or by increasing the diameter of the caliper piston(s). Increasing the size of the pads will not increase clamping force. Any increase in caliper piston area alone will be accompanied by an increase in pedal travel. The effectiveness of a caliper is also affected by the stiffness of the caliper body and its mountings. It is therefore possible to reduce piston size while increasing caliper stiffness and realize a net increase in clamping force applied. This would typically improve pedal feel.

3) Only increasing the effective radius of the disc, the caliper piston area, the line pressure, or the coefficient of friction can increase brake torque. Increasing the pad area will decrease pad wear and improve the fade characteristics of the pads but it will not increase the brake torque.

2) Clamping force can only be increased either by increasing the line pressure or by increasing the diameter of the caliper piston(s). Increasing the size of the pads will not increase clamping force. Any increase in caliper piston area alone will be accompanied by an increase in pedal travel. The effectiveness of a caliper is also affected by the stiffness of the caliper body and its mountings. It is therefore possible to reduce piston size while increasing caliper stiffness and realize a net increase in clamping force applied. This would typically improve pedal feel.

3) Only increasing the effective radius of the disc, the caliper piston area, the line pressure, or the coefficient of friction can increase brake torque. Increasing the pad area will decrease pad wear and improve the fade characteristics of the pads but it will not increase the brake torque.

#18

Senior Member

Join Date: Jun 2008

Location: Vancouver, BC

Posts: 9,201

Mentioned: 11 Post(s)

Tagged: 0 Thread(s)

Quoted: 1186 Post(s)

Liked 289 Times

in

177 Posts

See this is where your 1st year physics book is an oversimplification of the system. Perform a simple experiment with your hydraulic road brake lever, pull the lever until the pads make contact with the rotor. Now try to increase the force onto the lever without moving it any further. Possible? No. On both properly adjusted Shimano rs685 or Sram HRD Red 22 levers this occurs about 1/3 of the way through the lever arm travel. To actually stop the bike however, the lever needs to move at least an additional 1/3 of the travel distance. The lever arm and piston aren't flexing so more fluid displacement is occuring in the MC.

Draw a free body diagram around the piston in the caliper, while the pad side of the piston doesn't move any more relative to the rotor once it makes contact, the whole caliper body flexes an equal amount to counter the pressure exerted on the piston. There is additional fluid displacement as the pressure/force increases on the lever and subsequently at the pad/piston interface. What you need to do to determine lever travel is to integrate the change in force and volume displacement to determine the total amount of work done and subsequent lever travel. Your physics books exerpt even implies this at the bottom of the page in the box discussing conservation of energy, but it is beyond the scope of a 1st year physics student to perform the calculation. There is no free lunch, the same amount of work needs to be done.

Take your example to the extreme, and hook up a road brake lever to an automobile caliper, which has essentially no gap between the pad and rotor and according to you should be able to just multiply the force by 10+x based on the change in piston area size, but I would put money on it that you couldn't slow even a free moving rotor with the road lever, you would simply run out of lever stroke before any meaningful pad pressure would occur.

Still don't believe me? How about we go straight to the source, racing brake manufacturer Stoptech's white paper on the subject

Brake System and Upgrade Selection

Draw a free body diagram around the piston in the caliper, while the pad side of the piston doesn't move any more relative to the rotor once it makes contact, the whole caliper body flexes an equal amount to counter the pressure exerted on the piston. There is additional fluid displacement as the pressure/force increases on the lever and subsequently at the pad/piston interface. What you need to do to determine lever travel is to integrate the change in force and volume displacement to determine the total amount of work done and subsequent lever travel. Your physics books exerpt even implies this at the bottom of the page in the box discussing conservation of energy, but it is beyond the scope of a 1st year physics student to perform the calculation. There is no free lunch, the same amount of work needs to be done.

Take your example to the extreme, and hook up a road brake lever to an automobile caliper, which has essentially no gap between the pad and rotor and according to you should be able to just multiply the force by 10+x based on the change in piston area size, but I would put money on it that you couldn't slow even a free moving rotor with the road lever, you would simply run out of lever stroke before any meaningful pad pressure would occur.

Still don't believe me? How about we go straight to the source, racing brake manufacturer Stoptech's white paper on the subject

Brake System and Upgrade Selection

The other big source of imperfection in a bicycle system is air. It's not easy to properly bleed the hydraulics on a bike so there will always be some amount of air that needs to be compressed.

None of this changes the fact that the force applied to the pads on the caliper is directly proportional to the area of the caliper pistons. Provided your levers aren't bottoming out, the force on the pads will be multiplied the the caliper/master piston area ratio.

At this point I don't know what you're point is. My original statement that pad force is directly affected by piston area still stands.

Perhaps your only point now is that hydraulic brake systems on a bicycle are not ideal and there are elements of the system that flex or expand. On this I agree and have not said otherwise.

#19

Banned

Magura' Gustav disc brakes was an earlier 4 piston disc brake , the company makes motorbike stuff too..

#20

Senior Member

Join Date: Sep 2011

Posts: 4,764

Mentioned: 28 Post(s)

Tagged: 0 Thread(s)

Quoted: 1975 Post(s)

Liked 232 Times

in

173 Posts

Yes, the braking system on a bicycle is not ideal and flexes considerably more than in a vehicle. I'm sure the hydraulic brake lines used on a bike are far from ideal as well. In a car the lines are normally steel with the flexible portion limited to 12" or so. On high performance cars it isn't uncommon to replace the rubber hose with braided stainless steel in order to minimize expansion. A bicycle has fairly long flexible lines which will expand with increasing pressure on the lever.

The other big source of imperfection in a bicycle system is air. It's not easy to properly bleed the hydraulics on a bike so there will always be some amount of air that needs to be compressed.

None of this changes the fact that the force applied to the pads on the caliper is directly proportional to the area of the caliper pistons. Provided your levers aren't bottoming out, the force on the pads will be multiplied the the caliper/master piston area ratio.

At this point I don't know what you're point is. My original statement that pad force is directly affected by piston area still stands.

Perhaps your only point now is that hydraulic brake systems on a bicycle are not ideal and there are elements of the system that flex or expand. On this I agree and have not said otherwise.[/QUOTE]

You seem to continue to think that the lever travel isn't an issue because fluid movement stops once the pads contact, and that a larger piston area results in a more powerful brake. But you can't just apply a set force at a fixed lever position, you have to pull the lever until the resulting force has increased to a sufficient level. Where we disagree and my point is that lever travel is the limiting factor in road bike hydraulics so given you are limited in terms of the total amount of lever travel you have which is proportional to the pressure you can apply to the MC. but there is a reason Hope uses two different pairs of piston sizes for the different MC sizes in shimano vs sram road levers in the Hope RX4, 18/16 and 16/14 respectively. Based on your reasoning, they should have just used the larger caliper with SRAM because it is more powerful

Thread

Thread Starter

Forum

Replies

Last Post

motorthings

Cyclocross and Gravelbiking (Recreational)

32

10-25-18 12:54 PM

Wisco608

Bicycle Mechanics

2

05-28-13 07:13 PM