Dimpling/crimping 853 chainstays

#1

Junior Member

Thread Starter

Join Date: Jan 2020

Posts: 5

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

Dimpling/crimping 853 chainstays

I had new chainstays fitted to my Salsa El Mariachi - the original driveside stay was heavily gouged by chainsuck (I fitted my BB with the spacer on the wrong side!) and it snapped.

They fitted two new 853 stays and I ended up with far less tyre clearance. So I took it back (after I painted it) and they said they couldn't crimp them, but they could make them narrower by using heat. They did this, but it's still less clearance than the original stays had. Ok so they snapped, but I'd have assumed with 853 instead of the original 4130 I could have had at least some crimping and still ended up with more useful strength than the original.

So a few questions:

1) Should he have done this? Reynolds website, linked to from here, says that only a small amount of working is possible and any ovalising or dimpling should not be attempted. I don't know how hot he got it, but he paint was only stripped off about 15cm of chainstay, so I can't imagine he got it particularly hot otherwise more paint would have burned off.

2) How much is 'a small amount' ? Can I add a further dimple myself without wrecking the tensile strength? Is it already compromised?

They fitted two new 853 stays and I ended up with far less tyre clearance. So I took it back (after I painted it) and they said they couldn't crimp them, but they could make them narrower by using heat. They did this, but it's still less clearance than the original stays had. Ok so they snapped, but I'd have assumed with 853 instead of the original 4130 I could have had at least some crimping and still ended up with more useful strength than the original.

So a few questions:

1) Should he have done this? Reynolds website, linked to from here, says that only a small amount of working is possible and any ovalising or dimpling should not be attempted. I don't know how hot he got it, but he paint was only stripped off about 15cm of chainstay, so I can't imagine he got it particularly hot otherwise more paint would have burned off.

2) How much is 'a small amount' ? Can I add a further dimple myself without wrecking the tensile strength? Is it already compromised?

Likes For molgrips:

#2

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,053

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4194 Post(s)

Liked 3,837 Times

in

2,295 Posts

I'm no 853 expert but I don't know of anyone who heats a bike tube (of any kind) before they manipulate/shape it. If the shop that did the repair will back the stays (now that they have been shaped against Reynolds's guidelines) then leave them as is and run a narrower tire if the clearance needs it. If the shop won't give a warranty then do what you wish as you'll be the only one who cares.

I do have questions. Did you specify the CS brand/material? Did you have a discussion about other issues like tire clearance prior to the work? Did the shop offer any suggestions?

Since the OEM stays failed from a incident creating a stress riser it seems to me that they were strong enough to work under "normal" conditions. The 853 might be stronger but they might have less elongation and, if of thinner wall, have less of a fudge factor to deal with the next incident. Andy

I do have questions. Did you specify the CS brand/material? Did you have a discussion about other issues like tire clearance prior to the work? Did the shop offer any suggestions?

Since the OEM stays failed from a incident creating a stress riser it seems to me that they were strong enough to work under "normal" conditions. The 853 might be stronger but they might have less elongation and, if of thinner wall, have less of a fudge factor to deal with the next incident. Andy

__________________

AndrewRStewart

AndrewRStewart

Likes For Andrew R Stewart:

#3

Senior Member

Join Date: Dec 2019

Posts: 953

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Liked 263 Times

in

212 Posts

He could have got it very hot in spite of the only 15cm of paint damage. In any case he will have destroyed the heat treatment, which was the idea, so he could bend it. So you now basically have a partly 631 chainstay which is probably OK unless it was super thin to start with. In principle therefore it should be OK to cold-bend it a bit more but I would be careful. Also further out from the part he heated it will still be hardened.

#4

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,385

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,686 Times

in

2,509 Posts

I didn't know there were 853 stays that are anything like the El Mariachi stays. I have one of those with broken chainstays that's going to be an ebike someday

#5

Senior Member

Join Date: Nov 2014

Location: Eugene, Oregon, USA

Posts: 27,547

Mentioned: 217 Post(s)

Tagged: 0 Thread(s)

Quoted: 18349 Post(s)

Liked 4,502 Times

in

3,346 Posts

He could have got it very hot in spite of the only 15cm of paint damage. In any case he will have destroyed the heat treatment, which was the idea, so he could bend it. So you now basically have a partly 631 chainstay which is probably OK unless it was super thin to start with. In principle therefore it should be OK to cold-bend it a bit more but I would be careful. Also further out from the part he heated it will still be hardened.

A moderate heat might improve ductility without necessarily destroying the heat treatment. The 831 is supposed to be air hardening, but may ultimately be similar to the 631 after welding/brazing.

Are the chainstays simple tapered, or butted?

If there is no butting, then the weak spot will be at the bottom bracket which already was welded/brazed.

#6

Senior Member

Join Date: Dec 2019

Posts: 953

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Liked 263 Times

in

212 Posts

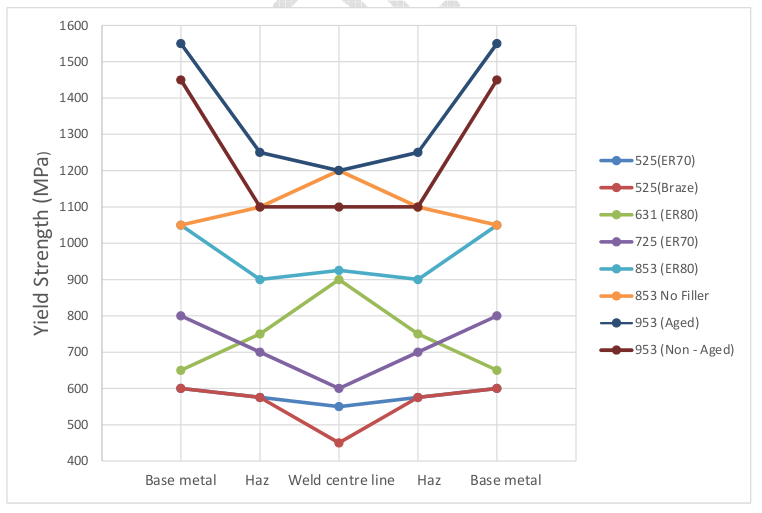

853 with no filler (obviously not how you would actually make a bike) is stronger all the way between the weld and the base metal, implying the air hardening more than makes up for any loss of heat treatment, and the 853 line stays a good 300MPa above the 631 line at all times. The reason they show a fusion weld on this graph is because the filler metal is weaker than the 853 to start with (so you would get the blue line in practice if you used ER80 filler).

They do say this graph is not based on actual testing but "on current knowledge and volume fraction data".

So maybe you can heat it right up to red hot, bend it, and it just air hardens back to exactly its original heat-treated strength. This seems a bit too good to be true though.

#7

Junior Member

Thread Starter

Join Date: Jan 2020

Posts: 5

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

Thanks for the responses, it's good to have informed opinions!

The original stays were heavily crimped, allowing use of both 2.4" tyres abd a triple chainset. It seems that this is a weakness in the original because they are prone to cracking. Although my non drive side was fine and not cracked so maybe my riding wasn't too hard on it. Anyway, when I went in I said "I didn't want to lose much tyre clearance". He airily agreed to this as if it wasn't going to be a problem. He didn't offer me a choice of materials or explain what he was going to do and what the implications would be.

When I got the frame back he did show me the results with the wheel in place and was fairy dismissive and being British I took it home and painted it up. But when I rebuilt the bike and had a proper look myself I decided that there was nowhere near enough clearance. So I went back and had a further chat, he said 'oh I could make these thinner'. Ok fine but why didn't you do this in the first place when I said I didn't want to lose clearance? The original stays were 11mm wide, the replacement were 20mm wide so a 9mm lost on each side, which is huge. Not only that but there was very little chainset clearance, and since I'm upgrading to 1x11 I've fitted a 32t oval ring and it wouldn't even go round.

He said he could not crimp them as he didn't have the equipment to do it, but he ovalised them some more. There's a few mm more clearance, but I don't think I'll be able to run the adjustable dropouts on their shortest setting with 2.3 tyres in there. And 2.3 tyres are important because it's rocky where I live. I didn't want to have to compromise.

I'm disinclined to go back again, I'm sure he'll say that's the best he can do. So that brought me to the original question of whether or not I can crimp them myself. I'm fairly confident I could construct a jig to press a shaped piece of steel rod on the inside, but I'm not sure I could hear it up red without getting the rest of it too hot. But I'm not sure if it's a good idea from a metallurgy point of view.

I think I would.have preferred a more workable steel allowing the shape I wanted, but perhaps with a thicker walled tube to add a little weight and strength. But none of this was discussed which is a pain. And it cost me £200... I think he just didn't want to out much thought into the job tbh.

The original stays were heavily crimped, allowing use of both 2.4" tyres abd a triple chainset. It seems that this is a weakness in the original because they are prone to cracking. Although my non drive side was fine and not cracked so maybe my riding wasn't too hard on it. Anyway, when I went in I said "I didn't want to lose much tyre clearance". He airily agreed to this as if it wasn't going to be a problem. He didn't offer me a choice of materials or explain what he was going to do and what the implications would be.

When I got the frame back he did show me the results with the wheel in place and was fairy dismissive and being British I took it home and painted it up. But when I rebuilt the bike and had a proper look myself I decided that there was nowhere near enough clearance. So I went back and had a further chat, he said 'oh I could make these thinner'. Ok fine but why didn't you do this in the first place when I said I didn't want to lose clearance? The original stays were 11mm wide, the replacement were 20mm wide so a 9mm lost on each side, which is huge. Not only that but there was very little chainset clearance, and since I'm upgrading to 1x11 I've fitted a 32t oval ring and it wouldn't even go round.

He said he could not crimp them as he didn't have the equipment to do it, but he ovalised them some more. There's a few mm more clearance, but I don't think I'll be able to run the adjustable dropouts on their shortest setting with 2.3 tyres in there. And 2.3 tyres are important because it's rocky where I live. I didn't want to have to compromise.

I'm disinclined to go back again, I'm sure he'll say that's the best he can do. So that brought me to the original question of whether or not I can crimp them myself. I'm fairly confident I could construct a jig to press a shaped piece of steel rod on the inside, but I'm not sure I could hear it up red without getting the rest of it too hot. But I'm not sure if it's a good idea from a metallurgy point of view.

I think I would.have preferred a more workable steel allowing the shape I wanted, but perhaps with a thicker walled tube to add a little weight and strength. But none of this was discussed which is a pain. And it cost me £200... I think he just didn't want to out much thought into the job tbh.

#8

Senior Member

Join Date: Dec 2019

Posts: 953

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Liked 263 Times

in

212 Posts

Yes it's a dilly of a pickle. The 853 stays are probably the same thickness as 631 ones anyway, just unnecessarily strong and difficult to manipulate. You'd think that if it was really OK to heat them up like that Reynolds would say so. I don't think he should have used them but got you some cromoly or 631 stays and maybe a drive side yoke would be the best way to get the tyre and chainring clearance, or the S-bend Columbus stays might do it. I guess you could try going back and saying your tyres don't fit and you're not happy with him ignoring Reynolds advice on the tubes. If he replaces them again I don't think there will be any issue with the BB shell getting another heat cycle as they are very thick. Ditto the dropouts.

#9

Junior Member

Thread Starter

Join Date: Jan 2020

Posts: 5

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

I've lost the will to keep going back. It's a 2 hour round trip and they keep awkward hours.

I think I'll add a little crimp myself then if it fails I'll take it to someone who cares unless I'm risking fatiguing the metal if I do this? Should I warm then anneal it after working it?

unless I'm risking fatiguing the metal if I do this? Should I warm then anneal it after working it?

I think I'll add a little crimp myself then if it fails I'll take it to someone who cares

unless I'm risking fatiguing the metal if I do this? Should I warm then anneal it after working it?

unless I'm risking fatiguing the metal if I do this? Should I warm then anneal it after working it?

#10

Senior Member

Join Date: Dec 2019

Posts: 953

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Liked 263 Times

in

212 Posts

In the normal scheme of things everything is done cold. The chainstay is tapered, drawn, bent, butted (if it is butted), all cold, starting from a solid billet in many cases, and this is considered good for it (it's called "cold working").

Then if it's 853 or 725 or another heat-treated product it's cooked up in an oven and allowed to cool down in a special and carefully controlled way that makes it stronger but less ductile.

You then make it into a frame being careful to only heat it up as much as necessary to weld or braze it together. Generally it gets a bit weaker in the heat affected zone whatever you do (which is partly why you use butted tubes) but Reynolds claims that 631 and 853 get stronger (although they're still butted). How exactly that strengthening works is unclear and it's also unclear how much of it you can expect if you don't just do the normal welding or brazing that the tube is designed for.

So I would avoid any kind of heating. It's possible that you can squash the bit they already squashed a bit more as it will have been normalized by the heating they did. If it doesn't crack it's probably OK. I think you will find that if that that part of the tube has stayed heat treated then it will be very reluctant to deform and if so that's a good time to call it a day and give up before you crack it.

Then if it's 853 or 725 or another heat-treated product it's cooked up in an oven and allowed to cool down in a special and carefully controlled way that makes it stronger but less ductile.

You then make it into a frame being careful to only heat it up as much as necessary to weld or braze it together. Generally it gets a bit weaker in the heat affected zone whatever you do (which is partly why you use butted tubes) but Reynolds claims that 631 and 853 get stronger (although they're still butted). How exactly that strengthening works is unclear and it's also unclear how much of it you can expect if you don't just do the normal welding or brazing that the tube is designed for.

So I would avoid any kind of heating. It's possible that you can squash the bit they already squashed a bit more as it will have been normalized by the heating they did. If it doesn't crack it's probably OK. I think you will find that if that that part of the tube has stayed heat treated then it will be very reluctant to deform and if so that's a good time to call it a day and give up before you crack it.

#11

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,385

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,686 Times

in

2,509 Posts

I'm pretty sure I have some single bend true temper in my stash that are almost the same as the El Mar stays. The stock stays are single bend and have a deep dimple, at least on the ones that I have seen.

#12

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,053

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4194 Post(s)

Liked 3,837 Times

in

2,295 Posts

"Yes it's a dilly of a pickle". as guy153 says. This is why many builders avoid repairs of frames they didn't build, too much chance to have the situation mushroom bigger then it needs to be. I asked about the shop's manor of working with you and with the very nice description I see issues on both sides that have resulted in where you're at now. I assume the shop is fairly new to this stuff, or I hope they are as it's easier to understand their choices then if they knew what they were doing the whole time and with the complete situation. I do wonder about if they would have done differently if they were the ones to also paint and assemble the bike, although changing components during this just further complicates the path.

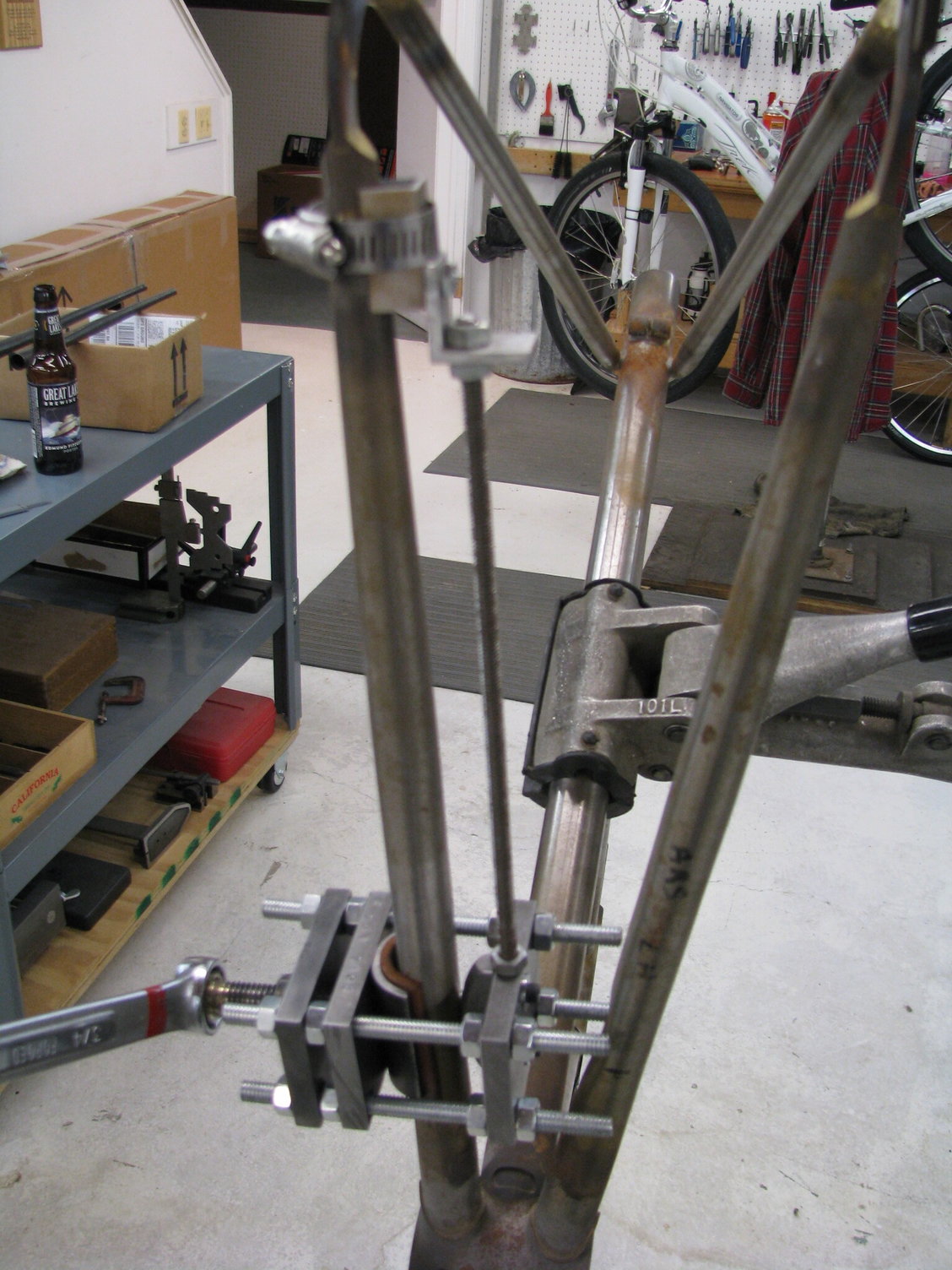

So as I earlier mentioned the only one that cares to do something is you. There are many ways to compress/crimp/dent stays for more clearance. I've done many and always cold. It's always preferred to use a method that if something slips or shifts from position unintended "damage" (remember a crimp is a specific and contained damage) doesn't happen. So using a force involving hammers takes some real focus Using screw driven forces reduce the OOPS results. Here's a shot of what I made to do this.

Using screw driven forces reduce the OOPS results. Here's a shot of what I made to do this.

So as I earlier mentioned the only one that cares to do something is you. There are many ways to compress/crimp/dent stays for more clearance. I've done many and always cold. It's always preferred to use a method that if something slips or shifts from position unintended "damage" (remember a crimp is a specific and contained damage) doesn't happen. So using a force involving hammers takes some real focus

Using screw driven forces reduce the OOPS results. Here's a shot of what I made to do this.

Using screw driven forces reduce the OOPS results. Here's a shot of what I made to do this.

__________________

AndrewRStewart

AndrewRStewart

#13

Senior Member

Join Date: Jan 2019

Posts: 528

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

Quoted: 237 Post(s)

Likes: 0

Liked 83 Times

in

64 Posts

Butted tubes are annealed several times in the butting process, there's a limit to how much cold working a tube can take, as cold work results in work hardening, so Reynolds selects particularly ductile grades of steel for butted tubes. The problem with the graph is that is shows only one spot for HAZ. Fusion welding is not a directly comparable process, and may affect what kinds of temperatures the HAZ point of reference was seeing. One would expect that it would show a state similar to as-quenched. Otherwise the heat treatment schedule of 631/853 is pretty much a mystery due to being proprietary.

631/853 will air harden if heated in excess of 850C. While Reynolds currently says that silver at 700C has a reduced propensity to anneal 853, the problem here is that air cooling grades of steel basically don't anneal in normal air. They must be cooled slowly and gradually, generally in a temperature controlled furnace, as to not quench the steel. Normal steels require the rapid thermal conduction of a quench medium like oil or water, and will anneal in air or a bucket of sand as an insulator. We often say anneal, but what we really mean here is temper. Once you reach anneal/quench temperature (brass brazing/welding), the original heat treatment is basically completely lost. Below this temperature is tempering which merely softens the heat treatment. What we're really concerned with here is tempering. Reynolds doesn't give us much on the heat treatment schedule since it's proprietary, however temperatures below 850C will soften 853.

While you might be able to effectively reduce 725 to 525 with a torch, 631 gets bumped up to something not quite 853 when heated to austenitization temps. Annealing or normalizing 853 into 631 would normally be a many hours long process of gradual cooling in a furnace. The trick here is to destroy the heat treatment with excessive tempering, which will reduce hardness and strength, but should also increase ductility a significant degree. While with a heat treated non-air-hardening steel like 753, you could go above 700C, and overtemper it and getting your certification rejected by Reynolds, then go even higher to 900C (brass) and anneal it with air cooling, do brass temperatures with 631 and it will harden with air cooling. Softening 853 without a heat treating furnace requires tempering as hot as possible without causing austenitization or even partial austenitization. Basically bringing it up past silver temps, but below bronze temps. Even then, it's uncertain how much crimping you can get away with. It's going to be 853 with a soft temper, not normalized/annealed 631.

631/853 will air harden if heated in excess of 850C. While Reynolds currently says that silver at 700C has a reduced propensity to anneal 853, the problem here is that air cooling grades of steel basically don't anneal in normal air. They must be cooled slowly and gradually, generally in a temperature controlled furnace, as to not quench the steel. Normal steels require the rapid thermal conduction of a quench medium like oil or water, and will anneal in air or a bucket of sand as an insulator. We often say anneal, but what we really mean here is temper. Once you reach anneal/quench temperature (brass brazing/welding), the original heat treatment is basically completely lost. Below this temperature is tempering which merely softens the heat treatment. What we're really concerned with here is tempering. Reynolds doesn't give us much on the heat treatment schedule since it's proprietary, however temperatures below 850C will soften 853.

While you might be able to effectively reduce 725 to 525 with a torch, 631 gets bumped up to something not quite 853 when heated to austenitization temps. Annealing or normalizing 853 into 631 would normally be a many hours long process of gradual cooling in a furnace. The trick here is to destroy the heat treatment with excessive tempering, which will reduce hardness and strength, but should also increase ductility a significant degree. While with a heat treated non-air-hardening steel like 753, you could go above 700C, and overtemper it and getting your certification rejected by Reynolds, then go even higher to 900C (brass) and anneal it with air cooling, do brass temperatures with 631 and it will harden with air cooling. Softening 853 without a heat treating furnace requires tempering as hot as possible without causing austenitization or even partial austenitization. Basically bringing it up past silver temps, but below bronze temps. Even then, it's uncertain how much crimping you can get away with. It's going to be 853 with a soft temper, not normalized/annealed 631.

Likes For Kuromori:

#14

Junior Member

Thread Starter

Join Date: Jan 2020

Posts: 5

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

To me, 'softer' suggests it's more ductile than in it's ex-factory form, so I should be ok to dimple it myself a bit. I don't think I can go anywhere near Salsa's original stays, but I could maybe add a few more mm which would bring the bike more in line with what you'd expect. There was tons of clearance on the original bike which was nice but perhaps not worth compromising strength for.

Re the shop - they've been around since 1973 and are a very famous name - one of few painting and repair shops that seem to be known nationally and the closest such place to me. Expensive, but I thought I was getting top notch work...

#15

Senior Member

Join Date: Jan 2019

Posts: 528

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

Quoted: 237 Post(s)

Likes: 0

Liked 83 Times

in

64 Posts

With air hardening steels there's only a certain range of heat that will soften it. If the builder went too far and tried to anneal the steel, he will have hardened it. If the builder went too little, he basically did nothing except damage the paint. If he got it just right, then it's still not as ductile as 653. Heat treatment generally isn't in the realm of a frame builder's toolset, and truisms for say heat-treated 4130 don't apply to 853, so I don't know what your framebuilder did or did not do.

The state of temper is more or less based on the maximum temperature the steel was brought up to post-quench. Generally speaking, as temperature goes up, strength decreases and ductility increases. For example a 600C temper will usually be harder and less ductile than a 700C temper. Heating it again afterwards to 500C isn't going to help. Now there's also stress relieving, where you bring up the temperature fairly high and hold it for a while then let it cool, but I don't know the correct procedure for 631/853. Reynolds intends for 631/853 to not require it for normal construction. In most cases, tempering the steel excessively would generally be considered damage to the heat treatment since it lowers strength. Again, there's an upper limit to tempering, once you hit critical temp (which brass/welding will), it's no longer tempering and will either harden when quenched (air for air-hardening, oil bath for 4130) or anneal (really more like normalize) when cooled slowly (hours of dropping temps in a furnace for air-hardening, air for 4130).

So the answer is maybe your frame builder tempered the steel and made it more ductile. Maybe he didn't. Maybe it could be tempered more.

The state of temper is more or less based on the maximum temperature the steel was brought up to post-quench. Generally speaking, as temperature goes up, strength decreases and ductility increases. For example a 600C temper will usually be harder and less ductile than a 700C temper. Heating it again afterwards to 500C isn't going to help. Now there's also stress relieving, where you bring up the temperature fairly high and hold it for a while then let it cool, but I don't know the correct procedure for 631/853. Reynolds intends for 631/853 to not require it for normal construction. In most cases, tempering the steel excessively would generally be considered damage to the heat treatment since it lowers strength. Again, there's an upper limit to tempering, once you hit critical temp (which brass/welding will), it's no longer tempering and will either harden when quenched (air for air-hardening, oil bath for 4130) or anneal (really more like normalize) when cooled slowly (hours of dropping temps in a furnace for air-hardening, air for 4130).

So the answer is maybe your frame builder tempered the steel and made it more ductile. Maybe he didn't. Maybe it could be tempered more.

Last edited by Kuromori; 01-19-20 at 06:18 PM.

#16

Junior Member

Thread Starter

Join Date: Jan 2020

Posts: 5

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

Hah, yes, good explanation thanks.

However given what people are saying about having had experience crimping 853 stays cold, it sounds as if I could maybe add a few mm of crimp and not be at too.mich risk of cracking it.

If he's heated it up enough, it'll be more ductile, if he hasn't then it'll be the same as spec, right?

However given what people are saying about having had experience crimping 853 stays cold, it sounds as if I could maybe add a few mm of crimp and not be at too.mich risk of cracking it.

If he's heated it up enough, it'll be more ductile, if he hasn't then it'll be the same as spec, right?

#18

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,890

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4788 Post(s)

Liked 3,914 Times

in

2,545 Posts

Breaking a chainstay is quite likely to be non-catastrophic failure, based on my experience. I had a Peugeot UO-8 chainstay break just behind the support. (I suspect a combination of the big crimping on both sides and many frame bending crashes. Also 22,000 miles. I never noticed it snapping. Just the bike felt a little different so I looked down and I saw the chainstay swinging in the breeze;

Ben

Ben

#19

Senior Member

Join Date: Jan 2019

Posts: 528

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

Quoted: 237 Post(s)

Likes: 0

Liked 83 Times

in

64 Posts

Hah, yes, good explanation thanks.

However given what people are saying about having had experience crimping 853 stays cold, it sounds as if I could maybe add a few mm of crimp and not be at too.mich risk of cracking it.

If he's heated it up enough, it'll be more ductile, if he hasn't then it'll be the same as spec, right?

However given what people are saying about having had experience crimping 853 stays cold, it sounds as if I could maybe add a few mm of crimp and not be at too.mich risk of cracking it.

If he's heated it up enough, it'll be more ductile, if he hasn't then it'll be the same as spec, right?

There's also a limit to how much steel can be cold worked before failure. The stays were already squished some, whatever you do is likely adding on top of that. Normally steel is annealed to reset the microstructure into a soft state ready for more cold working, like during the butting process. Heating an air hardening grade that high will result in hardening instead, and even if the stresses and microstructure are reset there, the whole tube isn't being heated. I don't really know the specific behaviors of 853 under heat treatment, but obviously, real actual controlled heat treating results in better results than waving a torch until it seems nice and hot for various reasons.

Sorry the advice isn't more practical, but this is clearly going against best practices, so everything is compromises and guesswork. I don't really know what the minimum you could get away with would be. Thinking on it some, first I would try to avoid this situation altogether. Since it's too late for that, I would probably try to temper it around ~750C, around the point when steel will stop being magnetic. This is pretty much critical temp for some steels, but Reynolds says temps lower than 850C will soften it, so I'd hope Reynold's metallurgists are relaying information accurately. I'd crimp until happy, with as gentle a form as possible, then bring it up to just north of 850C to minimize grain growth, maybe up to the point where bronze filler just starts melting but not further. Hopefully this deals with any of the stresses at the crimp, and makes it nice and hard to help resist abrasion from tire rub or nicking from chain suck.

#20

Senior Member

Join Date: Dec 2019

Posts: 953

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Liked 263 Times

in

212 Posts

I think Reynolds probably buy cold drawn seamless blanks and then butt them in their facility in Birmingham. Since they are only changing the diameter by a few tenths of a mm I don't think they do any more annealing of their own. But I'll see if I can find out more definitively.

#21

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,385

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,686 Times

in

2,509 Posts

I know there are people bending heat treated tubes, but I don't know how. Thinking about trying it with some chain stays. That's not quite as difficult as dimpling though

#22

Old fart

Join Date: Nov 2004

Location: Appleton WI

Posts: 24,776

Bikes: Several, mostly not name brands.

Mentioned: 153 Post(s)

Tagged: 0 Thread(s)

Quoted: 3582 Post(s)

Liked 3,394 Times

in

1,928 Posts

My recollection from the 753 days is that all the cold-working; butting, tapering, raking, etc., was done prior to the heat treatment.

Likes For JohnDThompson:

#23

Senior Member

Join Date: Jan 2019

Posts: 528

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

Quoted: 237 Post(s)

Likes: 0

Liked 83 Times

in

64 Posts

Thanks for the correction. I'm not sure if Reynolds do anneal between butting passes but I thought the whole thing was cold right from when it was a billet. But I have looked it up and there is some annealing between passes when making cold drawn seamless.

I think Reynolds probably buy cold drawn seamless blanks and then butt them in their facility in Birmingham. Since they are only changing the diameter by a few tenths of a mm I don't think they do any more annealing of their own. But I'll see if I can find out more definitively.

I think Reynolds probably buy cold drawn seamless blanks and then butt them in their facility in Birmingham. Since they are only changing the diameter by a few tenths of a mm I don't think they do any more annealing of their own. But I'll see if I can find out more definitively.

Regarding 853 however, Reynolds notes that 853 work hardens particularly easily and broke their drawing machines multiple times, thus requiring "repeated annealing (softening) after each stage" of drawing. This would be in line with Reynolds recommendations of not manipulating 853 much beyond cold setting, and makes it likely 631 tubes are annealed some point soon before leaving the factory.

#24

Senior Member

Join Date: Dec 2019

Posts: 953

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Liked 263 Times

in

212 Posts

You may enjoy this video:

Although they don't show the heat treatment (and those tubes they're making are 853).

Regarding 853 however, Reynolds notes that 853 work hardens particularly easily and broke their drawing machines multiple times, thus requiring "repeated annealing (softening) after each stage" of drawing. This would be in line with Reynolds recommendations of not manipulating 853 much beyond cold setting, and makes it likely 631 tubes are annealed some point soon before leaving the factory.

I have no idea where they get the 631 from though... Presumably they go to a steel mill and ask them to melt up an entire batch of their specified alloy, and maybe those guys do the inital cold drawing in the same facility.

#25

Senior Member

Join Date: Jan 2019

Posts: 528

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

Quoted: 237 Post(s)

Likes: 0

Liked 83 Times

in

64 Posts

Mandrel butting involves cold drawing a tube, but with a butted mandrel inside. If you want to cold draw other tubes, you use the same machine with the appropriate dies and without a butted mandrel. The butting process is just a modification of cold drawing. I don't know what Reynolds finds economical to do in house versus contracting out, but Reynolds is a tubing specialist, and it's not that unusual for tubing specialists to have this capability, even if they bring in seamless stock from outside. For non-cycling applications, butting is merely optional. I don't know what percent of sales is B2B non-cycling tubing and what percent is consumer facing cycling tubing, but non-cycling and non-butted tubes are part or Reynold's business. Reynolds says both that 631(853) is prone to work hardening, but is also suitable for the frame builder to manipulate cold. When I say that the tubes are annealed some point soon before leaving the factory, I mean that not much occurs after annealing, and that only minimal or no cold working has been done since the last annealing, not that they anneal them the last minute right before being loaded onto the truck.