Replacing a crankset

#26

Old fart

Join Date: Nov 2004

Location: Appleton WI

Posts: 24,792

Bikes: Several, mostly not name brands.

Mentioned: 153 Post(s)

Tagged: 0 Thread(s)

Quoted: 3591 Post(s)

Liked 3,401 Times

in

1,935 Posts

I'd be curious to know how they shorten them. I was first thinking cutting and welding, which may not be sound, but on the website, the cranks look so clean, my guess is starting with a long crank and drilling and tapping a pedal hole at a shorter length, then cutting off the end. (Starting with long crank, so original pedal hole is well away from new hole, so new hole has sufficient metal all the way around it.) Note, this will be a problem with a hollow arm crank, or one that is a U section (away from the original pedal hole) and not rectangular section.

Obviously, not all cranks are amenable to this treatment. Stonich knows which ones are, and those are the ones he sells from his site. He will also tell you if he thinks cranks you already own can be shortened.

#27

Old fart

Join Date: Nov 2004

Location: Appleton WI

Posts: 24,792

Bikes: Several, mostly not name brands.

Mentioned: 153 Post(s)

Tagged: 0 Thread(s)

Quoted: 3591 Post(s)

Liked 3,401 Times

in

1,935 Posts

Also, O.L.D.? Read about that but only the acronym. Haven't seen an explanation of what it stands for.

#28

Senior Member

Join Date: Aug 2009

Posts: 2,397

Mentioned: 14 Post(s)

Tagged: 0 Thread(s)

Quoted: 1563 Post(s)

Liked 1,737 Times

in

976 Posts

There is some misinformation floating around here. The >=11 speed Ultegra and Dura Ace cranksets are glued together with epoxy, which sometimes becomes unglued. The Shimano 105 crankset is all aluminum with no glue joints, and do not have that particular problem. So the 105 crankset is the best choice for a 160mm crankset.

If you want to go below 160mm, you can try the Origin8 square taper cranksets on Ebay. . I have used both the 110mm BCD type and the 130mm BCD type and they both worked fine on my kids and wife's bikes. I also tried the BBK crankset but that one uses the problematic GXP BB and I do not recommend that one. Cobb is another choice but that one also uses GXP BB.

If you want to go below 160mm, you can try the Origin8 square taper cranksets on Ebay. . I have used both the 110mm BCD type and the 130mm BCD type and they both worked fine on my kids and wife's bikes. I also tried the BBK crankset but that one uses the problematic GXP BB and I do not recommend that one. Cobb is another choice but that one also uses GXP BB.

#29

Senior Member

Join Date: Apr 2016

Posts: 1,244

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 504 Post(s)

Liked 437 Times

in

336 Posts

#30

Senior Member

Join Date: Apr 2019

Location: UK

Posts: 1,404

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 682 Post(s)

Liked 453 Times

in

338 Posts

Maybe I'm not explaining it well enough. The crankset on my K2 is a Ritchey and there is probably around 1.5" of full thickness aluminum at the ends of the crank arms. The existing pedal holes are towards the end of that thickness and they are stamped as 175mm arms. Now, I admit I'm just eye-balling this but I would guess there's at least 3/4" of an inch of full thickness aluminum from the inner most portion of the existing threaded hole to the scallop. Could be more. Either way, I'll probably take some measurements after work this week.

Kind of surprised regarding the Shimano recall. I guess they don't figure it's likely to be a life-and-death kind of failure.

Kind of surprised regarding the Shimano recall. I guess they don't figure it's likely to be a life-and-death kind of failure.

#31

Senior Member

Thread Starter

Thanks all for the information. Still a lot to digest.

Now at the risk of blending this topic with bike fit, I took a couple pictures today so you could get an idea of why and what I'm experiencing. Please forgive the rider, I was just wearing a raggedy t-shirt at the time.

But anyway, you can kind of see what my hip angle is when down on the aero bars at (more or less) the top of the stroke. I did this with a remote selfie stick so it was just a best guess as to crank arm position. This is at the top.

This is at the bottom of the crank stroke.

And for good measure, I took one at the 3 and 9 position.

Just as a reminder, this bike has FSA carbon 170mm crank arms. The thing I notice is this is as high as I can have my seat position without rocking my hips, which is all but slammed on the seat tube. But just looking at the pictures, it seems like I'm making too big of circles through the arc of travel. My leg is nearly locked at the bottom of the stroke and my hip angle is very acute at the top. I could probably go down to 155 or even 150 but I'm probably going to go with 160 simply for availability if I can't get shorter crank arms that work on this set.

Now at the risk of blending this topic with bike fit, I took a couple pictures today so you could get an idea of why and what I'm experiencing. Please forgive the rider, I was just wearing a raggedy t-shirt at the time.

But anyway, you can kind of see what my hip angle is when down on the aero bars at (more or less) the top of the stroke. I did this with a remote selfie stick so it was just a best guess as to crank arm position. This is at the top.

This is at the bottom of the crank stroke.

And for good measure, I took one at the 3 and 9 position.

Just as a reminder, this bike has FSA carbon 170mm crank arms. The thing I notice is this is as high as I can have my seat position without rocking my hips, which is all but slammed on the seat tube. But just looking at the pictures, it seems like I'm making too big of circles through the arc of travel. My leg is nearly locked at the bottom of the stroke and my hip angle is very acute at the top. I could probably go down to 155 or even 150 but I'm probably going to go with 160 simply for availability if I can't get shorter crank arms that work on this set.

#32

Senior Member

Photos: Thanks. Yeah, I think you need a much shorter crank, you would get less knee bend when at the top of stroke. I run my seat high to minimize that, with a straight leg at bottom of stroke, just like you show. Assuming you want to keep that straight leg at bottom, with a 15mm shorter crank, your seat would need to be raised 15mm to have the same straight leg, and that may mess up your position with respect to handle and aero bars. Just be aware of all that is going on.

Do-it-yourselfers: I'm the same, prefer to do it. HOWEVER... As a mechanical engineer and former toolmaker/machinist (worked my way through college), with a superpower of 3D geometry (even among other engineers), I must tell you that the new pedal hole axis, and thread axis (which can cock, even if the hole is correct), must be absolutely parallel with the crank rotating axis (bottom bracket). And I mean within a couple thousanths of an inch over the length of the pedal axis after installed. In the words of my high school vocational metals teacher, "That's gotta be dead nuts perfect." (Don't ask me the origin of that expression, might be the trade, might be Detroit.) If not, after you put the pedal on and rotate the crank, the pedal will not rotate straight, it will change in angle up/down and fore/aft as the crank goes through its rotation, because the pedal axis is fixed with respect to the crank, so any error in angle will be very felt in the pedal, not just feel low or high, but constantly moving the pedal, unless the pedal axis is *perfectly* parallel to the bottom bracket.

Now, cranks are not flat, and usually the surface is not perpindicular to the pedal hole axis (except perhaps on old 3-Speed cottered cranks). So eyeballing it in a drill press vice is essentially, playing roulette, and the odds of hitting your number are really small. Further, even if you do get the alignment perfect, long drills drift in angle, especially if it's been resharpened so not perfect. Best practice (as I stated in greater detail previously) is to align the crank perfect in a milling machine vice, lock the table down, spot face the area flat, and make the initial hole with a short and stout end mill, which will not drift, and then enlarge the hole. And then, tap the hole using the milling machine to keep it in alignment, but NO power, just rotate the tap by hand. All of the above will cost way more at a machine shop than you buying a new crank, as long as it's available, unless you have access to a vertical milling machine (like a "Bridgeport") and know how to run it.

If you pay to have your crank modified... my life experience has been, sometimes someone says they know how to do things, how dare you ask questions about competency, and they end up being a hack and destroying the item. So you may wish to ask, "How do you ensure the new pedal hole is absolutely parallel with the bottom bracket axis?" If they are just winging it in a drill press, I'd pass. Even if they made a jig that threads into the old pedal hole, to align by that, you can have error, due to "tolerance stacking". The old hole has a tolerance of error with respect to the BB axis, and that is added to any error for the new hole. You need to align with what needs alignment, that being the bottom bracket.

By the way, one of those shortened or factory short cranks above, the black one, appears (possibly) to not be threaded into the aluminum, but perhaps has a steel thread insert (those often have splines with a tight press fit into the material), I'd be curious about that if true.

Do-it-yourselfers: I'm the same, prefer to do it. HOWEVER... As a mechanical engineer and former toolmaker/machinist (worked my way through college), with a superpower of 3D geometry (even among other engineers), I must tell you that the new pedal hole axis, and thread axis (which can cock, even if the hole is correct), must be absolutely parallel with the crank rotating axis (bottom bracket). And I mean within a couple thousanths of an inch over the length of the pedal axis after installed. In the words of my high school vocational metals teacher, "That's gotta be dead nuts perfect." (Don't ask me the origin of that expression, might be the trade, might be Detroit.) If not, after you put the pedal on and rotate the crank, the pedal will not rotate straight, it will change in angle up/down and fore/aft as the crank goes through its rotation, because the pedal axis is fixed with respect to the crank, so any error in angle will be very felt in the pedal, not just feel low or high, but constantly moving the pedal, unless the pedal axis is *perfectly* parallel to the bottom bracket.

Now, cranks are not flat, and usually the surface is not perpindicular to the pedal hole axis (except perhaps on old 3-Speed cottered cranks). So eyeballing it in a drill press vice is essentially, playing roulette, and the odds of hitting your number are really small. Further, even if you do get the alignment perfect, long drills drift in angle, especially if it's been resharpened so not perfect. Best practice (as I stated in greater detail previously) is to align the crank perfect in a milling machine vice, lock the table down, spot face the area flat, and make the initial hole with a short and stout end mill, which will not drift, and then enlarge the hole. And then, tap the hole using the milling machine to keep it in alignment, but NO power, just rotate the tap by hand. All of the above will cost way more at a machine shop than you buying a new crank, as long as it's available, unless you have access to a vertical milling machine (like a "Bridgeport") and know how to run it.

If you pay to have your crank modified... my life experience has been, sometimes someone says they know how to do things, how dare you ask questions about competency, and they end up being a hack and destroying the item. So you may wish to ask, "How do you ensure the new pedal hole is absolutely parallel with the bottom bracket axis?" If they are just winging it in a drill press, I'd pass. Even if they made a jig that threads into the old pedal hole, to align by that, you can have error, due to "tolerance stacking". The old hole has a tolerance of error with respect to the BB axis, and that is added to any error for the new hole. You need to align with what needs alignment, that being the bottom bracket.

By the way, one of those shortened or factory short cranks above, the black one, appears (possibly) to not be threaded into the aluminum, but perhaps has a steel thread insert (those often have splines with a tight press fit into the material), I'd be curious about that if true.

Last edited by Duragrouch; 01-29-24 at 09:27 PM.

#33

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,369

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6222 Post(s)

Liked 4,222 Times

in

2,368 Posts

Photos: Thanks. Yeah, I think you need a much shorter crank, you would get less knee bend when at the top of stroke. I run my seat high to minimize that, with a straight leg at bottom of stroke, just like you show. Assuming you want to keep that straight leg at bottom, with a 15mm shorter crank, your seat would need to be raised 15mm to have the same straight leg, and that may mess up your position with respect to handle and aero bars. Just be aware of all that is going on.

Do-it-yourselfers: I'm the same, prefer to do it. HOWEVER... As a mechanical engineer and former toolmaker/machinist (worked my way through college), with a superpower of 3D geometry (even among other engineers), I must tell you that the new pedal hole axis, and thread axis (which can cock, even if the hole is correct), must be absolutely parallel with the crank rotating axis (bottom bracket). And I mean within a couple thousanths of an inch over the length of the pedal axis after installed. In the words of my high school vocational metals teacher, "That's gotta be dead nuts perfect." (Don't ask me the origin of that expression, might be the trade, might be Detroit.) If not, after you put the pedal on and rotate the crank, the pedal will not rotate straight, it will change in angle up/down and fore/aft as the crank goes through its rotation, because the pedal axis is fixed with respect to the crank, so any error in angle will be very felt in the pedal, not just feel low or high, but constantly moving the pedal, unless the pedal axis is *perfectly* parallel to the bottom bracket.

Do-it-yourselfers: I'm the same, prefer to do it. HOWEVER... As a mechanical engineer and former toolmaker/machinist (worked my way through college), with a superpower of 3D geometry (even among other engineers), I must tell you that the new pedal hole axis, and thread axis (which can cock, even if the hole is correct), must be absolutely parallel with the crank rotating axis (bottom bracket). And I mean within a couple thousanths of an inch over the length of the pedal axis after installed. In the words of my high school vocational metals teacher, "That's gotta be dead nuts perfect." (Don't ask me the origin of that expression, might be the trade, might be Detroit.) If not, after you put the pedal on and rotate the crank, the pedal will not rotate straight, it will change in angle up/down and fore/aft as the crank goes through its rotation, because the pedal axis is fixed with respect to the crank, so any error in angle will be very felt in the pedal, not just feel low or high, but constantly moving the pedal, unless the pedal axis is *perfectly* parallel to the bottom bracket.

Now, cranks are not flat, and usually the surface is not perpindicular to the pedal hole axis (except perhaps on old 3-Speed cottered cranks). So eyeballing it in a drill press vice is essentially, playing roulette, and the odds of hitting your number are really small. Further, even if you do get the alignment perfect, long drills drift in angle, especially if it's been resharpened so not perfect. Best practice (as I stated in greater detail previously) is to align the crank perfect in a milling machine vice, lock the table down, spot face the area flat, and make the initial hole with a short and stout end mill, which will not drift, and then enlarge the hole. And then, tap the hole using the milling machine to keep it in alignment, but NO power, just rotate the tap by hand. All of the above will cost way more at a machine shop than you buying a new crank, as long as it's available, unless you have access to a vertical milling machine (like a "Bridgeport") and know how to run it.

If you pay to have your crank modified... my life experience has been, sometimes someone says they know how to do things, how dare you ask questions about competency, and they end up being a hack and destroying the item. So you may wish to ask, "How do you ensure the new pedal hole is absolutely parallel with the bottom bracket axis?" If they are just winging it in a drill press, I'd pass. Even if they made a jig that threads into the old pedal hole, to align by that, you can have error, due to "tolerance stacking". The old hole has a tolerance of error with respect to the BB axis, and that is added to any error for the new hole. You need to align with what needs alignment, that being the bottom bracket.

By the way, one of those shortened or factory short cranks above, the black one, appears (possibly) to not be threaded into the aluminum, but perhaps has a steel thread insert (those often have splines with a tight press fit into the material), I'd be curious about that if true.

Finally, if you (or others) are really concerned about shortening an existing crank, the da Vinci crank is an option. Although people seem to be saying that there are lots of short cranks out there, Iíve had very poor luck actually finding one. 165mm has been the default for the better part of 40 years. TA and others are always ďrumoredĒ to have short cranks but getting one has been kind like hunting for unicorns. But, then, bicycle manufacturers havenít really made all that many small bikes for small people. Iíd love to put my small wife on a very light carbon bike but finding one that is less than 50cm is another unicorn hunt.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old SchoolÖWhen It Wasnít Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old SchoolÖWhen It Wasnít Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#34

Senior Member

(above) cyccommute,

All that you say above is reasonable. But with regard to precision alignment needed for the hole... have you ever ridden a bike with a bent pedal axle, even a little? If you have, exact same effect... with every... single... revolution. I totally agree that she needs a shorter crank, no question. But a wobbly pedal is gonna mess with her ankles, perhaps even knees as well. It's not a "small variance in the flatness of the pedal", because it's not static, but dynamic; It's not that the pedal is canted slightly down or up, it will do all of those things, flap every rev; up, forward, down, back. A variance in the flatness of the pedal *body*, will be static and unchanging.

All that you say above is reasonable. But with regard to precision alignment needed for the hole... have you ever ridden a bike with a bent pedal axle, even a little? If you have, exact same effect... with every... single... revolution. I totally agree that she needs a shorter crank, no question. But a wobbly pedal is gonna mess with her ankles, perhaps even knees as well. It's not a "small variance in the flatness of the pedal", because it's not static, but dynamic; It's not that the pedal is canted slightly down or up, it will do all of those things, flap every rev; up, forward, down, back. A variance in the flatness of the pedal *body*, will be static and unchanging.

Last edited by Duragrouch; 01-29-24 at 11:45 PM.

#35

Senior Member

Thread Starter

I have contacted Bikesmith and he is recommending a 150mm crankset. He has one available, but I have to admit, that big of a jump kind of scares me a little bit. I was thinking 160, or maybe down to 155mm. I'm probably going to go with it, especially since this is for the TT bike. If I like it, I'm probably going to go smaller on my road bikes, but may only go to 160 on them.

#36

Senior Member

I have contacted Bikesmith and he is recommending a 150mm crankset. He has one available, but I have to admit, that big of a jump kind of scares me a little bit. I was thinking 160, or maybe down to 155mm. I'm probably going to go with it, especially since this is for the TT bike. If I like it, I'm probably going to go smaller on my road bikes, but may only go to 160 on them.

#37

Method to My Madness

Join Date: Nov 2020

Location: Orange County, California

Posts: 3,674

Bikes: Trek FX 2, Cannondale Synapse, Cannondale CAAD4, Santa Cruz Stigmata GRX

Mentioned: 4 Post(s)

Tagged: 0 Thread(s)

Quoted: 1952 Post(s)

Liked 1,475 Times

in

1,022 Posts

But you have to wait a couple of weeks for the 160 mm version.

It seems both you and everyone else here just assumes your bike has a HollowTech bottom bracket (common enough and fits Shimano cranks); is that the case? I don't know as my experience only started with the 11-speed 105-5800 generation.

#38

Senior Member

Thread Starter

Let me let you in on a super secret: what you want is less at Bike Tires Direct than almost everywhere else: Shimano 105 FC-R7100 12 Speed Crankset [IFCR7100MX04] (biketiresdirect.com)

But you have to wait a couple of weeks for the 160 mm version.

It seems both you and everyone else here just assumes your bike has a HollowTech bottom bracket (common enough and fits Shimano cranks); is that the case? I don't know as my experience only started with the 11-speed 105-5800 generation.

But you have to wait a couple of weeks for the 160 mm version.

It seems both you and everyone else here just assumes your bike has a HollowTech bottom bracket (common enough and fits Shimano cranks); is that the case? I don't know as my experience only started with the 11-speed 105-5800 generation.

I just picked up a 2012 Synapse (stupid cheap) last week but I haven't even bothered getting into that one yet.

#39

Senior Member

Let me let you in on a super secret: what you want is less at Bike Tires Direct than almost everywhere else: Shimano 105 FC-R7100 12 Speed Crankset [IFCR7100MX04] (biketiresdirect.com)

But you have to wait a couple of weeks for the 160 mm version.

It seems both you and everyone else here just assumes your bike has a HollowTech bottom bracket (common enough and fits Shimano cranks); is that the case? I don't know as my experience only started with the 11-speed 105-5800 generation.

But you have to wait a couple of weeks for the 160 mm version.

It seems both you and everyone else here just assumes your bike has a HollowTech bottom bracket (common enough and fits Shimano cranks); is that the case? I don't know as my experience only started with the 11-speed 105-5800 generation.

#40

Senior Member

I don't think any of my bikes have Shimano cranksets off hand. I'll have to look tomorrow. Maybe my Roubiax. But I know for certain the Ridley has FSA and my K2 has Ritchey. But none of them are 12 speed. Both my Specialized and my K2 are 3x9 and the Ridley is 2x10

I just picked up a 2012 Synapse (stupid cheap) last week but I haven't even bothered getting into that one yet.

I just picked up a 2012 Synapse (stupid cheap) last week but I haven't even bothered getting into that one yet.

I truly LOVE the hollowtech II style design, axle integral with right crankarm/spider; The bearings are smoother, more durable, and able to adjust preload to take out slack. I'll never go back to square tapers (after I update bikes in time), nor will use any of the other proprietary interfaces (Octalink, et al). Hollowtech II was a masterstroke of design (assuming the axle never comes loose from the spider).

Last edited by Duragrouch; 01-30-24 at 12:21 AM.

#41

Method to My Madness

Join Date: Nov 2020

Location: Orange County, California

Posts: 3,674

Bikes: Trek FX 2, Cannondale Synapse, Cannondale CAAD4, Santa Cruz Stigmata GRX

Mentioned: 4 Post(s)

Tagged: 0 Thread(s)

Quoted: 1952 Post(s)

Liked 1,475 Times

in

1,022 Posts

2009_synapse_carbon_owners_manual_supplement_en.pdf (cannondale.com)

The latter works with a Shimano road crankset but the former does not.

I hope the new bike fits you better than your other bikes.

Last edited by SoSmellyAir; 01-31-24 at 12:28 AM.

#42

Senior Member

Join Date: Apr 2019

Location: UK

Posts: 1,404

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 682 Post(s)

Liked 453 Times

in

338 Posts

Yeah spindles are almost all 24mm (Shimano use this and GXP was mostly this with a 22mm end piece for the NDS bearing just to piss everyone off)

or 30mm (bb30 and PF30)

then SRAM introduced 29mm with DUB which also has longer spindles but that Ridley predates that so can ignore that possibility.

This chart is very useful. https://wheelsmfg.com/crankset-tech

I donít see that Jen would want to keep that straight leg so I reckon a 160 at most. Thatís losing power and maybe an injury waiting to happen. Your foot position on the pedal looks a bit forward of the ball of your foot too but Iím sure itís different in cleats.

or 30mm (bb30 and PF30)

then SRAM introduced 29mm with DUB which also has longer spindles but that Ridley predates that so can ignore that possibility.

This chart is very useful. https://wheelsmfg.com/crankset-tech

I donít see that Jen would want to keep that straight leg so I reckon a 160 at most. Thatís losing power and maybe an injury waiting to happen. Your foot position on the pedal looks a bit forward of the ball of your foot too but Iím sure itís different in cleats.

Last edited by choddo; 01-30-24 at 02:35 AM.

#43

Senior Member

Yeah spindles are almost all 24mm (Shimano use this and GXP was mostly this with a 22mm end piece for the NDS bearing just to piss everyone off)

or 30mm (bb30 and PF30)

then SRAM introduced 29mm with DUB which also has longer spindles but that Ridley predates that so can ignore that possibility.

This chart is very useful. https://wheelsmfg.com/crankset-tech

I donít see that Jen would want to keep that straight leg so I reckon a 160 at most. Thatís losing power and maybe an injury waiting to happen. Your foot position on the pedal looks a bit forward of the ball of your foot too but Iím sure itís different in cleats.

or 30mm (bb30 and PF30)

then SRAM introduced 29mm with DUB which also has longer spindles but that Ridley predates that so can ignore that possibility.

This chart is very useful. https://wheelsmfg.com/crankset-tech

I donít see that Jen would want to keep that straight leg so I reckon a 160 at most. Thatís losing power and maybe an injury waiting to happen. Your foot position on the pedal looks a bit forward of the ball of your foot too but Iím sure itís different in cleats.

I'm happy with my 24mm system with threaded external bearings into 68mm BB shell (replaced ancient-design separate square-taper axle, caged bearings, and cups, I stayed with that a long time, because it was *adjustable* to take up slack from wear, and rebuildable, cartridge BBs can't do that. NOTE: New caged bearings at LBS: $1 each); No need for any sort of press or tool to press bearings in and out. 24mm seems plenty stiff axle for me. I suppose if I bought a new road bike without a threaded BB, I'd need to use one of the newer standards, but that will never happen. I have one road bike, bought new in '89, and don't expect to ever buy another, I'm in townie and tour mode now. Durability, ease of service, low cost are what matters.

Last edited by Duragrouch; 01-30-24 at 04:15 AM.

#44

Senior Member

Join Date: Apr 2019

Location: UK

Posts: 1,404

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 682 Post(s)

Liked 453 Times

in

338 Posts

Nice link, thanks!

I'm happy with my 24mm system with threaded external bearings into 68mm BB shell (replaced ancient-design separate square-taper axle, caged bearings, and cups, I stayed with that a long time, because it was *adjustable* to take up slack from wear, and rebuildable, cartridge BBs can't do that. NOTE: New caged bearings at LBS: $1 each); No need for any sort of press or tool to press bearings in and out. 24mm seems plenty stiff axle for me. I suppose if I bought a new road bike without a threaded BB, I'd need to use one of the newer standards, but that will never happen. I have one road bike, bought new in '89, and don't expect to ever buy another, I'm in townie and tour mode now. Durability, ease of service, low cost are what matters.

I'm happy with my 24mm system with threaded external bearings into 68mm BB shell (replaced ancient-design separate square-taper axle, caged bearings, and cups, I stayed with that a long time, because it was *adjustable* to take up slack from wear, and rebuildable, cartridge BBs can't do that. NOTE: New caged bearings at LBS: $1 each); No need for any sort of press or tool to press bearings in and out. 24mm seems plenty stiff axle for me. I suppose if I bought a new road bike without a threaded BB, I'd need to use one of the newer standards, but that will never happen. I have one road bike, bought new in '89, and don't expect to ever buy another, I'm in townie and tour mode now. Durability, ease of service, low cost are what matters.

A lot to be said for keeping things maintainable. Someone expressed shock at my lack of electronic shifting and disc brakes on my 2019 bike at the weekend

#45

Senior Member

Join Date: Apr 2019

Location: UK

Posts: 1,404

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 682 Post(s)

Liked 453 Times

in

338 Posts

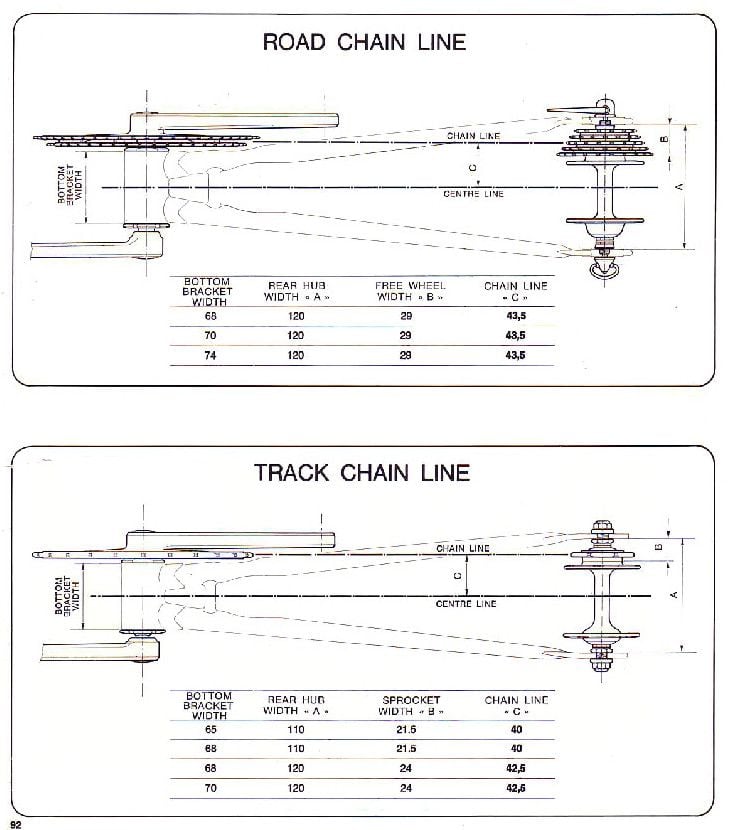

I managed to get hold of someone at Ridley and while they no longer list the Cheetah on their specs website as it's >10 years old (their words), they did tell me that it shipped with an FSA Platinum ISIS BB.

That's BSA threaded and most likely a 68mm shell and 108mm spindle and that gives a 43.5mm chainline which is the same as a Shimano (e.g.) 105 Hollowtech II crank on a BSA bottom bracket.

That's BSA threaded and most likely a 68mm shell and 108mm spindle and that gives a 43.5mm chainline which is the same as a Shimano (e.g.) 105 Hollowtech II crank on a BSA bottom bracket.

#46

Really Old Senior Member

152 mm / 6 inch is common on 24" wheel kids' bikes, also favoured by some fixie riders I believe. Finding some with interchangeable rings is not so easy, I have some that will work if I drill them, but then I found some proper 155 mm tandem cranks on clearance, which will work well for my 5'0" copilot.

I then ordered my 165mm triple once I discovered 165mm was for me.

TEST TEST TEST before you commit.

BTW- I made up a temporary cadence sensor to also help measure results. That's how I know 160mm didn't really give me but 3 RPM more than 165's and simply didn't "feel" good.

https://www.instructables.com/Very-E...-Your-Bike-12/

Last edited by Bill Kapaun; 01-30-24 at 05:27 AM.

#47

Senior Member

Join Date: Apr 2016

Posts: 1,244

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 504 Post(s)

Liked 437 Times

in

336 Posts

#48

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,369

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6222 Post(s)

Liked 4,222 Times

in

2,368 Posts

(above) cyccommute,

All that you say above is reasonable. But with regard to precision alignment needed for the hole... have you ever ridden a bike with a bent pedal axle, even a little? If you have, exact same effect... with every... single... revolution. I totally agree that she needs a shorter crank, no question. But a wobbly pedal is gonna mess with her ankles, perhaps even knees as well. It's not a "small variance in the flatness of the pedal", because it's not static, but dynamic; It's not that the pedal is canted slightly down or up, it will do all of those things, flap every rev; up, forward, down, back. A variance in the flatness of the pedal *body*, will be static and unchanging.

All that you say above is reasonable. But with regard to precision alignment needed for the hole... have you ever ridden a bike with a bent pedal axle, even a little? If you have, exact same effect... with every... single... revolution. I totally agree that she needs a shorter crank, no question. But a wobbly pedal is gonna mess with her ankles, perhaps even knees as well. It's not a "small variance in the flatness of the pedal", because it's not static, but dynamic; It's not that the pedal is canted slightly down or up, it will do all of those things, flap every rev; up, forward, down, back. A variance in the flatness of the pedal *body*, will be static and unchanging.

To put this is some perspective, if I were to ride a crank with the same 3.9 to 1 ratio, I’d be on cranks that are 208mm long. Even when using the smaller ratio of a 165mm crank, I’d be riding 198mm cranks. I’ve ridden 180mm cranks in the past and they were damned uncomfortable. I can’t imagine riding on a 198mm crank much less anything longer. No wonder my wife is less enthusiastic about riding then I am.

Another rant on this subject: Now that everyone and his brother…emphasis on the “his” and “brother” part…has discovered short cranks it’s amazing that they are starting to become available. Half the population could have benefitted from shorter cranks for the last 125+ years but bike manufacturers have a very long history of ignoring the needs of that half of the population.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old SchoolÖWhen It Wasnít Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old SchoolÖWhen It Wasnít Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Last edited by cyccommute; 01-30-24 at 10:07 AM.

#49

Senior Member

SRAM Rival and Apex cranks also come in 160mm length.

The Rival one is $140. The Apex one is $110 but only comes as a 1x.

The Rival one is $140. The Apex one is $110 but only comes as a 1x.

Last edited by Yan; 01-30-24 at 01:33 PM.

#50

Senior Member

A pedal that has a slight wobble in it is going to be far less damaging than the stress a very long crank puts on her knees. Iíll call your attention to this photo again. With cranks that are too long, her leg is folded at an angle that is 20% tighter than my knee is. Her hips are also at a slightly tighter angle than mine. Her leg has to extend further as well. Overall, her knees and hips are experiencing far more stress than mine are. She also can stand to climb which is not something that is easy to do if you are pushing cranks that are 35mm longer than they should be. Sure, a misaligned pedal may cause some discomfort but itís a small annoyance in comparison.

To put this is some perspective, if I were to ride a crank with the same 3.9 to 1 ratio, Iíd be on cranks that are 208mm long. Even when using the smaller ratio of a 165mm crank, Iíd be riding 198mm cranks. Iíve ridden 180mm cranks in the past and they were damned uncomfortable. I canít imagine riding on a 198mm crank much less anything longer. No wonder my wife is less enthusiastic about riding then I am.

Another rant on this subject: Now that everyone and his brotherÖemphasis on the ďhisĒ and ďbrotherĒ partÖhas discovered short cranks itís amazing that they are starting to become available. Half the population could have benefitted from shorter cranks for the last 125+ years but bike manufacturers have a very long history of ignoring the needs of that half of the population.

To put this is some perspective, if I were to ride a crank with the same 3.9 to 1 ratio, Iíd be on cranks that are 208mm long. Even when using the smaller ratio of a 165mm crank, Iíd be riding 198mm cranks. Iíve ridden 180mm cranks in the past and they were damned uncomfortable. I canít imagine riding on a 198mm crank much less anything longer. No wonder my wife is less enthusiastic about riding then I am.

Another rant on this subject: Now that everyone and his brotherÖemphasis on the ďhisĒ and ďbrotherĒ partÖhas discovered short cranks itís amazing that they are starting to become available. Half the population could have benefitted from shorter cranks for the last 125+ years but bike manufacturers have a very long history of ignoring the needs of that half of the population.