To Build A Better Brompton - Titanium custom Build [Advice Appreciated]

#76

Newbie

Thread Starter

I have one LTwoo Fold B derailleur.

In pictures, it looks nice but when you have it in your hands, its huge with a very big diameter wheel on its arm, heavy and cheap built. I do not understand why they put such a big diameter wheel on it, the Brompton tensionner has a small one and works well?

The other advantage of using an IGH is that most of them overdrive in their higher gears (by a factor of 1.467 for the Rohloff) what allows to have high enough gear inches with the Brompton small wheels with standard chainring and cog sizes (54t x 13t for the Rohloff) and avoid to use of very big chainring (like the 68t explained above).

In pictures, it looks nice but when you have it in your hands, its huge with a very big diameter wheel on its arm, heavy and cheap built. I do not understand why they put such a big diameter wheel on it, the Brompton tensionner has a small one and works well?

The other advantage of using an IGH is that most of them overdrive in their higher gears (by a factor of 1.467 for the Rohloff) what allows to have high enough gear inches with the Brompton small wheels with standard chainring and cog sizes (54t x 13t for the Rohloff) and avoid to use of very big chainring (like the 68t explained above).

Someones gotta be a space monkey I have no problem testing this out. If nothing else people can point to this thread and warn others in the future.

#77

Senior Member

Join Date: Feb 2017

Posts: 1,544

Mentioned: 4 Post(s)

Tagged: 0 Thread(s)

Quoted: 800 Post(s)

Likes: 0

Liked 247 Times

in

211 Posts

The same problem exists for 20" wheels.

To have about the same biggest gear inch as a Rohloff with a 54x13 with 35x349 wheels, with 35x406 wheels and a cassette with a 11t smallest cog, a 60t chainring is required.

Moulton that uses 20" wheels with 28x406 tires, mount a special cassette with a 10t smallest cog and a 58t biggest chainring.

Riese & Müller mount a 9-32t cassette with a 52t chainring on its derailleur Birdy Touring with 40x355 or 50x355 wheels (50x355 has an overall diameter very close to the one of 28x406, its the reason why its possible to mount ETRTO406 wheels on a Birdy).

To have about the same biggest gear inch as a Rohloff with a 54x13 with 35x349 wheels, with 35x406 wheels and a cassette with a 11t smallest cog, a 60t chainring is required.

Moulton that uses 20" wheels with 28x406 tires, mount a special cassette with a 10t smallest cog and a 58t biggest chainring.

Riese & Müller mount a 9-32t cassette with a 52t chainring on its derailleur Birdy Touring with 40x355 or 50x355 wheels (50x355 has an overall diameter very close to the one of 28x406, its the reason why its possible to mount ETRTO406 wheels on a Birdy).

#78

Newbie

Thread Starter

The same problem exists for 20" wheels.

To have about the same biggest gear inch as a Rohloff with a 54x13 with 35x349 wheels, with 35x406 wheels and a cassette with a 11t smallest cog, a 60t chainring is required.

Moulton that uses 20" wheels with 28x406 tires, mount a special cassette with a 10t smallest cog and a 58t biggest chainring.

Riese & Müller mount a 9-32t cassette with a 52t chainring on its derailleur Birdy Touring with 40x355 or 50x355 wheels (50x355 has an overall diameter very close to the one of 28x406, its the reason why its possible to mount ETRTO406 wheels on a Birdy).

To have about the same biggest gear inch as a Rohloff with a 54x13 with 35x349 wheels, with 35x406 wheels and a cassette with a 11t smallest cog, a 60t chainring is required.

Moulton that uses 20" wheels with 28x406 tires, mount a special cassette with a 10t smallest cog and a 58t biggest chainring.

Riese & Müller mount a 9-32t cassette with a 52t chainring on its derailleur Birdy Touring with 40x355 or 50x355 wheels (50x355 has an overall diameter very close to the one of 28x406, its the reason why its possible to mount ETRTO406 wheels on a Birdy).

#79

Senior Member

Join Date: Feb 2017

Posts: 1,544

Mentioned: 4 Post(s)

Tagged: 0 Thread(s)

Quoted: 800 Post(s)

Likes: 0

Liked 247 Times

in

211 Posts

Sorry, I thought that you were saying the 20" wheels would solve the gear inch problem and avoid the need for a big chainring if the smallest cog of the cassette is 11t!

There are several Brompton with cassette and the LTwoo Fold B derailleur also on 16" wheels and it seems to work but as written this derailleur is really heavy, big and low quality, I doubt that it will last long.

There are several Brompton with cassette and the LTwoo Fold B derailleur also on 16" wheels and it seems to work but as written this derailleur is really heavy, big and low quality, I doubt that it will last long.

#80

Newbie

Thread Starter

Sorry, I thought that you were saying the 20" wheels would solve the gear inch problem and avoid the need for a big chainring if the smallest cog of the cassette is 11t!

There are several Brompton with cassette and the LTwoo Fold B derailleur also on 16" wheels and it seems to work but as written this derailleur is really heavy, big and low quality, I doubt that it will last long.

There are several Brompton with cassette and the LTwoo Fold B derailleur also on 16" wheels and it seems to work but as written this derailleur is really heavy, big and low quality, I doubt that it will last long.

#81

Newbie

Thread Starter

I received a message from the factory I'm working with. The paint job is finished And will ship in about 7 business days give or take.

It looks gorgeous, but the moment I get my hands on the packaging I'm going straight to the titanium welders I know to examine this carefully. I did do some searching for another style of rear rack, the complication comes in the form of the disk brakes and handling that obstacle. Would be open to links to alternatives. I don't think however kinetics' is an option since he works with steel.

It looks gorgeous, but the moment I get my hands on the packaging I'm going straight to the titanium welders I know to examine this carefully. I did do some searching for another style of rear rack, the complication comes in the form of the disk brakes and handling that obstacle. Would be open to links to alternatives. I don't think however kinetics' is an option since he works with steel.

#82

Junior Member

Join Date: Sep 2012

Posts: 166

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Yes, the same problem exists with he 20" conversion of Kinetics and 20" wheels also increase the wheelbase, folded length and folded height (the amount depend of the overall wheel diameter, i.e. of the tire width).

Is this bike really available, I haven't seen anybody having one?

Is this bike really available, I haven't seen anybody having one?

#83

Newbie

Thread Starter

So quick update. The parts have finally arrived and as promised I went to the titanium welders I promised I would go to, and they were quite impressed with the results. There was some nit picks about the seatpost downtube but otherwise the parts in question seemed to meet their standards.

So I immediately went to my bike shop I was intending to build at and had a mechanic look at the parts and get ready to build. But almost instantly the mechanic was apprehensive to even consider it. While the shop I go to sells and repairs Bromptons, a from scratch build seems to be another level of complication. To make matters worse the mechanic spotted something the welders didn't...

The downtube for the front stem was slightly deformed at the top presumably from the weld for the attaching the front block. This made the mechanic question the quality of the rest of the build. I am looking at other mechanics meantime to see if this is tolerable or not and talking with the manufacturer about replacing this piece if this is the only issue. I wouldn't need to necessarily replace the whole piece as i could have the front half of the mainframe replaced if warranted. For now the seller asks to give it a chance see if it's within tolerance.

So I immediately went to my bike shop I was intending to build at and had a mechanic look at the parts and get ready to build. But almost instantly the mechanic was apprehensive to even consider it. While the shop I go to sells and repairs Bromptons, a from scratch build seems to be another level of complication. To make matters worse the mechanic spotted something the welders didn't...

The downtube for the front stem was slightly deformed at the top presumably from the weld for the attaching the front block. This made the mechanic question the quality of the rest of the build. I am looking at other mechanics meantime to see if this is tolerable or not and talking with the manufacturer about replacing this piece if this is the only issue. I wouldn't need to necessarily replace the whole piece as i could have the front half of the mainframe replaced if warranted. For now the seller asks to give it a chance see if it's within tolerance.

Likes For V1LLAGE_ID10T:

#84

Newbie

Thread Starter

Sorry it's been a while. wanted to provide a quick update one this build. I Was able to get this assembled with the help of a Brompton mechanic in my area, but there is still a lot that has to be done before it is deemed complete and will need extensive tweaks and tuning before the project is complete. Initial performance has been promising. The Bike at the time of wiring this is about 25 lbs. Lighter than my C line. Again my goal wasn't to use titanium for the sake of a lighter bike entirely as much as rust prevention and overall performance perks in shock absorption. The gearing on this has been impressive! I am a lot faster and have a much greater range now too. Gear slipping has happened and will need tuning as improvements are made.

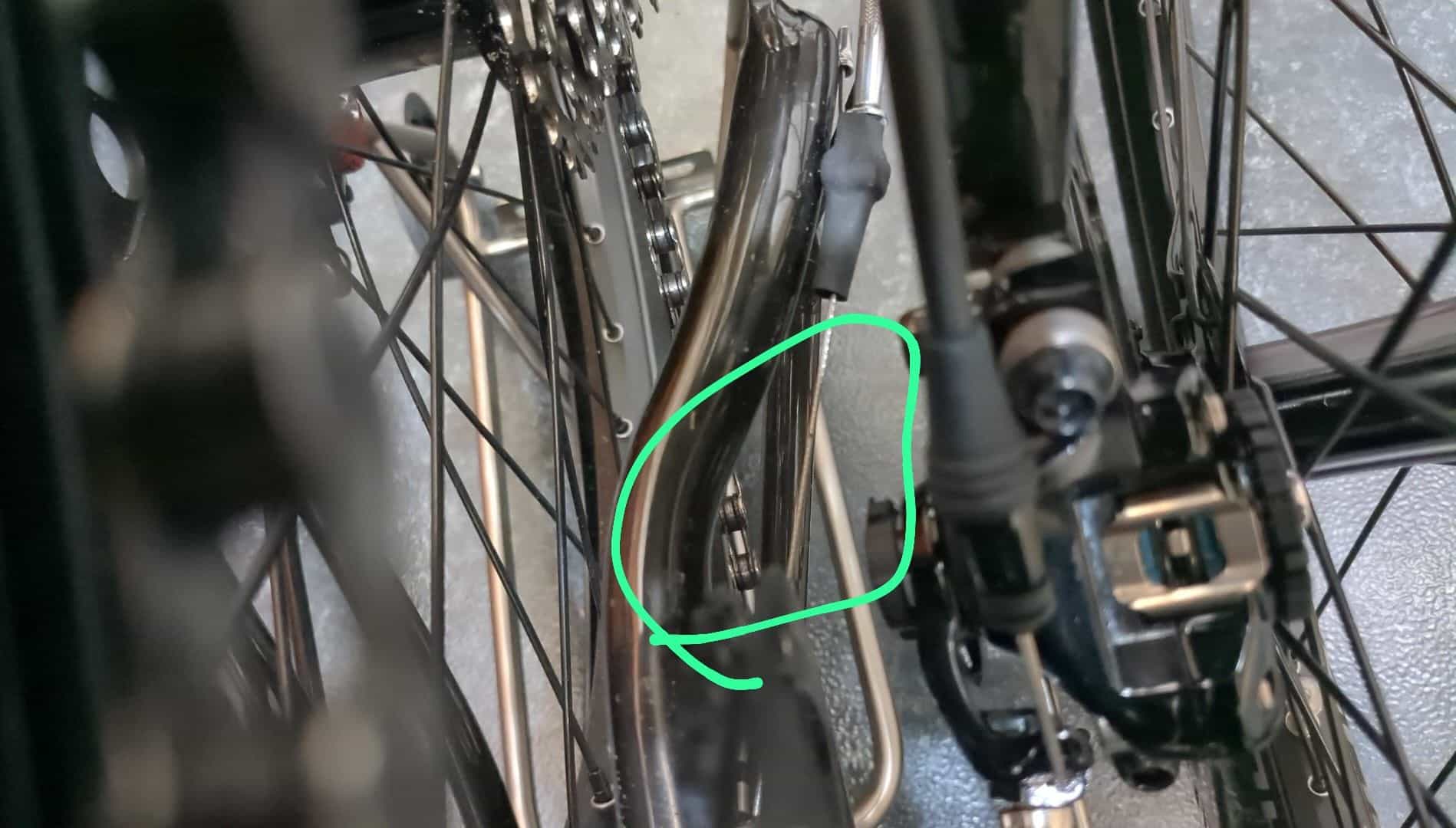

Keen eyed viewers will first notice the cable routing is wrong on this. Doing the cabling this way causes a catch on the stem clamp's crank. That's been taken care of already at the time of this writing. That along with moving the hub shifter to the left handlebar while the cassette shifter stays on the right bar. The majority of the remaining problems concern the folding hook and the catcher.

This shifting cable needs to be adjusted so when the rear triangle flips into folding mode it does not expose itself like this. The front fork hook could potentially catch it and cause issues. Given the curve in the rear triangle I will have to make a custom wire hook to grab the part of the rear triangle. It's further out. Would be curious to know what other people tried.

The catcher (not the bolt) needs to extend. I'll have to 3d print something to make this work. Alternatively cnc something out of aluminum. Will need measurements to better approximate this. Again really cool if others have figured this out.

#85

Senior Member

I'm new to this thread, have viewed some but not all. Nice build!

V1llage, sounds like you are in the Seattle area.

I have a Dahon Speed 20" outfit with 50/34 x 11-30, 21-85 gear inches on 1.75" section height I think. For me, the 85 is just tall enough, the 21 is mostly short enough. A local who has toured all over the world on his bike friday desires lower for the steeps, 15, but that slow, not sure if I would climb out of the saddle, or just walk it up (a nice change of pace, different muscles). I'd be interested in your gear range and if you use it all. So far, I've been very glad to have avoided an IGH, the double crank is simpler and I can do all maintenance. But 5 middle gears are duplicates.

I envy your more compact fold, I don't fold often, but for travel, yours' should be much superior, though it still requires a suitcase which would need to be stashed at the destination; Those who have been able to bring 16" Bromptons in a soft bag onboard as carry, that really appeals to me, versus careless baggage handlers, but that size has drawbacks for full pannier touring. I envy your disc brakes, both for better stopping, and not heating up the rims on long twisty downhills, nor eating the rim sidewalls.

I met someone who has a Burke 20" but was not riding it at the time. He liked my gearing setup better, he said his 1X external gearing had the derailleur nearly dragging on the ground.

Aaron's bike repair in White Center (a local IGH specialist) has stated on his website that he is against carbon fiber for anything except actual competing racers, due to fragility, and poor failure mode (as we engineers say, "non-graceful degradation mode) with shards, etc, and I've come to agree. You mentioned carbon early on as a possibility but looks like you have avoided. Titanium is great stuff.

Again, great build, keep us posted. Thanks.

V1llage, sounds like you are in the Seattle area.

I have a Dahon Speed 20" outfit with 50/34 x 11-30, 21-85 gear inches on 1.75" section height I think. For me, the 85 is just tall enough, the 21 is mostly short enough. A local who has toured all over the world on his bike friday desires lower for the steeps, 15, but that slow, not sure if I would climb out of the saddle, or just walk it up (a nice change of pace, different muscles). I'd be interested in your gear range and if you use it all. So far, I've been very glad to have avoided an IGH, the double crank is simpler and I can do all maintenance. But 5 middle gears are duplicates.

I envy your more compact fold, I don't fold often, but for travel, yours' should be much superior, though it still requires a suitcase which would need to be stashed at the destination; Those who have been able to bring 16" Bromptons in a soft bag onboard as carry, that really appeals to me, versus careless baggage handlers, but that size has drawbacks for full pannier touring. I envy your disc brakes, both for better stopping, and not heating up the rims on long twisty downhills, nor eating the rim sidewalls.

I met someone who has a Burke 20" but was not riding it at the time. He liked my gearing setup better, he said his 1X external gearing had the derailleur nearly dragging on the ground.

Aaron's bike repair in White Center (a local IGH specialist) has stated on his website that he is against carbon fiber for anything except actual competing racers, due to fragility, and poor failure mode (as we engineers say, "non-graceful degradation mode) with shards, etc, and I've come to agree. You mentioned carbon early on as a possibility but looks like you have avoided. Titanium is great stuff.

Again, great build, keep us posted. Thanks.

#86

Newbie

Thread Starter

I'm new to this thread, have viewed some but not all. Nice build!

V1llage, sounds like you are in the Seattle area.

I have a Dahon Speed 20" outfit with 50/34 x 11-30, 21-85 gear inches on 1.75" section height I think. For me, the 85 is just tall enough, the 21 is mostly short enough. A local who has toured all over the world on his bike friday desires lower for the steeps, 15, but that slow, not sure if I would climb out of the saddle, or just walk it up (a nice change of pace, different muscles). I'd be interested in your gear range and if you use it all. So far, I've been very glad to have avoided an IGH, the double crank is simpler and I can do all maintenance. But 5 middle gears are duplicates.

I envy your more compact fold, I don't fold often, but for travel, yours' should be much superior, though it still requires a suitcase which would need to be stashed at the destination; Those who have been able to bring 16" Bromptons in a soft bag onboard as carry, that really appeals to me, versus careless baggage handlers, but that size has drawbacks for full pannier touring. I envy your disc brakes, both for better stopping, and not heating up the rims on long twisty downhills, nor eating the rim sidewalls.

I met someone who has a Burke 20" but was not riding it at the time. He liked my gearing setup better, he said his 1X external gearing had the derailleur nearly dragging on the ground.

Aaron's bike repair in White Center (a local IGH specialist) has stated on his website that he is against carbon fiber for anything except actual competing racers, due to fragility, and poor failure mode (as we engineers say, "non-graceful degradation mode) with shards, etc, and I've come to agree. You mentioned carbon early on as a possibility but looks like you have avoided. Titanium is great stuff.

Again, great build, keep us posted. Thanks.

V1llage, sounds like you are in the Seattle area.

I have a Dahon Speed 20" outfit with 50/34 x 11-30, 21-85 gear inches on 1.75" section height I think. For me, the 85 is just tall enough, the 21 is mostly short enough. A local who has toured all over the world on his bike friday desires lower for the steeps, 15, but that slow, not sure if I would climb out of the saddle, or just walk it up (a nice change of pace, different muscles). I'd be interested in your gear range and if you use it all. So far, I've been very glad to have avoided an IGH, the double crank is simpler and I can do all maintenance. But 5 middle gears are duplicates.

I envy your more compact fold, I don't fold often, but for travel, yours' should be much superior, though it still requires a suitcase which would need to be stashed at the destination; Those who have been able to bring 16" Bromptons in a soft bag onboard as carry, that really appeals to me, versus careless baggage handlers, but that size has drawbacks for full pannier touring. I envy your disc brakes, both for better stopping, and not heating up the rims on long twisty downhills, nor eating the rim sidewalls.

I met someone who has a Burke 20" but was not riding it at the time. He liked my gearing setup better, he said his 1X external gearing had the derailleur nearly dragging on the ground.

Aaron's bike repair in White Center (a local IGH specialist) has stated on his website that he is against carbon fiber for anything except actual competing racers, due to fragility, and poor failure mode (as we engineers say, "non-graceful degradation mode) with shards, etc, and I've come to agree. You mentioned carbon early on as a possibility but looks like you have avoided. Titanium is great stuff.

Again, great build, keep us posted. Thanks.

In retrospect I was harsh on the burke. The Ti's properties might have lead to that. Performance wise best folding bike for me was a Bike Friday Pocket Rocket with an sram dual drive. I could keep up with road bikes with that thing. Only problems were the lack of disc brakes on it and the less elegant fold. Brompton's fold is the main attraction for me. It allows me in places other folding bikes arent allowed and doubles as my shopping bag and work bag for commutes. So this upgrade is meant for year round commuting and longer distances with performance. Refinement from here will simply bolster performance.

#87

Senior Member

Hmm, I'm not sure I understand you on this. The only thing "off-road" about it is that this particular prototype is that it has somewhat knobby tires, and who knows if those are even the only or final tires. Surely you could just install some road tires? You'd have so many to choose from at 20 inches

Having said the above, adding clip-on aero bars with a drink bottle, and a front rack and panniers, mostly forward of the steering axis, improved steering stability, for reasons having nothing to do with geometry; The weight, especially forward of the steering axis, added some mass damping (and polar moment) to the steering, and makes the bike want to steer in the direction it is banked/falling.

Last edited by Duragrouch; 01-18-24 at 12:06 AM.

#88

Senior Member

V1llage, you said earlier:

I am a retired M.E., so offering a little knowledge. You may be confusing material STIFFNESS with STRENGTH.

Let's says you have two pieces of steel, identical dimensions, one is "mild" low-strength steel, the other is high-strength spring steel. The mild one bends a little bit elastically, but then YIELDS (permanent deformation). The spring steel one can be bent much further without yield, because it has a higher yield strength (as well as a higher "ultimate tensile strength", i.e, the point at which is breaks/fractures). That is strength. BUT... NOTE!: Before the mild steel part yielded, when it was functioning within the ELASTIC LIMIT, its ELASTICITY/STIFFNESS was exactly the same as the higher strength steel part, in terms of force versus movement. This is the modulus of elasticity or stiffness, also known as Young's Modulus. Note: Within a given "family" of materials (like "steel", or "aluminum"), the stiffness changes very little, even as stength changes. (Some very new metal alloys have broken this rule, but let's dismiss that for now.) Steel stiffness is about 30x10^6 PSI. Aluminum is about 10x10^6 PSI, 1/3 as stiff, for the same geometry (size). Let's look at an example:

My 1989 Cannondale crit racer is made from 6061-T6 aluminum, and has a huge (for the time) 2" diameter down tube. To make from steel at low weight, the wall thickness would be so thin, it would be very dent-prone. With aluminum, for the same weight, the wall thickness can be 3X the thickness, so durable, because generally, the flat plate stiffness of something is a function of the cube of its thickness (this neglects hoop strength of the tubing curve, but let's stay simple). So even if the aluminum is 1/3 the stiffness, being 3X the thickness will give it 3^3 times stiffness, or 27X, but the material is 1/3 as stiff, so divide by 3, and you still get 9X as dent-stiff as a steel tube of same diameter and weight. But, torsional stiffness of a tube is a function of the 4th power of the radius, so that 2" down tube, versus 1", is gonna be about 2^4 stiffer in torsion, so about 16X stiffer, and that makes for an incredible bike in sprints and climbing, at the time, it was the stiffest frame Bicycling Magazine had ever tested. And it was probably not 3X wall thickness of a steel frame, because it was also lighter, 3 lbs. But, all that stiffness has a downside; It is so stiff in longitudinal bending, it had a terrible ride. After years of punishing ride and fatiguing two sets of rims, I fit touring rims with 32mm tires, far better.

Titanium is great, because it has much better fatigue strength than aluminum, and sometimes even steel, so it can offer a bit more spring to the frame, for better ride. I forget the stiffness modulus of Ti. It's also 1/2 the density of steel, so can still have a reasonable wall thickness for durability.

Carbon fiber composite is ideal in this respect, because they can orient the fibers on the frame tube to give superb torsional stiffness, but flex more in bending, to give both good ride and desired stiffness. However it is fragile, and if you bonk it, only a few places will repair it, maybe.

So, to conclude: Usually, bike frame STRENGTH comes into play for fatigue strength (long life) before the frame yielding is a factor. (Fatigue strength is cyclic loading at stresses below the yield strength of the part.) But for riding characteristics, the stiffness/elasticity is a whole different ball game. And that is a function of the material stiffness, the tube geometry (section modulus), and other geometric factors. A frame builder with a ton of experience with a particular material and geometry, can probably tell you off the top of their head, how a frame will behave, given the knowns above. The rest of us, would have to do a complete "solid model" of the frame on computer, do a Finite Element Analysis (FEA) of the frame under various load conditions, and even then, would need "baseline" values of a known frame with known ride characteristics, to then tell you, how the prospective new frame will "feel". Fortunately, at this point in history, the above will give "high-fidelity" in predicted results versus actual tests.

What is even MORE complex, is a computer program to predict the dynamic behavior of the bike, how it "handles". Dynamics of two-wheel bicycle systems (bikes and motorcycles, et al) is an entire field unto itself, only in recent decades having the computer simulation programs to predict; It used to be all trial and error.

Stiffness is exactly the reason I choose grade 5 for everything. I noticed the change in the frames on the official parts and saw that as a sign more strength would be required. I'm not a mechanical engineer but I assumed that using a stronger grade of titanium and as thick as I was able to get manufactured for me would take care of that.

Let's says you have two pieces of steel, identical dimensions, one is "mild" low-strength steel, the other is high-strength spring steel. The mild one bends a little bit elastically, but then YIELDS (permanent deformation). The spring steel one can be bent much further without yield, because it has a higher yield strength (as well as a higher "ultimate tensile strength", i.e, the point at which is breaks/fractures). That is strength. BUT... NOTE!: Before the mild steel part yielded, when it was functioning within the ELASTIC LIMIT, its ELASTICITY/STIFFNESS was exactly the same as the higher strength steel part, in terms of force versus movement. This is the modulus of elasticity or stiffness, also known as Young's Modulus. Note: Within a given "family" of materials (like "steel", or "aluminum"), the stiffness changes very little, even as stength changes. (Some very new metal alloys have broken this rule, but let's dismiss that for now.) Steel stiffness is about 30x10^6 PSI. Aluminum is about 10x10^6 PSI, 1/3 as stiff, for the same geometry (size). Let's look at an example:

My 1989 Cannondale crit racer is made from 6061-T6 aluminum, and has a huge (for the time) 2" diameter down tube. To make from steel at low weight, the wall thickness would be so thin, it would be very dent-prone. With aluminum, for the same weight, the wall thickness can be 3X the thickness, so durable, because generally, the flat plate stiffness of something is a function of the cube of its thickness (this neglects hoop strength of the tubing curve, but let's stay simple). So even if the aluminum is 1/3 the stiffness, being 3X the thickness will give it 3^3 times stiffness, or 27X, but the material is 1/3 as stiff, so divide by 3, and you still get 9X as dent-stiff as a steel tube of same diameter and weight. But, torsional stiffness of a tube is a function of the 4th power of the radius, so that 2" down tube, versus 1", is gonna be about 2^4 stiffer in torsion, so about 16X stiffer, and that makes for an incredible bike in sprints and climbing, at the time, it was the stiffest frame Bicycling Magazine had ever tested. And it was probably not 3X wall thickness of a steel frame, because it was also lighter, 3 lbs. But, all that stiffness has a downside; It is so stiff in longitudinal bending, it had a terrible ride. After years of punishing ride and fatiguing two sets of rims, I fit touring rims with 32mm tires, far better.

Titanium is great, because it has much better fatigue strength than aluminum, and sometimes even steel, so it can offer a bit more spring to the frame, for better ride. I forget the stiffness modulus of Ti. It's also 1/2 the density of steel, so can still have a reasonable wall thickness for durability.

Carbon fiber composite is ideal in this respect, because they can orient the fibers on the frame tube to give superb torsional stiffness, but flex more in bending, to give both good ride and desired stiffness. However it is fragile, and if you bonk it, only a few places will repair it, maybe.

So, to conclude: Usually, bike frame STRENGTH comes into play for fatigue strength (long life) before the frame yielding is a factor. (Fatigue strength is cyclic loading at stresses below the yield strength of the part.) But for riding characteristics, the stiffness/elasticity is a whole different ball game. And that is a function of the material stiffness, the tube geometry (section modulus), and other geometric factors. A frame builder with a ton of experience with a particular material and geometry, can probably tell you off the top of their head, how a frame will behave, given the knowns above. The rest of us, would have to do a complete "solid model" of the frame on computer, do a Finite Element Analysis (FEA) of the frame under various load conditions, and even then, would need "baseline" values of a known frame with known ride characteristics, to then tell you, how the prospective new frame will "feel". Fortunately, at this point in history, the above will give "high-fidelity" in predicted results versus actual tests.

What is even MORE complex, is a computer program to predict the dynamic behavior of the bike, how it "handles". Dynamics of two-wheel bicycle systems (bikes and motorcycles, et al) is an entire field unto itself, only in recent decades having the computer simulation programs to predict; It used to be all trial and error.

Last edited by Duragrouch; 01-15-24 at 01:52 AM.

#89

Newbie

Join Date: Feb 2021

Posts: 5

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 6 Post(s)

Liked 0 Times

in

0 Posts

I have one of those. But with a Nexus hub and it's electric. The battery is hidden in the frame.

The adjustable bars are a nice touch and the thicker/wider balloon tires are much better than the thinner bromptons.

The thing even with battery and motor doesn't weight more than a steel brompton.

The adjustable bars are a nice touch and the thicker/wider balloon tires are much better than the thinner bromptons.

The thing even with battery and motor doesn't weight more than a steel brompton.

#90

Senior Member

Join Date: Jun 2022

Location: The Ring of Fire

Posts: 932

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 463 Post(s)

Liked 567 Times

in

356 Posts

Last edited by Ron Damon; 02-14-24 at 05:24 AM.

Likes For Ron Damon:

#91

Newbie

Thread Starter

Hey everyone,

It's been a while since I posted but I wanted to provide some meaningful updates. Most of the time between this there have been very small very incremental updates that didn't really warrant a reply but now I thought I would share some updates...

I got the brake/shifting cables realigned on the bike making it ship shape for riding. I can confidently say this ride is FAST with was what I wanted. reaching top speed of course is still reserved for downhill and sparingly, but I can safely say mission accomplished in that department.

As I mentioned in previous posts the fold wasn't as tight as I was hoping it would be and my plans were to resolve this my making a few parts of my own. This was where I was starting to learn the valuable lesson of "if you want something done right you gotta do it yourself. The original plan was to 3d print an extended catcher and a custom hook that could be machined. The good news was I didn't need to 3d print the catcher it was just a matter of adjusting my shifters and brake lever's position as well as my front wheel's quick release lever so it didn't interfere with the fold.The next step was creating the longer hook...

Using a wire hanger I was able to get dimensions I needed to have designed a more suitable hook that I could use. I also angled it so the hook would not reach out as far as well as compensate for the curve. at the time of this writing I'm still waiting on a buddy to 3d print the part for me. While that happened I made a slightly better quick fix but it is not perfect....

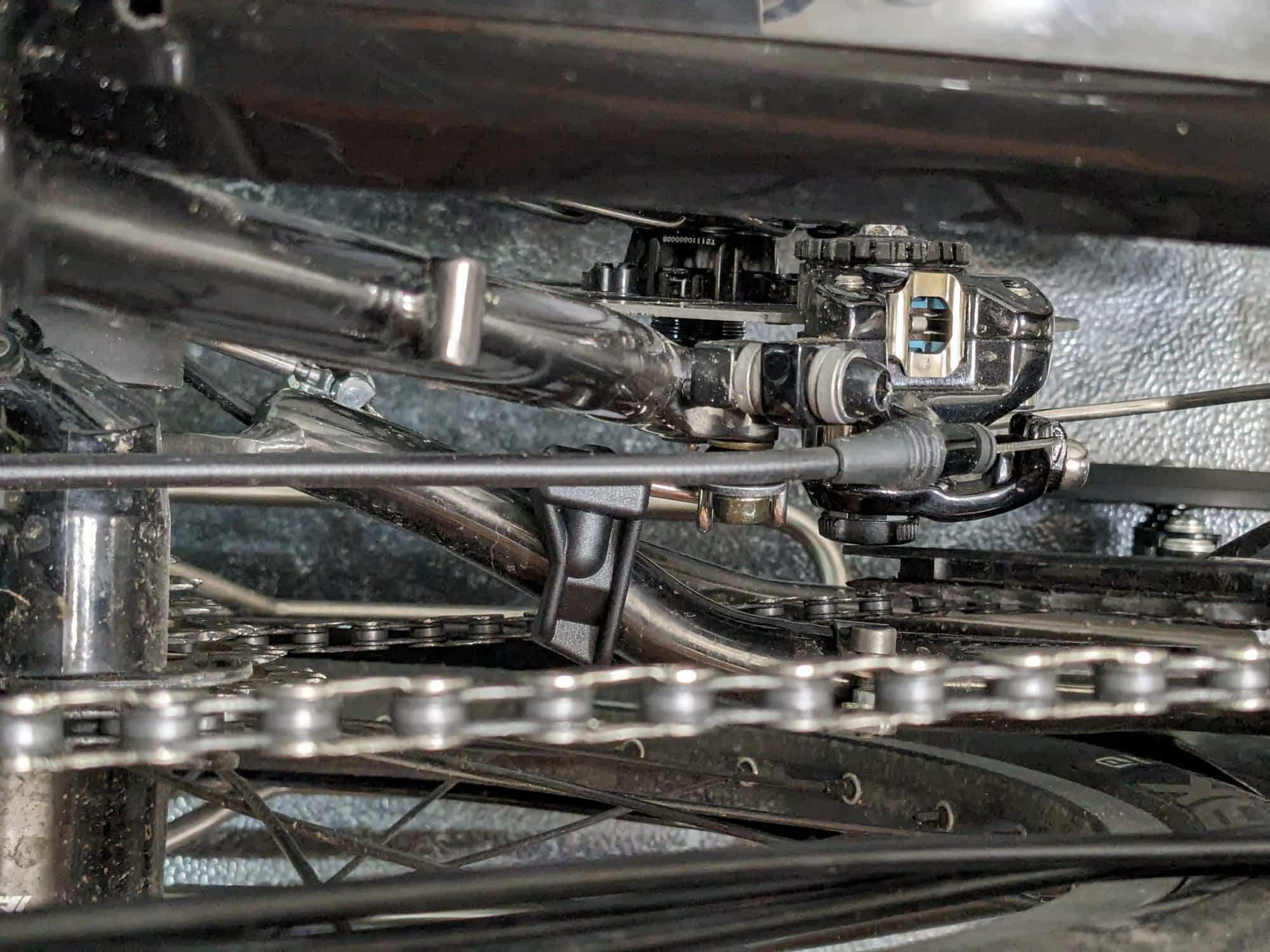

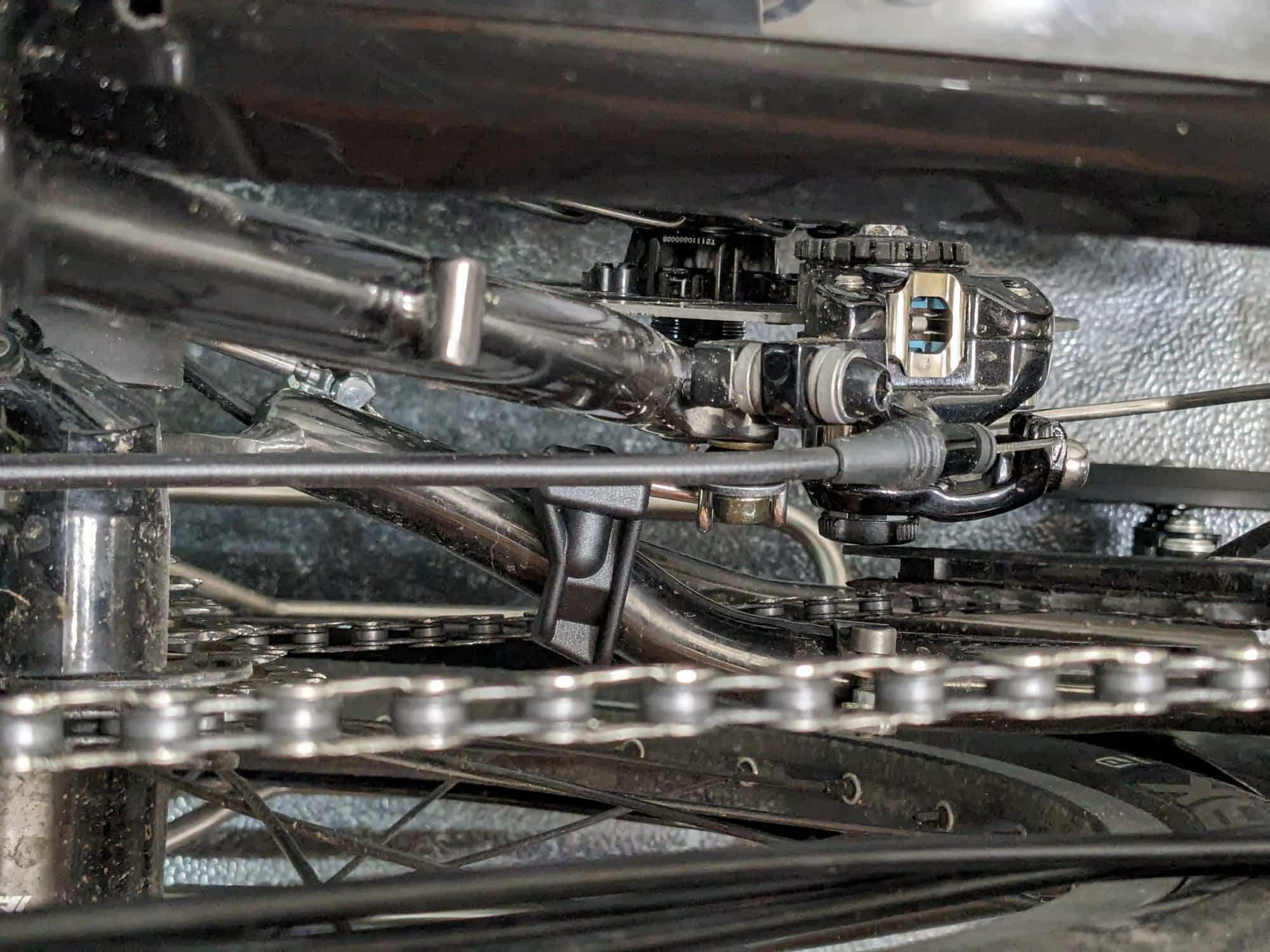

This hook is a much better approach that takes advantage of the disc brake's position and allows me to use an aftermarket hook. The problem is the wire is flimsy and so is the plastic. It's easy for it to bend and also pop out. Ideally the aftermarket stye of hook that clasps both ends of the frame preventing wiggle should be used but again that will have to be custom made.

I swapped out the front block and shock absorber with litepro counterparts as well as a , and from here I have been riding it but not as much as I would have hoped right now.

So when building this my big worry was how the fork would handle braking. The good news is it handled it extremely well! The main issue I have noticed flex happening in is in the mainframe, the stempost and the seatpost. When I initially saw the t-line I was dismissive of the frame's design changes believing them to be more about weight reduction than sturdiness. Turns out these changes also significantly reduce flex. Comparing my ride, the t-line was a stiffer ride. I also noticed the mainframe not only had bigger tubing to it but the mainframe of the t-line is also shorter.

When I ride It's a more comfortable ride, But I was hoping for a more rigid ride to go with the performance. The sizing up along with the disc brakes isn't as bad as people int eh forums here made it out to be. I can store it in places better than most 20" counterpart folding bikes still, but I will say that it gets in the way of what I call the "Fold Acceptance Factor" or FAF for short. Due to the complications I have faced with my hook issue I haven't been be to give the most concrete tests, But I found that in the cases I could I would become more of an interruption than a standard Brompton. I would have more cases where shopkeepers asked me to put it behind their counters verses roll it around with me like I did my c line. I think this might be different if I stuck with rim brakes for thinness, but hard to exactly test that right now. Ergonomically I really love the extra height in my handlebars when in cart mode.

Overall I'm glad I did this. I gave this a good shot and once I finish the hook I'm probably going to sell it. It's a great bike but a new build from scratch would likely need to be done to get the dream bike I want done.

When riding this I found myself constantly comparing against a pocket rocket I had, and my C line. I actually replaced replaced the drop bar of this with a with a flat bar because I liked riding out of the saddle and swinging with the stem to boost momentum and how solid it felt doing that which I learned to do with my C-line. I also loved the rear triangle doing away with a shock absorber in favor of a firm ride. Problem was the Fold Acceptance factor wasn't there like the Brompton was and the lack of disc brakes meant a hard no during winters. I'm still hoping for lighter so something titanium or carbon that's solid would be my go to. The closest Bike I found in the wold that matches this is the Java Neo 2 which folds similar to Brompton is in 20inch wheels with disc brakes but there's no rear rolling rack for a cart mode. I'm at a crossroad considering either just getting a proper t-line and calling it good or contacting the mechanical engineers I know to help me redesign something special. Either way I hope this gives some people something interesting worth sharing. Lemme know your thoughts.

It's been a while since I posted but I wanted to provide some meaningful updates. Most of the time between this there have been very small very incremental updates that didn't really warrant a reply but now I thought I would share some updates...

I got the brake/shifting cables realigned on the bike making it ship shape for riding. I can confidently say this ride is FAST with was what I wanted. reaching top speed of course is still reserved for downhill and sparingly, but I can safely say mission accomplished in that department.

As I mentioned in previous posts the fold wasn't as tight as I was hoping it would be and my plans were to resolve this my making a few parts of my own. This was where I was starting to learn the valuable lesson of "if you want something done right you gotta do it yourself. The original plan was to 3d print an extended catcher and a custom hook that could be machined. The good news was I didn't need to 3d print the catcher it was just a matter of adjusting my shifters and brake lever's position as well as my front wheel's quick release lever so it didn't interfere with the fold.The next step was creating the longer hook...

Using a wire hanger I was able to get dimensions I needed to have designed a more suitable hook that I could use. I also angled it so the hook would not reach out as far as well as compensate for the curve. at the time of this writing I'm still waiting on a buddy to 3d print the part for me. While that happened I made a slightly better quick fix but it is not perfect....

This hook is a much better approach that takes advantage of the disc brake's position and allows me to use an aftermarket hook. The problem is the wire is flimsy and so is the plastic. It's easy for it to bend and also pop out. Ideally the aftermarket stye of hook that clasps both ends of the frame preventing wiggle should be used but again that will have to be custom made.

I swapped out the front block and shock absorber with litepro counterparts as well as a , and from here I have been riding it but not as much as I would have hoped right now.

So when building this my big worry was how the fork would handle braking. The good news is it handled it extremely well! The main issue I have noticed flex happening in is in the mainframe, the stempost and the seatpost. When I initially saw the t-line I was dismissive of the frame's design changes believing them to be more about weight reduction than sturdiness. Turns out these changes also significantly reduce flex. Comparing my ride, the t-line was a stiffer ride. I also noticed the mainframe not only had bigger tubing to it but the mainframe of the t-line is also shorter.

When I ride It's a more comfortable ride, But I was hoping for a more rigid ride to go with the performance. The sizing up along with the disc brakes isn't as bad as people int eh forums here made it out to be. I can store it in places better than most 20" counterpart folding bikes still, but I will say that it gets in the way of what I call the "Fold Acceptance Factor" or FAF for short. Due to the complications I have faced with my hook issue I haven't been be to give the most concrete tests, But I found that in the cases I could I would become more of an interruption than a standard Brompton. I would have more cases where shopkeepers asked me to put it behind their counters verses roll it around with me like I did my c line. I think this might be different if I stuck with rim brakes for thinness, but hard to exactly test that right now. Ergonomically I really love the extra height in my handlebars when in cart mode.

Overall I'm glad I did this. I gave this a good shot and once I finish the hook I'm probably going to sell it. It's a great bike but a new build from scratch would likely need to be done to get the dream bike I want done.

When riding this I found myself constantly comparing against a pocket rocket I had, and my C line. I actually replaced replaced the drop bar of this with a with a flat bar because I liked riding out of the saddle and swinging with the stem to boost momentum and how solid it felt doing that which I learned to do with my C-line. I also loved the rear triangle doing away with a shock absorber in favor of a firm ride. Problem was the Fold Acceptance factor wasn't there like the Brompton was and the lack of disc brakes meant a hard no during winters. I'm still hoping for lighter so something titanium or carbon that's solid would be my go to. The closest Bike I found in the wold that matches this is the Java Neo 2 which folds similar to Brompton is in 20inch wheels with disc brakes but there's no rear rolling rack for a cart mode. I'm at a crossroad considering either just getting a proper t-line and calling it good or contacting the mechanical engineers I know to help me redesign something special. Either way I hope this gives some people something interesting worth sharing. Lemme know your thoughts.

Likes For V1LLAGE_ID10T:

#92

Senior Member

Stiffness: I'd mentioned before, material stiffness as a factor, cited values for steel and aluminum, but said I couldn't recall that for titanium. Well I just looked it up. The Young's modulus (elastic/stiffness) of titanium is half that of chrome-moly steel. It's better than aluminum, but still way less than steel. Note, this property tends to stay the same within a "family" of material, i.e., the same for grade-zip low-strength ("mild") steel as for high strength steel; It's not strength but material stiffness within the elastic region (stress lower than yield point). If you want equal stiffness to steel (original Brompton), you either need to go at least 2X the wall thickness, or, increase the tube diameter, and it doesn't take much, as torsional stiffness is a 4th power function; 2X the diameter equals 16X the torsional stiffness, for thin wall tubes of similar wall thickness. I'm only assuming the flex that is undesirable to you is frame torsion, because some flex in frame longitudinal bending helps ride quality.

From the looks of this, it's on 20" wheels, right? If true, that means a longer rear triangle, and given that it swings on a pivot and is not locked in place at the seat tubes, there is a longer lateral moment arm for flexing at that pivot, versus 349 Brompton. 20" wheels also mean a longer main frame tube than the 349 Brompton, to make the space for the bigger wheel when folded. That also contributes to more torsional flex, but at least it's linear; Ex- 20% longer means 20% more flex. If not proportionately longer frame tube, I think the folded alignment of the wheels will not match that of the Brompton, the front wheel will fold further aft than the swung-forward rear wheel. Also, if frame tube proportionately longer, for the same rider fit, the handlebar stem might not want to be near vertical like on a Brompton, but tilted aft, inline with the steering axis, for the same effective top-tube length.

The handlebar stem should not be longer than a 349 brompton, and if anything, shorter, which means better stiffness. If a 1-piece stem, it should be plenty rigid. (Some telescoping stems are a bit flexier than I desire.) But if the stem was made to Brompton dimensions but also from titanium, you would need to up the wall thickness or diameter to achieve the same bending stiffness, but I cannot recall if bending stiffness on a circular cross-section is a 2,3, or 4th power function of diameter (inner and outer, but less of a factor with a thin-wall tube).

If the seat tube is also titanium but same diameter and wall thickness as others made from steel, it's going to be less stiff. I've wondered about that on Bike Friday which has noticeably skinnier tubing than my Dahon, but I think they may consider than an advantage for ride.

The Bike Friday frame has 3 advantages in stiffness: 1) Larger section main tube (oval), 2) fixed rear triangle with clamped connection between seatstays and seat tube, 3) steel material.

Yours has been a valiant and courageous effort, and the results sound not bad, but not meeting your goals. I've run into this before with boats; People with no degree in naval architecture or even mechanical engineering, designing a boat hull and other systems, essentially by eyeball, and it not performing as expected. In the worst cases, immediately capsizing upon launching. You did better.

Without doing a whole computer solid model and finite element analysis, your effort would have been improved with just a few calculations, to ensure that the titanium tubes at least equaled the stiffness of the Brompton steel tubes, assuming you knew the wall thickness on all of the latter (outside dimensions can be easily measured). If changing proportions (which you are with 20" wheels), getting the frame fold perfect would require a computer solid model with kinematic manipulation (pretty much every CAD app these days), or, old-school, drawing it out using descriptive geometry. I was one of the last mechanical engineering graduates to have DG as a requirement.

From the looks of this, it's on 20" wheels, right? If true, that means a longer rear triangle, and given that it swings on a pivot and is not locked in place at the seat tubes, there is a longer lateral moment arm for flexing at that pivot, versus 349 Brompton. 20" wheels also mean a longer main frame tube than the 349 Brompton, to make the space for the bigger wheel when folded. That also contributes to more torsional flex, but at least it's linear; Ex- 20% longer means 20% more flex. If not proportionately longer frame tube, I think the folded alignment of the wheels will not match that of the Brompton, the front wheel will fold further aft than the swung-forward rear wheel. Also, if frame tube proportionately longer, for the same rider fit, the handlebar stem might not want to be near vertical like on a Brompton, but tilted aft, inline with the steering axis, for the same effective top-tube length.

The handlebar stem should not be longer than a 349 brompton, and if anything, shorter, which means better stiffness. If a 1-piece stem, it should be plenty rigid. (Some telescoping stems are a bit flexier than I desire.) But if the stem was made to Brompton dimensions but also from titanium, you would need to up the wall thickness or diameter to achieve the same bending stiffness, but I cannot recall if bending stiffness on a circular cross-section is a 2,3, or 4th power function of diameter (inner and outer, but less of a factor with a thin-wall tube).

If the seat tube is also titanium but same diameter and wall thickness as others made from steel, it's going to be less stiff. I've wondered about that on Bike Friday which has noticeably skinnier tubing than my Dahon, but I think they may consider than an advantage for ride.

The Bike Friday frame has 3 advantages in stiffness: 1) Larger section main tube (oval), 2) fixed rear triangle with clamped connection between seatstays and seat tube, 3) steel material.

Yours has been a valiant and courageous effort, and the results sound not bad, but not meeting your goals. I've run into this before with boats; People with no degree in naval architecture or even mechanical engineering, designing a boat hull and other systems, essentially by eyeball, and it not performing as expected. In the worst cases, immediately capsizing upon launching. You did better.

Without doing a whole computer solid model and finite element analysis, your effort would have been improved with just a few calculations, to ensure that the titanium tubes at least equaled the stiffness of the Brompton steel tubes, assuming you knew the wall thickness on all of the latter (outside dimensions can be easily measured). If changing proportions (which you are with 20" wheels), getting the frame fold perfect would require a computer solid model with kinematic manipulation (pretty much every CAD app these days), or, old-school, drawing it out using descriptive geometry. I was one of the last mechanical engineering graduates to have DG as a requirement.

Last edited by Duragrouch; 02-25-24 at 02:19 AM.