Shimano recalls cranksets

#51

Newbie

Join Date: Sep 2023

Location: Tex@55, USA

Posts: 15

Bikes: Waterford R-33, Salsa Journeyman Apex

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 6 Post(s)

Liked 10 Times

in

7 Posts

It is my interpretation of their wording that an actual physical paper check will be sent. I do not know if it will be sent to the consumer's mailing address or in the box with the replacement crank to the dealer.

Turn around time is also not known to me at this time.

Make certain that all of your contact information including your mailing address is up to date with your LBS, just in case Shimano intends to mail a check directly to you.

Cheers!

Turn around time is also not known to me at this time.

Make certain that all of your contact information including your mailing address is up to date with your LBS, just in case Shimano intends to mail a check directly to you.

Cheers!

Likes For Eddy_G:

#52

Senior Member

Join Date: Aug 2009

Posts: 2,395

Mentioned: 14 Post(s)

Tagged: 0 Thread(s)

Quoted: 1562 Post(s)

Liked 1,734 Times

in

974 Posts

.... Wipe it clean and give it a good visual on-the-bike inspection. I use a bright flashlight as well.

If the crankset is at all in question, then it will move forward to the Safety Notice Complete Inspection. This is much more detailed and involves removal, disassembly, and thorough cleaning before further visual inspection.

If the crankset is at all in question, then it will move forward to the Safety Notice Complete Inspection. This is much more detailed and involves removal, disassembly, and thorough cleaning before further visual inspection.

#53

Senior Member

Join Date: Apr 2011

Posts: 7,067

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4409 Post(s)

Liked 1,566 Times

in

1,028 Posts

Threadless was lighter. A new pedal standard is neither lighter nor safer.

#54

Senior Member

Join Date: Apr 2011

Posts: 7,067

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4409 Post(s)

Liked 1,566 Times

in

1,028 Posts

The shop should have asked.

#55

Mostly harmless

Join Date: Nov 2010

Location: Novi Sad

Posts: 4,430

Bikes: Heavy, with friction shifters

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 1107 Post(s)

Liked 216 Times

in

130 Posts

And yes, threadless is both lighter and safer. I suppose only lighter works for marketing, sales, and making money.

But at least they are happy to sell us helmets.

Relja

#56

Senior Member

Join Date: Apr 2019

Location: UK

Posts: 1,404

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 682 Post(s)

Liked 453 Times

in

338 Posts

The fretting damage and increased risk of cranks cracking at the pedal interface.

And yes, threadless is both lighter and safer. I suppose only lighter works for marketing, sales, and making money.

But at least they are happy to sell us helmets.

Relja

And yes, threadless is both lighter and safer. I suppose only lighter works for marketing, sales, and making money.

But at least they are happy to sell us helmets.

Relja

#57

Mostly harmless

Join Date: Nov 2010

Location: Novi Sad

Posts: 4,430

Bikes: Heavy, with friction shifters

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 1107 Post(s)

Liked 216 Times

in

130 Posts

The similar design is used for automobile wheel bolts (or nuts - depending on the wheel mount design, but there's always that tapered interface).

Relja

Likes For Bike Gremlin:

#58

Senior Member

Join Date: Apr 2011

Posts: 7,067

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4409 Post(s)

Liked 1,566 Times

in

1,028 Posts

The fretting damage and increased risk of cranks cracking at the pedal interface.

And yes, threadless is both lighter and safer. I suppose only lighter works for marketing, sales, and making money.

But at least they are happy to sell us helmets.

Relja

And yes, threadless is both lighter and safer. I suppose only lighter works for marketing, sales, and making money.

But at least they are happy to sell us helmets.

Relja

There is neither a safety or performance issue.

#60

Newbie

Join Date: Sep 2023

Location: Tex@55, USA

Posts: 15

Bikes: Waterford R-33, Salsa Journeyman Apex

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 6 Post(s)

Liked 10 Times

in

7 Posts

Not exactly the designer's intended use.

Likes For choddo:

#63

Mostly harmless

Join Date: Nov 2010

Location: Novi Sad

Posts: 4,430

Bikes: Heavy, with friction shifters

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 1107 Post(s)

Liked 216 Times

in

130 Posts

Apparently, the cycling industry (marketing teams) agree with your point of view, that it should not be fixed.

And so do most cyclists as far as I can tell.

Relja

#64

Senior Member

Join Date: Apr 2019

Location: UK

Posts: 1,404

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 682 Post(s)

Liked 453 Times

in

338 Posts

I don't have a problem with someone fixing it especially if it brings the cost down slightly in the long term since manufacturers could stop making left threaded pedals in about a century - but it's not a problem that has ever entered my sphere of consciousness in 40 years of cycling. In fact, knowing that you have to reverse thread the left side is one of those little things that makes you feel part of an "in group" so I can imagine some people don't want it "fixed".

#65

Mostly harmless

Join Date: Nov 2010

Location: Novi Sad

Posts: 4,430

Bikes: Heavy, with friction shifters

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 1107 Post(s)

Liked 216 Times

in

130 Posts

I don't have a problem with someone fixing it especially if it brings the cost down slightly in the long term since manufacturers could stop making left threaded pedals in about a century - but it's not a problem that has ever entered my sphere of consciousness in 40 years of cycling. In fact, knowing that you have to reverse thread the left side is one of those little things that makes you feel part of an "in group" so I can imagine some people don't want it "fixed".

The same situation we had with quill stems. It took an MTB enthusiast to fix the problem. Fortunately, in that case, his patent also allowed for lower weight (in addition to greater safety, which was his main concern as far as I understand), so it caught on, 'cause light weight sells in the cycling world.

Relja

#66

Senior Member

Join Date: Jan 2005

Location: Baltimore, MD

Posts: 5,378

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 2485 Post(s)

Liked 2,956 Times

in

1,679 Posts

I think most normal people don't even think about that until they have a problem. Even then, it's often blamed on "riding too hard," or a poor product sample (at best) - never on the poor design.

The same situation we had with quill stems. It took an MTB enthusiast to fix the problem. Fortunately, in that case, his patent also allowed for lower weight (in addition to greater safety, which was his main concern as far as I understand), so it caught on, 'cause light weight sells in the cycling world.

Relja

The same situation we had with quill stems. It took an MTB enthusiast to fix the problem. Fortunately, in that case, his patent also allowed for lower weight (in addition to greater safety, which was his main concern as far as I understand), so it caught on, 'cause light weight sells in the cycling world.

Relja

Same for the pedal eye design, except it has not yet been superseded. With the exception of some iffy Campy cranks and a few others, the failure rate has been so vanishingly low, no lawyers have managed to get rich suing over the issue.

#67

Mostly harmless

Join Date: Nov 2010

Location: Novi Sad

Posts: 4,430

Bikes: Heavy, with friction shifters

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 1107 Post(s)

Liked 216 Times

in

130 Posts

You can also decide (and debate on) whether they should be fixed or if it's just good enough.

But the noted problems (and their solutions for that matter) are a fact.

Relja

#68

Senior Member

Join Date: Apr 2011

Posts: 7,067

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4409 Post(s)

Liked 1,566 Times

in

1,028 Posts

You can describe them however you like (I suppose "challenge" is the modern term for the word "problem").

You can also decide (and debate on) whether they should be fixed or if it's just good enough.

But the noted problems (and their solutions for that matter) are a fact.

Relja

You can also decide (and debate on) whether they should be fixed or if it's just good enough.

But the noted problems (and their solutions for that matter) are a fact.

Relja

What is not an established fact is that the new design doesn't have it's own set of problems, under-tightened left pedals backing out being the most obvious. If the pedals were always installed by mechanics with torque wrenches, the chamfered design will work great. But if under-tightened it will back out, and if overtightened the taper will help split the crank end - something that the current design won't do.

The lack of 90 degree ledge in the pedal spindle will also make it harder to perceive when the pedal is started cross-thread.

To work correctly, the 45 degree taper can't be poorly machined. The current system is much more tolerant of sloppy fabrication.

The problem I always see with engineers is that they frequently see the upside of "the right way", while completely missing how consumer goods need to work even when used incorrectly - or at least be tolerant of misuse. They also seem to miss that change for change's sake is a mistake.

Take two bikes, one with the new pedal axle standard and one with the old. Which will perform better? Neither. It isn't lighter, smoother, stronger, easier to service or more aerodynamic.

Put 10,000 bikes on the road with the new pedal axle standard - how many will have pedal thread problems compared to 10,000 of the previous style? Quite possibly more. (See above)

Only a fool would take "Neither" and "Maybe more" and see the enormous waste of lost backwards compatibility as an advantage.

#69

Senior Member

Join Date: Apr 2011

Posts: 7,067

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4409 Post(s)

Liked 1,566 Times

in

1,028 Posts

I find the shape of those cranks to be designed for looks more than the strength or stiffness.

Circular cross-section or as close to it as reasonably possible would probably work better (but sell worse, 'cause it doesn't look cool & "aero").

Shimano Hollowtech II crank cross-section

Circular cross-section or as close to it as reasonably possible would probably work better (but sell worse, 'cause it doesn't look cool & "aero").

Shimano Hollowtech II crank cross-section

Given where the primary force is applied to the crank, this doesn't just sound like a bad ergonomic idea, but poor engineering. Like insisting an I beam needs to be as strong laterally as vertically.

Likes For Kontact:

#70

Mostly harmless

Join Date: Nov 2010

Location: Novi Sad

Posts: 4,430

Bikes: Heavy, with friction shifters

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 1107 Post(s)

Liked 216 Times

in

130 Posts

The noted problems are both a fact and rare.

What is not an established fact is that the new design doesn't have it's own set of problems, under-tightened left pedals backing out being the most obvious. If the pedals were always installed by mechanics with torque wrenches, the chamfered design will work great. But if under-tightened it will back out, and if overtightened the taper will help split the crank end - something that the current design won't do.

The lack of 90 degree ledge in the pedal spindle will also make it harder to perceive when the pedal is started cross-thread.

To work correctly, the 45 degree taper can't be poorly machined. The current system is much more tolerant of sloppy fabrication.

The problem I always see with engineers is that they frequently see the upside of "the right way", while completely missing how consumer goods need to work even when used incorrectly - or at least be tolerant of misuse. They also seem to miss that change for change's sake is a mistake.

Take two bikes, one with the new pedal axle standard and one with the old. Which will perform better? Neither. It isn't lighter, smoother, stronger, easier to service or more aerodynamic.

Put 10,000 bikes on the road with the new pedal axle standard - how many will have pedal thread problems compared to 10,000 of the previous style? Quite possibly more. (See above)

Only a fool would take "Neither" and "Maybe more" and see the enormous waste of lost backwards compatibility as an advantage.

What is not an established fact is that the new design doesn't have it's own set of problems, under-tightened left pedals backing out being the most obvious. If the pedals were always installed by mechanics with torque wrenches, the chamfered design will work great. But if under-tightened it will back out, and if overtightened the taper will help split the crank end - something that the current design won't do.

The lack of 90 degree ledge in the pedal spindle will also make it harder to perceive when the pedal is started cross-thread.

To work correctly, the 45 degree taper can't be poorly machined. The current system is much more tolerant of sloppy fabrication.

The problem I always see with engineers is that they frequently see the upside of "the right way", while completely missing how consumer goods need to work even when used incorrectly - or at least be tolerant of misuse. They also seem to miss that change for change's sake is a mistake.

Take two bikes, one with the new pedal axle standard and one with the old. Which will perform better? Neither. It isn't lighter, smoother, stronger, easier to service or more aerodynamic.

Put 10,000 bikes on the road with the new pedal axle standard - how many will have pedal thread problems compared to 10,000 of the previous style? Quite possibly more. (See above)

Only a fool would take "Neither" and "Maybe more" and see the enormous waste of lost backwards compatibility as an advantage.

A lot of those arguments could be used for threadless forks & stems. The main difference is that the threadless system promised lower weight - and was thus awesome for marketing.

The problem with the tapered pedal interface is it doesn't promise lower weight - if it did, it would probably have been adopted long ago in the cycling industry, even if all the potential problems you noted were very likely and very serious. I'm not convinced they are.

The system has been tested by enthusiasts on bikes, and it has been used for mounting automobile wheels for decades (automobile wheel bolts used to have left-handed thread on the left side at the start), since 1970s if I'm not mistaken.

Regarding the cranks splitting: I would expect threads to strip long before a crank gets split by a pedal being screwed in.

I find your argument about consumer misuse to be quite ironic. What I see very often is people not realizing that the left pedal has the left-hand thread. Tapered interface would solve that, real and common, problem too. The same goes for cranks cracking at the pedal interface - the existing system is prone to that so the consumers need to keep an eye out for any cracks on their cranks so their pedal doesn't rip-off (resulting in a fall, or a swerve into a cliff or traffic).

Relja Novovic

#71

Mostly harmless

Join Date: Nov 2010

Location: Novi Sad

Posts: 4,430

Bikes: Heavy, with friction shifters

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 1107 Post(s)

Liked 216 Times

in

130 Posts

Wait a minute, are you proposing to make cranks and Q factor even wider by increasing the width of the arm laterally?

Given where the primary force is applied to the crank, this doesn't just sound like a bad ergonomic idea, but poor engineering. Like insisting an I beam needs to be as strong laterally as vertically.

Given where the primary force is applied to the crank, this doesn't just sound like a bad ergonomic idea, but poor engineering. Like insisting an I beam needs to be as strong laterally as vertically.

So, they are bound to flex, especially when you stand on a pedal at 6 o'clock (with all your weight on the pedal), and that I believe helps with the cracking and water-induced galvanic corrosion.

There is some room on the inner (towards the bike) side - they are angled outwards already.

Relja

#72

Senior Member

Join Date: Apr 2011

Posts: 7,067

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4409 Post(s)

Liked 1,566 Times

in

1,028 Posts

I'm saying that the current design makes them look more aero, but the flat-width does nothing for making them stronger and stiffer where they need to be. It mostly just adds weight.

So, they are bound to flex, especially when you stand on a pedal at 6 o'clock (with all your weight on the pedal), and that I believe helps with the cracking and water-induced galvanic corrosion.

There is some room on the inner (towards the bike) side - they are angled outwards already.

Relja

So, they are bound to flex, especially when you stand on a pedal at 6 o'clock (with all your weight on the pedal), and that I believe helps with the cracking and water-induced galvanic corrosion.

There is some room on the inner (towards the bike) side - they are angled outwards already.

Relja

#73

Senior Member

Join Date: Apr 2011

Posts: 7,067

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4409 Post(s)

Liked 1,566 Times

in

1,028 Posts

I find your argument about consumer misuse to be quite ironic. What I see very often is people not realizing that the left pedal has the left-hand thread. Tapered interface would solve that, real and common, problem too. The same goes for cranks cracking at the pedal interface - the existing system is prone to that so the consumers need to keep an eye out for any cracks on their cranks so their pedal doesn't rip-off (resulting in a fall, or a swerve into a cliff or traffic).

Relja Novovic

Relja Novovic

Crank arms don't crack at pedal holes. If they tended to there would pictures of such occurrences.

https://www.google.com/search?q=cran...F_enUS972US972

No one is buying what you are selling.

#74

Full Member

For what it's worth, I have a crankset covered by this recall so I stopped into my LBS a few days ago and inquired about the process. The first words out of the owners' mouth were "You're not getting a new crank if it isn't broken." To which I replied, "How exactly is 'broken' defined?" The answer was, 'There has to be a visible gap between the two bonded surfaces of the crankarm.'

In other words, this is more like CYA from Shimano. They are absolutely not going to be giving away a million new high-end cranksets, so don't get your hopes up.

As an aside, this recall is an important topic, so perhaps it would be better to split the pedal-thread-standard conversion off into its own post. Just a suggestion.

In other words, this is more like CYA from Shimano. They are absolutely not going to be giving away a million new high-end cranksets, so don't get your hopes up.

As an aside, this recall is an important topic, so perhaps it would be better to split the pedal-thread-standard conversion off into its own post. Just a suggestion.

#75

Senior Member

Join Date: May 2010

Location: Bastrop Texas

Posts: 4,483

Bikes: Univega, Peu P6, Peu PR-10, Ted Williams, Peu UO-8, Peu UO-18 Mixte, Peu Dolomites

Mentioned: 13 Post(s)

Tagged: 0 Thread(s)

Quoted: 967 Post(s)

Liked 1,631 Times

in

1,047 Posts

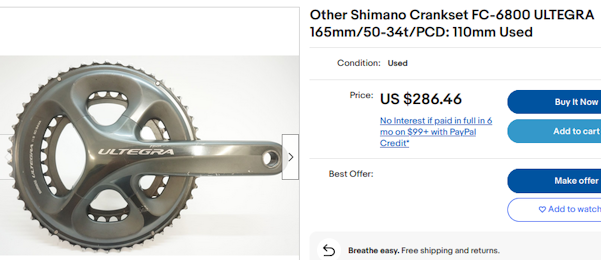

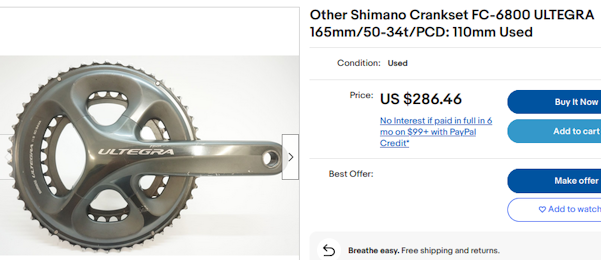

Wonder if this guy is going to go down in price?

Ebay 2023-09-28

Ebay 2023-09-28

__________________

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

No matter where you're at... There you are... Δf:=f(1/2)-f(-1/2)

Likes For zandoval: