Got NR/SR cranks and a torque wrench?

#27

Senior Member

Join Date: Apr 2011

Posts: 7,163

Mentioned: 42 Post(s)

Tagged: 0 Thread(s)

Quoted: 4469 Post(s)

Liked 1,608 Times

in

1,057 Posts

Ah, no. The worst case is that you keep forcing the crank further and further onto the spindle until the crank fails. Crank bolt torque is an installation number, not a permanent setting.

#28

Senior Member

Join Date: Oct 2015

Location: PDX

Posts: 13,103

Bikes: Merz x 5 + Specialized Merz Allez x 2, Strawberry/Newlands/DiNucci/Ti x3, Gordon, Fuso/Moulton x2, Bornstein, Paisley,1958-74 Paramounts x3, 3rensho, 74 Moto TC, 73-78 Raleigh Pro's x5, Marinoni x2, 1960 Cinelli SC, 1980 Bianchi SC, PX-10 X 2

Mentioned: 269 Post(s)

Tagged: 0 Thread(s)

Quoted: 4522 Post(s)

Liked 6,415 Times

in

3,692 Posts

Yep me too, I'm a greaser who has never owned a torque wrench. I use a ratchet wrench most often but it's the same length as a peanutbutter, just a bit more comfy on the hand so I might get them a bit tighter than most people would with a PB wrench. I don't re-tighten them after riding, it's set-and-forget until the next servicing. My cranks stay on and don't split or get wallowed out. When I was racing I trained and raced in all weather, so my NR BB bearings got repacked on the regular, lots of removal/re-installs, so if I was doing damage to my cranks, I would have noticed it. Oh and I probably did my first in about 1971, a tad more years than Steel Charlie . Some of those years I was a paid wrench at a LBS.

I'm not trying to get anyone else to do it my way, I just know what works for me.

I'm not trying to get anyone else to do it my way, I just know what works for me.

#29

Ride, Wrench, Swap, Race

Join Date: Jan 2010

Location: Northern California

Posts: 9,196

Bikes: Cheltenham-Pedersen racer, Boulder F/S Paris-Roubaix, Varsity racer, '52 Christophe, '62 Continental, '92 Merckx, '75 Limongi, '76 Presto, '72 Gitane SC, '71 Schwinn SS, etc.

Mentioned: 132 Post(s)

Tagged: 0 Thread(s)

Quoted: 1566 Post(s)

Liked 1,299 Times

in

867 Posts

I bought a rental bike once, a Marin Vicenza having Campagnolo Veloce cranks which cracked (on the left arm, at the spindle end) a few months after I bought it.

I theorized that the rental shop probably had a policy of "checking" bolt tightness all over every bike between rentals. Either that or perhaps someone huge had rented it out(?), and/or their mechanic perhaps used an extra long wrench handle on an 8mm hex key socket.

I theorized that the rental shop probably had a policy of "checking" bolt tightness all over every bike between rentals. Either that or perhaps someone huge had rented it out(?), and/or their mechanic perhaps used an extra long wrench handle on an 8mm hex key socket.

#30

seŮor miembro

Join Date: Dec 2018

Location: Pac NW

Posts: 6,648

Bikes: '70s - '80s Campagnolo

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 3901 Post(s)

Liked 6,511 Times

in

3,226 Posts

I'm a greaser.

Likes For SurferRosa:

#31

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,846

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 846 Post(s)

Liked 1,278 Times

in

674 Posts

Campy arms are quite soft and just blindly following "the torque spec" may not be the way to go. That said, I'd suggest no more than 240-260 in lb.for the "classic" NR / SR arms. Newer ones a bit more.

for Shimano square taper cranks, 280 - 300 in lb is fine.

An important mechanical skill is to develop a feel for when the "running torque" rises to a stall level, not just relying on when the torque wrench clicks. This "feel" is important when threading spark plugs into Porsche cylinder heads for example. Strip out a spark plug hole and it's engine out and the heads come off.

/markp

Likes For mpetry912:

#32

Senior Member

Join Date: Oct 2015

Location: PDX

Posts: 13,103

Bikes: Merz x 5 + Specialized Merz Allez x 2, Strawberry/Newlands/DiNucci/Ti x3, Gordon, Fuso/Moulton x2, Bornstein, Paisley,1958-74 Paramounts x3, 3rensho, 74 Moto TC, 73-78 Raleigh Pro's x5, Marinoni x2, 1960 Cinelli SC, 1980 Bianchi SC, PX-10 X 2

Mentioned: 269 Post(s)

Tagged: 0 Thread(s)

Quoted: 4522 Post(s)

Liked 6,415 Times

in

3,692 Posts

I would suggest to you that 300 inch / lb is too much torque for Campy cranks. I believe you are at risk of splitting the arms at that torque level.

Campy arms are quite soft and just blindly following "the torque spec" may not be the way to go. That said, I'd suggest no more than 240-260 in lb.for the "classic" NR / SR arms. Newer ones a bit more.

for Shimano square taper cranks, 280 - 300 in lb is fine.

An important mechanical skill is to develop a feel for when the "running torque" rises to a stall level, not just relying on when the torque wrench clicks. This "feel" is important when threading spark plugs into Porsche cylinder heads for example. Strip out a spark plug hole and it's engine out and the heads come off.

/markp

Campy arms are quite soft and just blindly following "the torque spec" may not be the way to go. That said, I'd suggest no more than 240-260 in lb.for the "classic" NR / SR arms. Newer ones a bit more.

for Shimano square taper cranks, 280 - 300 in lb is fine.

An important mechanical skill is to develop a feel for when the "running torque" rises to a stall level, not just relying on when the torque wrench clicks. This "feel" is important when threading spark plugs into Porsche cylinder heads for example. Strip out a spark plug hole and it's engine out and the heads come off.

/markp

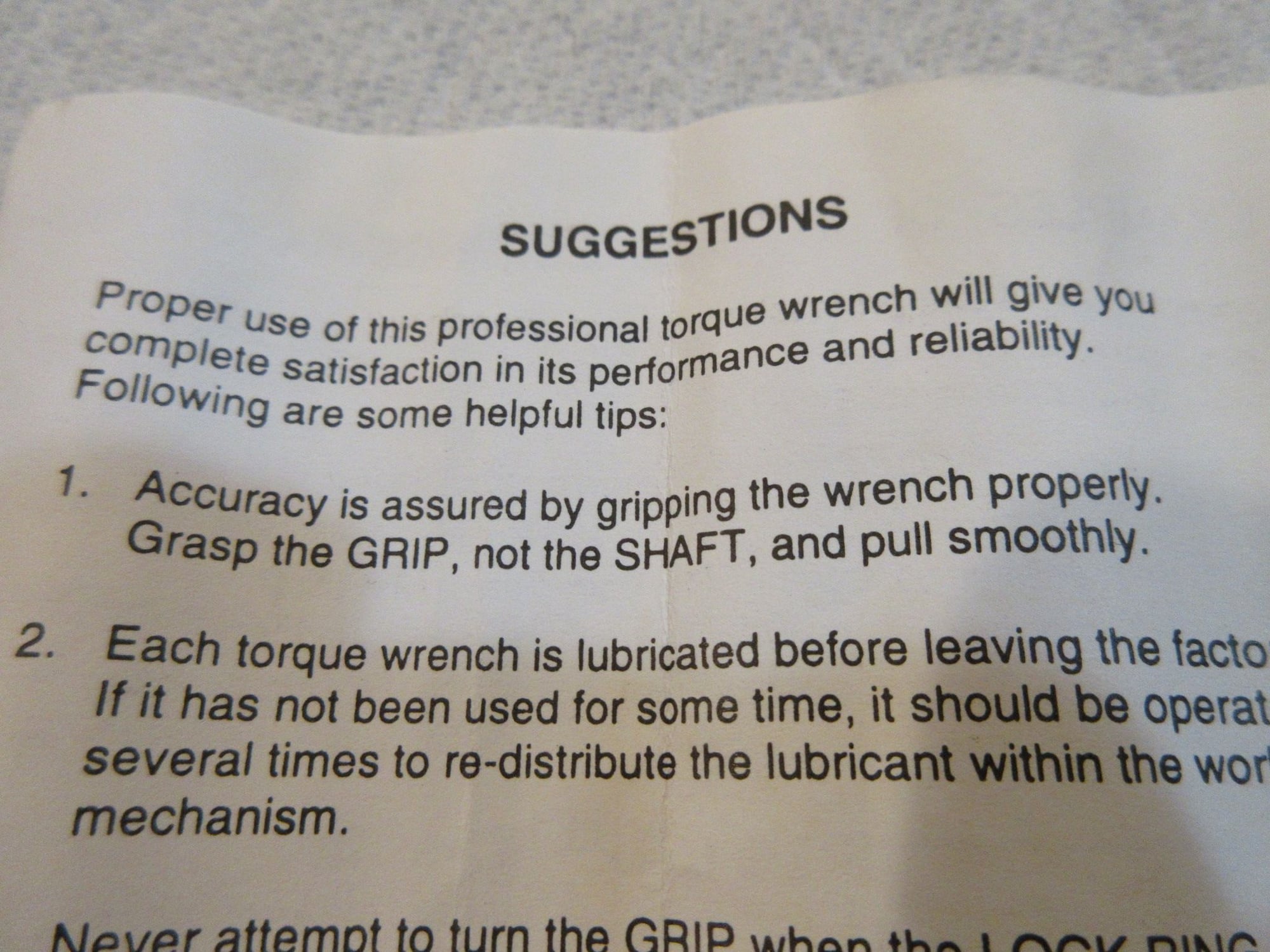

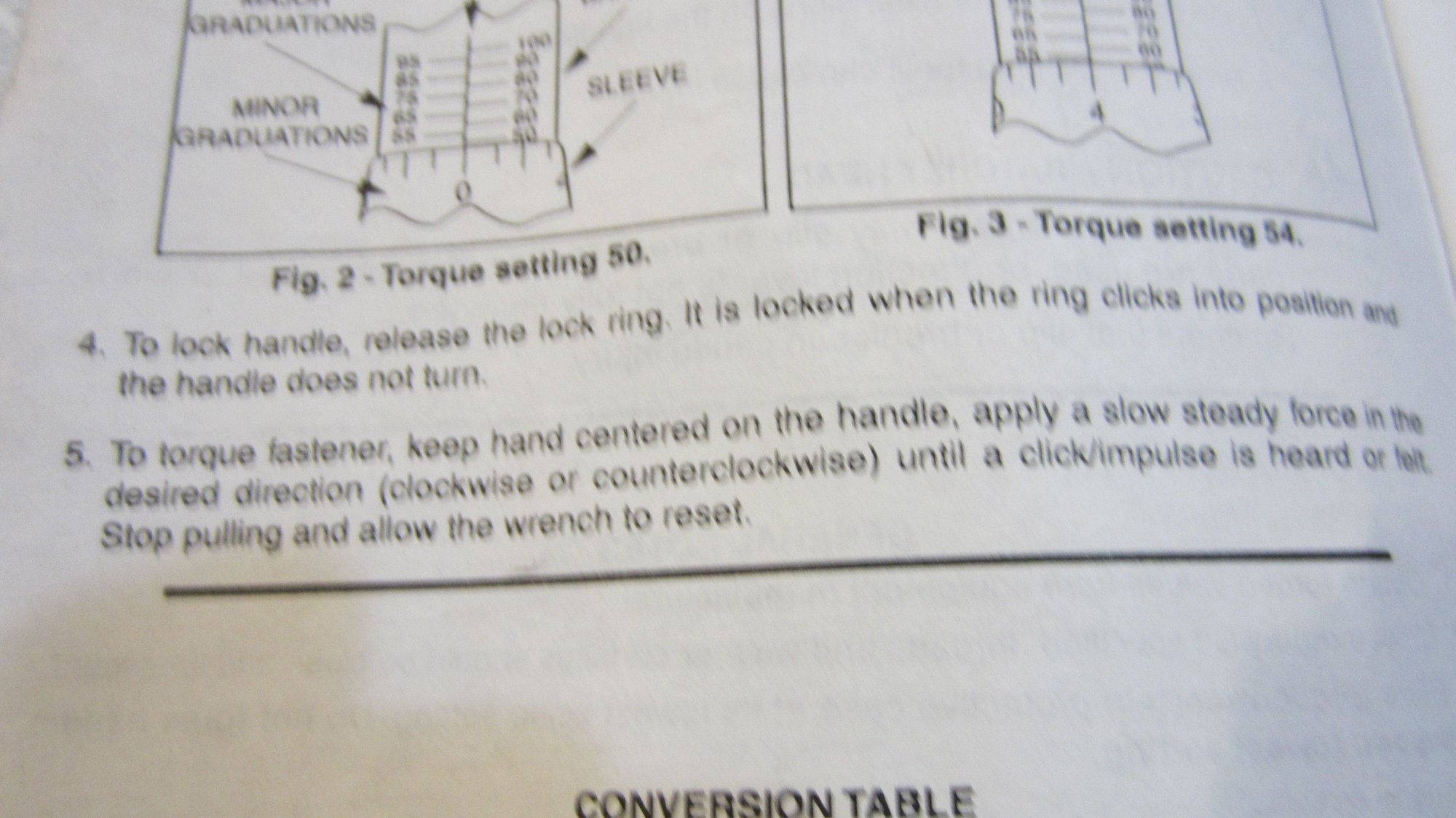

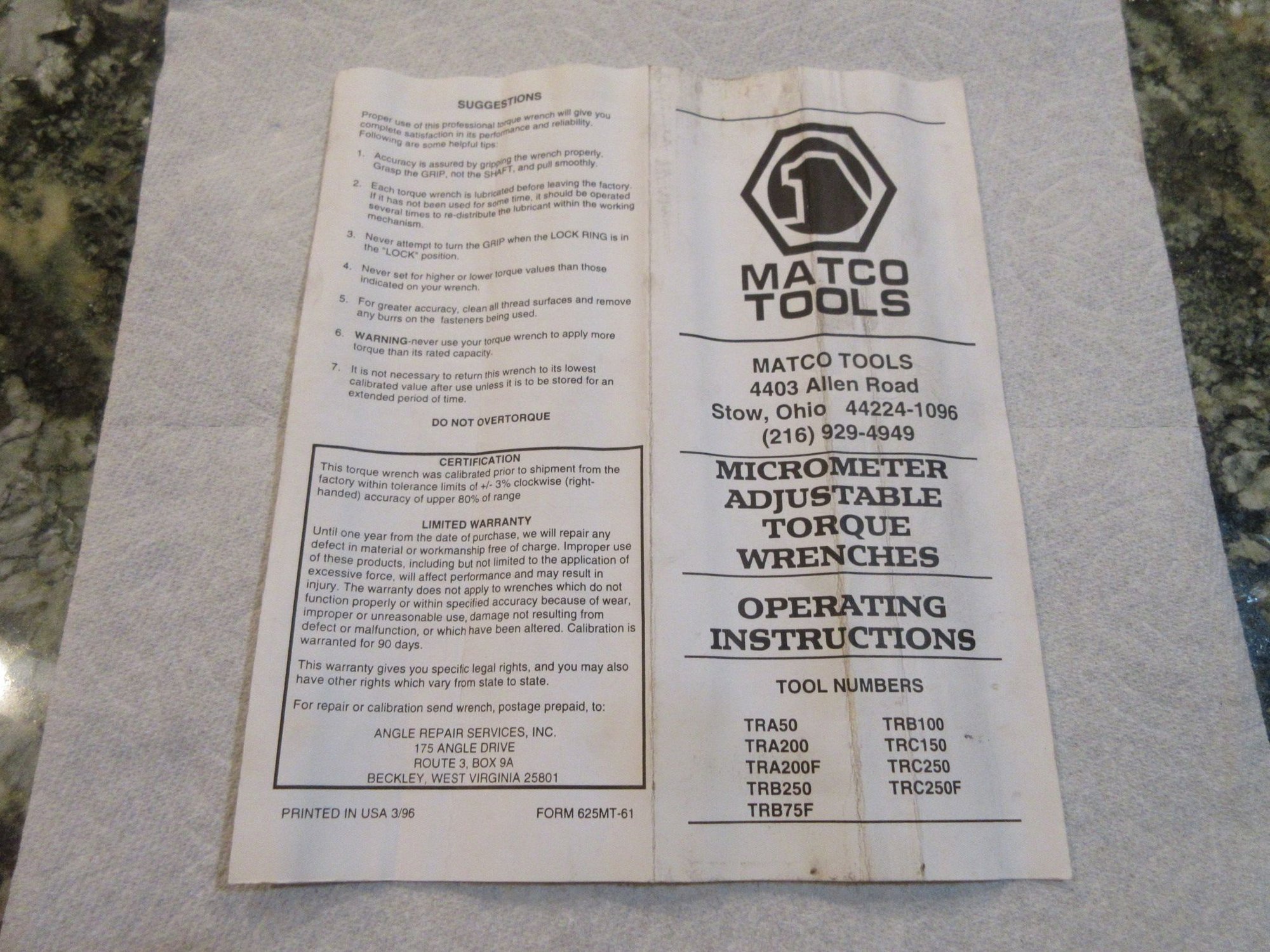

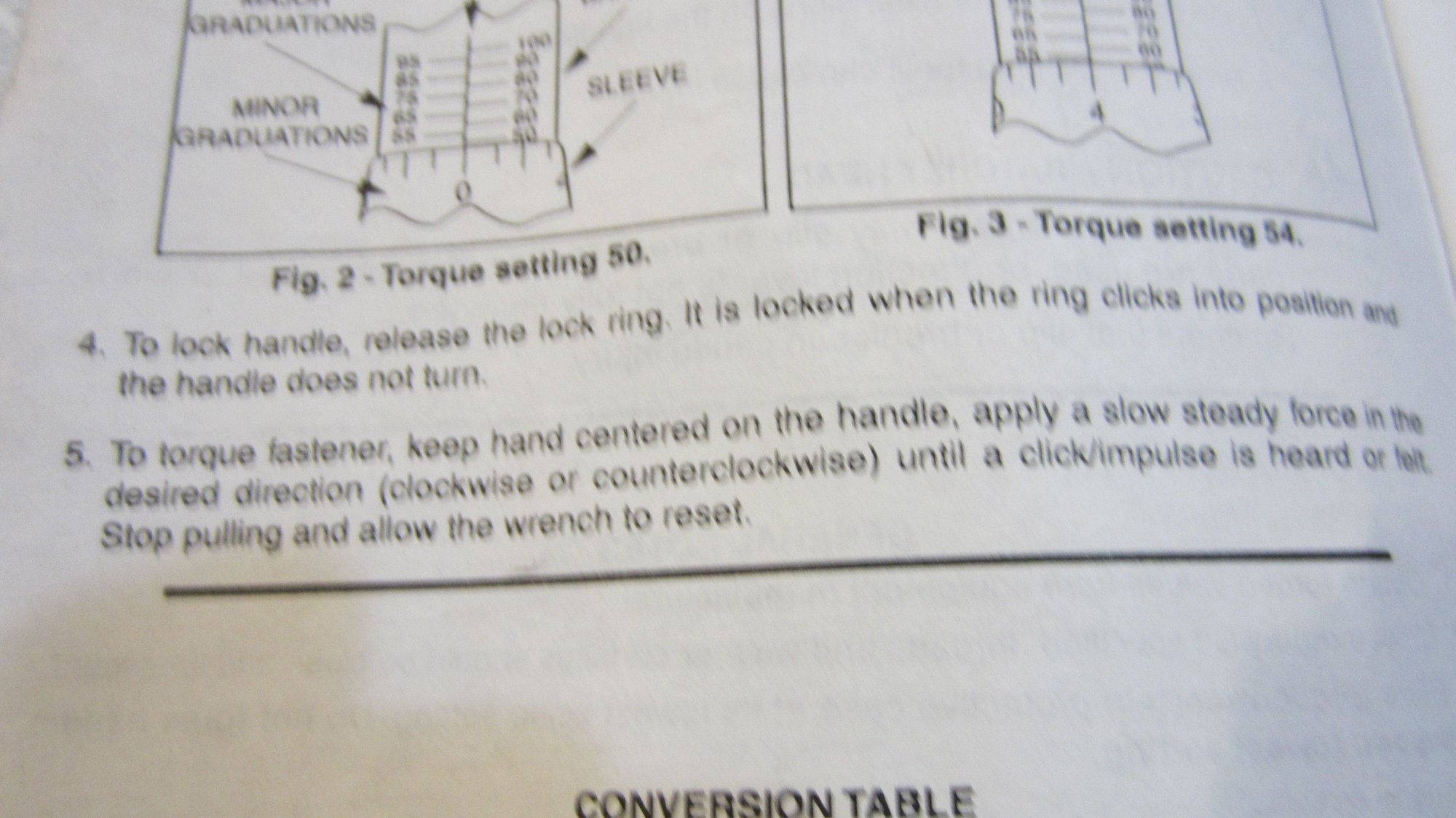

I was waiting for this, click stop torque wrenches can be dangerous in the wrong hands, Snap-On dictates activating the wrench at 50% of the target setting 3 X before the actual torquing.

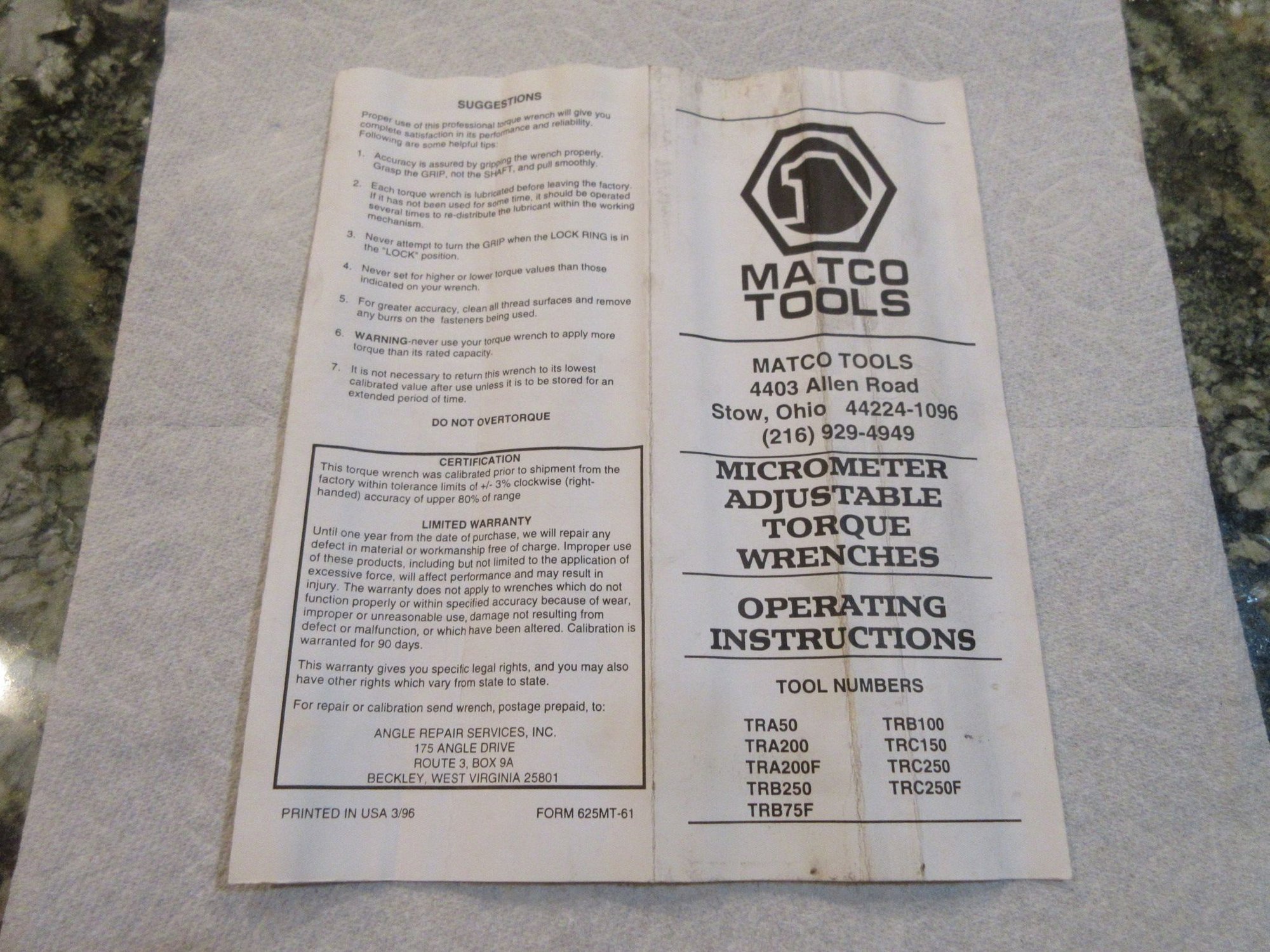

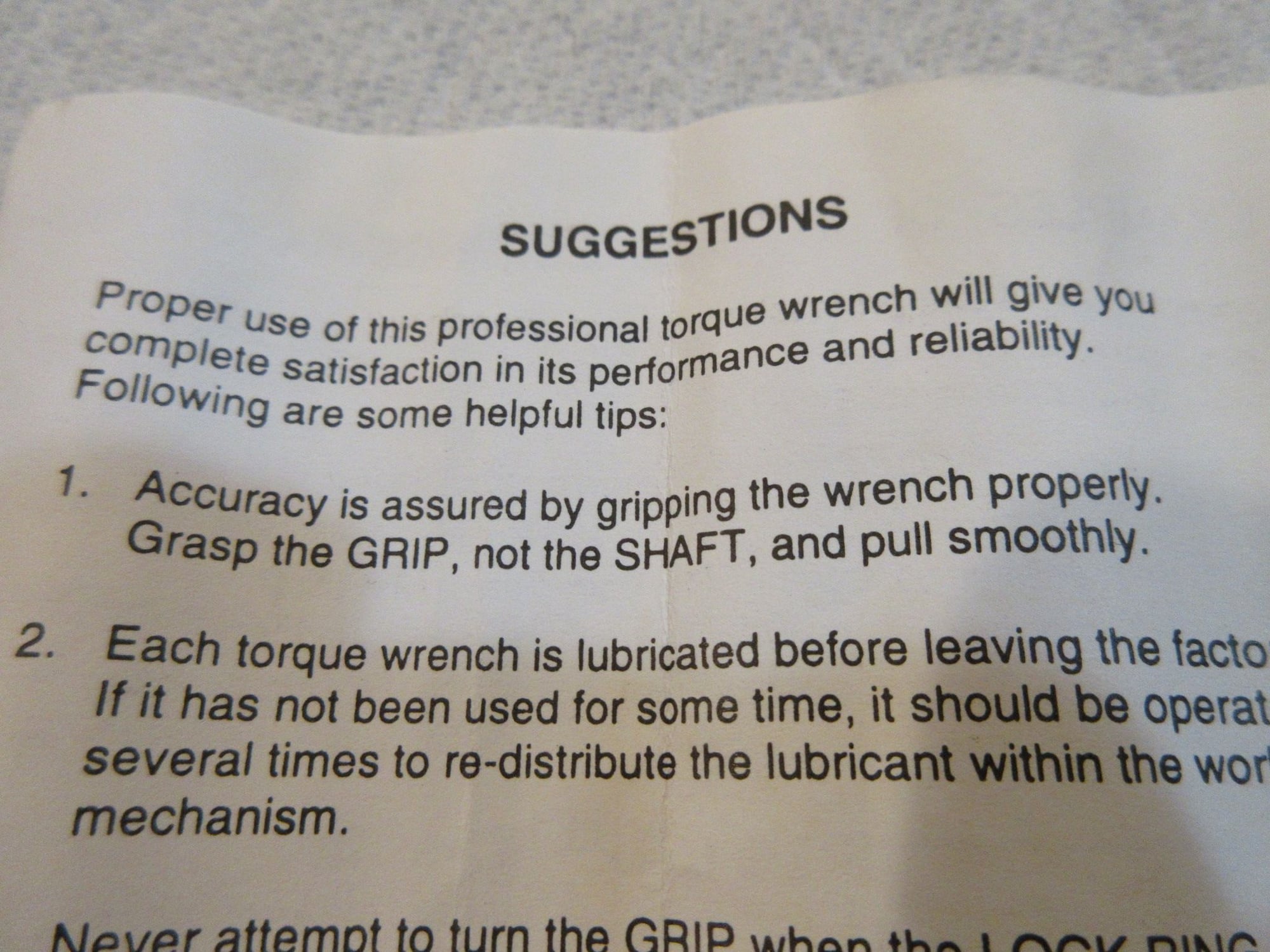

Matco calls for making certain for the fastener to be moving when the wrench clicks its preset.

It is also critical as these and and more apply to all including making sure the fastener, nut, bolt and receiving threads are clean, free of burrs and lubed if called for.

And yes, whether its KZ 1000, Porsche spark plug threads or Campy crank arms, alloy or aluminum absolutely calls for even more extra diligence, experience and common sense with a steady, even hand.

Last edited by merziac; 04-27-24 at 12:37 AM.

#33

Junior Member

You do mean a regular, non-torque ratchet wrench, right? Because if you do that with a torque wrench you'll throw the readings off, or so I'm told.

Likes For ManekiNico:

#34

Senior Member

Join Date: Apr 2011

Posts: 7,163

Mentioned: 42 Post(s)

Tagged: 0 Thread(s)

Quoted: 4469 Post(s)

Liked 1,608 Times

in

1,057 Posts

if you are talking about this style of wrench, the hinge that breaks at torque does not know where you held the rigid handle.

#35

Senior Member

Join Date: Oct 2015

Location: PDX

Posts: 13,103

Bikes: Merz x 5 + Specialized Merz Allez x 2, Strawberry/Newlands/DiNucci/Ti x3, Gordon, Fuso/Moulton x2, Bornstein, Paisley,1958-74 Paramounts x3, 3rensho, 74 Moto TC, 73-78 Raleigh Pro's x5, Marinoni x2, 1960 Cinelli SC, 1980 Bianchi SC, PX-10 X 2

Mentioned: 269 Post(s)

Tagged: 0 Thread(s)

Quoted: 4522 Post(s)

Liked 6,415 Times

in

3,692 Posts

Torque is only correctly applied by using the handle at the end, it is calibrated for the length.

Happy to provide this info if need be.

Happy to provide this info if need be.

Likes For merziac:

#36

Senior Member

Join Date: Oct 2015

Location: PDX

Posts: 13,103

Bikes: Merz x 5 + Specialized Merz Allez x 2, Strawberry/Newlands/DiNucci/Ti x3, Gordon, Fuso/Moulton x2, Bornstein, Paisley,1958-74 Paramounts x3, 3rensho, 74 Moto TC, 73-78 Raleigh Pro's x5, Marinoni x2, 1960 Cinelli SC, 1980 Bianchi SC, PX-10 X 2

Mentioned: 269 Post(s)

Tagged: 0 Thread(s)

Quoted: 4522 Post(s)

Liked 6,415 Times

in

3,692 Posts

#37

Senior Member

Join Date: Oct 2015

Location: PDX

Posts: 13,103

Bikes: Merz x 5 + Specialized Merz Allez x 2, Strawberry/Newlands/DiNucci/Ti x3, Gordon, Fuso/Moulton x2, Bornstein, Paisley,1958-74 Paramounts x3, 3rensho, 74 Moto TC, 73-78 Raleigh Pro's x5, Marinoni x2, 1960 Cinelli SC, 1980 Bianchi SC, PX-10 X 2

Mentioned: 269 Post(s)

Tagged: 0 Thread(s)

Quoted: 4522 Post(s)

Liked 6,415 Times

in

3,692 Posts

- Apply force to the handle only. The torque is calculated based on force being applied to the handle. Applying force on other parts of the wrench will result in a different torque value being applied.

Likes For merziac:

#38

Senior Member

Join Date: Apr 2011

Posts: 7,163

Mentioned: 42 Post(s)

Tagged: 0 Thread(s)

Quoted: 4469 Post(s)

Liked 1,608 Times

in

1,057 Posts

- Apply force to the handle only. The torque is calculated based on force being applied to the handle. Applying force on other parts of the wrench will result in a different torque value being applied.

Anything below the hinge at the head is "handle", not just the black part at the bottom. Because, physics.

#39

Senior Member

Join Date: Oct 2015

Location: PDX

Posts: 13,103

Bikes: Merz x 5 + Specialized Merz Allez x 2, Strawberry/Newlands/DiNucci/Ti x3, Gordon, Fuso/Moulton x2, Bornstein, Paisley,1958-74 Paramounts x3, 3rensho, 74 Moto TC, 73-78 Raleigh Pro's x5, Marinoni x2, 1960 Cinelli SC, 1980 Bianchi SC, PX-10 X 2

Mentioned: 269 Post(s)

Tagged: 0 Thread(s)

Quoted: 4522 Post(s)

Liked 6,415 Times

in

3,692 Posts

No, I'm sorry, you are confused.

The length of the wrench determines the torque and is calculated from the handle at the end.

The left hand is just steadying the socket and it says so in the text, the physics dictate the torque is is calibrated to the length of the lever, not correct or accurate from anywhere else, only from the black handle part.

Again, quote from the link, article.

"Apply force to the handle only."

"The torque is calculated based on force being applied to the handle. Applying force on other parts of the wrench will result in a different torque value being applied."

Any fulcrum or lever is dependent especially on length so it obviously matters where force is applied so the value changes if it is not correctly applied at the proper handle.

Here are instructions from SnapOn and Matco.

#40

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,846

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 846 Post(s)

Liked 1,278 Times

in

674 Posts

torque is expressed as length of the lever arm and the force applied. Foot-pounds, newton-meters etc.

the accurate application of a torque value is achieved by having your hand on the handle, as the force is applied. Period.

the pic of the torque wrench being used to tighten the lug nut - the left hand is making sure the socket does not slip off the lug nut.

you can argue about having your hand somewhere else, or being the southern hemisphere, or outer space, whatever.

this is not rocket science. Even tho my torque wrench has an (expired) calibration sticker from NASA Jet Propulsion Laboratory in Pasadena.

but what do I know ?

/markp

the accurate application of a torque value is achieved by having your hand on the handle, as the force is applied. Period.

the pic of the torque wrench being used to tighten the lug nut - the left hand is making sure the socket does not slip off the lug nut.

you can argue about having your hand somewhere else, or being the southern hemisphere, or outer space, whatever.

this is not rocket science. Even tho my torque wrench has an (expired) calibration sticker from NASA Jet Propulsion Laboratory in Pasadena.

but what do I know ?

/markp

Last edited by mpetry912; 04-28-24 at 08:16 AM.

Likes For mpetry912:

#41

Senior Member

Join Date: Apr 2009

Posts: 960

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 391 Post(s)

Liked 560 Times

in

293 Posts

If I have an adjustable wrench set to 50ft/lb and put a 6' cheater on it, it will still snap at 50ft/lb at the bolt. I just don't have to press as heavily. The mechanism doesn't know how much I weigh or how tall I am either.

#42

Senior Member

Join Date: Jan 2019

Location: Toledo Ohio

Posts: 1,498

Bikes: 1964 Huffy Sportsman, 1972 Fuji Newest, 1973 Schwinn Super Sport (3), 1982 Trek 412, 1983 Trek 700, 1989 Miyata 1000LT, 1991 Bianchi Boardwalk, plus others

Mentioned: 21 Post(s)

Tagged: 0 Thread(s)

Quoted: 583 Post(s)

Liked 700 Times

in

395 Posts

I used to tighten “darn snug” with a half inch drive ratchet. I’m no 300 lb gorilla, so thought it fine. Subsequently, I started using a 3/8” beam type torque wrench calibrated to inch/lbs. I was quite surprised how much extra torque it took to get the darn snug bolts up to 250 inch/lbs. that wrench is maybe 18” long so has a longer lever. Either way, I stop at 250 as it seems plenty. This would seem to match what others do by feel.

Likes For sd5782:

#43

Senior Member

Join Date: Apr 2011

Posts: 7,163

Mentioned: 42 Post(s)

Tagged: 0 Thread(s)

Quoted: 4469 Post(s)

Liked 1,608 Times

in

1,057 Posts

Yet again,

No, I'm sorry, you are confused.

The length of the wrench determines the torque and is calculated from the handle at the end.

The left hand is just steadying the socket and it says so in the text, the physics dictate the torque is is calibrated to the length of the lever, not correct or accurate from anywhere else, only from the black handle part.

Again, quote from the link, article.

"Apply force to the handle only."

"The torque is calculated based on force being applied to the handle. Applying force on other parts of the wrench will result in a different torque value being applied."

Any fulcrum or lever is dependent especially on length so it obviously matters where force is applied so the value changes if it is not correctly applied at the proper handle.

Here are instructions from SnapOn and Matco.

No, I'm sorry, you are confused.

The length of the wrench determines the torque and is calculated from the handle at the end.

The left hand is just steadying the socket and it says so in the text, the physics dictate the torque is is calibrated to the length of the lever, not correct or accurate from anywhere else, only from the black handle part.

Again, quote from the link, article.

"Apply force to the handle only."

"The torque is calculated based on force being applied to the handle. Applying force on other parts of the wrench will result in a different torque value being applied."

Any fulcrum or lever is dependent especially on length so it obviously matters where force is applied so the value changes if it is not correctly applied at the proper handle.

Here are instructions from SnapOn and Matco.

This is no different than a teeter-totter. The child at one end will only come off the ground if weight is applied to somewhere on the other side of the pivot. That can be a similar weight at the far end, or twice the weight closer in.. But the child can't measure the force/weight - they can only express if they start rising off the ground. The wrench clicking is like the child. Really basic physics.

Likes For Kontact:

#44

Senior Member

Join Date: Oct 2015

Location: PDX

Posts: 13,103

Bikes: Merz x 5 + Specialized Merz Allez x 2, Strawberry/Newlands/DiNucci/Ti x3, Gordon, Fuso/Moulton x2, Bornstein, Paisley,1958-74 Paramounts x3, 3rensho, 74 Moto TC, 73-78 Raleigh Pro's x5, Marinoni x2, 1960 Cinelli SC, 1980 Bianchi SC, PX-10 X 2

Mentioned: 269 Post(s)

Tagged: 0 Thread(s)

Quoted: 4522 Post(s)

Liked 6,415 Times

in

3,692 Posts

Again, this is simple physics. Everything south of the hinge is "handle", because it has no parts that move when pressure is applied. The user will notice more or less force required depending on where they hold the handle, but the device that measures torque does not and cannot know where your hand was placed. All it knows is that force of some sort was placed somewhere below the hinge, and that force exceeds the setting of the torque wrench mechanism. It can't read your mind or tell where your hand was.

This is no different than a teeter-totter. The child at one end will only come off the ground if weight is applied to somewhere on the other side of the pivot. That can be a similar weight at the far end, or twice the weight closer in.. But the child can't measure the force/weight - they can only express if they start rising off the ground. The wrench clicking is like the child. Really basic physics.

This is no different than a teeter-totter. The child at one end will only come off the ground if weight is applied to somewhere on the other side of the pivot. That can be a similar weight at the far end, or twice the weight closer in.. But the child can't measure the force/weight - they can only express if they start rising off the ground. The wrench clicking is like the child. Really basic physics.

If you say so.

Good to know.

#45

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,846

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 846 Post(s)

Liked 1,278 Times

in

674 Posts

the teeter totter argument is not right.

Imagine two kids, 50 lb each, on the seats, one one each side of the teeter totter. up, down, up down.

now one kid dismounts and sits on on the cross bar, inches from the fulcrum. What happens.?

Silly theoretical argument. I'll keep my hands on the grip area of the torque wrench, thanks very much

/markp

Imagine two kids, 50 lb each, on the seats, one one each side of the teeter totter. up, down, up down.

now one kid dismounts and sits on on the cross bar, inches from the fulcrum. What happens.?

Silly theoretical argument. I'll keep my hands on the grip area of the torque wrench, thanks very much

/markp

Likes For mpetry912:

#46

Senior Member

Join Date: Apr 2011

Posts: 7,163

Mentioned: 42 Post(s)

Tagged: 0 Thread(s)

Quoted: 4469 Post(s)

Liked 1,608 Times

in

1,057 Posts

the teeter totter argument is not right.

Imagine two kids, 50 lb each, on the seats, one one each side of the teeter totter. up, down, up down.

now one kid dismounts and sits on on the cross bar, inches from the fulcrum. What happens.?

Silly theoretical argument. I'll keep my hands on the grip area of the torque wrench, thanks very much

/markp

Imagine two kids, 50 lb each, on the seats, one one each side of the teeter totter. up, down, up down.

now one kid dismounts and sits on on the cross bar, inches from the fulcrum. What happens.?

Silly theoretical argument. I'll keep my hands on the grip area of the torque wrench, thanks very much

/markp

There are many reasons that Snap On would tell you not to hold the shaft, but it isn't because the torque reading is going to be different if you are putting perpendicular force on it. And anyone with a torque wrench can confirm this very easily.

#47

Senior Member

Join Date: Oct 2015

Location: PDX

Posts: 13,103

Bikes: Merz x 5 + Specialized Merz Allez x 2, Strawberry/Newlands/DiNucci/Ti x3, Gordon, Fuso/Moulton x2, Bornstein, Paisley,1958-74 Paramounts x3, 3rensho, 74 Moto TC, 73-78 Raleigh Pro's x5, Marinoni x2, 1960 Cinelli SC, 1980 Bianchi SC, PX-10 X 2

Mentioned: 269 Post(s)

Tagged: 0 Thread(s)

Quoted: 4522 Post(s)

Liked 6,415 Times

in

3,692 Posts

Your argument just shows that you don't know what torque is. 12 inch pounds is identical to 1 foot pound, which means that one 30 pound kid 6 feet from the pivot is identical to one 180 pound adult one foot from the pivot. They produce identical torque, and either will lift a 28 pound child at the other end of the board because their torque exceeds the force the 28 pounder's weight produces.

There are many reasons that Snap On would tell you not to hold the shaft, but it isn't because the torque reading is going to be different if you are putting perpendicular force on it. And anyone with a torque wrench can confirm this very easily.

There are many reasons that Snap On would tell you not to hold the shaft, but it isn't because the torque reading is going to be different if you are putting perpendicular force on it. And anyone with a torque wrench can confirm this very easily.

#48

Senior Member

Join Date: Feb 2008

Location: Peoria, IL

Posts: 4,485

Mentioned: 86 Post(s)

Tagged: 0 Thread(s)

Quoted: 1833 Post(s)

Liked 3,404 Times

in

1,589 Posts

Your argument just shows that you don't know what torque is. 12 inch pounds is identical to 1 foot pound, which means that one 30 pound kid 6 feet from the pivot is identical to one 180 pound adult one foot from the pivot. They produce identical torque, and either will lift a 28 pound child at the other end of the board because their torque exceeds the force the 28 pounder's weight produces.

There are many reasons that Snap On would tell you not to hold the shaft, but it isn't because the torque reading is going to be different if you are putting perpendicular force on it. And anyone with a torque wrench can confirm this very easily.

There are many reasons that Snap On would tell you not to hold the shaft, but it isn't because the torque reading is going to be different if you are putting perpendicular force on it. And anyone with a torque wrench can confirm this very easily.

For the click wrenches, the torque is actually being indirectly sensed at the pivot point that is a couple of cm away from the axis of the fastener. IIRC, this is why the force needs to be applied at the correct location of the handle.

I've seen various explanations of this, but this Park Tool video touches on it (about 1:48 into the video)....

They have a video on their beam torque wrenches too, and I should probably review that. My Park beam torque wrenches have handles with a pivot, in order to prevent the user from applying a torsional moment at the handle.

Steve in Peoria (but never used a torque wrench on my tapered axle cranks)

Likes For steelbikeguy:

#49

Senior Member

If the wrench was measuring the actual torque being directly applied to the fastener, then it wouldn't matter where you grabbed the handle.

For the click wrenches, the torque is actually being indirectly sensed at the pivot point that is a couple of cm away from the axis of the fastener. IIRC, this is why the force needs to be applied at the correct location of the handle.

I've seen various explanations of this, but this Park Tool video touches on it (about 1:48 into the video)....

They have a video on their beam torque wrenches too, and I should probably review that. My Park beam torque wrenches have handles with a pivot, in order to prevent the user from applying a torsional moment at the handle.

Steve in Peoria (but never used a torque wrench on my tapered axle cranks)

For the click wrenches, the torque is actually being indirectly sensed at the pivot point that is a couple of cm away from the axis of the fastener. IIRC, this is why the force needs to be applied at the correct location of the handle.

I've seen various explanations of this, but this Park Tool video touches on it (about 1:48 into the video)....

They have a video on their beam torque wrenches too, and I should probably review that. My Park beam torque wrenches have handles with a pivot, in order to prevent the user from applying a torsional moment at the handle.

Steve in Peoria (but never used a torque wrench on my tapered axle cranks)

I understood Kontact's arguement and it sounded viable to me. But, the video @3:00 demonstrates how torque is affected by grabbing the wrench at different positions.

Likes For gearbasher:

#50

Senior Member

Join Date: Oct 2015

Location: PDX

Posts: 13,103

Bikes: Merz x 5 + Specialized Merz Allez x 2, Strawberry/Newlands/DiNucci/Ti x3, Gordon, Fuso/Moulton x2, Bornstein, Paisley,1958-74 Paramounts x3, 3rensho, 74 Moto TC, 73-78 Raleigh Pro's x5, Marinoni x2, 1960 Cinelli SC, 1980 Bianchi SC, PX-10 X 2

Mentioned: 269 Post(s)

Tagged: 0 Thread(s)

Quoted: 4522 Post(s)

Liked 6,415 Times

in

3,692 Posts

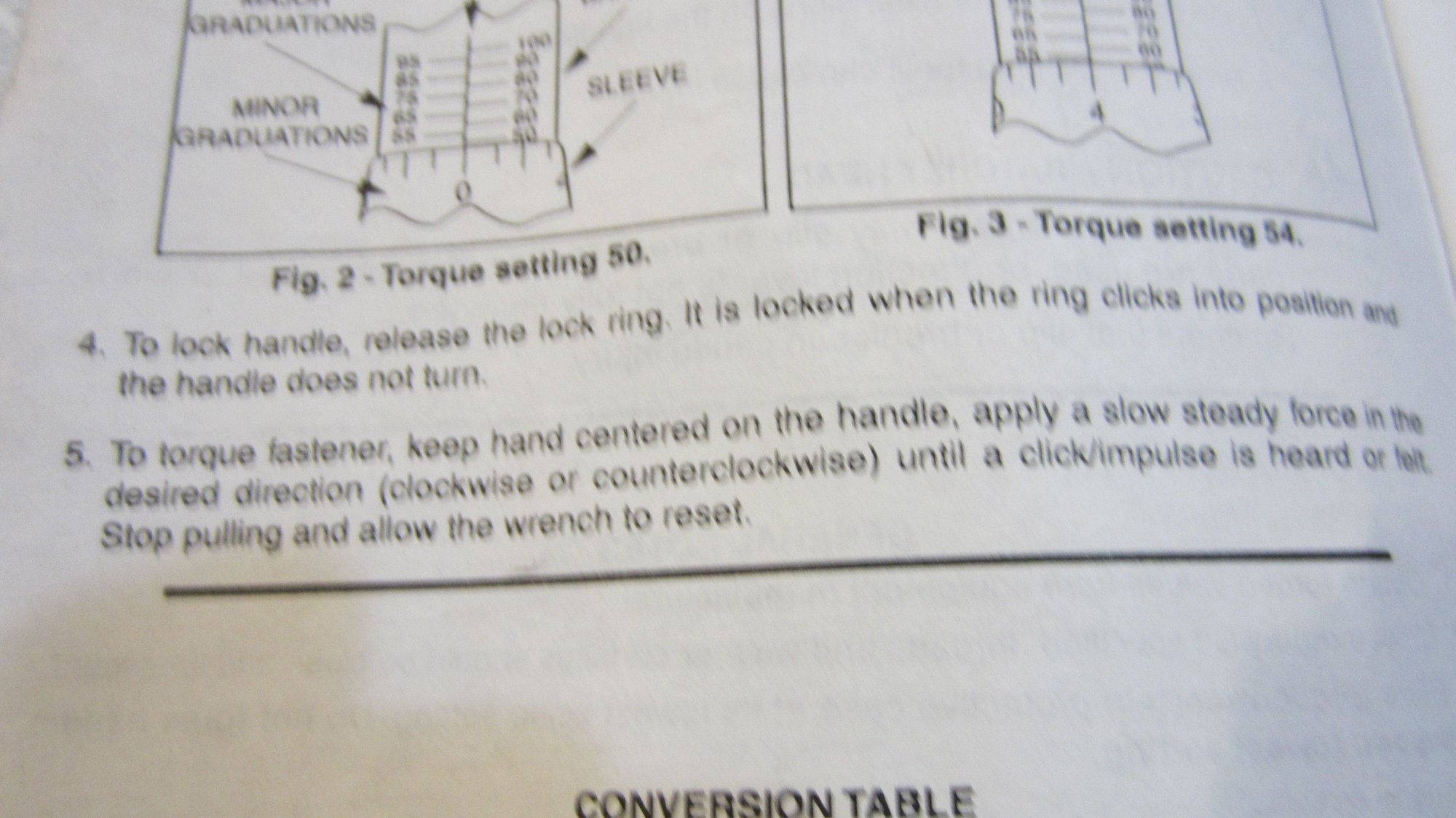

The 3:00 mark gives a better explanation.

I understood Kontact's arguement and it sounded viable to me. But, the video @3:00 demonstrates how torque is affected by grabbing the wrench at different positions.

I understood Kontact's arguement and it sounded viable to me. But, the video @3:00 demonstrates how torque is affected by grabbing the wrench at different positions.

All the shadetree, teeter toter logic in the world can't change or dispute the science.