Tig welding an aluminum seat tube back together?

#26

Senior Member

Join Date: Jun 2002

Location: San Jose, CA

Posts: 3,691

Bikes: Too many bikes, too little time to ride

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 430 Post(s)

Liked 460 Times

in

318 Posts

Assuming you cannot contact their support team and get a new frame, another option is to just JB Weld that piece back on and then JB Weld your seat post into the seat tube as well (at the correct height of course). The seat post will no longer be removable and it might still be a total fail but hey it's something cheap to try before throwing out the frame.

#27

Senior Member

Join Date: Feb 2020

Posts: 1,060

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 529 Post(s)

Likes: 0

Liked 255 Times

in

185 Posts

I would not be overly concerned about another part of the frame failing. Of course any part of any bike can fail at any time.

I would not just butt weld the broken piece. Something needs to be done to give it more strength. When you look at the options, I would not weld it at all. Just grind or file off the jagged edges, and think about other creative ways to secure the seat post.

For creative minded people, there are a lot of other ways the seat post could be secured.

Another idea. Make up two clamps joined together. Clamp one around the seat post, above the frame. Clamp the other around the bar.

I would not just butt weld the broken piece. Something needs to be done to give it more strength. When you look at the options, I would not weld it at all. Just grind or file off the jagged edges, and think about other creative ways to secure the seat post.

For creative minded people, there are a lot of other ways the seat post could be secured.

Another idea. Make up two clamps joined together. Clamp one around the seat post, above the frame. Clamp the other around the bar.

#28

Senior Member

Join Date: Nov 2014

Location: Eugene, Oregon, USA

Posts: 27,547

Mentioned: 217 Post(s)

Tagged: 0 Thread(s)

Quoted: 18369 Post(s)

Liked 4,507 Times

in

3,350 Posts

https://www.bikeforums.net/framebuil...ing-frame.html

Anyway, the user had a most unique tandem with a forward sloping top tube, and a tall mast on the seatpost similar to the OP's. He had to lower the seat by about 2".

However, the post used a unique half-moon lock in a tube.

So, that post lock was simply moved downward.

#29

Senior Member

I don't think that can be reliably repaired. My take is to bin it.

Even if you could repair it, it's a chinese frame of unknown quality, so the chances of it breaking somwhere else are too much risk IMHO.

I have bought lots of cheap china bike parts: bottle cages, cyclecomputers, bar ends, grips and even a saddle... but I have never bought anything that could compromise my safety. Frames, forks, wheels, tires, brakes, handlebars, stems, seatposts, quick releases, and anything that could compromise the integrity of the bike should be bought only from brands that you can trust.

You really don't want a frame or a handlebar to break in half while riding.

Even if you could repair it, it's a chinese frame of unknown quality, so the chances of it breaking somwhere else are too much risk IMHO.

I have bought lots of cheap china bike parts: bottle cages, cyclecomputers, bar ends, grips and even a saddle... but I have never bought anything that could compromise my safety. Frames, forks, wheels, tires, brakes, handlebars, stems, seatposts, quick releases, and anything that could compromise the integrity of the bike should be bought only from brands that you can trust.

You really don't want a frame or a handlebar to break in half while riding.

#30

SE Wis

Join Date: Apr 2005

Location: Milwaukee, WI

Posts: 10,505

Bikes: '68 Raleigh Sprite, '02 Raleigh C500, '84 Raleigh Gran Prix, '91 Trek 400, 2013 Novara Randonee, 1990 Trek 970

Mentioned: 40 Post(s)

Tagged: 0 Thread(s)

Quoted: 2743 Post(s)

Liked 3,390 Times

in

2,053 Posts

If I was to have that repaired by welding, I'd probably fab up some gusset plates and add them to the repair.

Maybe something like this

Maybe something like this

#31

Senior Member

Join Date: Jul 2018

Location: USA

Posts: 2,190

Bikes: Ti, Mn Cr Ni Mo Nb, Al, C

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 942 Post(s)

Liked 526 Times

in

349 Posts

You might find this thread interesting:

https://www.bikeforums.net/framebuil...ing-frame.html

Anyway, the user had a most unique tandem with a forward sloping top tube, and a tall mast on the seatpost similar to the OP's. He had to lower the seat by about 2".

However, the post used a unique half-moon lock in a tube.

So, that post lock was simply moved downward.

https://www.bikeforums.net/framebuil...ing-frame.html

Anyway, the user had a most unique tandem with a forward sloping top tube, and a tall mast on the seatpost similar to the OP's. He had to lower the seat by about 2".

However, the post used a unique half-moon lock in a tube.

So, that post lock was simply moved downward.

#32

Senior Member

The break is in the heat affected zone of the weld and a sign of poor welding or poor heat treatment. I would be afraid of this thing going forward.

Likes For davidad:

#33

Senior Member

Join Date: Jan 2009

Location: San Diego, CA

Posts: 3,666

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 836 Post(s)

Liked 1,060 Times

in

744 Posts

OK, well in that case it sounds like a faulty frame. 200lbs is not all that heavy, plenty of other riders in your weight class (including me) ride around on much less robust bikes with no problems for tens of thousands of miles. As mentioned you may want to get a little more assertive with RAD to resolve this for you. You could also give them a link to this thread which may get them to respond to protect their reputation.

Likes For Crankycrank:

#34

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

Regarding fixing the frame, I stand by my recommendation: Toss it after you cut the top tube. If this was a pristine example of a superb vintage aluminum frame, perhaps you could fix it (probably 1: heat treat, 2: grind out chamfers to allow for weld material, 3: weld, 4: heat treat, 5: refinish and 6) ride it nervously, because you'll never be certain it's not going to break at the original break, or elsewhere). But it's a PIECE OF CHEAP CHINESE JUNK THAT ALREADY BROKE ONCE! Even the best repair will result in a REPAIRED PIECE OF CHEAP CHINESE JUNK. Perhaps the bike mfr does build some quality frames. This wasn't one of them. And cost! Skilled TIG welders aren't the cheapest skilled labor around - they're pretty talented people with rare skills. Just refinishing a bike (required after heat treating the frame) will be as expensive as a new frame.

Do what you will, but I urge you to ask before starting: is the view worth the climb?

Likes For WizardOfBoz:

#35

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

You might find this thread interesting:

https://www.bikeforums.net/framebuil...ing-frame.html

Anyway, the user had a most unique tandem with a forward sloping top tube, and a tall mast on the seatpost similar to the OP's. He had to lower the seat by about 2".

However, the post used a unique half-moon lock in a tube.

So, that post lock was simply moved downward.

https://www.bikeforums.net/framebuil...ing-frame.html

Anyway, the user had a most unique tandem with a forward sloping top tube, and a tall mast on the seatpost similar to the OP's. He had to lower the seat by about 2".

However, the post used a unique half-moon lock in a tube.

So, that post lock was simply moved downward.

Upon further research, the tandem is a Counterpoint Tandem Opus, which has a steel frame. (Interesting tandem: recumbent in front, upright seat in rear). So not applicable to the Al frame repair discussion because if you did that mod, you'd still have to post weld heat treat the whole frame, or you'd expect another crack in the area of the weld quite shortly.

https://aroundthecycle.com/products/...=8370188943420

Last edited by WizardOfBoz; 02-13-20 at 09:44 AM.

#36

Junior Member

Thread Starter

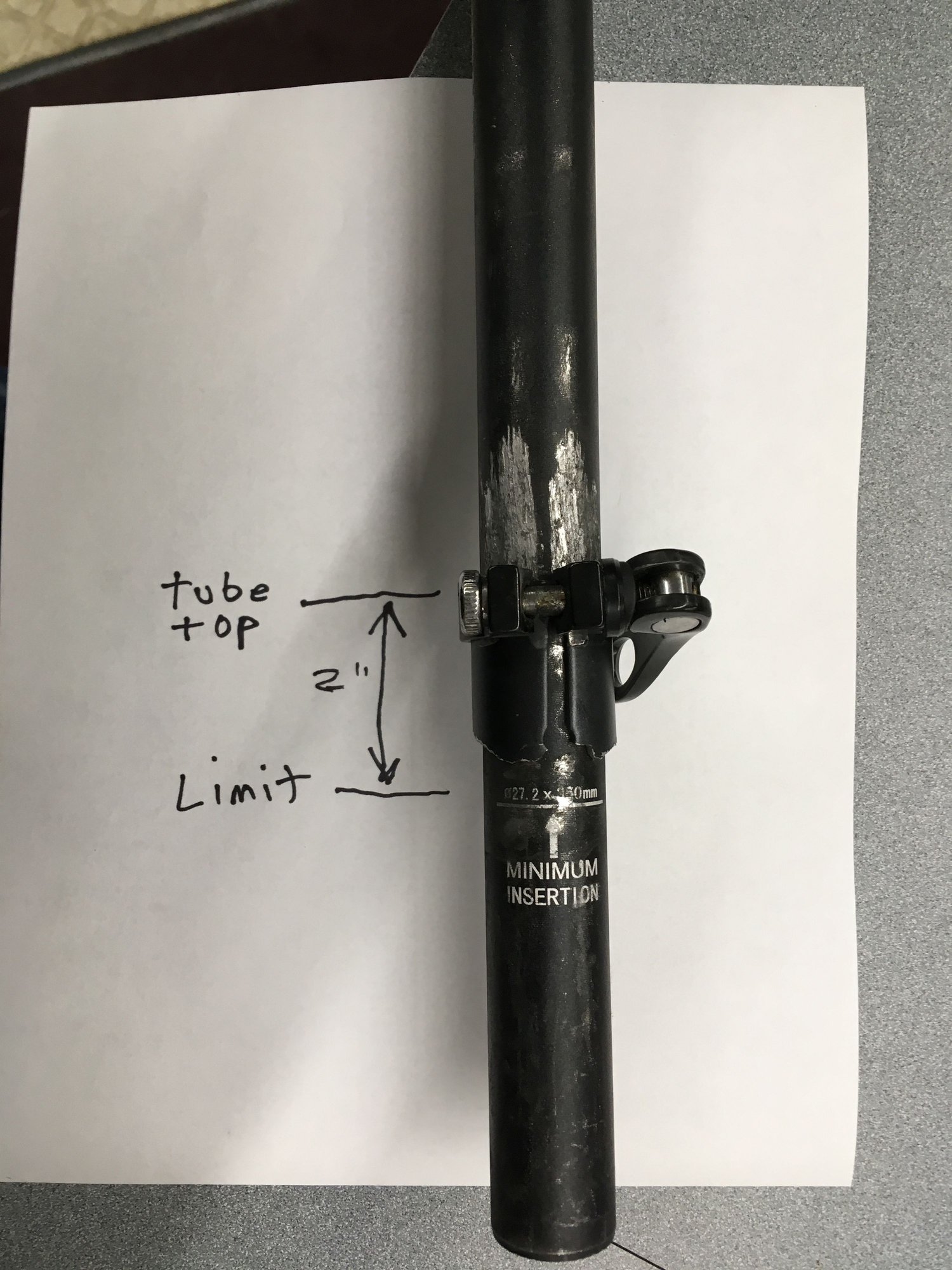

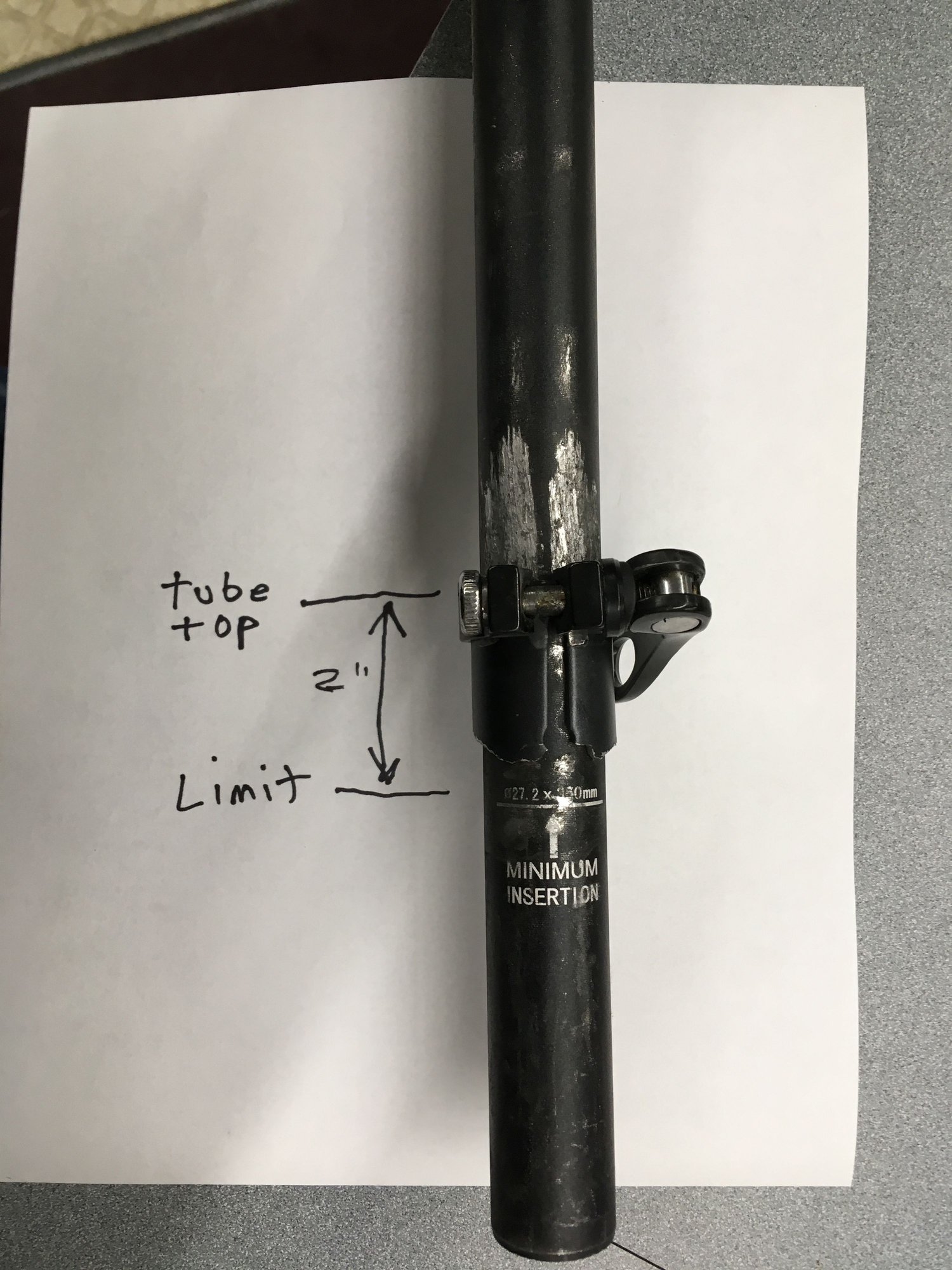

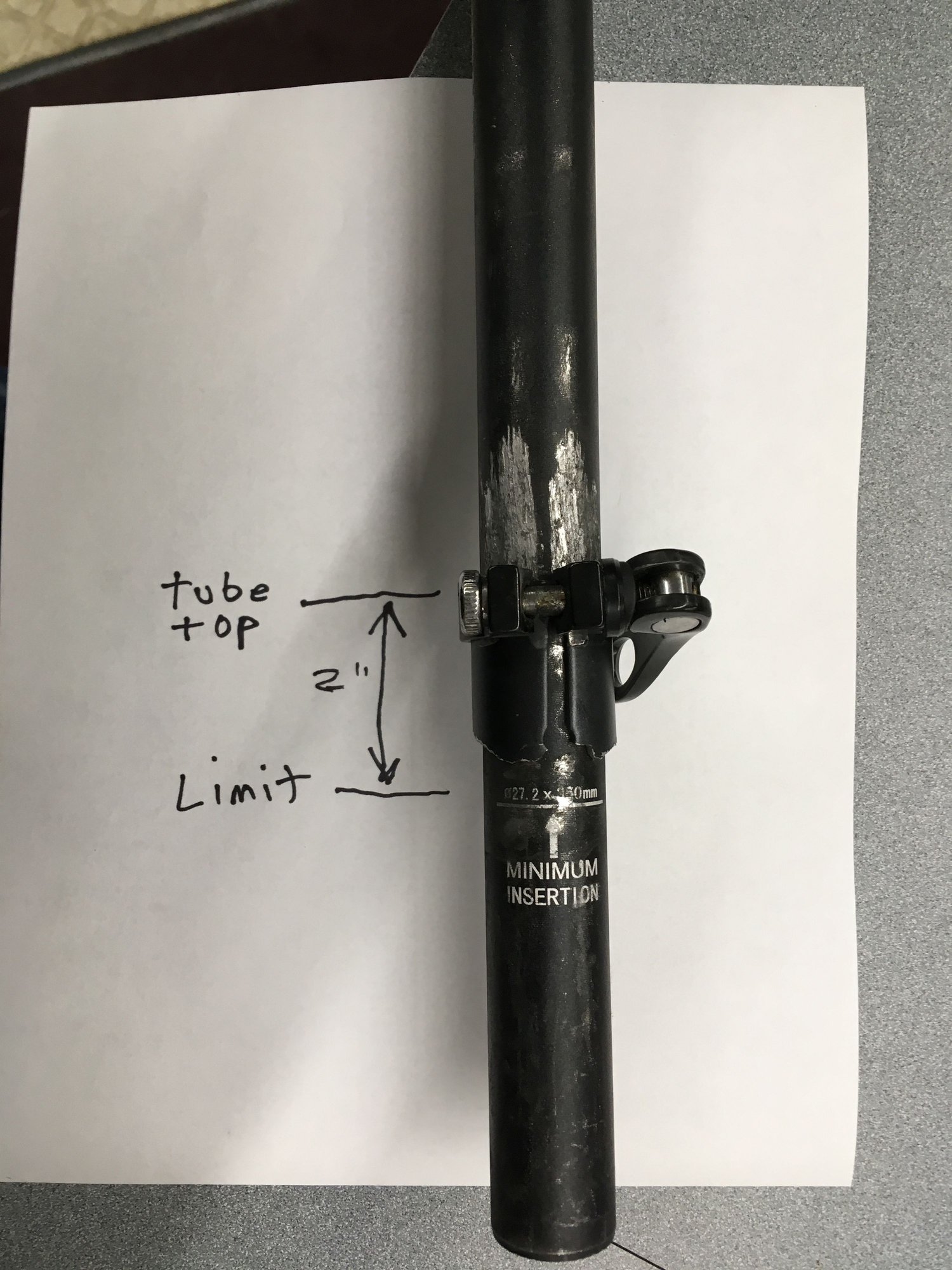

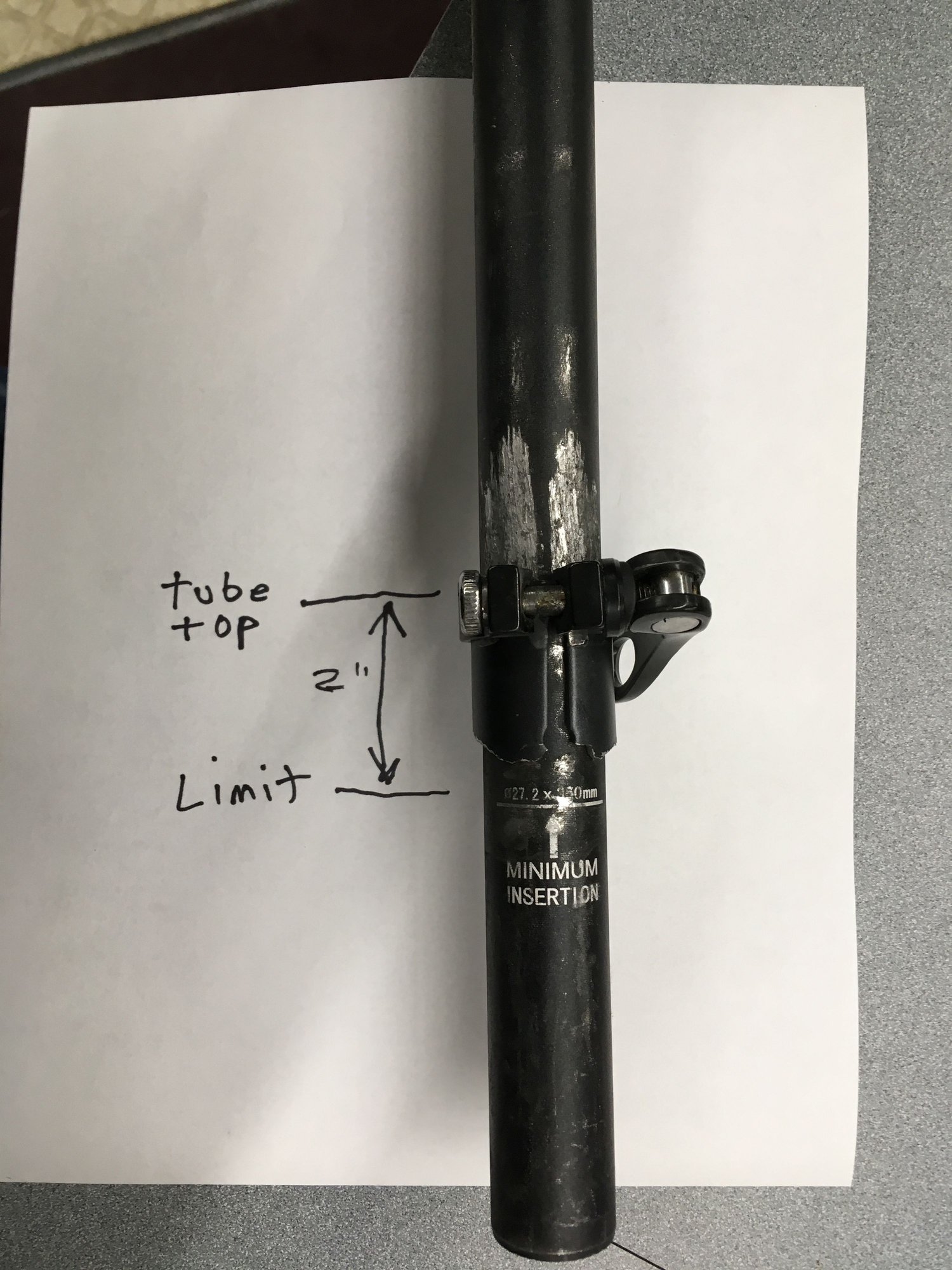

Someone asked to see the tube break edges end on so I have attached a pic of that and a pic of the location of the end of the tube in relation to the height limit mark on the seat post for those who questioned if this was operator error. I gather from reading in various Rad user groups that a fair number of people use these essentially as electric motorcycles so I suppose it's possible that by relying largely on the pedals and only using the motor sparingly I was stressing the frame more than the manufacturer expects and perhaps that constitutes user error.

I see that no one had anything to say about of my idea to install a new piece of similar aluminum tube eight inches or so into the broken seat tube cut and extending say four inches higher than the original tube ended, welding that at the broken top and installing a new seat post sized to fit that new and smaller tube. This would move the stress away from the original break location and the top tube welds. Doesn't seem a bad idea in theory compared to some others. What are the demerits of doing that?

I see that no one had anything to say about of my idea to install a new piece of similar aluminum tube eight inches or so into the broken seat tube cut and extending say four inches higher than the original tube ended, welding that at the broken top and installing a new seat post sized to fit that new and smaller tube. This would move the stress away from the original break location and the top tube welds. Doesn't seem a bad idea in theory compared to some others. What are the demerits of doing that?

Last edited by erileykc; 02-13-20 at 10:14 AM.

#37

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

I'm going to ask two questions, but if you want to persist, I'll give (e.g. shut) up.

Welding involves melting the metal being welded, and the heat required to do this leaves what is called a heat affected zone (HAZ). In aluminum especially, the metal in the HAZ is much weaker than properly heat -treated aluminum*, so normally you heat treat the frame after its welded. That either was not done, or not done properly on your bike, and you hold in your hands the broken parts that are a result of that poor manufacturing technique (or poor material quality).

Questions:

1) If you put a new tube in, presumably you'll need to weld it, creating a new HAZ. Are you prepared to heat treat your frame after doing this weld? Oh, and BTW, to refinish your frame after the heat treat destroys the finish?

2) Given that there's a chance that the material itself is of poor quality (e.g. improper metallurgy) are you prepared after doing all the work on the frame, to have it break again in a different place?

*In more common steels, the HAZ often does not lose much strength compared to the steel outsize the HAZ, and so you don't have to heat treat a steel frame after welding on it.

Welding involves melting the metal being welded, and the heat required to do this leaves what is called a heat affected zone (HAZ). In aluminum especially, the metal in the HAZ is much weaker than properly heat -treated aluminum*, so normally you heat treat the frame after its welded. That either was not done, or not done properly on your bike, and you hold in your hands the broken parts that are a result of that poor manufacturing technique (or poor material quality).

Questions:

1) If you put a new tube in, presumably you'll need to weld it, creating a new HAZ. Are you prepared to heat treat your frame after doing this weld? Oh, and BTW, to refinish your frame after the heat treat destroys the finish?

2) Given that there's a chance that the material itself is of poor quality (e.g. improper metallurgy) are you prepared after doing all the work on the frame, to have it break again in a different place?

*In more common steels, the HAZ often does not lose much strength compared to the steel outsize the HAZ, and so you don't have to heat treat a steel frame after welding on it.

#38

Senior Member

Join Date: Jan 2009

Location: San Diego, CA

Posts: 3,666

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 836 Post(s)

Liked 1,060 Times

in

744 Posts

. I gather from reading in various Rad user groups that a fair number of people use these essentially as electric motorcycles so I suppose it's possible that by relying largely on the pedals and only using the motor sparingly I was stressing the frame more than the manufacturer expects and perhaps that constitutes user error.

Likes For Crankycrank:

#39

Senior Member

Join Date: Jan 2013

Location: Llano Estacado

Posts: 3,702

Bikes: old clunker

Mentioned: 13 Post(s)

Tagged: 0 Thread(s)

Quoted: 684 Post(s)

Likes: 0

Liked 105 Times

in

83 Posts

...

I see that no one had anything to say about of my idea to install a new piece of similar aluminum tube eight inches or so into the broken seat tube cut and extending say four inches higher than the original tube ended, welding that at the broken top and installing a new seat post sized to fit that new and smaller tube. This would move the stress away from the original break location and the top tube welds. Doesn't seem a bad idea in theory compared to some others. What are the demerits of doing that?

I see that no one had anything to say about of my idea to install a new piece of similar aluminum tube eight inches or so into the broken seat tube cut and extending say four inches higher than the original tube ended, welding that at the broken top and installing a new seat post sized to fit that new and smaller tube. This would move the stress away from the original break location and the top tube welds. Doesn't seem a bad idea in theory compared to some others. What are the demerits of doing that?

As for pedaling, that usually puts less stress on the seat tube than just sitting.

Last edited by AnkleWork; 02-13-20 at 09:01 PM.

#40

Senior Member

Join Date: Nov 2014

Location: Eugene, Oregon, USA

Posts: 27,547

Mentioned: 217 Post(s)

Tagged: 0 Thread(s)

Quoted: 18369 Post(s)

Liked 4,507 Times

in

3,350 Posts

Someone asked to see the tube break edges end on so I have attached a pic of that and a pic of the location of the end of the tube in relation to the height limit mark on the seat post for those who questioned if this was operator error. I gather from reading in various Rad user groups that a fair number of people use these essentially as electric motorcycles so I suppose it's possible that by relying largely on the pedals and only using the motor sparingly I was stressing the frame more than the manufacturer expects and perhaps that constitutes user error.

I see that no one had anything to say about of my idea to install a new piece of similar aluminum tube eight inches or so into the broken seat tube cut and extending say four inches higher than the original tube ended, welding that at the broken top and installing a new seat post sized to fit that new and smaller tube. This would move the stress away from the original break location and the top tube welds. Doesn't seem a bad idea in theory compared to some others. What are the demerits of doing that?

I see that no one had anything to say about of my idea to install a new piece of similar aluminum tube eight inches or so into the broken seat tube cut and extending say four inches higher than the original tube ended, welding that at the broken top and installing a new seat post sized to fit that new and smaller tube. This would move the stress away from the original break location and the top tube welds. Doesn't seem a bad idea in theory compared to some others. What are the demerits of doing that?

27.2 is a pretty standard seatpost. You can get smaller posts. But, say going down to 25mm would be a quite a small post, and smaller than one commonly finds. That would only give you about a 1mm tube. Going to 2mm tubing, and you're down to 23mm. That wouldn't be my choice for a moderately heavy rider.

I think a couple of people mentioned the use of epoxy of one type or another.

Assuming you are the only rider, then there would be no reason not to simply clean everything up, then epoxy the post in place. At least it wouldn't make anything worse. You can use your clamp to help hold it in place as the epoxy cures.

Many bikes from 20 to 40 years ago had epoxy to avoid the heat issues that people have discussed. And, doing a 5" overlapping sleeve or so would be reasonably strong.

I'm not convinced that bike was designed to be heat treated. Not all 6061 is heat treated, & not all filler rod is designed for heat treating.

As far as "Chinese Bikes", perhaps 90% of the modern bikes are made in China, from Trek to Cannondale. The big companies may have a bit better quality control, and even better engineering than smaller companies, but we do get a lot of Chinese products here.

#41

Junior Member

Thread Starter

The scratching was from the first day I got the bike. Took a few tries to discover that the seat post clamp only worked reliably in one position. A large part of my world here in the US is built around Chinese made products and I am happy to use them. Pretty sure I'd never have been able to afford the nice laptop I'm typing this on had it been made in say Chicago. I have another cheap Chinese bike that is working fine although that bike is steel. That said there is a bell curve associated with much of this world and it's quite possible to buy products from China that are at the wrong place on that curve.

Thanks for the suggestion on the epoxy. That had really not occurred to me. My anxiety about all the red flags involved in welding aluminum makes the idea of epoxy very appealing.

Thanks for the suggestion on the epoxy. That had really not occurred to me. My anxiety about all the red flags involved in welding aluminum makes the idea of epoxy very appealing.

Do you know what has caused all the scratching on the seatpost? Has the post been slipping down?

...

As far as "Chinese Bikes", perhaps 90% of the modern bikes are made in China, from Trek to Cannondale. The big companies may have a bit better quality control, and even better engineering than smaller companies, but we do get a lot of Chinese products here.

...

As far as "Chinese Bikes", perhaps 90% of the modern bikes are made in China, from Trek to Cannondale. The big companies may have a bit better quality control, and even better engineering than smaller companies, but we do get a lot of Chinese products here.

Likes For erileykc:

#42

Full Member

[QUOTE=Bill Kapaun;21325637]Seeing how "cleanly" it broke near the toe of the weld (on the upper side) I'd consider this to be a lack of needed heat treatment after welding.

I agree with Bill's assessment of the damage. The welds look fine to me and if the frame was not post-weld heat-treated then artificially aged to a homogenous T6 condition it isn't the welders fault.

(Aerospace welding is my profession I've been qualified since 1981.)

West

I agree with Bill's assessment of the damage. The welds look fine to me and if the frame was not post-weld heat-treated then artificially aged to a homogenous T6 condition it isn't the welders fault.

(Aerospace welding is my profession I've been qualified since 1981.)

West

Likes For 2seven0:

#43

Senior Member

Join Date: Feb 2020

Posts: 1,060

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 529 Post(s)

Likes: 0

Liked 255 Times

in

185 Posts

I see that no one had anything to say about of my idea to install a new piece of similar aluminum tube eight inches or so into the broken seat tube cut and extending say four inches higher than the original tube ended, welding that at the broken top and installing a new seat post sized to fit that new and smaller tube. This would move the stress away from the original break location and the top tube welds. Doesn't seem a bad idea in theory compared to some others. What are the demerits of doing that?

#44

Friendship is Magic

Join Date: Nov 2010

Location: Sacramento, CA

Posts: 22,984

Bikes: old ones

Mentioned: 304 Post(s)

Tagged: 0 Thread(s)

Quoted: 26400 Post(s)

Liked 10,373 Times

in

7,202 Posts

I see that no one had anything to say about of my idea to install a new piece of similar aluminum tube eight inches or so into the broken seat tube cut and extending say four inches higher than the original tube ended, welding that at the broken top and installing a new seat post sized to fit that new and smaller tube. This would move the stress away from the original break location and the top tube welds. Doesn't seem a bad idea in theory compared to some others. What are the demerits of doing that?

As your weight pushes down on the saddle and seat post, you would, if anything, increase the stresses on the seat tube/top tube interface right there at the top surface of the top tube.

Otherwise, I guess this might work if you could find the tubing to accomplish it. It's probably worth a shot, because generally whatever you do is likely to give you some early warning signs of failure. So if you check regularly at your repair for signs of cracking or maybe welds breaking, you're less likely to crash and injure yourself. If I were attempting something like that, I'd try to get as much of the repair tubing down inside the seat tube as I could, and probably cut it off pretty short...just long enough above the top tube.seat tube junction to allow for slotting and clamping.

And epoxy might very well work for this sort of repair, if your internal tube is well fitted.

Last edited by 3alarmer; 02-13-20 at 02:22 PM.

#45

Senior Member

Join Date: Feb 2020

Posts: 1,060

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 529 Post(s)

Likes: 0

Liked 255 Times

in

185 Posts

Consider using a piece of aluminum or steel bent in a U shape under the bar. It would need to be fairly thick, or it would flex, and the seat would twist. You could have rubber inside the U bracket. You could try various thicknesses of rubber until you get a secure fit.

#46

I'm good to go!

Join Date: Jul 2017

Location: Mississippi

Posts: 14,976

Bikes: Tarmac Disc Comp Di2 - 2020

Mentioned: 51 Post(s)

Tagged: 0 Thread(s)

Quoted: 6186 Post(s)

Liked 4,803 Times

in

3,313 Posts

Even if embrittlement from the welding is an issue, I'd still have to wonder where the stress is coming from. Is the seat post itself not rigid enough and flexing while being ridden? Or is the seat tube diameter four to five inches down inside where the very end of the seat post sits too big, letting the post rock back and forth pivoting on the clamped area as it's ridden?

If I couldn't get another bike, I'd get it welded by someone I trusted or at least seemed knowledgeable and just watch everything a little closer. Unless you are racing this thing, then you got a fair chance of surviving as long as you don't land on your skull.

If I couldn't get another bike, I'd get it welded by someone I trusted or at least seemed knowledgeable and just watch everything a little closer. Unless you are racing this thing, then you got a fair chance of surviving as long as you don't land on your skull.

Likes For Iride01:

#47

Senior Member

Join Date: Nov 2014

Location: Eugene, Oregon, USA

Posts: 27,547

Mentioned: 217 Post(s)

Tagged: 0 Thread(s)

Quoted: 18369 Post(s)

Liked 4,507 Times

in

3,350 Posts

It is a good idea, but I would look for a way of securing it other than welding. You could even use steel, which would be even stronger. I would extend it more than four inches above the top. The seat post above that new extension, could be internal or external, which ever size tube you can find. External would be stronger.

#48

Senior Member

Join Date: Jul 2006

Location: San Jose (Willow Glen) Ca

Posts: 9,840

Bikes: Kirk Custom JK Special, '84 Team Miyata,(dura ace old school) 80?? SR Semi-Pro 600 Arabesque

Mentioned: 106 Post(s)

Tagged: 0 Thread(s)

Quoted: 2337 Post(s)

Liked 2,818 Times

in

1,539 Posts

it sure looks to me like it failed at the edge of the weld bead all around. Which suggest that something about the welding introduced a failure point that is what makes me feel the integrity of the frame as whole is suspect. This all goes out the window if the seat post was installed such that the bottom of it was at the edge of the weld bead, but I believe the OP said that was not the case.

__________________

Life is too short not to ride the best bike you have, as much as you can

(looking for Torpado Super light frame/fork or for Raleigh International frame fork 58cm)

Life is too short not to ride the best bike you have, as much as you can

(looking for Torpado Super light frame/fork or for Raleigh International frame fork 58cm)

#49

Senior Member

Join Date: Nov 2014

Location: Eugene, Oregon, USA

Posts: 27,547

Mentioned: 217 Post(s)

Tagged: 0 Thread(s)

Quoted: 18369 Post(s)

Liked 4,507 Times

in

3,350 Posts

it sure looks to me like it failed at the edge of the weld bead all around. Which suggest that something about the welding introduced a failure point that is what makes me feel the integrity of the frame as whole is suspect. This all goes out the window if the seat post was installed such that the bottom of it was at the edge of the weld bead, but I believe the OP said that was not the case.

The clamp does look pinched in slightly, but I'm not sure if that is normal or not. It certainly would be within an acceptable range for a steel bike.

#50

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

For filler you use 4043 filler mostly. You can use 4643 filler wire which has more magnesium to make it more susceptible to heat treatment. But neither wire gives you T6 (that is, the untreated joint remains very weak compared to surrounding metal) without the full treatment of solution at 1000°F and quenching, then precipitation aging. Ageing alone won't cut it.

If your bike can take joints that are only 30% of the strength of base metal, you don't need to heat treat. But because modern bike frames must already be beefy enough to keep stresses low to avoid fatigue failure, no modern frame will have the added mass to allow it to survive without proper heat treatment. As the OP found. I agree with the aerospace welder: the original bike welder may have done a great job (its certainly aesthetically adequate) and was let down by his heat-treating colleagues.