How much can steel flex without injury?

#26

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,402

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,701 Times

in

2,521 Posts

It probably wasn't the tubes that caused the shimmy. I bet if I threw that frame on my alignment table I could figure out what the problem was.

#27

Senior Member

Join Date: Nov 2015

Posts: 4,489

Mentioned: 102 Post(s)

Tagged: 0 Thread(s)

Quoted: 1641 Post(s)

Likes: 0

Liked 831 Times

in

540 Posts

The heat treat tempering on steels like Reynolds 753, should push the yeild point on the frame tube, much higher than steel without the heat treatment. That's why it is supposedly very difficult to cold set a 753 frameset. They just spring right back.

Supervitus 980 is supposed to also be heat treated but not sure if the properties of the Supervitus tubing is close to what Reynolds 753 has, because I have not heard of any special requirements mentioned for certifications from the tubing manufacturer to build Supervitus 980 framesets, unlike tye 753.

Supervitus 980 is supposed to also be heat treated but not sure if the properties of the Supervitus tubing is close to what Reynolds 753 has, because I have not heard of any special requirements mentioned for certifications from the tubing manufacturer to build Supervitus 980 framesets, unlike tye 753.

__________________

72 Line Seeker

83 Davidson Signature

84 Peugeot PSV

84 Peugeot PY10FC

84 Gitane Tour de France.

85 Vitus Plus Carbone 7

86 ALAN Record Carbonio

86 Medici Aerodynamic (Project)

88 Pinarello Montello

89 Bottecchia Professional Chorus SL

95 Trek 5500 OCLV (Project)

72 Line Seeker

83 Davidson Signature

84 Peugeot PSV

84 Peugeot PY10FC

84 Gitane Tour de France.

85 Vitus Plus Carbone 7

86 ALAN Record Carbonio

86 Medici Aerodynamic (Project)

88 Pinarello Montello

89 Bottecchia Professional Chorus SL

95 Trek 5500 OCLV (Project)

#28

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,994

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1181 Post(s)

Liked 2,576 Times

in

1,076 Posts

Titanium alloy has a similar combination of low stiffness and high strength, so you have to push it further in distance to get into plastic deformation, i.e. taking a set. When I worked at Ti Cycles I was impressed with the bottom-bracket gripping post on Dave's alignment fixture. Partly because it was so heavily built, to be stiff and strong, but mostly because of how tall it is. The extra height is useful because on an alignment fixture made for steel frames, you can push a tube all the way to where it hits the table and it still hasn't taken a set, it springs right back. When I worked at Davidson, I made the first Ti frames ever made there, and Bill's table was a good one but made for steel, with a lower BB post. So for Ti, if I had to push a tube down to align it, I had to flip the frame over to let me do the bending in the up direction. Dave's taller BB post gave extra room to push down, which is easier because you can use your body weight.

Oh and I did align a couple 753 frames, so the idea it can't be done is, um, exaggerated? The amount the dropouts pull in narrower from brazing in the bridges is a bit unpredictable, so even with proper blocking, pretty often the dropout spacing ends up slightly off. I'm a stickler for that width being right on, so I would insert an axle that's too wide (if the space is too narrow) or a narrow axle if the space is too wide, then stress-relieve with a torch. This is well below the trasformation temperature in steel, so I'm not "removing the heat treat" as I've heard some people say. It's barely into the tempering zone. So at most the stays were slightly more tempered, and the area I was heating was where brazing the bridges had already tempered the steel. The frames did not break there later.

I think if a framebuilder claims his rear spacing always comes out perfect every time with no setting required, then he probably has a looser definition of "perfect" than I do.

EDIT: I made it sound like Chombi1 was saying it was impossible. He didn't say that. I was referring to those other people I've heard say that, over the years. Sorry for the confusion I caused!

Last edited by bulgie; 01-29-24 at 02:18 PM.

Likes For bulgie:

#29

Paramount Fan

Join Date: Dec 2006

Location: Vermont

Posts: 293

Bikes: Paramounts, Raleigh Pros, Colnago, DeRosa, Gios, Masis, Pinarello, R. Sachs, Look, D. Moulton, Witcomb, Motobecane, Bianchis, Fat City, Frejus, Follis, Waterford, Litespeed, d'Autremont, others, mostly '70s-'80s

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 123 Post(s)

Liked 242 Times

in

133 Posts

Steel can flex and spring back until it reaches its yield strength, at which point there's "plastic deformation", i.e. it "takes a set" and doesn't spring back to its original shape. Shimmy NEVER does that, ever.

Millions of cycles of stress below the yield strength can cause a fatigue crack, but I'm highly doubtful that shimmy could cause that either. Fatigue is hard to predict, highly variable with small changes, like a nick in the tubing, or localized overheating while brazing. The way to find the fatigue endurance of a structure is to exceed it, in other words destructive testing. I don't know of any way to determine what the "remaining" fatigue life of your frame is, but I strongly encourage you to "just ride it". Maybe, if you're worried about it, look at the frame now and then to see if fatigue cracks are starting. Steel frames are usually very mellow in their failure mode — after a crack starts, it grows slowly, and gives you lots of warning. Usually.

Shimmy is a complex situation, difficult to predict and/or cure. Sometimes the same change that causes it on one bike cures it on another bike. But I bet if you rode the frame unloaded or lightly loaded it will no longer shimmy.

I once made his'n'hers custom touring frames for a couple that wanted to tour around the world, but they were afraid that a heavily-built frame would make it dead-feeling when unloaded, so they wanted a compromise, a lightly-built loaded touring bike that would feel lively with no load. We discussed it at length and I thought they were OK with taking the risk that it might be on the flexy side for 'round the world. But then they came back in a panic because they felt the bikes were nealry unrideable once loaded up. They wanted new frames built, and of course they didn't want to pay for them — it was my fault! I saw the way they loaded them, too much weight, and all on the back and in a high-mounted handlebar bag. I convinced them to try a 3-pronged approach:

Millions of cycles of stress below the yield strength can cause a fatigue crack, but I'm highly doubtful that shimmy could cause that either. Fatigue is hard to predict, highly variable with small changes, like a nick in the tubing, or localized overheating while brazing. The way to find the fatigue endurance of a structure is to exceed it, in other words destructive testing. I don't know of any way to determine what the "remaining" fatigue life of your frame is, but I strongly encourage you to "just ride it". Maybe, if you're worried about it, look at the frame now and then to see if fatigue cracks are starting. Steel frames are usually very mellow in their failure mode — after a crack starts, it grows slowly, and gives you lots of warning. Usually.

Shimmy is a complex situation, difficult to predict and/or cure. Sometimes the same change that causes it on one bike cures it on another bike. But I bet if you rode the frame unloaded or lightly loaded it will no longer shimmy.

I once made his'n'hers custom touring frames for a couple that wanted to tour around the world, but they were afraid that a heavily-built frame would make it dead-feeling when unloaded, so they wanted a compromise, a lightly-built loaded touring bike that would feel lively with no load. We discussed it at length and I thought they were OK with taking the risk that it might be on the flexy side for 'round the world. But then they came back in a panic because they felt the bikes were nealry unrideable once loaded up. They wanted new frames built, and of course they didn't want to pay for them — it was my fault! I saw the way they loaded them, too much weight, and all on the back and in a high-mounted handlebar bag. I convinced them to try a 3-pronged approach:

- CARRY LESS. Long-distance tourists (especially first-timers) often end up mailing unnecessary stuff back home once they realize they didn't need that stuff. So get serious about paring down your list of must-haves before you leave.

- Put most of the weight in front low-riders, with mostly large low-density stuff like clothes and sleeping bags in back. Minimize weight in the handlebar bag.

- Ride a lot with the full load, to get used to it. A bike that seems unrideable at first, starts to feel normal after a while. You can adapt to almost anything. Long-haul tourists have often remarked that they don't like how the bike handles unloaded, after they get completely used to how it handles loaded.

Likes For sbarner:

#31

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,994

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1181 Post(s)

Liked 2,576 Times

in

1,076 Posts

Good story, nice looking bike! I think Laurie and I used to have that same jacket.

First time I've seen a Stronglight 93 crossover tandem crankset. Was it made to be a tandem, with "backwards" pedal thread on 3 of the 4 cranks? Or converted somehow?

Did the fork judder when you applied the front brake? Some bikes with cantilevers do that when the steerer is on the wimpy side. Especially at low speed like right before coming to a stop.

First time I've seen a Stronglight 93 crossover tandem crankset. Was it made to be a tandem, with "backwards" pedal thread on 3 of the 4 cranks? Or converted somehow?

Did the fork judder when you applied the front brake? Some bikes with cantilevers do that when the steerer is on the wimpy side. Especially at low speed like right before coming to a stop.

#32

Senior Member

I've had one instance of shimmy on a bike and it is certainly scary. The reason why of course is that it always happens at the worst possible moment. I live in Colorado so speeds >40mph are pretty common here going down hills and that is where the shimmy will inevitably occur. I'm retired now, but in my previous life I was a servo engineer so I'm very familiar with mechanical 'modes' so I knew what to do once the shimmy started: I just put my knee against the top tube to dampen the structure until it went away. Easier said than done when descending at close to 50 mph....

I'd guess a significant percentage of bike frames could be made to shimmy with the right combination of loading, weight distribution and external excitation (eg rough road surface, body reacting in rhythm with the movement, etc). I'd guess this is even more true for high performance or 'lively' frames than a lead slug Huffy.

If you do ever experience a shimmy, move your weight around or just put your knee against the top tube, or try to slow down. Slowing down is probably the worst option (will take too long or will be too hard) so knowing what is going on and how to respond and not panic is essential.

I'd guess a significant percentage of bike frames could be made to shimmy with the right combination of loading, weight distribution and external excitation (eg rough road surface, body reacting in rhythm with the movement, etc). I'd guess this is even more true for high performance or 'lively' frames than a lead slug Huffy.

If you do ever experience a shimmy, move your weight around or just put your knee against the top tube, or try to slow down. Slowing down is probably the worst option (will take too long or will be too hard) so knowing what is going on and how to respond and not panic is essential.

Likes For Iowegian:

#33

Paramount Fan

Join Date: Dec 2006

Location: Vermont

Posts: 293

Bikes: Paramounts, Raleigh Pros, Colnago, DeRosa, Gios, Masis, Pinarello, R. Sachs, Look, D. Moulton, Witcomb, Motobecane, Bianchis, Fat City, Frejus, Follis, Waterford, Litespeed, d'Autremont, others, mostly '70s-'80s

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 123 Post(s)

Liked 242 Times

in

133 Posts

Good story, nice looking bike! I think Laurie and I used to have that same jacket.

First time I've seen a Stronglight 93 crossover tandem crankset. Was it made to be a tandem, with "backwards" pedal thread on 3 of the 4 cranks? Or converted somehow?

Did the fork judder when you applied the front brake? Some bikes with cantilevers do that when the steerer is on the wimpy side. Especially at low speed like right before coming to a stop.

First time I've seen a Stronglight 93 crossover tandem crankset. Was it made to be a tandem, with "backwards" pedal thread on 3 of the 4 cranks? Or converted somehow?

Did the fork judder when you applied the front brake? Some bikes with cantilevers do that when the steerer is on the wimpy side. Especially at low speed like right before coming to a stop.

When I got the bike it had been setup as right-side timing with two Stronglight 93s. I always liked that crank but we wanted lower gears, so I bought another crank and rethreaded the arms. We were using Campagnolo Record pedals, so swapping axles would have run the rifling in the wrong direction and might have sucked contaminants into the pedals on wet rides. I was going to ream the arms out and install inserts, but decided I had nothing to lose by just re-tapping them, so that's what I did and it worked so well, I never installed the inserts. I never had a bit of trouble with the pedal threads. Suntour freewheels were a different story.

The steerer was a 1" 531 piece designed for a road bike, as was all the other tubing except the boom tube. (EDIT: I forgot to note that it has round, track fork blades!) Never experienced issues with braking, though. In fact, we would take descents at vey high speeds until I foolishly mentioned to my stoker that pulling up on the brake cable would apply the rear brake--end of that fun. The builder was so inexperienced that he didn't know that the cantilever braze-ons have different offsets for front and rear and managed to braze a mixed pair in both locations, making centering the brakes a real challenge. The paint is too nice to correct little issues like that. The biggest problem was that when the load in the rear was going one way, the load in the front was almost entirely free to go in another. It was a bit like trying to carry a fishing pole from the wrong end.

Last edited by sbarner; 01-29-24 at 07:44 PM.

#34

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,994

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1181 Post(s)

Liked 2,576 Times

in

1,076 Posts

The steerer was a 1" 531 piece designed for a road bike

"It's always been fine so far" isn't a good reason not to reinforce it. Fatigue can strike at any time and your fork might be a ticking time bomb. It's very difficult to inspect there for cracks since you have to disassemble the headset to see them, so you're unlikely to catch a crack while it's still small.

I have a lathe and I'm willing to turn the reinforcing tube to the dimension you need — PM me if interested, or have someone local do it to avoid boxing and shipping.

When I worked at Santana in the '70s, they had 1" steerers too, but they were the extra-thick tandem butted variety, and they also had an extra piece of steel pressed in for even more security. Maybe that was overkill, but that's better than underkill ! Santana of course later went to 1-1/4" steerers, after I moved on. Rodriguez offered 28 mm steerers on their bikes when Santana was still using 1". That was before the modern 1-1/8" steerer was invented, so 28 mm was the best tandem steerer you could get. They required a somewhat-rare French headset, but still worth it I think. Of course the head tube has to be oversized too, to take this steerer/headset, so you can't easily upgrade your tandem to that. Would require replacing the headtube, which is major surgery, as you can well imagine. But do-able though, if the bike means enough to you. Me, I'd just go with the reinforcing tube in your existing steerer.

Mark in Seattle

#35

Full Member

Join Date: Jun 2020

Location: Marin County, Alta California

Posts: 385

Bikes: Since new: 86 Rodriguez Tandem, wife's 87 Gitane Team Pro, 92 Burley Rock-n-Roll, 85 Fisher Comp, 88 Puch Pro, two 92 Bridgestone X0-1s; later: 66/67 Gitane Champion du Monde, 70 Gitane Super Corsa, 70 Carre, 87 Gitane Team Pro, 77/78 Ritchey Tandem

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 149 Post(s)

Liked 366 Times

in

161 Posts

Couple things…the bridge analogy is misplaced as with a bridge you have a structure set between two rigidly set points. The oscillations run up against these fixed ends and if severe and long lasting enough, failure can occur. You do not have this scenario on a bike as no end is fixed so you shouldn’t envision the stresses to your frame in that way. Speed wobbles are not limited to bicycles and motorcycles…bombing downhills on a skateboard can produce terrifying speed wobbles and this is atop a rigid plank. Speed wobbles are pretty much restricted to vehicles with a single steering pivot at front…your frame may have been flexing some but not to a degree that significant frame damage would occur as what you were experiencing was first the front wheel oscillating through the head tube, then the mass of the bike behind the head tube oscillating from that pivot back to ground surface through flexible tires which were also sliding on the road surface (and now we are back to not having rigidly fixed points anchoring the structure at either end like a bridge).

Last edited by Markeologist; 01-30-24 at 08:27 AM.

Likes For Markeologist:

#36

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,402

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,701 Times

in

2,521 Posts

I'd guess a significant percentage of bike frames could be made to shimmy with the right combination of loading, weight distribution and external excitation (eg rough road surface, body reacting in rhythm with the movement, etc). I'd guess this is even more true for high performance or 'lively' frames than a lead slug Huffy.

#37

Paramount Fan

Join Date: Dec 2006

Location: Vermont

Posts: 293

Bikes: Paramounts, Raleigh Pros, Colnago, DeRosa, Gios, Masis, Pinarello, R. Sachs, Look, D. Moulton, Witcomb, Motobecane, Bianchis, Fat City, Frejus, Follis, Waterford, Litespeed, d'Autremont, others, mostly '70s-'80s

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 123 Post(s)

Liked 242 Times

in

133 Posts

May I ask, were you using the Tandem freewheel, or just the run-of-the-mill model (Pro-Compe or whatever)? I found the Tandem freewheels to be tougher by enough to be worth it. They still had a bad habit of unthreading the lockring while riding, dumping their guts, so we used to take each ring off, degreasing, adding strong Loctite and reassembling tightly. That last step often resulted in the bearings being adjusted too tight, showing us that Suntour hadn't put enough adjustment shims in, and they'd compensated by not tightening the ring enough. So we'd quickly remove the ring (before the Loctite set), add a shim, then hammer it home. Never had one come loose after that. At first we had to cannibalize old worn-out freewheels to get more adjusting shims, but then we were able to order a bag of 100 shims from Suntour. Sending them all out like that, adjusted wrong and too loose to stay together, was not their finest hour! All our custom work to make them reliable made them the most expensive freewheel out there, but we still felt they were worth it for our boutique high-end custom tandems. (This was at R+E Cycles, making the Rodriguez tandems, roughly '79 to '84)

Do you still ride it? If so I'd recommend reinforcing the steerer at the bottom, with a pressed-in Cr-Mo tube, custom sized to be a tight fit inside the steerer. They have a butt as I'm sure you know, but I don't consider it enough. Reynolds made a Tandem steerer with a thicker butt, but I doubt that was used on your fork. You don't want to end up like this:

"It's always been fine so far" isn't a good reason not to reinforce it. Fatigue can strike at any time and your fork might be a ticking time bomb. It's very difficult to inspect there for cracks since you have to disassemble the headset to see them, so you're unlikely to catch a crack while it's still small.

I have a lathe and I'm willing to turn the reinforcing tube to the dimension you need — PM me if interested, or have someone local do it to avoid boxing and shipping.

When I worked at Santana in the '70s, they had 1" steerers too, but they were the extra-thick tandem butted variety, and they also had an extra piece of steel pressed in for even more security. Maybe that was overkill, but that's better than underkill ! Santana of course later went to 1-1/4" steerers, after I moved on. Rodriguez offered 28 mm steerers on their bikes when Santana was still using 1". That was before the modern 1-1/8" steerer was invented, so 28 mm was the best tandem steerer you could get. They required a somewhat-rare French headset, but still worth it I think. Of course the head tube has to be oversized too, to take this steerer/headset, so you can't easily upgrade your tandem to that. Would require replacing the headtube, which is major surgery, as you can well imagine. But do-able though, if the bike means enough to you. Me, I'd just go with the reinforcing tube in your existing steerer.

Mark in Seattle

Do you still ride it? If so I'd recommend reinforcing the steerer at the bottom, with a pressed-in Cr-Mo tube, custom sized to be a tight fit inside the steerer. They have a butt as I'm sure you know, but I don't consider it enough. Reynolds made a Tandem steerer with a thicker butt, but I doubt that was used on your fork. You don't want to end up like this:

"It's always been fine so far" isn't a good reason not to reinforce it. Fatigue can strike at any time and your fork might be a ticking time bomb. It's very difficult to inspect there for cracks since you have to disassemble the headset to see them, so you're unlikely to catch a crack while it's still small.

I have a lathe and I'm willing to turn the reinforcing tube to the dimension you need — PM me if interested, or have someone local do it to avoid boxing and shipping.

When I worked at Santana in the '70s, they had 1" steerers too, but they were the extra-thick tandem butted variety, and they also had an extra piece of steel pressed in for even more security. Maybe that was overkill, but that's better than underkill ! Santana of course later went to 1-1/4" steerers, after I moved on. Rodriguez offered 28 mm steerers on their bikes when Santana was still using 1". That was before the modern 1-1/8" steerer was invented, so 28 mm was the best tandem steerer you could get. They required a somewhat-rare French headset, but still worth it I think. Of course the head tube has to be oversized too, to take this steerer/headset, so you can't easily upgrade your tandem to that. Would require replacing the headtube, which is major surgery, as you can well imagine. But do-able though, if the bike means enough to you. Me, I'd just go with the reinforcing tube in your existing steerer.

Mark in Seattle

Not knowing the story behind that bent tandem, I'm not sure the steerer should be faulted. As you know, once steel exceeds its elastic limit, the force required to bend it goes down and it's not at all uncommon for the failure to be localized to the weakest member. It's why some bikes in front end impacts have bent tubes but perfect forks, while with others it's exactly the opposite. More concerning are those failures where the fork snaps off at the crown. Since as a complete team we weighed less than some large people on single bikes, I wasn't overly concerned. Tandems in general have pretty low resale value, and old tandems are worth almost nothing. That, combined with the oddball design and nostalgic factors, have kept it in storage. It has been ridden once in the past 20 years, but we have no plans to sell it. Turning down a plug isn't a bad idea, and I might do it someday just as a failsafe in case someone else does end up with it, but of course there is an internal taper in the steerer that would have to be taken into consideration. I have a taper attachment on my 10" lathe, so it would be a fun and easy project. If I ever find a taper attachment for my ancient 16" LeBlond, I will definitely buy it!

We have four other tandems to ride, plus a couple Paramount tandems that are in pieces right now (no one wants them anymore, either). Interestingly, the one my wife always requests is the ugliest, cheapest one, a Rodriguez Tucan, from a decade or so after your time at R&E. It was intended to be a starter tandem that had a frame worthy of upgrading, which is what we've done. What she really likes about it are the fat 26" tires that soak up the bumps, plus it has the lowest overall gear ratio of any of our road tandems. Someday, when I get some other projects out of the way, I hope to braze up a steel 650B tandem, which I think would be the bomb.

Last edited by sbarner; 01-30-24 at 01:16 PM.

#38

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,994

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1181 Post(s)

Liked 2,576 Times

in

1,076 Posts

Not knowing the story behind that bent tandem, I'm not sure the steerer should be faulted.

Anyway, I confess that using that picture is a bit unfair in this context, sorry for the FUD.

More concerning are those failures where the fork snaps off at the crown.

Turning down a plug isn't a bad idea, and I might do it someday just as a failsafe in case someone else does end up with it, but of course there is an internal taper in the steerer that would have to be taken into consideration. I have a taper attachment on my 10" lathe, so it would be a fun and easy project. If I ever find a taper attachment for my ancient 16" LeBlond, I will definitely buy it!

We have four other tandems to ride, plus a couple Paramount tandems that are in pieces right now (no one wants them anymore, either). Interestingly, the one my wife always requests is the ugliest, cheapest one, a Rodriguez Tucan

Someday, when I get some other projects out of the way, I hope to braze up a steel 650B tandem, which I think would be the bomb.

Note the housing-stop "tower" is an I-beam, tapered in two directions, made of 4 stainless pieces silver brazed together. (The dark color is tarnish on the silver.) It would be a lot of work to recreate that in a longer size for fat tires. Maybe I can replace just the curved tube that goes from post to post, but these mini-rollercams may not have enough width for the tires I want (42 mm minimum). Anyway it's been back-burnered for at least 20 years. We did actually race on this bike, so I'm not super embarrassed that I made it as a skinny-tire racing bike, but I do regret now not making it with clearance for fat tires. What would have been the harm in leaving extra room? We still could have raced it just fine with extra clearance! But hey it was the '80s, era of way-too-skinny tires, and I did make it fit true 35mm tires without fenders, 30 mm (tight fit) with fenders. The bike has enough sentimental value to be worth updating, to fit our much more comfort-oriented riding nowadays.

Back to the subject of shimmy: this bike was under 29 lb in racing trim (with no carbon or titanium, clincher wheels, triple crank), but it's plenty stiff enough, and I'm a fast-twitch, sprint-oriented clydesdale. Oversized thinwall tubes FTW. Somwhat prone to denting though, especially the diagonal bracing bubes which are 0.3 mm in the unbutt. They're mostly just there to hold up water bottles though, which they do just fine.

Likes For bulgie:

#39

Senior Member

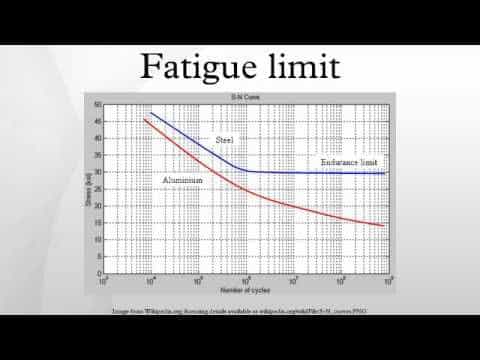

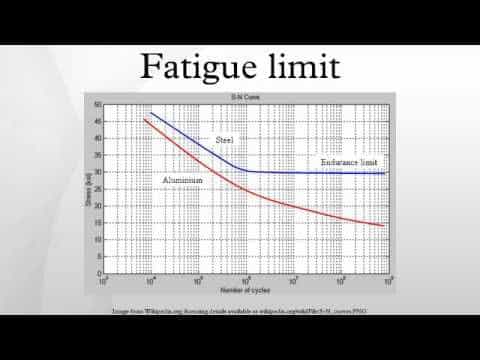

mpetry showed you the behavior of steel subjected to high loads - how much can I strain it one time before it stretches or cracks?

Here is the other type of behavior - fatigue due to low-level, repetitive, cyclic loading (well, usually low level).

This type of data addresses the question, how many times can I flex it?

My bike is 50 years old, with gazillions of miles. I sometimes worry if the fork will ever fail from fatigue. I think about this especially in high speed, downhill turns.

Note that steel, kept at or below below a certain stress level (the endurance limit), can be cycled forever. Aluminum cannot do that.

Sorry for crappy image -

Horizontal axis is cycles to failure

Vertical axis is stress level.

Here is the other type of behavior - fatigue due to low-level, repetitive, cyclic loading (well, usually low level).

This type of data addresses the question, how many times can I flex it?

My bike is 50 years old, with gazillions of miles. I sometimes worry if the fork will ever fail from fatigue. I think about this especially in high speed, downhill turns.

Note that steel, kept at or below below a certain stress level (the endurance limit), can be cycled forever. Aluminum cannot do that.

Sorry for crappy image -

Horizontal axis is cycles to failure

Vertical axis is stress level.

Last edited by Bad Lag; 01-31-24 at 02:07 AM.

Likes For Bad Lag:

#40

Senior Member

Join Date: Jan 2005

Location: Baltimore, MD

Posts: 5,383

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 2490 Post(s)

Liked 2,960 Times

in

1,682 Posts

Cracks caused by fatigue, especially at the bottom bracket or at the head tube/down tube junction, are not particularly uncommon in steel bike frames. The lighter the frame, other things equal, the smaller the margin of strength. Among other possible contributing factors, a rider who is heavier or stronger might regularly subject a frame to stresses that are close to or exceed that "certain stress level."

Designers of aluminum bikes are fully aware of the fatigue characteristics of the material, so their frames are usually built with a margin of strength that is at least slightly greater than that of a comparable steel frame, since adding more material carries a lower weight penalty. That might at least partly explain why, in the 1997 German Tour magazine fatigue test of 12 high-end steel, titanium, carbon, and aluminum frames, two of the aluminum frames (and one carbon frame) passed the tests whereas all the steel and titanium frames failed.

#41

Strong Walker

True. But the way the structure is designed is important, too.

Cracks caused by fatigue, especially at the bottom bracket or at the head tube/down tube junction, are not particularly uncommon in steel bike frames. The lighter the frame, other things equal, the smaller the margin of strength. Among other possible contributing factors, a rider who is heavier or stronger might regularly subject a frame to stresses that are close to or exceed that "certain stress level."

Designers of aluminum bikes are fully aware of the fatigue characteristics of the material, so their frames are usually built with a margin of strength that is at least slightly greater than that of a comparable steel frame, since adding more material carries a lower weight penalty. That might at least partly explain why, in the 1997 German Tour magazine fatigue test of 12 high-end steel, titanium, carbon, and aluminum frames, two of the aluminum frames (and one carbon frame) passed the tests whereas all the steel and titanium frames failed.

Cracks caused by fatigue, especially at the bottom bracket or at the head tube/down tube junction, are not particularly uncommon in steel bike frames. The lighter the frame, other things equal, the smaller the margin of strength. Among other possible contributing factors, a rider who is heavier or stronger might regularly subject a frame to stresses that are close to or exceed that "certain stress level."

Designers of aluminum bikes are fully aware of the fatigue characteristics of the material, so their frames are usually built with a margin of strength that is at least slightly greater than that of a comparable steel frame, since adding more material carries a lower weight penalty. That might at least partly explain why, in the 1997 German Tour magazine fatigue test of 12 high-end steel, titanium, carbon, and aluminum frames, two of the aluminum frames (and one carbon frame) passed the tests whereas all the steel and titanium frames failed.

The lugged steel crowd, on the other hand, at that time especially, built based on tradition and followed procedures that hat migrated into rites (everyone did it this way, but the last guy who knew why had passed away 20 years ago)

I would account a good deal of the results of that Tour test, and the EFBE tests that were behind this, to those circumstances. IIRC, the lugged steel that failed was not a weakness of the material, but wrongful processing - simply put, brazing mistakes.

Likes For martl:

#42

Senior Member

Join Date: Jan 2005

Location: Baltimore, MD

Posts: 5,383

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 2490 Post(s)

Liked 2,960 Times

in

1,682 Posts

the first commercially successful generation of welded thin-walled aluminium frames came from people who came from engineering schools and universities, not from tradition, designing their frames so-to-speak from zero, applying standard engineering techniques (as opposed to "what grandpa used to do").

The lugged steel crowd, on the other hand, at that time especially, built based on tradition and followed procedures that hat migrated into rites (everyone did it this way, but the last guy who knew why had passed away 20 years ago)

I would account a good deal of the results of that Tour test, and the EFBE tests that were behind this, to those circumstances. IIRC, the lugged steel that failed was not a weakness of the material, but wrongful processing - simply put, brazing mistakes.

The lugged steel crowd, on the other hand, at that time especially, built based on tradition and followed procedures that hat migrated into rites (everyone did it this way, but the last guy who knew why had passed away 20 years ago)

I would account a good deal of the results of that Tour test, and the EFBE tests that were behind this, to those circumstances. IIRC, the lugged steel that failed was not a weakness of the material, but wrongful processing - simply put, brazing mistakes.

And that further illustrates that the margin for error is smaller for builders of steel and titanium frames.

And, yes, traditional steel bikes represent a long history of seat-of-the-pants (!) "engineering."

From this page (and originally written by one of Bike Forum's most highly esteemed contributors):

"Bike frame design has advanced for over a century by *almost* random mutations (well hopefully some of the designers had *some* clue!). A recurring theme is making a part lighter until the death toll becomes prohibitive, then adding a little material where the breakage occurs."

#43

Senior Member

Join Date: Feb 2008

Location: Peoria, IL

Posts: 4,481

Mentioned: 86 Post(s)

Tagged: 0 Thread(s)

Quoted: 1830 Post(s)

Liked 3,383 Times

in

1,584 Posts

Couple things…the bridge analogy is misplaced as with a bridge you have a structure set between two rigidly set points. The oscillations run up against these fixed ends and if severe and long lasting enough, failure can occur. You do not have this scenario on a bike as no end is fixed so you shouldn’t envision the stresses to your frame in that way. Speed wobbles are not limited to bicycles and motorcycles…bombing downhills on a skateboard can produce terrifying speed wobbles and this is atop a rigid plank. Speed wobbles are pretty much restricted to vehicles with a single steering pivot at front…your frame may have been flexing some but not to a degree that significant frame damage would occur as what you were experiencing was first the front wheel oscillating through the head tube, then the mass of the bike behind the head tube oscillating from that pivot back to ground surface through flexible tires which were also sliding on the road surface (and now we are back to not having rigidly fixed points anchoring the structure at either end like a bridge).

And as noted, it's definitely not just bikes!

As an aviation nerd, there have been various cases of the nose gear of an aircraft shimmying during taxi tests. The usual fix, I believe, is to increase the stiffness of the components, but in the trainer jet built by Fouga, they chose to use a very wide tire on the nose gear. In fact, it's not just wide, they put a deep channel in the middle so that the tire would ride on the two outer ribs. This means that turning the nose wheel left or right will cause tire scrub and requiring more force to turn.

Here's an overall shot of the Fouga "Magister" at an airshow....

and a close shot that shows the nose gear tire....

Steve in Peoria

Likes For steelbikeguy:

#44

aged to perfection

Join Date: Jun 2009

Location: PacNW

Posts: 1,820

Bikes: Dinucci Allez 2.0, Richard Sachs, Alex Singer, Serotta, Masi GC, Raleigh Pro Mk.1, Hetchins, etc

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 840 Post(s)

Liked 1,263 Times

in

667 Posts

I saw a Fouga like that fly over last weekend ! the V tail is distinctive. Clearly too much trail on that nose gear.

that front tire is probably not available from Sporty's Pilot Shop. Or aircraft spruce & specialty, for that matter.

/markp

that front tire is probably not available from Sporty's Pilot Shop. Or aircraft spruce & specialty, for that matter.

/markp

Likes For mpetry912:

#45

Senior Member

Join Date: May 2022

Location: USA - Southwest PA

Posts: 3,100

Bikes: Cannondale - Gary Fisher - Giant - Litespeed - Schwinn Paramount - Schwinn (lugged steel) - Trek OCLV

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 1401 Post(s)

Liked 1,886 Times

in

1,085 Posts

Agreed. I hope to convert my late-'80s 700c Davidson to 650b, but that'll be more of a project than on most bikes, because I have WTB mini-rollercam brakes. They're fantastic tandem stoppers that I'd hate to get rid of. And I made "boosters" that reduce pivot post flex, "unfortunately" integrated with the housing hanger, and they were a lot of work to make. It'll make me sad to get rid of this (below) but there's not nearly enough reach to use with a fat 650b tire:

.

#46

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,994

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1181 Post(s)

Liked 2,576 Times

in

1,076 Posts

From this page (and originally written by one of Bike Forum's most highly esteemed contributors):

"Bike frame design has advanced for over a century by *almost* random mutations (well hopefully some of the designers had *some* clue!). A recurring theme is making a part lighter until the death toll becomes prohibitive, then adding a little material where the breakage occurs."

"Bike frame design has advanced for over a century by *almost* random mutations (well hopefully some of the designers had *some* clue!). A recurring theme is making a part lighter until the death toll becomes prohibitive, then adding a little material where the breakage occurs."

I hope everyone knows I meant "death toll" metaphorically.

Remind me, I haven't looked at the Tour tests in a long time, but didn't they get failures at a water bottle braze-on? That made me question their testing design a little, because that's not where bikes break usually, whether steel or anything else. Possibly the loads they used in the test weren't a realistic approximation of real life loading. Maybe moot, as in might not have changed the relative rankings much, though we'll probably never know. Proper loading should make cracks in the DT, underneath, near the HT, or the side of the ST at the BB, or in the right rear dropout.

Likes For bulgie:

#47

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,994

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1181 Post(s)

Liked 2,576 Times

in

1,076 Posts

#48

Strong Walker

Hey, I resemble that guy. Only he's skinnier than me and with less white in his hair. Nice to be esteemed, rather than my usual, just steamed.

I hope everyone knows I meant "death toll" metaphorically.

Remind me, I haven't looked at the Tour tests in a long time, but didn't they get failures at a water bottle braze-on? That made me question their testing design a little, because that's not where bikes break usually, whether steel or anything else. Possibly the loads they used in the test weren't a realistic approximation of real life loading. Maybe moot, as in might not have changed the relative rankings much, though we'll probably never know. Proper loading should make cracks in the DT, underneath, near the HT, or the side of the ST at the BB, or in the right rear dropout.

I hope everyone knows I meant "death toll" metaphorically.

Remind me, I haven't looked at the Tour tests in a long time, but didn't they get failures at a water bottle braze-on? That made me question their testing design a little, because that's not where bikes break usually, whether steel or anything else. Possibly the loads they used in the test weren't a realistic approximation of real life loading. Maybe moot, as in might not have changed the relative rankings much, though we'll probably never know. Proper loading should make cracks in the DT, underneath, near the HT, or the side of the ST at the BB, or in the right rear dropout.

If a frame is designed and built well, but one bottle mount was totally messed up in the brazing process, this may well be where the frame will crack. Others cracked around the shifter bosses - in real life, not at a test stand

#49

Senior Member

Join Date: Jan 2005

Location: Baltimore, MD

Posts: 5,383

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 2490 Post(s)

Liked 2,960 Times

in

1,682 Posts

Hey, I resemble that guy. Only he's skinnier than me and with less white in his hair. Nice to be esteemed, rather than my usual, just steamed.

I hope everyone knows I meant "death toll" metaphorically.

Remind me, I haven't looked at the Tour tests in a long time, but didn't they get failures at a water bottle braze-on? That made me question their testing design a little, because that's not where bikes break usually, whether steel or anything else. Possibly the loads they used in the test weren't a realistic approximation of real life loading. Maybe moot, as in might not have changed the relative rankings much, though we'll probably never know. Proper loading should make cracks in the DT, underneath, near the HT, or the side of the ST at the BB, or in the right rear dropout.

I hope everyone knows I meant "death toll" metaphorically.

Remind me, I haven't looked at the Tour tests in a long time, but didn't they get failures at a water bottle braze-on? That made me question their testing design a little, because that's not where bikes break usually, whether steel or anything else. Possibly the loads they used in the test weren't a realistic approximation of real life loading. Maybe moot, as in might not have changed the relative rankings much, though we'll probably never know. Proper loading should make cracks in the DT, underneath, near the HT, or the side of the ST at the BB, or in the right rear dropout.

Here's the Tour test link archived on the Sheldon Brown website. Some aspects of the test protocols are detailed there.

From that page, about the crack propagating from the bottle boss:

Weak point at a drilling: Schmolke's titanium frame cracked starting at a water-bottle-cage drilling. Stress peaks at drillings are classic crack-initiation points. In this case, however, the drilling was well reinforced. Presumably, the weld initiated the crack.

#50

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,994

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1181 Post(s)

Liked 2,576 Times

in

1,076 Posts

I have also never seen a steel frame crack at the shifter boss, that I can remember anyway. Seen a couple that kinked (buckled) there, from a crash or running into the garage on the car roof, but no fatigue cracks that I can recall. Gotta be way rare.

I did hear about some Ti frames that broke there, and saw one with my own eye, but I assume that was due to not argon-purging the inside enough while they welded those. Can't prove it, but I did a fair number of repairs on Ti frames, including replacing cracked tubes but more often just retrofitting them with S&S couplers. Either way, when we got to see the inside, there were often at least moderate amounts of evidence of insufficient purge. They can clean it off the outside, but I got to see where the sun don't shine, and I could tell ya some stories! Big famous brands. They were just trying to make a living in a tough business, but rushing the weld before the insides are fully purged is, in my opionion, the most likely cause of those cracks at the shifter boss. Since those are so far from the sites of highest stress, cracks pretty much have to be from improper welding, and failure to purge is practically the only thing you can do wrong there. Assuming you're good enough to stick the main tubes together anyway, a reasonably safe bet with the big-name brands. The shifter boss is much easier, much less chance of screwing it up — any other way than by not purging.

There's nothing equivalent to that in brazed steel frames. The H2O and shifter bosses are easily silver brazed in a couple seconds, doing very little metallurgical damage, and that's a task that you can teach an apprentice to do and have him doing an adequate job by the end of day after a few test runs on scrap tubing. It's so easy to braze those that I almost never see one that's not thoroughly brazed. On better quality lightweights anyway; we're not talking about frames from big-box stores here, are we? (I should look at those tests again, it's been years...)