Brompton introducing a 12 speed

#26

Senior Member

Join Date: Feb 2017

Posts: 1,545

Mentioned: 4 Post(s)

Tagged: 0 Thread(s)

Quoted: 800 Post(s)

Likes: 0

Liked 249 Times

in

213 Posts

No of course not since as far as I know there are no efficiency measurements of the BWR IGH at all. But the BSR has already a poor efficiency on its first and third ratios and the BWR can only be worse.

The difference in efficiency between 9, 10 and 11T aren't really big its the reason why nowadays all three main groupset manufacturers, SRAM-Shimano-Campagnolo offer cassettes with a 10t smallest cog and why Campagnolo has cassettes with a 9t smallest cog:

The issue that remains is the wear of the smaller cogs but its not a major issue since they aren't often used due to the fact they provide the seldom used highest gear inch.

The difference in efficiency between 9, 10 and 11T aren't really big its the reason why nowadays all three main groupset manufacturers, SRAM-Shimano-Campagnolo offer cassettes with a 10t smallest cog and why Campagnolo has cassettes with a 9t smallest cog:

The issue that remains is the wear of the smaller cogs but its not a major issue since they aren't often used due to the fact they provide the seldom used highest gear inch.

#27

Schwinnasaur

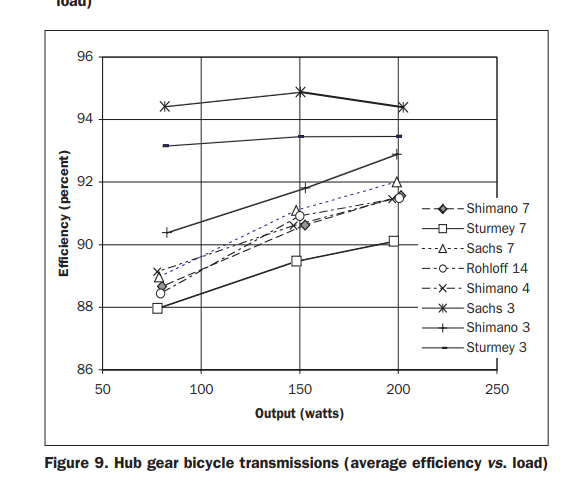

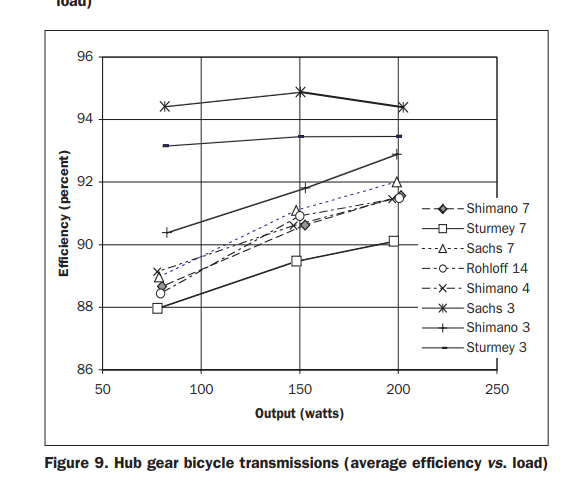

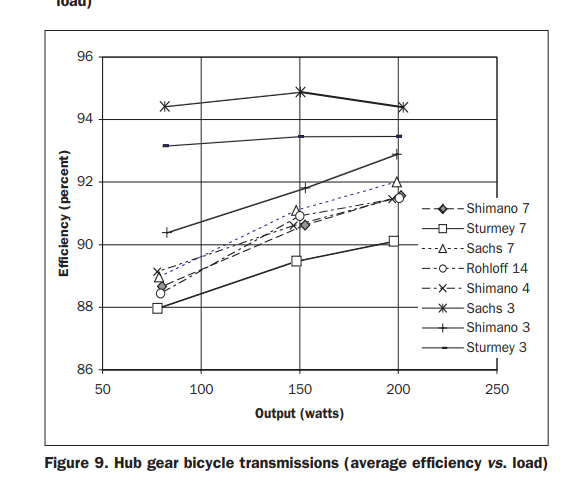

This is from https://ihpva.org/HParchive/PDF/hp52-2001.pdf

International Human Powered Vehicle Association. Note, this is an independent source, not from a manufacturer. As you can see, the three speeds were more efficient than your Rohloff. Though, the Rohloff does well considering how many gears it has.

#28

Senior Member

Join Date: Feb 2017

Posts: 1,545

Mentioned: 4 Post(s)

Tagged: 0 Thread(s)

Quoted: 800 Post(s)

Likes: 0

Liked 249 Times

in

213 Posts

I said that the BWR that has bigger reduction/multiplication ratio is worse than the Sturmey 3 which is similar to the BSR. Its an inherent feature of planetary design that, everything else remaining the same, increasing the ratio reduces the efficiency.

Its exactly the same for the 2s Schlumpf: MD and HSD with a 2.5 ratio have a worse efficiency than SD with 1.65 ratio (for their 2.5:1 an 1:2.5 vs. 1:1.65 ratio, not for their 1:1 ratio of course).

For the Brompton, anybody who had the opportunity to compare the ride on a 2s or 4s with the ride on a 3s BSR and 6s BWR knows that the latest are less efficient.

Its exactly the same for the 2s Schlumpf: MD and HSD with a 2.5 ratio have a worse efficiency than SD with 1.65 ratio (for their 2.5:1 an 1:2.5 vs. 1:1.65 ratio, not for their 1:1 ratio of course).

For the Brompton, anybody who had the opportunity to compare the ride on a 2s or 4s with the ride on a 3s BSR and 6s BWR knows that the latest are less efficient.

#29

Schwinnasaur

I said that the BWR that has bigger reduction/multiplication ratio is worse than the Sturmey 3 which is similar to the BSR. Its an inherent feature of planetary design that, everything else remaining the same, increasing the ratio reduces the efficiency.

Its exactly the same for the 2s Schlumpf: MD and HSD with a 2.5 ratio have a worse efficiency than SD with 1.65 ratio (for their 2.5:1 an 1:2.5 vs. 1:1.65 ratio, not for their 1:1 ratio of course).

For the Brompton, anybody who had the opportunity to compare the ride on a 2s or 4s with the ride on a 3s BSR and 6s BWR knows that the latest are less efficient.

Its exactly the same for the 2s Schlumpf: MD and HSD with a 2.5 ratio have a worse efficiency than SD with 1.65 ratio (for their 2.5:1 an 1:2.5 vs. 1:1.65 ratio, not for their 1:1 ratio of course).

For the Brompton, anybody who had the opportunity to compare the ride on a 2s or 4s with the ride on a 3s BSR and 6s BWR knows that the latest are less efficient.

Last edited by Schwinnsta; 01-11-24 at 06:36 AM. Reason: added to text

#30

Senior Member

Join Date: Feb 2017

Posts: 1,545

Mentioned: 4 Post(s)

Tagged: 0 Thread(s)

Quoted: 800 Post(s)

Likes: 0

Liked 249 Times

in

213 Posts

Yes, a 3 speed IGH is more efficient than most IGH with more gears.

But not than a derailleur only solution.

The problem remains that Brompton, for any reason; doesn't want to make a 135mm OLD rear triangle needed to be able to use a standard cassette (even if Kinetics has demonstrated that it has no impact on folding/folding width).

The 6s 2x3 was very well engineered with hub gear spacing and cogs sizes chosen to avoid duplicated gears and provide a more or less equal (but too big) spacing between gears which isn't the case with the 4x3 12s solution.

For me the 4x3 12s is a quick and dirty solution introduced to solve the too small gear inch range of the 4s P-line (and T-line, a 11s derailleur T-line would be a great bike, very lightweight and versatile, a unique selling proposition, there is no other folding bike at that weight with such versatility).

But not than a derailleur only solution.

The problem remains that Brompton, for any reason; doesn't want to make a 135mm OLD rear triangle needed to be able to use a standard cassette (even if Kinetics has demonstrated that it has no impact on folding/folding width).

The 6s 2x3 was very well engineered with hub gear spacing and cogs sizes chosen to avoid duplicated gears and provide a more or less equal (but too big) spacing between gears which isn't the case with the 4x3 12s solution.

For me the 4x3 12s is a quick and dirty solution introduced to solve the too small gear inch range of the 4s P-line (and T-line, a 11s derailleur T-line would be a great bike, very lightweight and versatile, a unique selling proposition, there is no other folding bike at that weight with such versatility).

Likes For Jipe:

#31

Schwinnasaur

Agree with this last post. Myself, I prefer a deraileur.to IGH. I could imagine getting a P line and adding a couple of gears, but it would not give me that much for the money. As it is, I have a three speed derailleur B 160% range, but it is adequate for the flat lands I live on. I think one of the problems with making a multispeed derailleur for Brompton is that they want to be able to fold it reliably in any gear.

#32

Palmer

Join Date: Mar 2007

Location: Parts Unknown

Posts: 8,627

Bikes: Mike Melton custom, Alex Moulton AM, Dahon Curl

Mentioned: 37 Post(s)

Tagged: 0 Thread(s)

Quoted: 1671 Post(s)

Liked 1,826 Times

in

1,062 Posts

#33

Senior Member

Join Date: Aug 2010

Location: Madison, WI

Posts: 11,213

Bikes: 1961 Ideor, 1966 Perfekt 3 Speed AB Hub, 1994 Bridgestone MB-6, 2006 Airnimal Joey, 2009 Thorn Sherpa, 2013 Thorn Nomad MkII, 2015 VO Pass Hunter, 2017 Lynskey Backroad, 2017 Raleigh Gran Prix, 1980s Bianchi Mixte on a trainer. Others are now gone.

Mentioned: 48 Post(s)

Tagged: 0 Thread(s)

Quoted: 3462 Post(s)

Liked 1,468 Times

in

1,145 Posts

No, that is not well known. I don't know it. We are talking about two three speed hubs. In this case, we have three gears involved. The design of both are similar, with the number of teeth in the planet and sun gears differing. As you add more driven gears to the system, inefficiency increases. The inefficiency is mainly due to internal friction. The reason that Rohloff has good relatively good efficiency for the number of gears it has is the high tolerances in its manufacture, use of ball bearings versus roller bearings and bushes in the less costly IGH. Also, it uses light oil, too, versus grease.

This is from https://ihpva.org/HParchive/PDF/hp52-2001.pdf

International Human Powered Vehicle Association. Note, this is an independent source, not from a manufacturer. As you can see, the three speeds were more efficient than your Rohloff. Though, the Rohloff does well considering how many gears it has.

This is from https://ihpva.org/HParchive/PDF/hp52-2001.pdf

International Human Powered Vehicle Association. Note, this is an independent source, not from a manufacturer. As you can see, the three speeds were more efficient than your Rohloff. Though, the Rohloff does well considering how many gears it has.

Ask any Rohloff owner if it gets better with use after the seals loosen up some and the gear teeth get more polished, and you will hear that they are much more efficient after several thousand miles (or kms). My 10 year old Rohloff is a lot smoother now than when I first bought it.

I am not saying you are wrong, the three speed hubs could easily be more efficient than the Rohloff, the oil seals in the Rohloff are there to minimize how fast the liquid oil leaks out of the hub, and those seals reduce efficiency.

#34

Senior Member

Join Date: Aug 2010

Location: Madison, WI

Posts: 11,213

Bikes: 1961 Ideor, 1966 Perfekt 3 Speed AB Hub, 1994 Bridgestone MB-6, 2006 Airnimal Joey, 2009 Thorn Sherpa, 2013 Thorn Nomad MkII, 2015 VO Pass Hunter, 2017 Lynskey Backroad, 2017 Raleigh Gran Prix, 1980s Bianchi Mixte on a trainer. Others are now gone.

Mentioned: 48 Post(s)

Tagged: 0 Thread(s)

Quoted: 3462 Post(s)

Liked 1,468 Times

in

1,145 Posts

...

One of the comments mentions a do it yourself double chainring he uses without a shifter. A response suggests that you nudge with your foot to the smaller ring (dangerous?) and getting off the bike and using your hands to go back to the larger ring. That seems to ruin any ride IMO.

...

One of the comments mentions a do it yourself double chainring he uses without a shifter. A response suggests that you nudge with your foot to the smaller ring (dangerous?) and getting off the bike and using your hands to go back to the larger ring. That seems to ruin any ride IMO.

...

Later I added a Sram Dual Drive to my Joey. That gave me the wider gearing that I wanted.

If you want to try two chainrings, I suggest a wax type chain lube. Over a decade ago I used an oil based chain lube and that is what I used during my two chainring experiment. Now I use a wax type chain lube, the chain is a lot less greasy.

The newer Airnimal Joey frames can be fitted with a front derailleur, unfortunately my older frame can't.

#35

Senior Member

Join Date: Feb 2017

Posts: 1,545

Mentioned: 4 Post(s)

Tagged: 0 Thread(s)

Quoted: 800 Post(s)

Likes: 0

Liked 249 Times

in

213 Posts

Those types of efficiency tests generally use brand new hubs. I did not check to see if this test did, I just assume it did.

Ask any Rohloff owner if it gets better with use after the seals loosen up some and the gear teeth get more polished, and you will hear that they are much more efficient after several thousand miles (or kms). My 10 year old Rohloff is a lot smoother now than when I first bought it.

I am not saying you are wrong, the three speed hubs could easily be more efficient than the Rohloff, the oil seals in the Rohloff are there to minimize how fast the liquid oil leaks out of the hub, and those seals reduce efficiency.

Ask any Rohloff owner if it gets better with use after the seals loosen up some and the gear teeth get more polished, and you will hear that they are much more efficient after several thousand miles (or kms). My 10 year old Rohloff is a lot smoother now than when I first bought it.

I am not saying you are wrong, the three speed hubs could easily be more efficient than the Rohloff, the oil seals in the Rohloff are there to minimize how fast the liquid oil leaks out of the hub, and those seals reduce efficiency.

There are 3 major generation of Rohloff than can be distinguished by the marking on the hub:

- first, oldest one: Rohloff and marking are written on a yellow-blue sticker glued on the hub. Red hub is painted in red.

- second: hub anodized, marking are engraved, Made in Germany is not underlined.

- third, current: same anodizing+engraving but Made in Germany is underlined, flange are different 'require different flange reinforcement rings than previous generation), no long break-in, no leakage anymore. Noise is different too, less noisy on 7 first gear first.

I have one hub bought in 2012 second gen, it leaks.

And a second one bought mid 2016 gen 3 it doesn't leak.

Mid 2016, the way the cog is mounted changed too. There is a retrofit kit to put the new mounting on older hubs. This change of cog mounting also slightly changed the chainline.

Last edited by Jipe; 01-13-24 at 09:50 AM.

#36

Senior Member

Join Date: Aug 2010

Location: Madison, WI

Posts: 11,213

Bikes: 1961 Ideor, 1966 Perfekt 3 Speed AB Hub, 1994 Bridgestone MB-6, 2006 Airnimal Joey, 2009 Thorn Sherpa, 2013 Thorn Nomad MkII, 2015 VO Pass Hunter, 2017 Lynskey Backroad, 2017 Raleigh Gran Prix, 1980s Bianchi Mixte on a trainer. Others are now gone.

Mentioned: 48 Post(s)

Tagged: 0 Thread(s)

Quoted: 3462 Post(s)

Liked 1,468 Times

in

1,145 Posts

Current Rohloff do not leak anymore and they do not need the long break-in of several thousands of km of the first type of Rohloff.

There are 3 major generation of Rohloff than can be distinguished by the marking on the hub:

- first, oldest one: Rohloff and marking are written on a yellow-blue sticker glued on the hub. Red hub is painted in red.

- second: hub anodized, marking are engraved, Made in Germany is not underlined.

- third, current: same anodizing+engraving but Made in Germany is underlined, flange are different 'require different flange reinforcement rings than previous generation), no long break-in, no leakage anymore. Noise is different too, less noisy on 7 first gear first.

I have one hub bought in 2012 second gen, it leaks.

And a second one bought mid 2016 gen 3 it doesn't leak.

Mid 2016, the way the cog is mounted changed too. There is a retrofit kit to put the new mounting on older hubs. This change of cog mounting also slightly changed the chainline.

There are 3 major generation of Rohloff than can be distinguished by the marking on the hub:

- first, oldest one: Rohloff and marking are written on a yellow-blue sticker glued on the hub. Red hub is painted in red.

- second: hub anodized, marking are engraved, Made in Germany is not underlined.

- third, current: same anodizing+engraving but Made in Germany is underlined, flange are different 'require different flange reinforcement rings than previous generation), no long break-in, no leakage anymore. Noise is different too, less noisy on 7 first gear first.

I have one hub bought in 2012 second gen, it leaks.

And a second one bought mid 2016 gen 3 it doesn't leak.

Mid 2016, the way the cog is mounted changed too. There is a retrofit kit to put the new mounting on older hubs. This change of cog mounting also slightly changed the chainline.

Mine leaks but I know of others that are older that do not leak. Mine is anodized, no underline, serial number 180XXX. Leaks out of the gear change mechanism on the non-drive side.

#37

Senior Member

Join Date: Feb 2017

Posts: 1,545

Mentioned: 4 Post(s)

Tagged: 0 Thread(s)

Quoted: 800 Post(s)

Likes: 0

Liked 249 Times

in

213 Posts

The whole casing of the hub has been modified on the third generation with Made in Germany underlined (reason why the reinforcement rings for the gen 3 are also different), the seals are also different, all this explains that it doesn't leak anymore.

Yours like mine of 2012 are gen 2 that doesn't have the new casing+new seals. Mine of 2012 leaks also on the non drive side, the external gearbox is always wet and dirty, the one of 2016 never, it remains dry and clean.

Yours like mine of 2012 are gen 2 that doesn't have the new casing+new seals. Mine of 2012 leaks also on the non drive side, the external gearbox is always wet and dirty, the one of 2016 never, it remains dry and clean.

#38

Senior Member

The drawbacks of external (derailleur) gearing? 1) Lateral wheel dish, especially critical on a 349 wheel, so the angles are even worse, 2) Skinny chain if you want a LOT of gears, so less durable, 3) Derailleur clearance to ground, tricky on a 20" with 1X gearing, though 9-36 may do it, SUPER tricky with that much cassette range on a 16"/349 wheel.

Last edited by Duragrouch; 01-18-24 at 10:15 PM.

#39

Senior Member

. Maybe a candidate for a Schlumpf drive. I should put it up for sale. I even printed out the whole Sachs technician manual for the hub, figuring to disassemble to lube it, as no lube port (says in owner manual, "permanently lubricated", B.S., Mercedes Benz went through a slew of automatic transmissions that made that claim). But I only recently realized, I could drip in gear lube through the shift linkage port.

. Maybe a candidate for a Schlumpf drive. I should put it up for sale. I even printed out the whole Sachs technician manual for the hub, figuring to disassemble to lube it, as no lube port (says in owner manual, "permanently lubricated", B.S., Mercedes Benz went through a slew of automatic transmissions that made that claim). But I only recently realized, I could drip in gear lube through the shift linkage port.The other thing that strikes me about the above chart, is in general, efficiency increasing with increasing power output. That strikes me as backwards, as higher power output means more torque, so pushing harder on the gear teeth, or more revs, so greater displacement, or both. What the chart tells me is that most of the efficiency loss is "parasitic"(?), meaning fairly constant drag, so with increasing power, that same fixed drag constitutes a smaller portion of the total power, therefore, greater efficiency. (EDIT: Confirmed in deep dig on above report, "Obviously the residual friction in a gear train becomes less important as the input power increases, while the friction factors that increase with load go up less rapidly than the load.")

Also, there should be a big jump in efficiency in the center, for any hub where one of the gears (usually 2nd on a 3 speed), is "fixed gear", neither reduction or overdrive; at that point, the hub efficiency loss should be purely the wheel bearing friction, if chain/sprocket friction is neglected (unknown with the above). So I have questions about the above chart values. (I wanted to investigate deeper, but the link failed. EDIT: I located the PDF manually, need to digest... AHA! "The efficiencies reported in this article include ergometer wheel drive losses, so the actual transmission efficiencies would be higher by 2-2.5%." I see other causes for variation in their test, such as including bottom bracket friction, chain friction, etc. They also state that most of the IGHs were internally greased from the factory, but some had that replaced with light oil. They state that these factors don't matter, as their goal was simply to compare the efficiencies of various hubs and derailleur systems, not determine actual efficiencies of each. But they are still way off. Some hubs were new, some were used. One hub could only use 2 of 7 gears, indicating something was broken, which could drastically affect the results. The Sachs 3 was used and worn-in (known to polish IGH gear surfaces and improve efficiency), AND had the grease changed out for lighter oil (which they acknowledge increases efficiency, which is why they recommend that changout for racing, even though it "doesn't last as long"), those two factors alone could skew the results a ton.)

All the 3-speed IGHs in gear 2 (direct drive, 1.00 ratio), all performed above 94% or 95%. Damned straight. The design, quality of the gears and internal bearings, lube, etc, matters not when it's basically a fixed gear. The rest of the inefficiency is in other parts of the drivetrain.

Everything else about the tests, including that chart above, should be completely discarded, you can't infer anything from it. Very poor test procedures (way too much variation in condition of different sample parts). Read the study if you don't believe me. Link that works for me is:

https://ihpva.org/hparchive.htm

Look for HP52 - 2001

Further note!:

The middle chart is a comparison between the Shimano 4 (1st gear 1:00) IGH, and "Browning 4", an external derailleur system with some sort of torque sensing that functions as an "automatic". Shimano having max efficiency in gear 1 makes complete sense. The Browning, being all external cogs, makes sense having more constant efficiency, until the smallest cog, being a tighter chain curve, has a bit less efficiency. But note: a) These tests were all conducted at "Browning Research", who designed said system, and b) it's not mentioned if the Browning derailleur has things like ball bearing pullies, or larger diameter pulleys, accounting for its superior efficiency versus other (rather dated and possibly worn) commercial derailleur systems they tested. Yeah. Because I can see no other reasons for superior efficiency. It's just a derailleur system, without an actuation cable. EDIT: I stand corrected, this is a different external gearing system with "split" chainrings and cogs, but efficiency should match other external systems; It was designed to shift better under load:

https://www.bikeforums.net/classic-vintage/1225519-equipment-product-review-1987-browning-transmission.html

But I can still grok some conclusions. For efficiency, external gearing systems are king (99.99% of the time, this also means derailleur systems for multi-speeds, but not always). You'll lose a bit of efficiency on the smallest cogs, but otherwise great. IGHs are inherently less efficient, unless when operating in the 1:00 direct drive gear, if the hub offers one, and it doesn't achieve that by stepping down and back up or something like that, if needed with a really complex IGH; Just everything locked and direct drive. In all other gears, there is generally more energy loss, increasing with greater gear ratios, always more than a good derailleur system with good quality pulleys (low friction pulley bearings, and largest pulley diameter that will package), and a chain in good condition and well-lubed.

Last edited by Duragrouch; 01-19-24 at 06:24 AM.

#40

Senior Member

My personal perception is that the test was a boondoggle put on by "Browning Research" to tout their two products, without any investment in new parts of competing hubs for comparison, either to not spend the money, or no incentive to have the competitors perform better, or both. Truth be told, just like all other external gearing systems, the Browning external system should have better efficiency than an IGH. But you cannot compare efficiencies between IGHs from that study, as they had too many variables on the IGH test samples.

Last edited by Duragrouch; 01-19-24 at 06:25 AM.

#41

Junior Member

Super interesting thread ,what with the efficiency discussion, Rohloff info and such; but the thing that baffles me is that Brompton is f___ing around with the transmission and the thing still lacks proper brakes! Maybe a 140mm disc up front moved towards center to offer better protection to the disc, come to think of it, it would be on the inside of the fold anyway. Of course until I see one for sale here (USA) I really don't know that it will ever be available.

#42

Schwinnasaur

Super interesting thread ,what with the efficiency discussion, Rohloff info and such; but the thing that baffles me is that Brompton is f___ing around with the transmission and the thing still lacks proper brakes! Maybe a 140mm disc up front moved towards center to offer better protection to the disc, come to think of it, it would be on the inside of the fold anyway. Of course until I see one for sale here (USA) I really don't know that it will ever be available.

#43

Junior Member

The motor vehicle I drive daily has drum brakes, far from state of the art and they can overheat and fail, but they are not destroying the rims nor are they directly heating the tires. Brakes are far from a new thing as disc, drum and band brakes all existed by 1900. A bike wheel is not a consumable , or at least it shouldn't be .

#44

Senior Member

Lots of bikes have rim brakes. Coming to a Brompton thread to insinuate all rim brakes are bad is silly.

#45

Senior Member

The motor vehicle I drive daily has drum brakes, far from state of the art and they can overheat and fail, but they are not destroying the rims nor are they directly heating the tires. Brakes are far from a new thing as disc, drum and band brakes all existed by 1900. A bike wheel is not a consumable , or at least it shouldn't be .

#46

Schwinnasaur

#47

Senior Member

Join Date: Feb 2017

Posts: 1,545

Mentioned: 4 Post(s)

Tagged: 0 Thread(s)

Quoted: 800 Post(s)

Likes: 0

Liked 249 Times

in

213 Posts

Rim brakes on small diameter wheels like on the Brompton have specific problems:

- rims become hot much faster than on a bigger diameter rims.

- rims wear faster than bigger diameter rims.

It is a well known issue on fast small wheels bikes like for instance recumbent with a ETRTO406 front wheel (in case of downhill, there were exploded tires due to overheating).

And Brompton double wall rims wear quite fast (faster than the previous single wall rims) because of the poor quality aluminum alloy they are made of.

- rims become hot much faster than on a bigger diameter rims.

- rims wear faster than bigger diameter rims.

It is a well known issue on fast small wheels bikes like for instance recumbent with a ETRTO406 front wheel (in case of downhill, there were exploded tires due to overheating).

And Brompton double wall rims wear quite fast (faster than the previous single wall rims) because of the poor quality aluminum alloy they are made of.

#48

Junior Member

#49

Schwinnasaur

#50

Senior Member

Join Date: Sep 2005

Location: Michigan

Posts: 3,706

Bikes: Trek 730 (quad), 720 & 830, Bike Friday NWT, Brompton M36R & M6R, Dahon HAT060 & HT060, ...

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 840 Post(s)

Liked 336 Times

in

251 Posts

It takes me 10 years to wear out rims on a full-size bike ridden daily. I would need to ride around the clock with little sleep to wear them out in 9 months. I recall, though, that I needed to change pads twice a year when riding a bike with cheap components and being unable to differentiate between low and good-quality components. I vividly remember my anxiety after changing to better-quality brakes and finding out that the pads were still good after 2 years of riding.