6mm tap, US/standard drill bit size?

#1

Senior Member

Thread Starter

6mm tap, US/standard drill bit size?

I have tap for a 6mm hole but don't have the correct, metric drill bit (5.2mm).

13/64in = 5.159mm

Can I use a 13/64in bit? The answer seems like a yes to me but I would love an answer from someone with experience. First time using a tap.

Thanks!

*I am tapping a brazeon on my seat stay that stripped. Previously 5mm.

13/64in = 5.159mm

Can I use a 13/64in bit? The answer seems like a yes to me but I would love an answer from someone with experience. First time using a tap.

Thanks!

*I am tapping a brazeon on my seat stay that stripped. Previously 5mm.

#2

SE Wis

Join Date: Apr 2005

Location: Milwaukee, WI

Posts: 10,505

Bikes: '68 Raleigh Sprite, '02 Raleigh C500, '84 Raleigh Gran Prix, '91 Trek 400, 2013 Novara Randonee, 1990 Trek 970

Mentioned: 40 Post(s)

Tagged: 0 Thread(s)

Quoted: 2743 Post(s)

Liked 3,390 Times

in

2,053 Posts

Close enough especially given the slop of using a hand drill.

Use cutting oil, tap straight, back in and out often

Use cutting oil, tap straight, back in and out often

Likes For dedhed:

#3

Senior Member

Join Date: Sep 2010

Location: Roswell, GA

Posts: 8,319

Bikes: '93 Trek 750, '92 Schwinn Crisscross, '93 Mongoose Alta

Mentioned: 30 Post(s)

Tagged: 0 Thread(s)

Quoted: 1438 Post(s)

Liked 1,092 Times

in

723 Posts

According to this chart, assuming M6x1 you would be better off using a #8 or #4 drill. For M6x0.75, #4 or 7/32. I always err on oversized, tapping into an undersized hole greatly increases the risk of breaking the tap. https://littlemachineshop.com/images...DrillSizes.pdf

#4

Senior Member

The 13/64 should work fine. I found a set of metric combination drill/ tap bits at harbor freight that work great for through hole tapping. I put them in my makita impact driver.

Likes For andrewclaus:

#6

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,063

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4197 Post(s)

Liked 3,849 Times

in

2,300 Posts

The M6 tap is a 6mm x 1mm per thread. Not .75mm per thread. MY understanding is that the "M" references a single "standard" thread pitch, in this case 1mm per thread. Andy

BTW this type of info is readily available by a quick Google search for tap drill size. (Just like a lot of other info) Andy

BTW this type of info is readily available by a quick Google search for tap drill size. (Just like a lot of other info) Andy

__________________

AndrewRStewart

AndrewRStewart

#7

Really Old Senior Member

.041mm is .00163".

I doubt you could drill 2 consecutive holes with the same drill bit and get that close on both.

I doubt you could drill 2 consecutive holes with the same drill bit and get that close on both.

Likes For Bill Kapaun:

#8

Senior Member

Join Date: Sep 2010

Location: Roswell, GA

Posts: 8,319

Bikes: '93 Trek 750, '92 Schwinn Crisscross, '93 Mongoose Alta

Mentioned: 30 Post(s)

Tagged: 0 Thread(s)

Quoted: 1438 Post(s)

Liked 1,092 Times

in

723 Posts

The M6 tap is a 6mm x 1mm per thread. Not .75mm per thread. MY understanding is that the "M" references a single "standard" thread pitch, in this case 1mm per thread. Andy

BTW this type of info is readily available by a quick Google search for tap drill size. (Just like a lot of other info) Andy

BTW this type of info is readily available by a quick Google search for tap drill size. (Just like a lot of other info) Andy

#9

Senior Member

Thread Starter

Thanks to all for help. This worked great, rear rack is back on.

For anyone else needing to do this here's what I did.

Thanks again!

For anyone else needing to do this here's what I did.

- M6 x 1 (coarse) tap

- 13/64 bit - made a couple passes after going through.

- used 3-in-one oil to lubricate tap but WD-40 would probably be fine and i saw that suggested in my research.

- I went really slowly and backed out every 1/4 turn or so and cleaned tap and re-oiled. Overkill I'm sure but not hard to do.

Thanks again!

#10

Really Old Senior Member

IIRC, taps came in starter, full & plug.

Plug for finish threading blind holes.

Plug for finish threading blind holes.

#11

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

You worked faster than I typed! Glad it came out ok. Glad the 13/64 dill worked. Generally, 3in1 or WD40 DON'T work as well as tap cutting oil, but this is water over the dam now. And for a through (and not a blind) hole, a tapered tap is fine. Running it into the hole to the point where its not tapered is what you want to do.

Typed before I read what you'd done:

Just a point of correction: the nominal correct size for an M6 cutting tap is often given as 5mm. That's for 100% thread depth. As a nod to practicality, most holes drilled for tapping specify about 65-70% of full thread depth. That's where you 5.2mm comes in (one formula is drill size = nominal thread OD - Percent thread engagement/76.98). A bit more accurate estimate using the formulas in the webpage below is between 5.1556 and 5.089mm. But here's the thing: if you use a hand drill, and/or a poor quality drill bit, your hole diameter is going to be larger than the drill. I would target a little less than the 5.09-5.16 target. For this reason, I'd use a number 8 drill (note that this is a NUMBER drill, and the number 8 is not mm). Or a number 7 drill if I had it. But you'd probably be fine with a 13/64 as well. With a number 6 drill of good quality and steady hand you'd be close, but still be too big for my taste. It might work. Use tapping fluid (normal oil doesn't do as good a job).

The penalty for too big a hole is a weak threaded connection. For too small a hole is difficult tapping and possibly a broken tap.

The advice above is for tapping into steel. If you have a notion to try your hand and at tapping titanium, my suggestion would be ... don't. Even drilling Ti can be problematic - it work hardens something fierce and the drill tends to wander as a result. Get someone who's done this. If you must, read up first on drilling Ti, then on tapping Ti, and do some research and get a really good drills and taps. Emuge, Prototyp... etc. And use moly-dee or some other good lubricant.

No. 8, 5.05mm, 0.1990 inch

No. 7, 5.11mm, 0.2010 inch

Fractional 13/64, 5.16mm, 0 .2031 inch

No. 6, 5.18mm, 0.2040 inch

For tap drill sizes:

https://www.natool.com/wp-content/up...atp113-116.pdf

For available drill sizes:

https://www.imperialsupplies.com/pdf...DrillChart.pdf

Typed before I read what you'd done:

Just a point of correction: the nominal correct size for an M6 cutting tap is often given as 5mm. That's for 100% thread depth. As a nod to practicality, most holes drilled for tapping specify about 65-70% of full thread depth. That's where you 5.2mm comes in (one formula is drill size = nominal thread OD - Percent thread engagement/76.98). A bit more accurate estimate using the formulas in the webpage below is between 5.1556 and 5.089mm. But here's the thing: if you use a hand drill, and/or a poor quality drill bit, your hole diameter is going to be larger than the drill. I would target a little less than the 5.09-5.16 target. For this reason, I'd use a number 8 drill (note that this is a NUMBER drill, and the number 8 is not mm). Or a number 7 drill if I had it. But you'd probably be fine with a 13/64 as well. With a number 6 drill of good quality and steady hand you'd be close, but still be too big for my taste. It might work. Use tapping fluid (normal oil doesn't do as good a job).

The penalty for too big a hole is a weak threaded connection. For too small a hole is difficult tapping and possibly a broken tap.

The advice above is for tapping into steel. If you have a notion to try your hand and at tapping titanium, my suggestion would be ... don't. Even drilling Ti can be problematic - it work hardens something fierce and the drill tends to wander as a result. Get someone who's done this. If you must, read up first on drilling Ti, then on tapping Ti, and do some research and get a really good drills and taps. Emuge, Prototyp... etc. And use moly-dee or some other good lubricant.

No. 8, 5.05mm, 0.1990 inch

No. 7, 5.11mm, 0.2010 inch

Fractional 13/64, 5.16mm, 0 .2031 inch

No. 6, 5.18mm, 0.2040 inch

For tap drill sizes:

https://www.natool.com/wp-content/up...atp113-116.pdf

For available drill sizes:

https://www.imperialsupplies.com/pdf...DrillChart.pdf

Last edited by WizardOfBoz; 05-28-20 at 12:34 PM.

#12

SE Wis

Join Date: Apr 2005

Location: Milwaukee, WI

Posts: 10,505

Bikes: '68 Raleigh Sprite, '02 Raleigh C500, '84 Raleigh Gran Prix, '91 Trek 400, 2013 Novara Randonee, 1990 Trek 970

Mentioned: 40 Post(s)

Tagged: 0 Thread(s)

Quoted: 2743 Post(s)

Liked 3,390 Times

in

2,053 Posts

My only concern was that I hadn't realized that some taps are 'tapered' and some are 'bottom'. It seems my tap was slightly tapered but reached the correct width (6mm) within about 1/4" of tip. Had the taper been any longer (not sure if this is standard), it would have been a problem because it would have maxed-out against the inside of the seat stay prior to reaching full width.

You can turn a tapered tap into a bottoming tap by grinding the tip as needed.

#13

Senior Member

Join Date: Jul 2009

Posts: 5,945

Bikes: Colnago, Van Dessel, Factor, Cervelo, Ritchey

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 3948 Post(s)

Liked 7,291 Times

in

2,945 Posts

4.7 mm drill => 100% threads

5.0 mm drill => 77% threads

5.2 mm drill => 61% threads.

#14

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

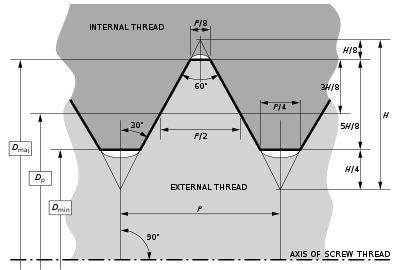

The metric thread form specification is shown on Wikipedia (below). I suspect that we agree that the theoretical thread height H, is sqrt(3)/2 * pitch. Pitch being 1mm, then, H equals 0.866mm. The thread form does not contain the top H/8 of the thread crest, nor the bottom H/4 of the thread root. This makes it stronger than the early American National Standard which used sharp root and crest. The current Unified (flat root) or Metric (allows for rounded root) standards are stronger. Anyway, the internal thread radius is 5/8H less than the nominal, or 5*0.866/8 mm, or 0.541mm. That's 1.082mm less in diameter. So 4.88mm should be 100%. The 13/64 drill bit is 5.159mm. I get this as being 77.6%. Given that most folks target 65 to 70%, and a hand-held drill is gonna make a hole that is a bit oversize I think the OP chose just about the perfect setup.

But where is this discrepancy coming from? 4.7 vs 4.88 for 100%, and 5.16 being either 77% or about 63%?

Can you share your source? I'm going to dig out may Machninists Handbook to see if I can find the numbers in there.

Last edited by WizardOfBoz; 05-29-20 at 08:03 AM.

#15

Senior Member

Join Date: Jul 2009

Posts: 5,945

Bikes: Colnago, Van Dessel, Factor, Cervelo, Ritchey

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 3948 Post(s)

Liked 7,291 Times

in

2,945 Posts

Don't ask me why, but 3/4H is usually considered 100% thread percentage rather than 5/8H. (I think it's actually due to an historical issue in the U.S.). The differences you note arise from whether you choose 3/4H or 5/8H as 100%.

Using the 3/4H convention, the simple rule of thumb for 77% threads is: (Drill size = Thread diameter - Thread pitch). That's the basis for the vast majority of thread charts, with sizes rounded to the nearest common drill size.

For other thread percentages, there are many online calculators:

https://www.guhring.com/tech/TapDrill/

https://www.kennametal.com/us/en/res...rill-size.html

Using the 3/4H convention, the simple rule of thumb for 77% threads is: (Drill size = Thread diameter - Thread pitch). That's the basis for the vast majority of thread charts, with sizes rounded to the nearest common drill size.

For other thread percentages, there are many online calculators:

https://www.guhring.com/tech/TapDrill/

https://www.kennametal.com/us/en/res...rill-size.html

We're getting information from different sources apparently. I'd like to know 1) the correct sizes (and yours may be), and 2) the source. I put links in my post - do you have source info, or a citation for the above?

The metric thread form specification is shown on Wikipedia (below). I suspect that we agree that the theoretical thread height H, is sqrt(3)/2 * pitch. Pitch being 1mm, then, H equals 0.866mm. The thread form does not contain the top H/8 of the thread crest, nor the bottom H/4 of the thread root. This makes it stronger than the early American National Standard which used sharp root and crest. The current Unified (flat root) or Metric (allows for rounded root) standards are stronger. Anyway, the internal thread radius is 5/8H less than the nominal, or 5*0.866/8 mm, or 0.541mm. That's 1.082mm less in diameter. So 4.88mm should be 100%. The 13/64 drill bit is 5.159mm. I get this as being 77.6%. Given that most folks target 65 to 70%, and a hand-held drill is gonna make a hole that is a bit oversize I think the OP chose just about the perfect setup.

But where is this discrepancy coming from? 4.7 vs 4.88 for 100%, and 5.16 being either 77% or about 63%?

Can you share your source? I'm going to dig out may Machninists Handbook to see if I can find the numbers in there.

The metric thread form specification is shown on Wikipedia (below). I suspect that we agree that the theoretical thread height H, is sqrt(3)/2 * pitch. Pitch being 1mm, then, H equals 0.866mm. The thread form does not contain the top H/8 of the thread crest, nor the bottom H/4 of the thread root. This makes it stronger than the early American National Standard which used sharp root and crest. The current Unified (flat root) or Metric (allows for rounded root) standards are stronger. Anyway, the internal thread radius is 5/8H less than the nominal, or 5*0.866/8 mm, or 0.541mm. That's 1.082mm less in diameter. So 4.88mm should be 100%. The 13/64 drill bit is 5.159mm. I get this as being 77.6%. Given that most folks target 65 to 70%, and a hand-held drill is gonna make a hole that is a bit oversize I think the OP chose just about the perfect setup.

But where is this discrepancy coming from? 4.7 vs 4.88 for 100%, and 5.16 being either 77% or about 63%?

Can you share your source? I'm going to dig out may Machninists Handbook to see if I can find the numbers in there.

Last edited by tomato coupe; 05-29-20 at 10:39 AM.

#16

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

I guess the key point is that 0% is 6mm. And 5mm is either 92 or 77%. And 5.16 is either 77 or 64% All reasonably good numbers (tho 92%, if true, might cause some taps to break).

I asked the question: 5/8 or 3/4 on a site for professional machinists I visit. Will report back if there's any clarification. In the mean-time... Use a number 7 drill! It's 5.105mm!

#17

Senior Member

Join Date: Jul 2009

Posts: 5,945

Bikes: Colnago, Van Dessel, Factor, Cervelo, Ritchey

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 3948 Post(s)

Liked 7,291 Times

in

2,945 Posts

The two charts you referenced in a previous post list 5.00 mm and #10 (4.91 mm) as the drill size for M6 x 1 threads.

Last edited by tomato coupe; 05-29-20 at 12:51 PM.

#18

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

Just got a note from an experienced machinist. He's in England, so presumably knows metric specs. He says that while 5mm is the standard, "However 5mm = 0.1969'' ……….on tough / hard / horrible material, where I can, I use 13/64 = 0.2031'' the extra 0.0062'' making life easier."

#19

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

The topic has been discussed numerous times on Practical Machinist. Search the website ...

The two charts you referenced in a previous post list 5.00 mm and #10 (4.91 mm) as the drill size for M6 x 1 threads.

The two charts you referenced in a previous post list 5.00 mm and #10 (4.91 mm) as the drill size for M6 x 1 threads.

#20

Generally bewildered

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

Also noted that you have questions on PM regarding tapping M6x0.5, and tapping Invar... (Assuming that you use the same Tomato Coupe name). Above my experience.

But, as I said, 13/64 gives you a pretty good (77% or 65%) thread engagement either way. And the OP (who has long ago gone out for a bike ride) got his rack mounted.

But, as I said, 13/64 gives you a pretty good (77% or 65%) thread engagement either way. And the OP (who has long ago gone out for a bike ride) got his rack mounted.

#21

Banned

Old trick my Dad a machinist , (& WW2 Vet), showed me,, hold the tap up and the twist drill ,

right size you see the valleys of the teeth in the tap behind the drill you are holding in front of it..

right size you see the valleys of the teeth in the tap behind the drill you are holding in front of it..

#22

Senior Member

Join Date: Jul 2009

Posts: 5,945

Bikes: Colnago, Van Dessel, Factor, Cervelo, Ritchey

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 3948 Post(s)

Liked 7,291 Times

in

2,945 Posts