Do Chain Checkers really measure the stated %0.5, %0.75 etc. ?

#51

Senior Member

A precision rule placed on the edge of one pin completely covers the pin at the opposite end. As the chain elongates, the covered pin is exposed. It's easy to see the exposure of 1/2 the pin, with adequate accuracy. Brandt contends that 1% or the entire diameter of the pin being exposed is the limit. If the full length is measured, .5% is just over 1/4 inch. If you can't see that with a tape measure, you're blind.

I'm also seeing the minimal elongation with the new SRAM AXS chains. Users are report very high mileage with little elongation. They'll find out the hard way that they should have used a rotation or changed their chains sooner, when they get new-chain skip.

As for Campy's recommendation, that measurement is mostly roller wear and little elongation over that short length. The roller hole wears far more than the OD.

I'm also seeing the minimal elongation with the new SRAM AXS chains. Users are report very high mileage with little elongation. They'll find out the hard way that they should have used a rotation or changed their chains sooner, when they get new-chain skip.

As for Campy's recommendation, that measurement is mostly roller wear and little elongation over that short length. The roller hole wears far more than the OD.

Likes For DaveSSS:

#52

Senior Member

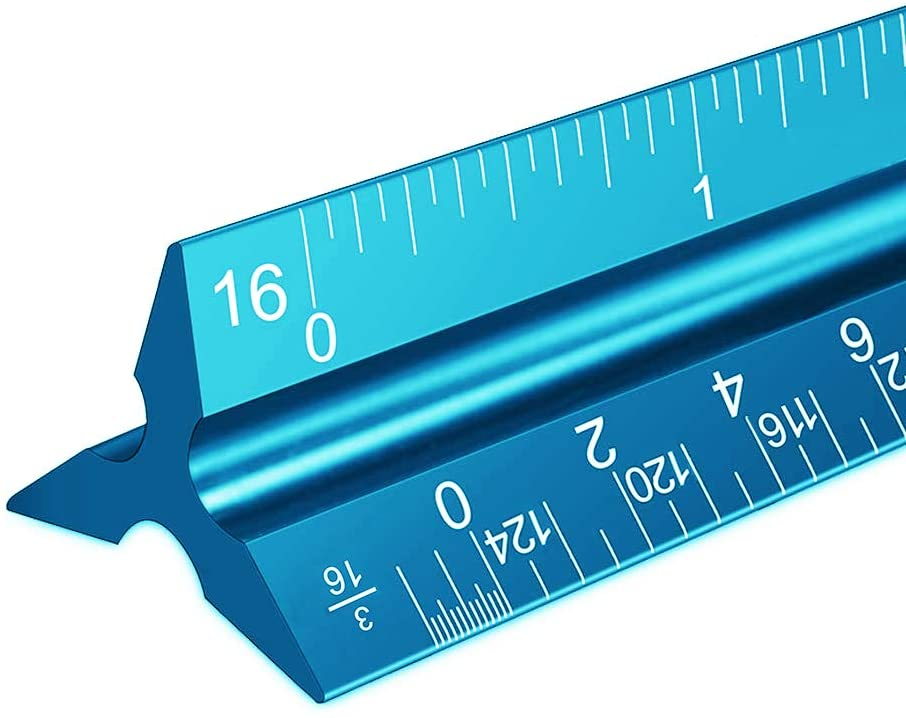

Temperature is not relevant when measuring only a 12 inch length. A 10 degree change would expand the length by 0.0008 inch. Just get a 12 inch machinist's rule and place one end on the edge of a pin. The pin at the other end will be completely covered when the chain is new. When 1/2 of that pin is exposed, you have a little over .5% elongation. As I've already noted, some chains will show little elongation even when severely worn, so the elongation measurement may be worthless. That's why Campy suggests measuring with calipers between outer plates to a length of 132.6mm. It deliberately adds roller wear to elongation. The roller wear is greatest on the hole in the roller.

I have no idea how campy came up with the 132.6 figure, but it seems the forgot to include initial slop in the rollers that all chains have or a campy chain simply has different dimensions than shimano and KMC.

Last edited by Racing Dan; 12-07-20 at 12:04 PM.

#53

Senior Member

The standard for a #41 bicycle chain only limits the roller diameter to a maximum of .306 inch. Most are around 0.305, but KMC rollers are often only .303. The hole size in the rollers may also differ, but the nominal pitch is always 0.500 inch. KMC chains, like the X11.93 will elongate very quickly, so a 12 inch rule will work and they work last long.

Using calipers is no different than most chain checkers, except for the few that don't add roller wear to elongation. To measure different brands, you have to measure a new chain, then add 0.5%. Even then you're not measuring just elongation.

The new AXS chains follow the #40 dimensions, but if you measure between the rollers, they measure about the same as a #41. That means the holes are a little larger.

Using calipers is no different than most chain checkers, except for the few that don't add roller wear to elongation. To measure different brands, you have to measure a new chain, then add 0.5%. Even then you're not measuring just elongation.

The new AXS chains follow the #40 dimensions, but if you measure between the rollers, they measure about the same as a #41. That means the holes are a little larger.

Last edited by DaveSSS; 12-07-20 at 01:45 PM.

#54

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,342

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6200 Post(s)

Liked 4,203 Times

in

2,358 Posts

From lots and lots of experience. From 10 years of working at a bicycle co-op and laying hands on around 15,000 bikes. A bicycle with a chain that is beyond the 0.75% level will likely have a jumpy chain if you install a new one. Perhaps “99.9%” is a bit too accurate on my part but the vast majority of chains can be checked with a Park, Pedro, Shimano, etc checker and reliably replaced before it wears the other drivetrain parts too much.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#55

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,342

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6200 Post(s)

Liked 4,203 Times

in

2,358 Posts

Brandt contends that 1% or the entire diameter of the pin being exposed is the limit. If the full length is measured, .5% is just over 1/4 inch. If you can't see that with a tape measure, you're blind.

1/4 inch, by the way is a 2% increase in length. I’m certain that no one would accept that kind of wear. 1% is about 1/8” or about 1/32” past 0.75%.

As for Campy's recommendation, that measurement is mostly roller wear and little elongation over that short length. The roller hole wears far more than the OD.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#56

Advocatus Diaboli

Join Date: Feb 2015

Location: Wherever I am

Posts: 8,631

Bikes: Merlin Cyrene, Nashbar steel CX

Mentioned: 14 Post(s)

Tagged: 1 Thread(s)

Quoted: 4729 Post(s)

Liked 1,531 Times

in

1,002 Posts

Um...you might want to redo the math. A 0.5% increase would be 0.06” or slightly less than 1/16”. A 0.75% increase in length is 0.09” or 3/32” of an inch. The difference between a chain that might be okay and one that needs to be replaced is 0.03” or about 1/32. Not all that easy to estimate...nor would an “estimate” be all that accurate.

1/4 inch, by the way is a 2% increase in length. I’m certain that no one would accept that kind of wear. 1% is about 1/8” or about 1/32” past 0.75%.

.

1/4 inch, by the way is a 2% increase in length. I’m certain that no one would accept that kind of wear. 1% is about 1/8” or about 1/32” past 0.75%.

.

#57

It's MY mountain

Join Date: Sep 2006

Location: Mt.Diablo

Posts: 10,001

Bikes: Klein, Merckx, Trek

Mentioned: 70 Post(s)

Tagged: 0 Thread(s)

Quoted: 4335 Post(s)

Liked 2,977 Times

in

1,614 Posts

People don’t say that using a 12” rule is “adequate accuracy”. They say that it is superior accuracy. They will even go so far as saying that a chain checker is almost as good as just guessing. “...Exposure of 1/2 of a pin” is the equivalent of saying “just a squidge past 12 inches”.

#58

Senior Member

Measuring only between the pins is true change in pitch. My math for the 12 inch rule is correct. A 12 inch machinist's rule will be made with extreme accuracy over it's entire length, so it's appropriate for the job. 0.5% over 12 inches is .0625 and half a pin is about .070. Close enough for an arbitrarily assigned value.

I still prefer an overall length measurement. On a 50 inch chain, 0.5% is 1/4 inch. My current chains are 55 inch, so 1/4 inch is a little less than 0.5% elongation. To be exact 0.275. You will find brand new chains shorter and longer than nominal, just due to accumulative error. I've found both cases with brand new Sram Force AXS chains. One has 1000 miles on it and it's still a little short.

#59

Senior Member

Thread Starter

I did the Pedro's and as I have written in the original post it measured around 5.018 which is ~ %0.36. I lost my Park tool cc 3.2 so it would be great is someone who has the tool make the measurement.

#60

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,342

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6200 Post(s)

Liked 4,203 Times

in

2,358 Posts

And, again with the “thereabouts” isn’t exactly an accurate amount.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#61

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,342

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6200 Post(s)

Liked 4,203 Times

in

2,358 Posts

You're totally wrong there. A change in pitch only includes wear between the pins and inner plates. That's what makes a chain actually become longer. Using calipers like Campy illustrates is not a measurement of change in pitch, because it adds the wear of both the lD and OD of two rollers to the actual elongation or change in pitch.

Measuring only between the pins is true change in pitch. My math for the 12 inch rule is correct. A 12 inch machinist's rule will be made with extreme accuracy over it's entire length, so it's appropriate for the job. 0.5% over 12 inches is .0625 and half a pin is about .070. Close enough for an arbitrarily assigned value.

Additionally, any time you use “about” that is also an inaccurate statement. Is half a pin 0.070”? Or is some other number? We are being told that the machinist rule is superior in measuring chain wear compared to a chain checker but then everyone uses terms like “about”. And if the value is some “arbitrarily assigned value” why do you and others use such precise values?

I still prefer an overall length measurement. On a 50 inch chain, 0.5% is 1/4 inch. My current chains are 55 inch, so 1/4 inch is a little less than 0.5% elongation. To be exact 0.275. You will find brand new chains shorter and longer than nominal, just due to accumulative error. I've found both cases with brand new Sram Force AXS chains. One has 1000 miles on it and it's still a little short.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#62

Advocatus Diaboli

Join Date: Feb 2015

Location: Wherever I am

Posts: 8,631

Bikes: Merlin Cyrene, Nashbar steel CX

Mentioned: 14 Post(s)

Tagged: 1 Thread(s)

Quoted: 4729 Post(s)

Liked 1,531 Times

in

1,002 Posts

oh brother..

#63

Senior Member

Join Date: Sep 2014

Posts: 3,893

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1062 Post(s)

Liked 665 Times

in

421 Posts

The people who suggest using a ruler may be experienced at using one. Eyeballing an extra 1/16 off the end of a mainstream ruler isn't prohibitively difficult, and every measurement is an estimate. If you're not sure, then 0.5% of 11.5 inches is probably acceptably close to 0.5% of 12 inches.

It's one thing to casually check when your chain needs to be replaced, and another to attempt a precise comparison of multiple chains and measuring tools. The appropriateness of any tool depends on the purpose for which it's being used, and the skill of the user.

With that said, I can't think of why I wouldn't trust a chain checker if I had one, but I don't have one.

It's one thing to casually check when your chain needs to be replaced, and another to attempt a precise comparison of multiple chains and measuring tools. The appropriateness of any tool depends on the purpose for which it's being used, and the skill of the user.

With that said, I can't think of why I wouldn't trust a chain checker if I had one, but I don't have one.

Last edited by Gresp15C; 12-07-20 at 08:01 PM.

#64

Senior Member

Join Date: Aug 2016

Posts: 712

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 283 Post(s)

Liked 262 Times

in

164 Posts

Hypothetical chain has quite a bit of wear on the inner part of all rollers, all rollers are worn evenly. No wear on the outer part of the rollers. The chain length when measured over 24 links is 12 in, pitch is .5in just like a new chain. I'm thinking this chain will perform just like a new chain.

#65

Senior Member

Join Date: May 2020

Posts: 490

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 252 Post(s)

Liked 67 Times

in

48 Posts

Not read the whole thread, so don't know if someone brought up the following view: those custom gauges that people said, they can measure some wear even on a brand new chain and from that they concluded that those gauges are not all that exact and that you can either file your own (guided by your new chain) or do the measuring by tape, metal ruler... Well, isn't that assuming that new chains are all manufactured to perfection?

The chains are made to some tolerance and the exact length can even vary from batch to batch. If one is really picky, maybe shop for new chain in LBS where they unwrap chains for you and you can pick the one that best qualifies as 'realy new', that is un-stretched, by your gauge.

The chains are made to some tolerance and the exact length can even vary from batch to batch. If one is really picky, maybe shop for new chain in LBS where they unwrap chains for you and you can pick the one that best qualifies as 'realy new', that is un-stretched, by your gauge.

#66

It's MY mountain

Join Date: Sep 2006

Location: Mt.Diablo

Posts: 10,001

Bikes: Klein, Merckx, Trek

Mentioned: 70 Post(s)

Tagged: 0 Thread(s)

Quoted: 4335 Post(s)

Liked 2,977 Times

in

1,614 Posts

For some reason the chain-checker haters always want to argue that no one should use them because they're less accurate than machinist rules.

We used to have threads where people would argue for dozens of pages about how to measure the most perfect tire diameter to enter into their cyclo computer for perfect precision... then GPS came along and suddenly +/-2% was good enough for everybody.

Last edited by DiabloScott; 12-07-20 at 11:32 PM.

Likes For DiabloScott:

#67

Senior Member

Again, how can a 12 inch precision rule be accurate at measuring 12” plus any amount? It is precise to exactly 12 inches. Anything over 12” is an estimate and, therefore, inaccurate. Over 12 inches and you might as well use axe handles as a measurement.

As for your assertion that some chains don’t wear by elongation, then why does Campagnolo say to measure the elongation? The suggestion I’ve found says

That’s a length measurement. In other words, a measure of elongation. The numbers, by the way don’t seem to work. 12 inches is 304.8mm. 12 inches of chain is 24 links. Divide that by 4 and you get 76.2mm over 6 links. That’s 56.4mm short. Something is not right here.

However, Campagnolo chains aren’t really that widely used. Chain gauges work for 99.9% of chains as a quick measurement. Using one isn’t going to deprive a rider of too many miles on their chain.

As for your assertion that some chains don’t wear by elongation, then why does Campagnolo say to measure the elongation? The suggestion I’ve found says

That’s a length measurement. In other words, a measure of elongation. The numbers, by the way don’t seem to work. 12 inches is 304.8mm. 12 inches of chain is 24 links. Divide that by 4 and you get 76.2mm over 6 links. That’s 56.4mm short. Something is not right here.

However, Campagnolo chains aren’t really that widely used. Chain gauges work for 99.9% of chains as a quick measurement. Using one isn’t going to deprive a rider of too many miles on their chain.

#68

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,342

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6200 Post(s)

Liked 4,203 Times

in

2,358 Posts

The people who suggest using a ruler may be experienced at using one. Eyeballing an extra 1/16 off the end of a mainstream ruler isn't prohibitively difficult, and every measurement is an estimate. If you're not sure, then 0.5% of 11.5 inches is probably acceptably close to 0.5% of 12 inches.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#69

Mostly harmless ™

Join Date: Nov 2010

Location: Novi Sad

Posts: 4,430

Bikes: Heavy, with friction shifters

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 1107 Post(s)

Liked 216 Times

in

130 Posts

My 2c on chain wear measuring methods (and the pros and cons of each).

Chain checkers, apart from Shimano TL-CN41 and TL-CN42 take roller wear into the account. This results in that chains with softer rollers that wear faster, get replaced a lot sooner than is needed. Suppose that's better than replacing them later than needed, but it is a fact they are inherently inaccurate - measuring the wrong dimension (my experiment on how roller wear doesn't affect chain engagement).

They can be used as a quick-test. If they say it's OK - it is OK. If they say a chain is worn - then one can take the ruler out and check if that really is the case.

For reasons explaicyccommute I would agree that ruler is not very precise - unless one is really careful when measuring. But I would argue that measuring from one side of the pin (left, or right) to the same side 12 chain link pairs further does give a good reference point. And - one can tell when this aligns with 12" and 1/16, or it is shorter/longer than that. If equal, or longer - replace the chain.

I suppose Shimano TL-CN42 is faster and easier to use - while not being inherently imprecise like the other chain wear tools. The downside is that it measures across only a few links. So it's best to measure at 2-3 points along the chain's length, since chain wear is not uniform along its entire length (some sections often wear faster).

Chain checkers, apart from Shimano TL-CN41 and TL-CN42 take roller wear into the account. This results in that chains with softer rollers that wear faster, get replaced a lot sooner than is needed. Suppose that's better than replacing them later than needed, but it is a fact they are inherently inaccurate - measuring the wrong dimension (my experiment on how roller wear doesn't affect chain engagement).

They can be used as a quick-test. If they say it's OK - it is OK. If they say a chain is worn - then one can take the ruler out and check if that really is the case.

For reasons explaicyccommute I would agree that ruler is not very precise - unless one is really careful when measuring. But I would argue that measuring from one side of the pin (left, or right) to the same side 12 chain link pairs further does give a good reference point. And - one can tell when this aligns with 12" and 1/16, or it is shorter/longer than that. If equal, or longer - replace the chain.

I suppose Shimano TL-CN42 is faster and easier to use - while not being inherently imprecise like the other chain wear tools. The downside is that it measures across only a few links. So it's best to measure at 2-3 points along the chain's length, since chain wear is not uniform along its entire length (some sections often wear faster).

#70

Senior Member

I worked as a machinist for 10 years and as a machining process engineer for nuclear weapons components for another 10, so I need no education on precision versus accuracy. A 12 inch machinist's rule is very thin, with 0.010 inch graduations. The overall length deviation from 12 is typically only a few thousandths of an inch. It's precise enough to measure chain elongation with no need for a special tool. If you disagree about using one full length, then measure 11 inches or buy a longer rule. Better yet, use a full length measurement.

Calipers may not go deep enough between the outer plates to reach beyond the roller center and give incorrect readings. I have some cheap digital calipers with the tips ground thinner to use for chain measuring.

The term about is entirely appropriate when there is no reason to consider 0.5% any more valuable information than any other amount below 1%. 0.5% is just a number that someone decided to promote as the time to toss a chain. It's neither right or wrong, it's just a number. There is NO proof that tossing chains at that point is better than some other arbitrary value, so debating about the accuracy of measurement is really silly. Regardless of what you do, there will be a time when new-chain skip occurs, if new chains are put into service on well worn cassettes. I avoid that by using at least 3 and maybe 5 chains in a rotation. I'll never get new-chain skip and each chain can be used longer. When all of the chains are well worn, the cassette and chains can eventually to trashed as a group.

Calipers may not go deep enough between the outer plates to reach beyond the roller center and give incorrect readings. I have some cheap digital calipers with the tips ground thinner to use for chain measuring.

The term about is entirely appropriate when there is no reason to consider 0.5% any more valuable information than any other amount below 1%. 0.5% is just a number that someone decided to promote as the time to toss a chain. It's neither right or wrong, it's just a number. There is NO proof that tossing chains at that point is better than some other arbitrary value, so debating about the accuracy of measurement is really silly. Regardless of what you do, there will be a time when new-chain skip occurs, if new chains are put into service on well worn cassettes. I avoid that by using at least 3 and maybe 5 chains in a rotation. I'll never get new-chain skip and each chain can be used longer. When all of the chains are well worn, the cassette and chains can eventually to trashed as a group.

Last edited by DaveSSS; 12-09-20 at 07:56 AM.

#71

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,342

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6200 Post(s)

Liked 4,203 Times

in

2,358 Posts

I worked as a machinist for 10 years and as a machining process engineer for nuclear weapons components for another 10, so I need no education on precision versus accuracy. A 12 inch machinist's rule is very thin, with 0.010 inch graduations. The overall length deviation from 12 is typically only a few thousandths of an inch. It's precise enough to measure chain elongation with no need for a special tool. If you disagree about using one full length, then measure 11 inches or buy a longer rule. Better yet, use a full length measurement.

This example is chosen because it is an exact analog to using a 12 inch rule to measure 12” of chain with the same amount of “estimation”. A sixteenth of an inch over 12 inches is 12.06”. You can estimate it but don’t try to pass it off as more accurate than other methods. Those of us using chain checkers accept that the measurement using that tool is somewhat inaccurate but it is close enough.

I also don’t understand how you, as a machinist, can say that an estimation is accurate. If someone were to ask you to machine something to a precise measurement would you just eyeball the measurement? Every time this discussion has occurred, the rule guys tell us that a 12 inch rule will measure exactly 24 links on a new chain...although others are now indicating that this isn’t necessarily true because of variances in the chains. They never explain how you get the 0.06” to 0.09” measurement off the end of the rule but they assure us that it is the more exact measurement.

Calipers may not go deep enough between the outer plates to reach beyond the roller center and give incorrect readings. I have some cheap digital calipers with the tips ground thinner to use for chain measuring.

The term about is entirely appropriate when there is no reason to consider 0.5% any more valuable information than any other amount below 1%. 0.5% is just a number that someone decided to promote as the time to toss a chain. It's neither right or wrong, it's just a number. There is proof that tossing chains at that point is better than some other arbitrary value, so debating about the accuracy of measurement is really silly. Regardless of what you do, there will be a time when new-chain skip occurs, if new chains are put into service on well worn cassettes. I avoid that by using at least 3 and maybe 5 chains in a rotation. I'll never get new-chain skip and each chain can be used longer. When all of the chains are well worn, the cassette and chains can eventually to trashed as a group.

While I agree that new chains will probably skip on worn cassettes, there is more than one solution to that problem. Your solution of 3 to 5 chains in rotation just means that you have to keep track of mileage on 3 to 5 chains per bike. I have 8 bikes that are mine and 4 that are my wife’s. I probably wouldn’t want to rotate chains between bicycles for various reasons...some are road bikes and some are mountain bikes so they see different levels of stress and wear. I also have 9 speed and 10 speed drivetrains. So that would mean I would need 36 chains, minimum and so way to keep track of mileage on each chain. Not all my bikes get ridden with the same regularity so that complicates the tracking further. Additionally, there the cost of 36 to 60 chains to consider. Having $600 to $1000 invested in chains is a bit excessive, even when using cheap chains.

There’s also storage to consider. With 12 bikes in rotation, I might get 3000 miles on a single bike every other year. I would have to store up to 60 chains for up to 60 years. This quickly becomes an exercise in reduction ad adsurdum.

An easier way to deal with the possible problem of worn cassettes is to check the chain frequently (and easily) with a chain checker and replace it when the checker says that it is at 0.75% wear. That might be too early but that won’t hurt anything. And it’s a whole lot easier than managing a data base.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#72

Senior Member

Thread Starter

I worked as a machinist for 10 years and as a machining process engineer for nuclear weapons components for another 10, so I need no education on precision versus accuracy. A 12 inch machinist's rule is very thin, with 0.010 inch graduations. The overall length deviation from 12 is typically only a few thousandths of an inch. It's precise enough to measure chain elongation with no need for a special tool. If you disagree about using one full length, then measure 11 inches or buy a longer rule. Better yet, use a full length measurement.

Calipers may not go deep enough between the outer plates to reach beyond the roller center and give incorrect readings. I have some cheap digital calipers with the tips ground thinner to use for chain measuring.

....

Calipers may not go deep enough between the outer plates to reach beyond the roller center and give incorrect readings. I have some cheap digital calipers with the tips ground thinner to use for chain measuring.

....

Since you were a machinist I will appreciate your expertise here.

How would you use a digital caliper that has a max length of 6" to measure the elognation (no roller wear)? Where would you take the measurement?

In theory there are many places. But once I tried I realized that aligning the caliper to take consistent measurements at that distance is hard.

My final try was to measure the distance from the end of one outer plate to the beginning of the 6th one. Then I subtract the distance between the edges of two consequent ones.

The distance between two consecutive plates seem to be around 0.172 (I will assume 0.17 to not underestimate the distance). Now new one under tension measured 5.172-5.173, the one that has 600+ miles on it measured 5.173-5.174. The one that shows barely %0.5 wear measured ~5.182. All of these chains are same model KMC chains. Well now it seems the chain which is supposed to have ~%0.24-0.25 wear is shown to reach %0.5.

The only consistent reading I have compared to the chain checker is for the 10 speed chain that is over %75. My readings were 5.208-5.212 and that translates into %0.76-%0.84 wear.

The ruler also does not show anywhere close to %0.5 but of course it relies on my eyesight. I am not starting from the center of a pin since it is impossible to really know where the center is , instead I start from the edge of a pin.

Because I am a new member I can post pictures which would have helped here.

Last edited by John_E; 12-08-20 at 02:24 PM.

#73

Senior Member

Join Date: Sep 2014

Posts: 3,893

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1062 Post(s)

Liked 665 Times

in

421 Posts

Again, the issue I’m raising with the ruler method isn’t the accuracy of the tool...it’s the accuracy in the “eyeballing” part. Let’s put it this way: The difference between a chain that is okay (0.25%) and marginal (0.5%) is only 0.03” or less than 1/32” (0.031”). The difference between a marginal chain and one that probably needs to be replace (0.75%) is the same 0.03”. Eyeballing about 1/16 inch may not be hard but saying that you can eyeball the difference between 1/16” and 3/32” with any hopes of accuracy is just fooling yourself.

When you're eyeballing a ruler, you've got the standard for 1/16 sitting right in front of you, called the ruler.

Last edited by Gresp15C; 12-08-20 at 06:17 PM.

#74

Mostly harmless ™

Join Date: Nov 2010

Location: Novi Sad

Posts: 4,430

Bikes: Heavy, with friction shifters

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 1107 Post(s)

Liked 216 Times

in

130 Posts

An amusing story: When I was in grad school, a colleague was complaining about the antiquated US screw thread standards. Being a punk, I told him, just learn how to recognize the sizes. He brought me a bucket of screws, all mixed up, and started pulling them out: "That one's 6-32. That one's 8-32. That one must be metric." He was amazed that I could recognize the screw threads by looking at them, but like I said maybe the people recommending a ruler, are experienced with using a ruler. That's a problem with recommending any technique, which is that you don't know the skill level of the person who's going to use it. A so called "go-no-go gage" is the solution to that problem, which is what a chain checker is. I have no objection to that.

When you're eyeballing a ruler, you've got the standard for 1/16 sitting right in front of you, called the ruler.

When you're eyeballing a ruler, you've got the standard for 1/16 sitting right in front of you, called the ruler.

Why no one else makes a tool like Shimano TL-CN42 (i.e. why they make any other chain gauge tool design) is beyond me. Am I missing something?

#75

Advocatus Diaboli

Join Date: Feb 2015

Location: Wherever I am

Posts: 8,631

Bikes: Merlin Cyrene, Nashbar steel CX

Mentioned: 14 Post(s)

Tagged: 1 Thread(s)

Quoted: 4729 Post(s)

Liked 1,531 Times

in

1,002 Posts

Makes sense - with one "complaint": 99.9% of the chain gauges don't measure the correct dimension - they are inherently imprecise, by design.

Why no one else makes a tool like Shimano TL-CN42 (i.e. why they make any other chain gauge tool design) is beyond me. Am I missing something?

Why no one else makes a tool like Shimano TL-CN42 (i.e. why they make any other chain gauge tool design) is beyond me. Am I missing something?

Something like the below design from Progold Prolink, though not as compact for fitting in a toolbox, if it were made with the 2 link engagements like the Park or Pedro's might be interesting, as the idea is that it shows wear on a graduated basis.