Brazing technique for fillets

#52

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,053

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4194 Post(s)

Liked 3,837 Times

in

2,295 Posts

Until the recent airline restrictions sourcing from overseas was a pretty easy and smooth process. About once a year I order from Ceeway. Sometimes I get their package sooner then I would have received from Nova (or HJ, Framebuilder's Supply, Torch and File...) The only negative is that of shipping cost being higher. If you're building for yourself then a one off extra $20 is no big deal. If you're building for a customer the cost should be factored in on the materials cost of the frame. Andy

__________________

AndrewRStewart

AndrewRStewart

#53

Senior Member

Thread Starter

Join Date: Mar 2012

Location: santa barbara CA

Posts: 1,087

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 96 Post(s)

Liked 30 Times

in

21 Posts

I do think bondo fillets would probably result in a stronger frame due to heat issues. Yet another reason for 631/853, as I don't think you can realistically or safely hit the hardening window for 4130 with the way a big fillet is done, even if you do fully wet out the filler and don't touch it. But no customer is ever going to be happy with bondo fillets any more than a customer would be happy if you glued some fake plastic lugs on before painting.

thanks

__________________

Brian

Brian

Last edited by calstar; 03-17-20 at 10:22 AM.

#54

Senior Member

Join Date: Jan 2019

Posts: 528

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

Quoted: 237 Post(s)

Likes: 0

Liked 83 Times

in

64 Posts

It's not really right to say any of the traditional construction techniques cause failure. All the traditional construction techniques when used conservatively can produce frames that last a lifetime. If there was a construction technique that caused failure, then it wouldn't be used. Dead soft 4130 is still stronger than hi-ten. Frame failures are rare in general, and frames usually get retired for reasons other than spontaneous failure. Especially with fillet brazing, skill is going to be second guessed whenever there's a failure, and fillet brazed frames aren't as common as lugged or welded frames. Some construction techniques are just likely to be more prone to failure. Every single surviving traditional technique is adequate when used in a conservative and traditional manner. The issue is when people want to do things because they think it's better or deviate from traditional and time tested designs. If you want an authority figure to put your faith in about fillet size, that would be Keith Bontrager.

#55

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,984

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1172 Post(s)

Liked 2,566 Times

in

1,072 Posts

It does remind me of a stripped Jo Routens frame I saw pictures of though. Jo Routens tended to use very small fillets except at the headtube. Anyways, this one had some kind of silver-gray filler, the owner said it was gas welded. I couldn't help but wonder if it filled in with some low temperature solder like they used to do for auto dent repair. Much lower temperature and it's actually shaped with wooden tools instead of just being allowed to flow.

Gas-welding was a thing in France, even in high-end lightweights, going back pretty far, '30s - '40s. Sorry no reference for that, just tidbits I picked up ("oral history?"), consider it unreliable. But I have seen a couple pictures of them sandblasted, where the fillet is the exact same color as the tubes. A vintage bike expert in France told me they call it "autogenous welding", and he mentioned Pitard as one of the practitioners, but he said there were many others.

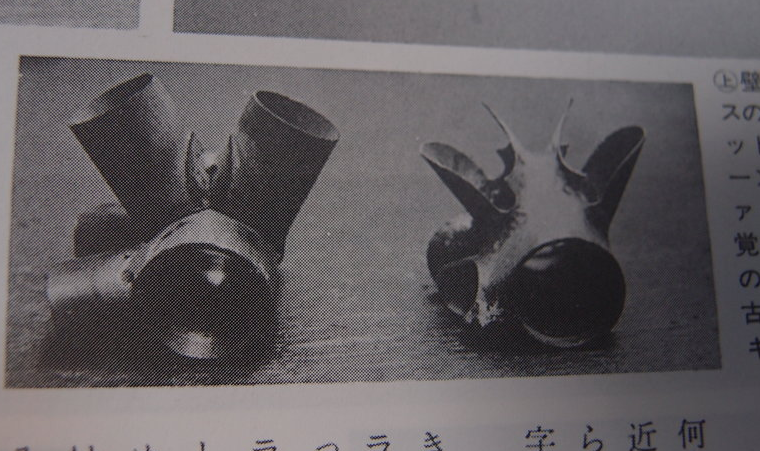

More recently it has been seen as a way to make lugs, which the tubes are brazed into. Here's a shot of two Herse bottom brackets in process, from a Japanese book on Herse.

Sorry about the bad photo of a printed photo, but the text says they are welded not brazed.

The skill required to gas-weld on thin tubing is difficult to acquire. The French guys who did on bike frames came from the aircraft industry, and/or welded a lot of town bikes and porteurs before they graduated to doing it on lightweights.

Barra and a couple others even gas-welded aluminum frames, before WWII. Some broke, but some survive to this day.

Mark B in Seattle

#56

Senior Member

Join Date: Jan 2019

Posts: 528

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

Quoted: 237 Post(s)

Likes: 0

Liked 83 Times

in

64 Posts

Yeah, I've heard about gas welding too, but it's difficult to translate technical articles both because they use lots of jargon and even worse, historical jargon. I've run across it in some older French articles. It's more just the idea popped into my head offhand because the mix between the tiny Routens brass fillets and the big non-brass fillets was so conspicuous. Also now that you mentioned the Schwinn, I remember reading that one little mention on Sheldon's site about them, so maybe it just subconsciously made me think of that.

I've also heard about the custom Herse BB shells before, but now that I think more about it, I rather like the idea of it. It seems a little more authentic than brassed "lugs" for silver, and any serious heat damage is kept to the lugs.

I've also heard about the custom Herse BB shells before, but now that I think more about it, I rather like the idea of it. It seems a little more authentic than brassed "lugs" for silver, and any serious heat damage is kept to the lugs.

Last edited by Kuromori; 03-17-20 at 06:56 PM.

#57

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,984

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1172 Post(s)

Liked 2,566 Times

in

1,072 Posts

Here's an excellent blog with lots of pics of a stripped Routens with some joints brazed (small fillets) and some gas-welded:

https://vintagebicycle.wordpress.com...-c-1948-naked/

Mark B

#58

Senior Member

Join Date: Jan 2019

Posts: 528

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

Quoted: 237 Post(s)

Likes: 0

Liked 83 Times

in

64 Posts

Might have been those very pictures I was looking at. Looking again, it seems like it's probably gas welded after all. There's a little difference in color, but that could just be the lighting and solder filler usually doesn't match the color of steel very well, but it also varies on how it was sanded.

Last edited by Kuromori; 03-17-20 at 08:57 PM.

#59

Senior Member

Thread Starter

Join Date: Mar 2012

Location: santa barbara CA

Posts: 1,087

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 96 Post(s)

Liked 30 Times

in

21 Posts

Everyone please do what you can as individuals and/or families to help get us through this crisis,

regards, Brian

__________________

Brian

Brian

Last edited by calstar; 03-18-20 at 12:30 PM.

#60

Senior Member

Thread Starter

Join Date: Mar 2012

Location: santa barbara CA

Posts: 1,087

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 96 Post(s)

Liked 30 Times

in

21 Posts

__________________

Brian

Brian

#61

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,984

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1172 Post(s)

Liked 2,566 Times

in

1,072 Posts

Here are some flickr pics from Jamie Swan experimenting with this method (start there and click right to see lots more). He's a good framebuilder, I don't want to call him an amateur exactly because of the negative connotations but it's not his main line of work. Only builds a few but they're beautiful.

This method has a long history, and it's well-proven to be strong enough if done well, near-perfect miters for example and enough filler to make a fillet big enough to have the required safety margin.

I don't recommend that beginners try it however. There's a lot of development and testing that has to go into it to know you're making joints that are strong and durable.

Mark Bulgier

Likes For bulgie:

#62

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,984

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1172 Post(s)

Liked 2,566 Times

in

1,072 Posts

Couple things I wanted to add, hit Submit too soon.

Peugeot and Motobecane both used internal fillet brazing, I think in the '80s, maybe starting late '70s? Motobecane called their process "inexternal".

Some Peugeots I have seen somehow managed to not let any of the filler metal get out -- close to zero external fillet. Looks scary to me, though I assume they were strong enough.

The other thing I wanted to mention was that unlike Jamie Swan's preforms (see the flickr link in my last post), which were a single ring, I recommend multiple loops of thinner filler wire, formed into a sort of spring. This gives multiple advantages.

Think about how a ring touches the inside of the tube in a circular line with close to zero thickness, and that's if the ring is in a plane perpendicular to the tube axis. The ring can rotate, like a butterfly valve in a carburetor, to where it's no longer touching in a circular line, just touching in two places that are close to mathematical points, almost zero area of contact. A "spring" is more like a cylinder, can't rotate out perpendicular like a single-wind ring can. Even just two windings is usually enough to prevent rotating out of plane.

Plus a spring has more contact with the tube, for faster heating by conduction, and each wind has less thermal mass "behind" that contact area, so it melts faster.

The springs need to be wound to a diameter that doesn't quite fit into the tube in their relaxed shape -- they need springing down while inserting, so they're tightly pressed against the inside of the tube.

I somewhat doubt Peugeot and Moto used springs like I describe; their preforms might have been something closer to the final fillet shape. But unless someone who worked there back then chimes in, we'll probably never know. That info was proprietary and I doubt they gave much away in public documents or ads. I'd be glad to be wrong though, anybody got more info from back then? Patent application? (Though I doubt this was patentable, being such an ancient method.)

Anyway I think those bikes are a bit ugly, so this is not something I want to emulate. Jamie Swan also said he would do a fillet pass over those joints whether they needed it or not, for the aesthetic look people expect in a lugless joint.

Mark B

Peugeot and Motobecane both used internal fillet brazing, I think in the '80s, maybe starting late '70s? Motobecane called their process "inexternal".

Some Peugeots I have seen somehow managed to not let any of the filler metal get out -- close to zero external fillet. Looks scary to me, though I assume they were strong enough.

The other thing I wanted to mention was that unlike Jamie Swan's preforms (see the flickr link in my last post), which were a single ring, I recommend multiple loops of thinner filler wire, formed into a sort of spring. This gives multiple advantages.

Think about how a ring touches the inside of the tube in a circular line with close to zero thickness, and that's if the ring is in a plane perpendicular to the tube axis. The ring can rotate, like a butterfly valve in a carburetor, to where it's no longer touching in a circular line, just touching in two places that are close to mathematical points, almost zero area of contact. A "spring" is more like a cylinder, can't rotate out perpendicular like a single-wind ring can. Even just two windings is usually enough to prevent rotating out of plane.

Plus a spring has more contact with the tube, for faster heating by conduction, and each wind has less thermal mass "behind" that contact area, so it melts faster.

The springs need to be wound to a diameter that doesn't quite fit into the tube in their relaxed shape -- they need springing down while inserting, so they're tightly pressed against the inside of the tube.

I somewhat doubt Peugeot and Moto used springs like I describe; their preforms might have been something closer to the final fillet shape. But unless someone who worked there back then chimes in, we'll probably never know. That info was proprietary and I doubt they gave much away in public documents or ads. I'd be glad to be wrong though, anybody got more info from back then? Patent application? (Though I doubt this was patentable, being such an ancient method.)

Anyway I think those bikes are a bit ugly, so this is not something I want to emulate. Jamie Swan also said he would do a fillet pass over those joints whether they needed it or not, for the aesthetic look people expect in a lugless joint.

Mark B

Last edited by bulgie; 03-19-20 at 01:14 AM. Reason: typo

#63

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,385

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,686 Times

in

2,509 Posts

Those Peugeots looked scary to me too. I'm sure they had the process worked out very well though. My thought is there were no humans involved in the brazing.

#64

Senior Member

Join Date: Dec 2019

Posts: 953

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Liked 263 Times

in

212 Posts

My Peug is very well-aligned and hasn't fallen apart after main thousands of km. The only criticism I have of the build is the bottle cage holes in the ST are clocked slightly to one side.

#65

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,385

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,686 Times

in

2,509 Posts

I know intellectually that there is nothing wrong with them, although I wonder how they inspected the joints. I'm sure the process was designed by engineers and it's perfectly safe. And as you say, you can see that the miters were all perfect, which had to be a first for a European production bike. I still see examples of them on campus, so they are still in use.

#66

Senior Member

Join Date: Jan 2019

Posts: 528

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

Quoted: 237 Post(s)

Likes: 0

Liked 83 Times

in

64 Posts

Couple things I wanted to add, hit Submit too soon.

Peugeot and Motobecane both used internal fillet brazing, I think in the '80s, maybe starting late '70s? Motobecane called their process "inexternal".

Some Peugeots I have seen somehow managed to not let any of the filler metal get out -- close to zero external fillet. Looks scary to me, though I assume they were strong enough.

The other thing I wanted to mention was that unlike Jamie Swan's preforms (see the flickr link in my last post), which were a single ring, I recommend multiple loops of thinner filler wire, formed into a sort of spring. This gives multiple advantages.

Think about how a ring touches the inside of the tube in a circular line with close to zero thickness, and that's if the ring is in a plane perpendicular to the tube axis. The ring can rotate, like a butterfly valve in a carburetor, to where it's no longer touching in a circular line, just touching in two places that are close to mathematical points, almost zero area of contact. A "spring" is more like a cylinder, can't rotate out perpendicular like a single-wind ring can. Even just two windings is usually enough to prevent rotating out of plane.

Plus a spring has more contact with the tube, for faster heating by conduction, and each wind has less thermal mass "behind" that contact area, so it melts faster.

The springs need to be wound to a diameter that doesn't quite fit into the tube in their relaxed shape -- they need springing down while inserting, so they're tightly pressed against the inside of the tube.

I somewhat doubt Peugeot and Moto used springs like I describe; their preforms might have been something closer to the final fillet shape. But unless someone who worked there back then chimes in, we'll probably never know. That info was proprietary and I doubt they gave much away in public documents or ads. I'd be glad to be wrong though, anybody got more info from back then? Patent application? (Though I doubt this was patentable, being such an ancient method.)

Anyway I think those bikes are a bit ugly, so this is not something I want to emulate. Jamie Swan also said he would do a fillet pass over those joints whether they needed it or not, for the aesthetic look people expect in a lugless joint.

Mark B

Peugeot and Motobecane both used internal fillet brazing, I think in the '80s, maybe starting late '70s? Motobecane called their process "inexternal".

Some Peugeots I have seen somehow managed to not let any of the filler metal get out -- close to zero external fillet. Looks scary to me, though I assume they were strong enough.

The other thing I wanted to mention was that unlike Jamie Swan's preforms (see the flickr link in my last post), which were a single ring, I recommend multiple loops of thinner filler wire, formed into a sort of spring. This gives multiple advantages.

Think about how a ring touches the inside of the tube in a circular line with close to zero thickness, and that's if the ring is in a plane perpendicular to the tube axis. The ring can rotate, like a butterfly valve in a carburetor, to where it's no longer touching in a circular line, just touching in two places that are close to mathematical points, almost zero area of contact. A "spring" is more like a cylinder, can't rotate out perpendicular like a single-wind ring can. Even just two windings is usually enough to prevent rotating out of plane.

Plus a spring has more contact with the tube, for faster heating by conduction, and each wind has less thermal mass "behind" that contact area, so it melts faster.

The springs need to be wound to a diameter that doesn't quite fit into the tube in their relaxed shape -- they need springing down while inserting, so they're tightly pressed against the inside of the tube.

I somewhat doubt Peugeot and Moto used springs like I describe; their preforms might have been something closer to the final fillet shape. But unless someone who worked there back then chimes in, we'll probably never know. That info was proprietary and I doubt they gave much away in public documents or ads. I'd be glad to be wrong though, anybody got more info from back then? Patent application? (Though I doubt this was patentable, being such an ancient method.)

Anyway I think those bikes are a bit ugly, so this is not something I want to emulate. Jamie Swan also said he would do a fillet pass over those joints whether they needed it or not, for the aesthetic look people expect in a lugless joint.

Mark B

I think for the kind of preform you imagine, they'd use what looks like a slit tube. Companies working with industrial scale brazing usually just order preforms, which may or may not be made from rod, but are often made from sheet, and the major filler manufacturers will usually make preforms to spec. It was not uncommon in mass produced lugged frames either, and there were also vintage department store bikes that appear to have internal fillets with really bad pressed miters. I think the varsity ST/TT joint is also like this.

I think it looks cleaner up close than welded joints at least and well, similar aesthetics from 10 feet away, and pairs really nicely with those pug stripes.

#67

Junior Member

Join Date: Apr 2020

Location: Edmonton, AB

Posts: 23

Bikes: 1990 Marinoni Special, 1986 Proctor Custom, 1989 Kuwahara Caravan, Singular Firebird Stainless, Niner RIP9, Sekine SHT

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 7 Post(s)

Likes: 0

Liked 15 Times

in

6 Posts

So much great information in this thread!

Thanks to everyone for sharing. I* hope to start playing around with brazing in the next few months.

Thanks to everyone for sharing. I* hope to start playing around with brazing in the next few months.

#68

Senior Member

Thread Starter

Join Date: Mar 2012

Location: santa barbara CA

Posts: 1,087

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 96 Post(s)

Liked 30 Times

in

21 Posts

Beginning to understand what's going on a little better. Tube stub mitered about 10 degrees, both tubes 1 1/8" OD, one tinning pass, one fillet, second fillet built up on top(one fillet a day, this is how I do it), propane, Victor #2 tip(not TEN, a regular TE works fine for me, no problem with flame blowout), 1/16" filler today, trying to minimize the need for filing. Building up the second fillet is a bit tricky for me as heat control with the larger mass needs to be more precise to avoid overheating while flowing it out, at least that's what I think.

__________________

Brian

Brian

Last edited by calstar; 04-21-20 at 09:29 AM.

#69

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,053

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4194 Post(s)

Liked 3,837 Times

in

2,295 Posts

Brian- Not too bad looking for your start. At some point you'll want to file the practice for a few reasons. The biggie is to see if you have pocks or holes be uncovered with the removal. More likely with more then one fillet pass IME, The other reason is to drill into your brain why you don't want to have to file any more then you need to so you'll have the motivation to improve your fillets even more

BTW I just read an interesting tip posted to the Classic Rendezvous Google list by Mark Bulgier. I never had heard of this trick before and will try it someday. The post was in a thread about US framebuilding history and the connections between various builders, whence they started, who they learned from, where they went over the years and who influenced them. I have a framebuilding email folder for interesting stuff that has only a couple of dozen emails in it, been saving them for years. Today I saved two... don't remember two in 1 month before. This is one. Andy

I just remembered some tricks Angél taught me, that I never saw at Santana. He would fillet braze a joint, a little lumpy -- better than the guys at Santana, but still not smooth enough to send out into the world without filing. But then he'd immediately start filing, with a very large coarse file, while the joint was still super hot, almost glowing. The brass comes off like butter. Those who have filed fillets know, the brass is slippery to the file, so you have to guard against the file slipping off onto the steel. But not when the brass is hot -- the file digs right in, great "traction", no skittering. He would take just the bigger lumps off this way, but it took like 5 seconds and the joint would be almost ready to paint. I was impressed. I bet he learned that in France.

Mark Bulgier

Seattle WA USA

BTW I just read an interesting tip posted to the Classic Rendezvous Google list by Mark Bulgier. I never had heard of this trick before and will try it someday. The post was in a thread about US framebuilding history and the connections between various builders, whence they started, who they learned from, where they went over the years and who influenced them. I have a framebuilding email folder for interesting stuff that has only a couple of dozen emails in it, been saving them for years. Today I saved two... don't remember two in 1 month before. This is one. Andy

I just remembered some tricks Angél taught me, that I never saw at Santana. He would fillet braze a joint, a little lumpy -- better than the guys at Santana, but still not smooth enough to send out into the world without filing. But then he'd immediately start filing, with a very large coarse file, while the joint was still super hot, almost glowing. The brass comes off like butter. Those who have filed fillets know, the brass is slippery to the file, so you have to guard against the file slipping off onto the steel. But not when the brass is hot -- the file digs right in, great "traction", no skittering. He would take just the bigger lumps off this way, but it took like 5 seconds and the joint would be almost ready to paint. I was impressed. I bet he learned that in France.

Mark Bulgier

Seattle WA USA

__________________

AndrewRStewart

AndrewRStewart

#70

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,984

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1172 Post(s)

Liked 2,566 Times

in

1,072 Posts

Brian- Not too bad looking for your start. At some point you'll want to file the practice for a few reasons. The biggie is to see if you have pocks or holes be uncovered with the removal. More likely with more then one fillet pass IME, The other reason is to drill into your brain why you don't want to have to file any more then you need to so you'll have the motivation to improve your fillets even more

BTW I just read an interesting tip posted to the Classic Rendezvous Google list by Mark Bulgier. I never had heard of this trick before and will try it someday. The post was in a thread about US framebuilding history and the connections between various builders, whence they started, who they learned from, where they went over the years and who influenced them. I have a framebuilding email folder for interesting stuff that has only a couple of dozen emails in it, been saving them for years. Today I saved two... don't remember two in 1 month before. This is one. Andy

I just remembered some tricks Angél taught me, that I never saw at Santana. He would fillet braze a joint, a little lumpy -- better than the guys at Santana, but still not smooth enough to send out into the world without filing. But then he'd immediately start filing, with a very large coarse file, while the joint was still super hot, almost glowing. The brass comes off like butter. Those who have filed fillets know, the brass is slippery to the file, so you have to guard against the file slipping off onto the steel. But not when the brass is hot -- the file digs right in, great "traction", no skittering. He would take just the bigger lumps off this way, but it took like 5 seconds and the joint would be almost ready to paint. I was impressed. I bet he learned that in France.

Mark Bulgier

Seattle WA USA

BTW I just read an interesting tip posted to the Classic Rendezvous Google list by Mark Bulgier. I never had heard of this trick before and will try it someday. The post was in a thread about US framebuilding history and the connections between various builders, whence they started, who they learned from, where they went over the years and who influenced them. I have a framebuilding email folder for interesting stuff that has only a couple of dozen emails in it, been saving them for years. Today I saved two... don't remember two in 1 month before. This is one. Andy

I just remembered some tricks Angél taught me, that I never saw at Santana. He would fillet braze a joint, a little lumpy -- better than the guys at Santana, but still not smooth enough to send out into the world without filing. But then he'd immediately start filing, with a very large coarse file, while the joint was still super hot, almost glowing. The brass comes off like butter. Those who have filed fillets know, the brass is slippery to the file, so you have to guard against the file slipping off onto the steel. But not when the brass is hot -- the file digs right in, great "traction", no skittering. He would take just the bigger lumps off this way, but it took like 5 seconds and the joint would be almost ready to paint. I was impressed. I bet he learned that in France.

Mark Bulgier

Seattle WA USA

jk, once you put in your 10,000 hours*, you don't forget, it's like riding a bike. I picked up a torch after 20 years away from it and made essentially perfect fillets, first try.

* No, it doesn't literally take 10,000 hours, that's just some guy's estimate in some book. Even that guy now admits that estimate was all wrong. Now they're saying that 10,000 hours is just the average that people on the way to mastery have accumulated by age 20, and they aren't masters yet, just really good.

And 10,000 hours only leads to mastery if you're constantly being pushed and criticized by a real master. Doing it wrong over and over for 10 years doesn't cut it.

Depressing? No, don't worry about it. Fillet brazing isn't as hard to master as chess or the violin.

-- Or is it? hahahaha

Just keep practicing and pushing yourself, and try to get criticism from masters whenever you can.

Mark B

#71

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,053

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4194 Post(s)

Liked 3,837 Times

in

2,295 Posts

Mark- Thanks for not being sore at my stealing your comments from the CR list. I figure I've got about 2500 hours of frame building under my belt, about twice that amount if you include the practice and other fabrication projects. But this is over 42 years...

Your further comments about the manor of the hours are spot on IMO. I can see two points of rapid advance of my skills and focus. The first was the two week Eisentraut class in 1979 (Rutland, VT. His last East coast class IIRC). This introduced me to the math, specific design ideas and gave me a chance to watch a true master. Number two was in 1985 when I worked at Cyclery North in Chicago. Over 6 months I built (or completed a couple of sort of started) frames, again in the company of a very good builder (Tommy Winn). Both times I came away with new and improved abilities. I did attend one of Doug Fattic's brazing classes much later but by then my techniques were pretty much written in stone, much to Doug's disappointment it seemed at times .

.

Old timers here know that I have long suggested working with/under a mentor if at all possible. The motivation to better your teacher is a strong one. Andy

Your further comments about the manor of the hours are spot on IMO. I can see two points of rapid advance of my skills and focus. The first was the two week Eisentraut class in 1979 (Rutland, VT. His last East coast class IIRC). This introduced me to the math, specific design ideas and gave me a chance to watch a true master. Number two was in 1985 when I worked at Cyclery North in Chicago. Over 6 months I built (or completed a couple of sort of started) frames, again in the company of a very good builder (Tommy Winn). Both times I came away with new and improved abilities. I did attend one of Doug Fattic's brazing classes much later but by then my techniques were pretty much written in stone, much to Doug's disappointment it seemed at times

.

.Old timers here know that I have long suggested working with/under a mentor if at all possible. The motivation to better your teacher is a strong one. Andy

__________________

AndrewRStewart

AndrewRStewart

#72

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,984

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1172 Post(s)

Liked 2,566 Times

in

1,072 Posts

"To surpass the master is to repay the debt." (old adage, dunno who coined it)

"Poor is the pupil who does not surpass his master." -- Leonardo da Vinci

High-falutin' words for what's basically fancy pipe-fitting!

"Poor is the pupil who does not surpass his master." -- Leonardo da Vinci

High-falutin' words for what's basically fancy pipe-fitting!

#73

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,053

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4194 Post(s)

Liked 3,837 Times

in

2,295 Posts

Mark- I'm sure that these or other smart people also say there's mastery in simple things too. (Or at least I recall that Master Po said something like that in the Kung Fu TV show) Andy

__________________

AndrewRStewart

AndrewRStewart

#74

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,053

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4194 Post(s)

Liked 3,837 Times

in

2,295 Posts

Mark- Seriously, to try to do an initial rough file shaping of a hot fillet suggests to me that the joint is filed right after the brazing, as you said. Then what of the other joints? Is this done when the rest are just still tacked/ Or did Angel build one joint at a time? Andy

__________________

AndrewRStewart

AndrewRStewart

#75

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,984

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1172 Post(s)

Liked 2,566 Times

in

1,072 Posts

Mark- Seriously, to try to do an initial rough file shaping of a hot fillet suggests to me that the joint is filed right after the brazing, as you said. Then what of the other joints? Is this done when the rest are just still tacked/ Or did Angel build one joint at a time? Andy

If you mean did he turn the torch off, then yes, the big flame anyway. He had this cool French-made aircraft-style torch that had a pilot-light feature, where you'd flip a lever that kept your oxy-fuel knobs adjusted but knocked the flame down to just a tiny one. Like hanging your torch on a gas-saver, only it was built in to the torch. No sparking and re-adjusting when you get back to brazing. Super nice for multiple short sessions, like braze-ons. <brag> Fun Fact, I have the very gas-saver once used by Mario Confente.</brag>

I can't think of any downside to pausing a minute to file before going on to braze the next joint, can you?

Mark B